Abstract

Triboelectric nanogenerator (TENG) based on contact electrification between heterogeneous materials has been widely studied. Inspired from wind-blown sand electrification, we design a novel kind of TENG based on size dependent electrification using homogeneous inorganic materials. Based on the asymmetric contact theory between homogeneous material surfaces, a calculation of surface charge density has been carried out. Furthermore, the theoretical output of homogeneous material based TENG has been simulated. Therefore, this work may pave the way of fabricating TENG without the limitation of static sequence.

Similar content being viewed by others

Introduction

In the earth’s crust, silicon is the second most abundant element and various forms of silica is the most common composition unit of sand. For wind-blown sand granular systems, such as dust devil, sand storm, wind-blown sand saltation, etc, the upward electric field phenomenon originated from the positively charged large particles saltate/creep near the surface and small negatively charged smaller particles suspend into the air is widely observed1. The charged wind-blown sand granular systems always cause various damages, especially to the attenuation of electromagnetic wave signals caused by the light scattering and absorption of wind-blown sand&dust2. Nowadays, people reluctantly seem this huge static electric energy in those systems as harmful and waste energy and suffers their damages. However, an interesting and desired topic, how to take advantage of this natural phenomenon and convert the tremendous, harmful energy to useful electricity, hasn’t been paid enough attention and is a lack of study.

Based on different physical rules including electromagnetic induction effect3, electrostatic effect4, piezoelectric effect5 and so on, human beings convert mechanical energy to electricity that is one of the main kind of power source. Since 2012, triboelectric nanogenerator (TENG) has been invented as a novel technology to harvest waste mechanical energy which is a possible solution of not only portable electronics but also the energy crisis for human beings6. Comparing with piezoelectric materials based nanogenerator, TENG represents some unique merits such as high conversion efficiency, low fabrication cost, reliable robustness, which attaches great research interests both on theoretical and experimental studies7,8,9,10,11,12,13.

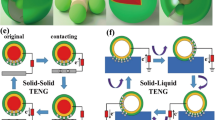

Generally, the working principle of TENG includes two processes9,14. First, two different kinds of materials located at different sites of electrostatic sequence obtain opposite charges on the surface via contact electrification with or without rubbing. Second, the electrodes made of oppositely charged materials move to change the capacitance for creating an electric potential difference that drives the free electrons in the external circuit to flow back and forth as alternating current (AC). Both in contact and sliding mode, the electrification between two different materials is a key step for generating electricity12,15,16. Till now, TENGs have been developed by assembling two different kinds of materials with the empirical arrangement in the static sequence, for example, PET and Kapton6, PTFE and Al17, PDMS and Al18, PMMA and Kapton19, PDMS and ITO20, TiO2 and PTFE21, PDMS and Au22, PVDF and nylon23, etc. With the limitation of static sequence, almost either of these two kinds of materials is polymer. Contact electrification occurs not only between heterogeneous but also homogeneous materials, which has been demonstrated by several experimental works, such as silica-silica24,25,26,27,28,29, aluminum oxide-aluminum oxide25, polymer-polymer30,31,32. Some homogeneous materials based TENGs also have promising performance33. Although polymer is always cheap, flexible and light, polymer based TENG is highly unfavorable to work in harsh environment such as desert, outer space and so on for its narrow working temperature area, fast aging and poor antiwear property34. Therefore, it is valuable to design and develop a new kind of TENG made with total inorganic materials like silica-silica to work in special environment.

For the electrification between identical materials, high energy trapped surface states theory proposed by Lowell and Truscutt35 has been widely used to explain charge transfer during asymmetric rubbing26,36,37 Based on high energy trapped states theory, particle-size-dependent charging, such as larger particles tends to be positively charged and smaller particles tends to be negatively charged, has been well explained26,28,36,37,38. In the wind-blown sand granular system, mechanisms of size-dependent electrification between identical insulator particles have been widely studied16,26,36,37,38,39,40, such as asymmetric contact between two particles with transfer of high-energy trapped electrons37 or holes26 (HETH). In our previous work, a contact charge model of high-energy trapped holes has been developed26 and verified with experiments24,26 for collision of homogeneous silica particles to predict the size-dependent contact electrification. From the experimental point view, silica film, made with earth abundant element oxygen and silicon, is chemical inertia and compatible with many semiconductor fabrication process like thermal oxidation41, magnetron sputtering42, sol-gel coating43, plasma enhanced chemical vapor deposition44, atom layer deposition45 and so on. Meanwhile, the synthesis of silica nanoparticles is also widely studied for many years46. Therefore, inspired by these natural phenomenon and studies, using homogenous silica based materials with different sizes as the contact electrification layer to fabricate TENG for energy harvesting, is highly feasible, which may pave a new way to develop a novel kind of TENG working in harsh environment.

In this manuscript, we propose a new kind of TENG based on contact electrification between homogeneous silica materials with different sizes for harvesting energy. A comprehensive theoretical model is established to understand the effect of size dependent elasticity on the surface charge density of chemically identical silica nanoparticles under normal loads. To our best knowledge, it is the first time of calculating the surface charge density after single time contact electrification for TENG through theoretical simulation. Then, these results are applied to predict the output characteristics of the contact-mode and sliding-mode TENGs. We demonstrate that the maximum output power of TENG using earth abundant and identical silica as contact electrification layer will reach 12.98 μW and 13.92 nW in contact and sliding model respectively. Indeed, the output will be greatly enhanced after multi-times contact electrification for more accumulated charges and higher surface charge density30,47 Furthermore, the whole TENG is covered with homogenous materials (silica), which may broaden the application of TENG in harsh environment.

Results

Denote two neutrally-charged sphere particles,  and

and  with radii

with radii  and

and  respectively, in a normally elastic colliding process, as shown in Fig. 1(a). Based on high-energy trapped hole contact charging model26, the net charge transfer of particle

respectively, in a normally elastic colliding process, as shown in Fig. 1(a). Based on high-energy trapped hole contact charging model26, the net charge transfer of particle  equals to the number of high-energy trapped holes gained from particle

equals to the number of high-energy trapped holes gained from particle  to particle

to particle  subtracting that lost from particle

subtracting that lost from particle  to particle

to particle  , that is,

, that is,

where  is the surface area of the contact part of sphere particle

is the surface area of the contact part of sphere particle  (

( ),

),  is the elementary charge,

is the elementary charge,  is the surface density of the high-energy trapped holes which is assumed to be identical for all particles initially26,37 The net charge transfer

is the surface density of the high-energy trapped holes which is assumed to be identical for all particles initially26,37 The net charge transfer  of particle

of particle  equals to

equals to  .When

.When  , Hertzian normal contact of two spheres will become the contact between a sphere and a rigid flat, as shown in Fig. 1(b). If the contact surface radius

, Hertzian normal contact of two spheres will become the contact between a sphere and a rigid flat, as shown in Fig. 1(b). If the contact surface radius  is given, the surface area of the contact part

is given, the surface area of the contact part  of sphere

of sphere  can be predicted,

can be predicted,

The net charge transfer of normal contact spheres is determined by the difference of surface areas of contact part  . Let

. Let  , the contacted surface area

, the contacted surface area  will be greater than the contacted surface area

will be greater than the contacted surface area  and then the net charge transfer

and then the net charge transfer  and

and  . If pre-collisional particles are both neutrally charged, the larger particle tends to be positively charged and the smaller particle tends to be negatively charged.

. If pre-collisional particles are both neutrally charged, the larger particle tends to be positively charged and the smaller particle tends to be negatively charged.

In order to achieve an optimal design of TENGs, the surface charge density is a vital parameter determining the output characteristics. When  is fixed, Fig. 2 shows that the surface charge density

is fixed, Fig. 2 shows that the surface charge density  of the post-collisional particle

of the post-collisional particle  decreases with radius

decreases with radius  (or increases with

(or increases with  ) and finally reaches its minimum value while

) and finally reaches its minimum value while  (or

(or  ). When the radius

). When the radius  tends to infinite, the particle-particle Hertzian contact can be treated as the particle-plane contact and in such case the surface charge density tends to its extreme value. Therefore the particle-plane Hertzian contact case will be an optimal design to obtain the maximum charge & power outputs for TENGs.

tends to infinite, the particle-particle Hertzian contact can be treated as the particle-plane contact and in such case the surface charge density tends to its extreme value. Therefore the particle-plane Hertzian contact case will be an optimal design to obtain the maximum charge & power outputs for TENGs.

In the case of elastic particle-plane Hertzian contact, we predict the surface charge density  varying with the normal load

varying with the normal load  and the radius

and the radius  , as shown in Fig. 3. The absolute value of the surface charge density,

, as shown in Fig. 3. The absolute value of the surface charge density,  , increases with the normal load

, increases with the normal load  increasing, but decreases with the increase of the radius

increasing, but decreases with the increase of the radius  .

.

Materials reduced to submicron or/and nanoscale show different mechanical properties compared to what they show on macroscale. Wang et al.48 pointed out that the Young’s module of silica nanowires of 100 nm diameter SiO2 nanowires is much lower than that of bulk SiO2 materials. Since the Young’s module reveals the strain-stress relationship, it will have an impact on the contact area of Hertzian contact and also on the contact charge. Figures 2 and 3 demonstrate that the Young’s module have significant effects on the surface charge density. For instance, as shown in Fig. 2, when  = 25 GPa, the absolute value of the extreme surface charge density, will be 53.5% greater than the case

= 25 GPa, the absolute value of the extreme surface charge density, will be 53.5% greater than the case  = 70 GPa, respectively. Therefore, in this study we consider the nanoscale effect and take the Young’s module as 25 GPa.

= 70 GPa, respectively. Therefore, in this study we consider the nanoscale effect and take the Young’s module as 25 GPa.

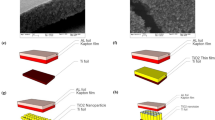

Instead of taking advantage of contact electrification between different insulators6,17,18,19,20,21,22,23, we choose the identical silica insulators with the property of size-dependent polarity during contact electrification. Figure 4 shows the schemes of contact-mode and sliding-mode TENGs. The top surface is decorated with a layer of SiO2 nanoparticles and the bottom surface is flat SiO2 plate. Thin layers of metal film are deposited on two SiO2 material plates as the metal electrodes. The metal electrodes in the upper and lower plates are called the top and down electrodes, respectively.

Figure 4(a) is the schematic diagram of the structure of our TENG containing two metal electrodes, silica nanoparticle and silica plate. Initially, the two surfaces are neutrally charged. As observed in wind-blown sand granular systems and our previous work, the surface coated with SiO2 nanoparticles will be negatively charged and the SiO2 plane surface will be positively charged after single time contacting26 and the bottom surface has the surface charge density  and the top surface the surface charge density

and the top surface the surface charge density  as shown in Fig. 4(b–d) are the schematic diagrams of sliding and contact mode separately. After separation, the electric charge of a single SiO2 nanoparticle will be

as shown in Fig. 4(b–d) are the schematic diagrams of sliding and contact mode separately. After separation, the electric charge of a single SiO2 nanoparticle will be

If there are N particles decorated on a plane with the surface area  (S = wl,

(S = wl,  : length;

: length;  : width), the number density will be

: width), the number density will be  . After separation of two planes, the total electric charge of nanoparticle-decorated top plane will be,

. After separation of two planes, the total electric charge of nanoparticle-decorated top plane will be,

And the averaged surface charge density of the down plane  will be

will be

Then, the averaged surface charge density of the top plane will be  . For a rectangle plane with length

. For a rectangle plane with length  and width

and width  , the maximum number of particles coated on such surface will be

, the maximum number of particles coated on such surface will be  , where

, where  and

and  can be solved by

can be solved by  and

and  , respectively. Noticeably, the surface charge density

, respectively. Noticeably, the surface charge density  increases with

increases with  and the maximum surface charge density

and the maximum surface charge density will be

will be  , where

, where  denotes the maximum elastic contact surface radius which can be solved according to the critical normal load. For a square surface,

denotes the maximum elastic contact surface radius which can be solved according to the critical normal load. For a square surface,  and the maximum surface charge density

and the maximum surface charge density  tends to be

tends to be  . For instance, when

. For instance, when  = 10 nm,the maximum surface charge density. Figure 5 shows that

= 10 nm,the maximum surface charge density. Figure 5 shows that slightly increase linearly with

slightly increase linearly with  and is nearly a constant value −0.953 μC m−2 with

and is nearly a constant value −0.953 μC m−2 with  in the range 10 ~ 100 nm and the relative error

in the range 10 ~ 100 nm and the relative error  is very small. The above maximum surface charge density means that particles are densely distributed and this is an ideal state. While in this ideal state, the squeezing action between a particle and its adjacent particles under external forces also affects the Hertzian deformation of particle-plane contact. In order to avoid such inter-particle effects, sparse distribution of nanoparticles is more reasonable. For example, when a quarter of the maximum number of particles such as

is very small. The above maximum surface charge density means that particles are densely distributed and this is an ideal state. While in this ideal state, the squeezing action between a particle and its adjacent particles under external forces also affects the Hertzian deformation of particle-plane contact. In order to avoid such inter-particle effects, sparse distribution of nanoparticles is more reasonable. For example, when a quarter of the maximum number of particles such as  are decorated on the top surface, the surface charge density will be

are decorated on the top surface, the surface charge density will be  .

.

For normal contact-mode and sliding-mode TENGs connected to an arbitrary resistor , the output properties have been respectively discussed14,49. Figures 6 and 7 respectively depicts the theoretical output properties of normal contact-model and sliding-mode of TENGs. The parameters of our TENGs are given in Table 1. For instance, the width

, the output properties have been respectively discussed14,49. Figures 6 and 7 respectively depicts the theoretical output properties of normal contact-model and sliding-mode of TENGs. The parameters of our TENGs are given in Table 1. For instance, the width  , the length l = 100 mm, the thicknesses

, the length l = 100 mm, the thicknesses  and

and  for both contact-mode and sliding-mode TENGs. The maximum departing distance of contact-mode TENGs is 80mm and the maximum sliding distance

for both contact-mode and sliding-mode TENGs. The maximum departing distance of contact-mode TENGs is 80mm and the maximum sliding distance  of sliding-mode TENGs is also 80mm. When the velocities are respectively 0.1 m/s, 0.5 m/s, 1 m/s, theoretical calculations of maximum power outputs are carried out with different resistances, as shown in Figs 6(a) and 7(a). Obviously, there will be optimum values of resistance

of sliding-mode TENGs is also 80mm. When the velocities are respectively 0.1 m/s, 0.5 m/s, 1 m/s, theoretical calculations of maximum power outputs are carried out with different resistances, as shown in Figs 6(a) and 7(a). Obviously, there will be optimum values of resistance  for contact model and sliding-mode14,49. For instance, as shown in Fig. 6(a), when the power outputs reach their optimum values 1.298 μW, 6.491 μW and 12.98 μW after single time contact electrification for contact-model TENGs, the resistances are respectively 1250 GΩ (separating velocity is 0.1 m/s), 275 GΩ (separating velocity is 0.5m/s) and 125 GΩ (separating velocity is 1 m/s). For sliding-model TENGs, the maximum power output could reach 13.92 nW after single time electrification when sliding velocity is 1 m/s. According to optimization of resistance value, Figs 6(b) and 7(b) respectively demonstrate the voltage and charge outputs of contact-model TENGs and sliding-mode TENGs when separating & sliding velocities are both 0.1m/s. Therefore, our optimized designs of contact-mode and sliding-mode TENGs based on contact electrification of homogeneous materials with different sizes would provide a new way for harvesting natural wind-blown energy to drive the nano/micro scale instruments.

for contact model and sliding-mode14,49. For instance, as shown in Fig. 6(a), when the power outputs reach their optimum values 1.298 μW, 6.491 μW and 12.98 μW after single time contact electrification for contact-model TENGs, the resistances are respectively 1250 GΩ (separating velocity is 0.1 m/s), 275 GΩ (separating velocity is 0.5m/s) and 125 GΩ (separating velocity is 1 m/s). For sliding-model TENGs, the maximum power output could reach 13.92 nW after single time electrification when sliding velocity is 1 m/s. According to optimization of resistance value, Figs 6(b) and 7(b) respectively demonstrate the voltage and charge outputs of contact-model TENGs and sliding-mode TENGs when separating & sliding velocities are both 0.1m/s. Therefore, our optimized designs of contact-mode and sliding-mode TENGs based on contact electrification of homogeneous materials with different sizes would provide a new way for harvesting natural wind-blown energy to drive the nano/micro scale instruments.

Discussion

Inspired from wind-blown sand electrification, we design a novel kind of TENG based on size dependent electrification using identical silica materials for harvesting energy. A theoretical mode is established to elucidate the mechanism of the contact electrification process and a calculation of surface charge density has been carried out. Furthermore, the output of homogeneous material based TENG has been simulated. We demonstrate that the maximum power outputs of TENG using earth abundant and homogenous silica as contact electrification layer will reach 12.98 μW and 13.92 nW in contact and sliding model after single time contact electrification, respectively. Indeed, the output will be greatly enhanced after multi-times contact electrification for more accumulated charges and higher surface charge density. The design of our TENG is polymer free and breaks the limitation of static sequence, which may broaden the application of TENG in harsh environment.

Method

The high-energy trapped hole contact charging model26 is used to predict the net charge transfer and the surface charge density when identical SiO2 particle-particle or particle-plane contact. The net charge transfer is related to the Hertzian contact area.

According to Hertzian normal contact theory, each sphere will undergo a normal deflection and a contact surface when the two spheres are subjected to a normal load , as shown in Fig. 1(a). And the normal deflection

, as shown in Fig. 1(a). And the normal deflection  is given by,

is given by,

where K is a material constant and commonly referred to as the effective stiffness,

where  ,

,  are the Young’s modules and

are the Young’s modules and  ,

,  are the Poisson’s ratios, respectively. The effective radius of curvature

are the Poisson’s ratios, respectively. The effective radius of curvature  of the two spheres is defined as,

of the two spheres is defined as,

where  is the radius of sphere

is the radius of sphere  (

( ).When

).When  , Hertzian normal contact of two spheres will become the contact of a sphere and a rigid flat, as shown in Fig. 1(b). The contact surface radius

, Hertzian normal contact of two spheres will become the contact of a sphere and a rigid flat, as shown in Fig. 1(b). The contact surface radius  and the normal deflection

and the normal deflection  satisfy

satisfy  and thus the contact surface radius

and thus the contact surface radius  will be,

will be,

Here, we only consider the elastic Hertzian contact; therefore we need to calculate the critical normal load  from elastic stage to plastic stage. Love et al. demonstrated the stress produced in a semi-infinite body50,

from elastic stage to plastic stage. Love et al. demonstrated the stress produced in a semi-infinite body50,

where  . Under normal point load, the plastic deformation starts at the contact area and the initially yielding point will be on the axis of

. Under normal point load, the plastic deformation starts at the contact area and the initially yielding point will be on the axis of  of the elastic semi-infinite body. When

of the elastic semi-infinite body. When  , the stress at points on the axis of

, the stress at points on the axis of  will be

will be

Here,  , the second invariant of stress deviator tensor is applied to predicted the critical normal load and

, the second invariant of stress deviator tensor is applied to predicted the critical normal load and  . According to the Von Mises criteria, the yielding function

. According to the Von Mises criteria, the yielding function  for axial extension experiments, where

for axial extension experiments, where  is the yield strength. Therefore, the critical normal point load can be derived by solving function

is the yield strength. Therefore, the critical normal point load can be derived by solving function  .

.

Finally, we carry out a theoretical study and prediction of wind-blown sand electrification inspired triboelectric energy harvesting based on homogeneous inorganic materials contact. For normal contact-mode and sliding-mode TENGs connected to an arbitrary resistor  , the charges on the top electrode as a function of time are respectively given as14,49,

, the charges on the top electrode as a function of time are respectively given as14,49,

where  ,

,  ,

,  . The current, voltage and power outputs are respectively,

. The current, voltage and power outputs are respectively,

Additional Information

How to cite this article: Hu, W. et al. Wind-blown Sand Electrification Inspired Triboelectric Energy Harvesting Based on Homogeneous Inorganic Materials Contact: A Theoretical Study and Prediction. Sci. Rep. 6, 19912; doi: 10.1038/srep19912 (2016).

References

Zheng, X. Mechanics of Wind-blown Sand Movements, (Springer, 2009).

Redmond, H. E., Dial, K. D. & Thompson, J. E. Light Scattering and Absorption by Wind Blown Dust: Theory, Measurement and Recent Data. Aeolian Res. 2, 5–26 (2010).

Sadiku, M. Elements of electromagnetics (the oxford series in electrical and computer engineering). (Oxford University Press, 2014).

Suzuki, Y. Recent Progress in MEMS Electret Generator for Energy Harvesting. IEEJ T. Electr. Electr. 6, 101–111 (2011).

Wang, Z. L. & Song, J. Piezoelectric Nanogenerators based on Zinc Oxide Nanowire Arrays. Science 312, 242–246 (2006).

Fan, F. R., Tian, Z. Q. & Wang, Z. L. Flexible Triboelectric Generator. Nano Energy 1, 328–334 (2012).

Wang, S. et al. Charge-separation Mechanism. Nano Lett. 13, 2226–2233 (2013).

Bae, J. et al. Flutter-driven Triboelectrification for Harvesting Wind Energy. Nat. Commun. 5, 4929 (2014).

Niu, S. et al. Theoretical Investigation and Structural Optimization of Single‐Electrode Triboelectric Nanogenerators. Adv. Funct. Mater. 24, 3332–3340 (2014).

Niu, S. et al. A Theoretical Study of Grating Structured Triboelectric Nanogenerators. Energ. Environ. Sci. 7, 2339–2349 (2014).

Niu, S. et al. Simulation Method for Optimizing the Performance of an Integrated Triboelectric Nanogenerator Energy Harvesting System. Nano Energy 8, 150–156 (2014).

Wang, S. et al. Maximum Surface Charge Density for Triboelectric Nanogenerators Achieved by Ionized‐Air Injection: Methodology and Theoretical Understanding. Adv. Mater. 26, 6720–6728 (2014).

Zhu, G., Chen, J., Zhang, T., Jing, Q. & Wang, Z. L. Radial-arrayed Rotary Electrification for High Performance Triboelectric Generator. Nat. Commun. 5, 3426 (2014).

Niu, S. et al. Theory of Sliding‐Mode Triboelectric Nanogenerators. Adv. Mater. 25, 6184–6193 (2013).

Lowell, J. & Rose-Innes, A. C. Contact Electrification. Adv. Phys. 29, 947–1023, (1980).

Daniel, J. L. & Sankaran, R. M. Contact Electrification of Insulating Materials. J. Phys. D: Appl. Phys. 44, 453001 (2011).

Chen, J. et al. Harmonic‐Resonator‐Based Triboelectric Nanogenerator as a Sustainable Power Source and a Self‐Powered Active Vibration Sensor. Adv. Mater. 25, 6094–6099 (2013).

Wang, S., Lin, L. & Wang, Z. L. Nanoscale Triboelectric-Effect-Enabled Energy Conversion for Sustainably Powering Portable Electronics. Nano Lett. 12, 6339–6346, (2012).

Zhu, G. et al. Triboelectric-Generator-Driven Pulse Electrodeposition for Micropatterning. Nano Lett. 12, 4960–4965 (2012).

Fan, F. R. et al. Transparent Triboelectric Nanogenerators and Self-Powered Pressure Sensors Based on Micropatterned Plastic Films. Nano Lett. 12, 3109–3114 (2012).

Lin, Z. H. et al. Enhanced Triboelectric Nanogenerators and Triboelectric Nanosensor Using Chemically Modified TiO2 Nanomaterials. ACS nano 7, 4554–4560 (2013).

Zhu, G. et al. Toward Large-Scale Energy Harvesting by a Nanoparticle-Enhanced Triboelectric Nanogenerator. Nano Lett. 13, 847–853 (2013).

Zheng, Y. et al. An Electrospun Nanowire-based Triboelectric Nanogenerator and its Application in a Fully Self-Powered UV Detector. Nanoscale 6, 7842–7846 (2014).

Poppe, T., Blum, J. & Henning, T. Experiments on Collisional Grain Charging of Micron-sized Preplanetary Dust. Astrophys. J. 533, 472–480 (2000).

Forward, K. M., Lacks, D. J. & Sankaran, R. M. Triboelectric Charging of Granular Insulator Mixtures Due Solely to Particle− Particle Interactions. Ind. Eng. Chem. Res. 48, 2309–2314 (2008)

Hu, W., Xie, L. & Zheng, X. Contact Charging of Silica Glass Particles in a Single Collision. Appl. Phys. Lett. 101, 114107 (2012).

Siu, T., Cotton, J., Mattson, G. & Shinbrot, T. Self-sustaining charging of identical colliding particles. Phys. Rev. E 89, 052208 (2014).

Bilici, M. A. et al. Particle size effects in particle-particle triboelectric charging studied with an integrated fluidized bed and electrostatic separator system. Rev. Sci. Instrum. 85, 103903 (2014).

Xie, L., Han, K., Ma, Y. & Zhou, J. An electrification mechanism of sand grains based on the diffuse double layer and Hertz contact theory. Appl. Phys. Lett. 103, 104103 (2013).

Pham, R. et al. Contact charging between surfaces of identical insulating materials in asymmetric geometries. J.Electrostat. 69, 456–460 (2011).

Xie, L. et al. An experiment investigation on electrification by collision between chemically identical glass particles. AIP Conf. Proc. 1542, 859–862 (2013).

Xie, L., Bao, N. & Zhou, J. Contact electrification by collision of homogenous particles. J. Appl. Phys. 113, 184908 (2013)

Wei, X. Y., Zhu, G. & Wang, Z. L. Surface-charge engineering for high-performance triboelectric nanogenerator based on identical electrification materials. Nano Energy 10, 83–89 (2014).

Aly, A. A. et al. Friction and Wear of Polymer Composites Filled by Nano-Particles: A Review. World J. Nano Sci. Eng. 2, 21006 (2012).

Lowell, J. & Truscott, W. S. Triboelectrification of identical insulators. II. Theory and further experiments. J. Phys. D:Appl. Phys. 19, 1281–1298 (1986).

Forward, K. M., Lacks, D. J. & Sankaran, R. M. Charge segregation depends on particle size in triboelectrically charged granular materials. Phys.Rev.Lett. 102, 028001 (2009).

Kok, J. F. & Lacks, D. J. Electrification of Granular Systems of Identical Insulators. Phys. Rev. E 79, 051304 (2009).

Lacks, D. J., Duff, N. & Kumar, S. K. Nonequilibrium Accumulation of Surface Species and Triboelectric Charging in Single Component Particulate Systems. Phys. Rev. Lett. 100, 188305 (2008).

Kok, J. F. & Renno, N. O. Electrostatics in Wind-Blown Sand. Phys. Rev. Lett. 100, 014501 (2008).

Zheng, X., Zhang, R. & Huang, H. Theoretical Modeling of Relative Humidity on Contact Electrification of Sand Particles. Sci. Rep. 4, 4399 (2014).

Fortunato, E., Barquinha, P. & Martins, R. Oxide Semiconductor Thin-Film Transistors: A Review of Recent Advances. Adv. Mater. 24, 2945–2986, (2012).

Song, H. Z., Bao, X. M., Li, N. S. & Wu, X. L. Strong Ultraviolet Photoluminescence from Silicon Oxide Films Prepared by Magnetron Sputtering. Appl. Phys. Lett. 72, 356–358, (1998).

Thim, G. P., Oliveira, M. A. S., Oliveira, E. D. A. & Melo, F. C. L. Sol–gel Silica Film Preparation from Aqueous Solutions for Corrosion Protection. J. Non-Cryst. Solids 273, 124–128, (2000).

Kenyon, A. J., Trwoga, P. F., Federighi, M. & Pitt, C. W. Optical Properties of PECVD Erbium-Doped Silicon-Rich Silica: Evidence for Energy Transfer Between Silicon Microclusters and Erbium Ions. J. Phys. Condens. Matter 6, L319 (1994).

De Rouffignac, P., Li, Z. & Gordon, R. G. Sealing Porous Low-k Dielectrics with Silica. Electrochem. Solid State Lett. 7, G306–G308 (2004).

Stöber, W., Fink, A. & Bohn, E. Controlled Growth of Monodisperse Silica Spheres in the Micron Size Range. J. Colloid. Interf. Sci. 26, 62–69, (1968).

Cui, N. et al. High performance sound driven triboelectric nanogenerator for harvesting noise energy. Nano Energy 15, 321–328 (2015).

Wang, Z. L., Gao, R. P., Pan, Z. W. & Dai, Z. R. Nano-Scale Mechanics of Nanotubes, Nanowires and Nanobelts. Adv. Eng. Mater. 3, 657 (2001).

Niu, S. et al. Theoretical Study of Contact-Mode Triboelectric Nanogenerators as an Effective Power Source. Energy Environ. Sci. 6, 3576–3583 (2013)

Love, A. E. H. The Stress Produced in a Semi-Infinite Solid by Pressure on Part of the Boundary. Philos. T. R. Soc. A 228, 377–420 (1929).

Acknowledgements

Thanks Professor Yan Zhang(Lanzhou University, PR. China) for giving good suggestions to improve this study. We are grateful to the National Natural Science Foundation of China(Grand Nos.11302217, 11172285 and 11472259) for financial support.

Author information

Authors and Affiliations

Contributions

W.W. and W.H. designed the TENG with homogenous silica electrification layer. W.H. did the theoretical research. W.W. and W.H. wrote the manuscript. All authors attended discussion with this work and gave suggestions.

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Rights and permissions

This work is licensed under a Creative Commons Attribution 4.0 International License. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in the credit line; if the material is not included under the Creative Commons license, users will need to obtain permission from the license holder to reproduce the material. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/

About this article

Cite this article

Hu, W., Wu, W. & Zhou, Hm. Wind-blown Sand Electrification Inspired Triboelectric Energy Harvesting Based on Homogeneous Inorganic Materials Contact: A Theoretical Study and Prediction. Sci Rep 6, 19912 (2016). https://doi.org/10.1038/srep19912

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/srep19912

This article is cited by

-

Contact Area of Electrification Materials Relating to Triboelectric Generators: A Comparative Study

Electronic Materials Letters (2023)

-

Development, applications, and future directions of triboelectric nanogenerators

Nano Research (2018)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.

; (b) a rigid flat object under a normal point load

; (b) a rigid flat object under a normal point load  .

.  is the overlapped deformation and

is the overlapped deformation and  is the contact radius.

is the contact radius.

of sphere RA varies with the radii ratio RA/RB.

of sphere RA varies with the radii ratio RA/RB.

varies with

varies with = 50 nN; and (b) normal point load P with

= 50 nN; and (b) normal point load P with  = 50 nm.

= 50 nm.

and the top surface the surface charge density

and the top surface the surface charge density  .

.

varies with the radius RA.

varies with the radius RA.