Abstract

Depth-sensing indentation is used to study the effect of grain refinement to submicro- and nanograins on the mechanical properties (hardness, plasticity, Young’s modulus) of armco iron subjected to severe plastic deformation by attrition in argon. In contrast to fcc metals, where the hardness increases and the plasticity decreases as the grain size decreases to 20 nm, the hardness of bcc iron decreases from 5.8 to 3.7 GPa and plasticity δ A increases from 0.82 to 0.87 as the grain size decreases from 50 to 20 nm.

Similar content being viewed by others

References

R. Z. Valiev and I. V. Aleksandrov, Nanostructured Materials Produced by Severe Plastic Deformation (Logos, Moscow, 2000) [in Russian].

N. I. Noskova and R. R. Mulyukov, Submicrocrystalline and Nanocrystalline Metals and Alloys (UrO RAN, Yekaterinburg, 2003) [in Russian].

R. A. Andrievskii and A. M. Glezer, “Size Effects in Nanocrystalline Materials: I. Structure Characteristics, Thermodynamics, Phase Equilibria, and Transport Phenomena,” Fiz. Met. Metalloved. 88(1), 50–73 (1999) [Phys. Met. Metallogr. 88 (1), 45–66 (1999)]; “II. Mechanical and Physical Properties,” Fiz. Met. Metalloved. 89 (1), 91–112 (2000) [Phys. Met. Metallogr. 89 (1), 83–104 (2000)].

H. Van Swygenhoven and J. R. Weertman, “Deformation in Nanocrystalline Metals,” Materialstoday 9(5), 24–31 (2006).

K. S. Kumar, H. Van Swygenhoven, S. Suresh, “Mechanical Behavior of Nanocrystalline Metals and Alloys,” Acta Materialia 51, 5743–5774 (2003).

V. A. Pozdnyakov and A. M. Glezer, “Structural Mechanisms of Plastic Deformation of Nanocrystalline Materials,” Fiz. Tverd. Tela 44(4) 705–710 (2002) [Phys. Solid State 44 (4), 600–605 (2002)].

N. I. Noskova, “Structural Features and Mechanisms of Deformation of Nanocrystalline Materials,” J. Phys. Metals and Metallography 94(Supplement), S119–S130 (2002).

G. A. Malygin, “Violation of the Hall-Petch Law in Micro- and Nanocrystalline Materials,” Fiz. Tverd. Tela 37(8), 2281–2292 (1995).

V. A. Pozdnyakov, “Mechanisms of Plastic Deformation and the Anomalies of the Hall-Petch Dependence in Metallic Nanocrystalline Materials,” Fiz. Met. Metalloved. 96(1), 114–128 (2003) [Phys. Met. Metallogr. 96, 105–119 (2003)].

A. M. Glezer, “Strength and Plasticity of Nanocrystals,” in Proceedings of the Ist International Conference on Deformation and Fracture of Materials, Moscow, Russia (Moscow, 2006), pp. 14–16.

M. Yu. Gutkin and I. A. Ovid’ko, Defects and Plasticity Mechanisms in Nanostructured and Noncrystalline Materials (Yanus, St. Petersburg, 2001) [in Russian].

G. Palumbo, U. Erb, and K. T. Aust, “Triple Line Dislocation Effects on the Mechanical Behavior of Materials,” Scr. Metall. Mater. 24, 2347–2350 (1990).

R. Z. Valiev and R. Sh. Musalimov, “High-Resolution Transmission Electron Microscopy of Nanocrystalline Materials,” Fiz. Met. Metalloved. 78(6), 114–121 (1994) [Phys. Met. Metallogr. 78 (6) 666–670 (1994)].

R. Z. Valiev and R. K. Islamgaliev, “Structure and Mechanical Behavior of Ultrafine-Grained Metals and Alloys Subjected to Intense Plastic Deformation,” Fiz. Met. Metalloved. 85(3), 161–177 (1998) [Phys. Met. Metallogr. 85 (3), 367–377 (1998)].

Z. Horita, D. Smith, M. Furakawa, et al., “An Investigation of Grain Boundaries in Submicrometer-Grained Al-Mg Solid Solution Alloys Using High-Resolution Electron Microscopy,” J. Mater. Res. 11(8), 1880–1890 (1996).

M. Yu. Gutkin and I. A. Ovid’ko, Physical Mechanics of Deformed Nanostructures. Vol. I. Nanocrystalline Materials (Yanus, St. Petersburg, 2003) [in Russian].

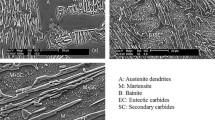

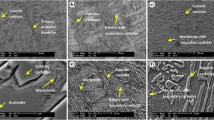

A. I. Yurkova, A. V. Belotskii, Yu. V. Milman, and A. V. Byakova, “Nanostructure Formation on the Iron Surface during Attrition,” Nanofizika, Nanosistemy, Nanomaterialy 2(2), 633–644 (2004).

A. I. Yurkova, Yu. V. Milman, and A. V. Byakova, “Structure and Mechanical Properties of Iron after Surface Severe Plastic Deformation by Attrition: I. Structure Formation,” Deformatsiya Razrushenie Materialov, No. 1, 2–12 (2009).

W. C. Oliver and G. M. Pharr, “An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments,” J. Mater. Res. 7(6), 1564–1583 (1992).

D. Tabor, The Hardness of Metals (Clarendon, Oxford, 2000).

Int. Standard ISO 14577-1-2002 (E).

Yu. V. Milman, B. A. Galanov, and S. T. Chugunova, “Plasticity Characteristics Obtained through Hardness Measurement,” Acta Metal. Mater. 41(9), 2523–2532 (1993).

Yu. V. Milman, S. T. Chugunova, and I. V. Goncharova, “Plasticity Characteristic Obtained by Indentation Technique for Crystalline and Noncrystalline Materials in Wide Temperature Range,” High Temperature Materials and Processes 25(1–2), 39–46 (2006).

A. Byakova, Yu. V. Milman, and A. Vlasov, “High Performance Ceramic Coatings for Cutting Tool-Perspective in Improvement of Coating Mechanical Properties,” in Proceedings of the 8th CIRP iNternational Workshop on Modeling of Machining Operations, Chemnitz, Germany (Chemnitz, 2005), pp. 559–568.

I. N. Frantsevich, F. F. Voronov, and S. A. Bakuta, Elastic Constants and Elastic Moduli of Metals and Nonmetals: A Handbook (Naukova Dumka, Kiev, 1982) [in Russian].

Yu. V. Milman, “Plasticity Characteristic Obtained by Indentation,” J. Phys. D: Appl. Phys. 41, 1–9 (2008).

Yu. Milman, S. Dub, and A. Golubenko, “Plasticity Characteristic Obtained through Instrumental Indentation,” Mater. Res. Soc. Symp. Proc. 1049, 123–128 (2008).

V. I. Trefilov, V. F. Moiseev, E. P. Pechkovskii, et al., Strain Hardening and Fracture of Polycrystalline Materials (Naukova Dumka, Kiev, 1987) [in Russian].

V. I. Trefilov, Yu. V. Milman, and S. A. Firstov, Physical Foundations of the Strength of Refractory Materials (Naukova Dumka, Kiev, 1975) [in Russian].

T. Ungar, H. Mughraby, D. Könnpagel, and M. Wilkens, “Line-Broadening Study of the Dislocation Cell Structure in Deformed [001]-Oriented Copper Single Crystals,” Acta Metall. 32(3), 333–342 (1984).

H. Mughraby, “Dislocation Wall and Cell Structures and Long-Range Internal Stresses in Deformed Metal Crystals,” Acta Metall. 31, 1367–1379 (1983).

S. Cheng, E. Ma, M. Y. Wang, et al., “Tensile Properties of In Situ Consolidated Nanocrystalline Cu,” Acta Materialia 53, 1521–1533 (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.I. Yurkova, Yu.V. Milman, A.V. Byakova, 2009, published in Deformatsiya i Razrushenie Materialov, 2009, No. 2, pp. 2–8.

Rights and permissions

About this article

Cite this article

Yurkova, A.I., Milman, Y.V. & Byakova, A.V. Structure and mechanical properties of iron subjected to surface severe plastic deformation by attrition: II. Mechanical properties of nano- and submicrocrystalline iron. Russ. Metall. 2010, 258–263 (2010). https://doi.org/10.1134/S0036029510040026

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029510040026