Abstract

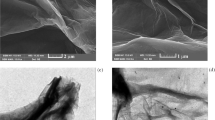

Magnesium and its alloys have great capability for degradation in the body in a natural way, so they are one of the main new candidates as biodegradable implant materials. Of course, one of the disadvantages of pure Mg is its rapid degradation in the physiological environment that prior to bone healing has a negative impact on its mechanical integrity. In the present paper, a semipowder metallurgy coupled with hot extrusion process was utilized to fabricate Mg-6Zn/xGO (0.2 and 0.4 wt %) biocomposite. According to the microstructural characterization, graphene oxide (GO) nanosheets had uniform distribution in the composite, and also partial and gradually wrapped α-Mg grains were observed inside the Mg matrix. Results showed that the hardness and compressive yield of the Mg-6Zn/xGO composite were notably higher in comparison to pure Mg. It was revealed that the mechanical properties were enhanced because of the mechanisms of crack bridging, crack deflection, and crack tip shielding. The H2 evolution throughout their immersion in simulated body fluid (SBF) was decreased remarkably because GO nanosheets were distributed uniformly in the Mg matrix. In addition, less corrosion current density and higher corrosion resistance of the extruded Mg-6Zn and Mg-6Zn/GO in comparison to pure Mg were shown by electrochemical tests. Since the rate of the degradation process was decreased, the extruded Mg-6Zn/GO biocomposite presented great cytocompatibility. The research results show that GO nanosheets are efficient reinforcement to fabricate the extruded Mg-6Zn/GO biocomposite, which leads to the improvement of mechanical, corrosion and biological properties.

Similar content being viewed by others

Change history

31 August 2021

Corrected issue title

REFERENCES

Abazari, S., Shamsipur, A., Bakhsheshi-Rad, H.R., Ramakrishna, S., and Berto, F., Graphene Family Nanomaterial Reinforced Magnesium-Based Matrix Composites for Biomedical Application: A Comprehensive Review, Metals, 2020, vol. 10, no. 8, p. 1002.

Shuai, C., Wang, B., Yang, Y., Peng, S., and Gao, C., 3D Honeycomb Nanostructure-Encapsulated Magnesium Alloys with Superior Corrosion Resistance and Mechanical Properties, Compos. Eng. B, 2019, vol. 162, pp. 611–620.

Panin, V.E., Egorushkin, V.E., Moiseenko, D.D., Maksimov, P.V., Kulkov, S.N., and Panin, S.V., Functional Role of Polycrystal Grain Boundaries and Interfaces in Micromechanics of Metal Ceramic Composites under Loading, Comput. Mater. Sci., 2016, vol. 116, pp. 74–81.

Panin, V.E. and Egorushkin, V.E., Physical Mesomechanics and Nonequilibrium Thermodynamics as a Methodological Basis for Nanomaterials Science, Phys. Mesomech., 2009, vol. 12, no. 5–6, pp. 204–220.

Panin, S.V., Byakov, A.V., Gvenke, V.V., Shakirov, I.V., and Yussif, S.A.K., Multiscale Monitoring of Localized Plastic Strain Evolution Stages in Notched Aluminum AA 2024 Alloy Tension Specimens by Acoustic Emission and Television-Optical Techniques, Phys. Mesomech., 2010, vol. 13, no. 3–4, pp. 203–211.

Saud, S.N., Hosseinian, R.S., Bakhsheshi-Rad, H.R., Yaghoubidoust, F., Iqbal, N., Hamzah, E., and Ooi, C.H.R., Corrosion and Bioactivity Performance of Graphene Oxide Coating on TiNb Shape Memory Alloys in Simulated Body Fluid, Mater. Sci. Eng. C, 2016, vol. 68, pp. 687–694.

Abazari, S., Shamsipur, A., Bakhsheshi-Rad, H.R., Ismail, A.F., Sharif, S., Razzaghi, M., Ramakrishna, S., and Berto, F., Carbon Nanotubes (CNTs)-Reinforced Magnesium-Based Matrix Composites: A Comprehensive Review, Materials, 2020, vol. 13, no. 19, p. 4421.

Munir, K., Wen, C., and Li, Y., Graphene Nanoplatelets-Reinforced Magnesium Metal Matrix Nanocomposites with Superior Mechanical and Corrosion Performance for Biomedical Applications, J. Magnes. Alloys, 2020, vol. 8, no. 1, pp. 269–290.

Fan, Y., Ye, L., Tian, Q., Zhuang, Y., Zhang, Y., and Li, X., Effects of Aligned Graphene Sheets on Mechanical Properties of ZK61 Alloy, Mater. Sci. Eng. A, 2021, vol. 801, p. 140417.

Wu, L., Wu, R., Hou, L., Zhang, J., and Zhang, M., Microstructure, Mechanical Properties and Wear Performance of AZ31 Matrix Composites Reinforced by Graphene Nanoplatelets (GNPs), J. Alloys Comp., 2018, vol. 750, pp. 530–536.

Dutta, S., Gupta, S., and Roy, M., Recent Developments in Magnesium Metal–Matrix Composites for Biomedical Applications: A Review, ACS Biomater. Sci. Eng., 2020, vol. 6, no. 9, p. 4748.

Ramezanzade, S., Ebrahimi, G.R., Parizi, M.T., and Ezatpour, H.R., Microstructure and Mechanical Characterizations of Graphene Nanoplatelets-Reinforced Mg–Sr–Ca Alloy as a Novel Composite in Structural and Biomedical Applications, J. Compos. Mater., 2019, vol. 54, no. 5, pp. 711–728.

Tong, L.B., Zhang, J.B., Xu, C., Wang, X., Song, S.Y., Jiang, Z.H., Kamado, S., Cheng, L.R., and Zhang, H.J., Enhanced Corrosion and Wear Resistances by Graphene Oxide Coating on the Surface of Mg-Zn-Ca Alloy, Carbon, 2016, vol. 109, pp. 340–351.

Güler, Ö. and Bağcı, N., A Short Review on Mechanical Properties of Graphene Reinforced Metal Matrix Composites, J. Mater. Res. Technol., 2020, vol. 9, no. 3, pp. 6808–6833.

Rashad, M., Pan, F., Tang, A., Asif, M., and Aamir, M., Synergetic Effect of Graphene Nanoplatelets (GNPs) and Multi-Walled Carbon Nanotube (MW-CNTs) on Mechanical Properties of Pure Magnesium, J. Alloys Compnd., 2014, vol. 603, pp. 111–118.

Turan, M.E., Sun, Y., and Akgul, Y., Mechanical, Tribological and Corrosion Properties of Fullerene Reinforced Magnesium Matrix Composites Fabricated by Semi Powder Metallurgy, J. Alloys Compnd., 2018, vol. 740, pp. 1149–1158.

Rashad, M., Pan, F., Asif, M., and Tang, A., Powder Metallurgy of Mg–1% Al–1% Sn Alloy Reinforced with Low Content of Graphene Nanoplatelets (GNPs), J. Indust. Eng. Chem., 2014, vol. 20, no. 6, pp. 4250–4255.

Shuai, C., Feng, P., Wu, P., Liu, Y., Liu, X., Lai, D., Gao, C., and Peng, S., A Combined Nanostructure Constructed by Graphene and Boron Nitride Nanotubes Reinforces Ceramic Scaffolds, Chem. Eng. J., 2017, vol. 313, pp. 487–497.

Gao, C., Feng, P., Peng, S., and Shuai, C., Carbon Nanotube, Graphene and Boron Nitride Nanotube Reinforced Bioactive Ceramics for Bone Repair, Acta Biomater., 2017, vol. 61, pp. 1–20.

Soleymani Eil Bakhtiari, S., Bakhsheshi-Rad, H.R., Karbasi, S., Tavakoli, M., Razzaghi, M., Ismail, A.F., RamaKrishna, S., and Berto, F., Polymethyl Methacrylate-Based Bone Cements Containing Carbon Nanotubes and Graphene Oxide: An Overview of Physical, Mechanical, and Biological Properties, Polymers, 2020, vol. 12, no. 7, p. 1469.

Shuai, C., Guo, W., Wu, P., Yang, W., Hu, S., Xia, Y., and Feng, P., A Graphene Oxide-Ag Co-Dispersing Nanosystem: Dual Synergistic Effects on Antibacterial Activities and Mechanical Properties of Polymer Scaffolds, Chem. Eng. J., 2018, vol. 347, pp. 322–333.

Saberi, A., Bakhsheshi-Rad, H.R., Karamian, E., Kasiri-Asgarani, M., and Ghomi, H., Magnesium-Graphene Nano-Platelet Composites: Corrosion Behavior, Mechanical and Biological Properties, J. Alloys Compnd., 2020, vol. 821, p. 153379.

Saberi, A., Bakhsheshi-Rad, H.R., Karamian, E., Kasiri-Asgarani, M., and Ghomi, H., A Study on the Corrosion Behavior and Biological Properties of Polycaprolactone/Bredigite Composite Coating on Biodegradable Mg–Zn–Ca–GNP Nanocomposite, Progr. Organic Coat., 2020, vol. 147, p. 105822.

Bakhsheshi-Rad, H.R., Ismail, A.F., Aziz, M., Akbari, M., Hadisi, Z., Khoshnava, S.M., Pagan, E., and Chen, X., Co-incorporation of Graphene Oxide/Silver Nanoparticle Into Poly-L-Lactic Acid Fibrous: A Route Toward the Development of Cytocompatible and Antibacterial Coating Layer on Magnesium Implants, Mater. Sci. Eng. C, 2020, vol. 111, p. 110812.

Guler, O., Say, Y., and Dikici, B., The Effect of Graphene Nano-Sheet (GNS) Weight Percentage on Mechanical and Corrosion Properties of AZ61 and AZ91 Based Magnesium Matrix Composites, J. Compos. Mater., 2020, vol. 54, no. 28, pp. 4473–4485.

Shuai, C., Liu, T., Gao, C., Feng, P., Xiao, T., Yu, K., and Peng, S., Mechanical and Structural Characterization of Diopside Scaffolds Reinforced with Graphene, J. Alloys Compnd., 2016, vol. 655, pp. 86–92.

Bordbar-Khiabani, A., Ebrahimi, S., and Yarmand, B., Highly Corrosion Protection Properties of Plasma Electrolytic Oxidized Titanium Using rGO Nanosheets, Appl. Surf. Sci., 2019, vol. 486, pp. 153–165.

Shuai, C., Wang, B., Bin, S., Peng, S., and Gao, C., TiO2-Induced in Situ Reaction in Graphene Oxide-Reinforced AZ61 Biocomposites to Enhance the Interfacial Bonding, ACS Appl. Mater. Interfac., 2020, vol. 12, no. 20, pp. 23464–23473.

Tao, J.-X., Zhao, M.-C., Zhao, Y.-C., Yin, D.-F., Liu, L., Gao, C., Shuai, C., and Atrens, A., Influence of Graphene Oxide (GO) on Microstructure and Biodegradation of ZK30-xGO Composites Prepared by Selective Laser Melting, J. Magnes. Alloys, 2020, vol. 8, no. 3, pp. 952–962.

Ali, M., Hussein, M.A., and Al-Aqeeli, N., Magnesium-Based Composites and Alloys for Medical Applications: A Review of Mechanical and Corrosion Properties, J. Alloys Compnd., 2019, vol. 792, pp. 1162–1190.

Shahin, M., Munir, K., Wen, C., and Li, Y., Magnesium-Based Composites Reinforced with Graphene Nanoplatelets as Biodegradable Implant Materials, J. Alloys Compnd., 2020, vol. 828, p. 154461.

Pahlevanzadeh, F., Bakhsheshi-Rad, H.R., and Hamzah, E., In-Vitro Biocompatibility, Bioactivity, and Mechanical Strength of PMMA-PCL Polymer Containing Fluorapatite and Graphene Oxide Bone Cements, J. Mech. Behav. Biomed. Mater., 2018, vol. 82, pp. 257–267.

Pahlevanzadeh, F., Bakhsheshi-Rad, H.R., Ismail, A.F., Aziz, M., and Chen, X.B., Development of PMMA-Mon-CNT Bone Cement with Superior Mechanical Properties and Favorable Biological Properties for Use in Bone-Defect Treatment, Mater. Lett., 2019, vol. 240, pp. 9–12.

Bakhsheshi-Rad, H.R., Hamzah, E., Kasiri-Asgarani, M., Saud, S.N., Yaghoubidoust, F., and Akbari, E., Structure, Corrosion Behavior, and Antibacterial Properties of Nano-Silica/Graphene Oxide Coating on Biodegradable Magnesium Alloy for Biomedical Applications, Vacuum, 2016, vol. 131, pp. 106–110.

Gao, C., Liu, T., Shuai, C., and Peng, S., Enhancement Mechanisms of Graphene in Nano-58S Bioactive Glass Scaffold: Mechanical and Biological Performance, Sci. Rep., 2014, vol. 4, no. 1, p. 4712.

Shuai, C., Wang, B., Bin, S., Peng, S., and Gao, C., Interfacial Strengthening by Reduced Graphene Oxide Coated with MgO in Biodegradable Mg Composites, Mater. Design, 2020, vol. 191, p. 108612.

Du, X., Du, W., Wang, Z., Liu, K., and Li, S., Ultra-High Strengthening Efficiency of Graphene Nanoplatelets Reinforced Magnesium Matrix Composites, Mater. Sci. Eng. A, 2018, vol. 711, pp. 633–642.

Rashad, M., Pan, F., Zhang, J., and Asif, M., Use of High Energy Ball Milling to Study the Role of Graphene Nano-Platelets and Carbon Nanotubes Reinforced Magnesium Alloy, J. Alloys Compnd., 2015, vol. 646, pp. 223–232.

Rashad, M., Pan, F., and Asif, M., Exploring Mechanical Behavior of Mg–6Zn Alloy Reinforced with Graphene Nanoplatelets, Mater. Sci. Eng. A, 2016, vol. 649, pp. 263–269.

Rashad, M., Pan, F., Liu, Y., Chen, X., Lin, H., Pan, R., Asif, M., and She, J., High Temperature Formability of Graphene Nanoplatelets-AZ31 Composites Fabricated by Stir-Casting Method, J. Magnes. Alloys, 2016, vol. 4, no. 4, pp. 270–277.

Han, W., Wu, Z., Li, Y., and Wang, Y., Graphene Family Nanomaterials (GFNs)—Promising Materials for Antimicrobial Coating and Film: A Review, Chem. Eng. J., 2019, vol. 358, pp. 1022–1037.

ACKNOWLEDGMENTS

The authors would like to thank the Norwegian University of Science and Technology, Islamic Azad University, Najafabad, and Universiti Teknologi Malaysia for providing the facilities for this research.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Saberi, A., Bakhsheshi-Rad, H.R., Karamian, E. et al. Synthesis and Characterization of Hot Extruded Magnesium-Zinc Nano-Composites Containing Low Content of Graphene Oxide for Implant Applications. Phys Mesomech 24, 486–502 (2021). https://doi.org/10.1134/S1029959921040135

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S1029959921040135