Abstract

The transient photocurrent is one of the key parameters of the spatial radiation effect of photoelectric devices, and the energy level defect affects the transient photocurrent. In this paper, by studying the deep level transient spectrum of a self-designed Schottky diode, the defect properties of the interface region of the anode metal AlCu and Si caused by high-temperature annealing at 150 ℃, 200 ℃ and 300 ℃ for 1200 h have been quantitatively analyzed. The study shows that the defect is located at the position of + 0.41 eV on the valence band, the concentration is 2.8 \(\times\) 1013/cm2, and the capture cross section is \(\sigma\) = 8.5 \(\times\) 1017. The impurity energy level mainly comes from the diffusion of Al atom in anode metal. We found that the defect did not cause the electrical performance degradation and obvious morphology change of the device, but the transient photocurrent increased significantly. The reason is that the high temperature treatment results in a growth in the density of states at the interface between AlCu–Si. The more mismatched dislocations and recombination center increased the reverse current of the heterojunction. The above view is proved by the TCAD simulation test.

Similar content being viewed by others

Introduction

Under the space radiation of different dose rates, the device will produce various problems such as disturbance, overturn, latch and even burn. At present, the reliability research of researchers mostly adopts the method of experiment or simulation1,2,3, which is based on the performance results of the device, and the mechanism research mainly focuses on the mechanism of the device structure4, 5. However, the research at the material level, especially the influence of the defects of semiconductor materials on the space radiation effect, is relatively insufficient. In this paper, a simple Schottky diode is designed to introduce defects and retest the transient photocurrent through high temperature treatment. Combining DLTS (Deep Level Transient Spectroscopy) technology and TCAD (Technology Computer Aided Design) simulation, the influence mechanism of energy level defects on the transient dose rate effect is studied.

Experimental setup

Sample preparation

In order to facilitate the study on the mechanism of the influence of energy level defects on transient photocurrent, a typical Schottky diode is designed in this paper. As shown in Fig. 1, the Si substrate is N-type, (111) crystal plane, with a resistivity of 0.001–0.005 Ω cm, on which a layer of N-type Si is epitaxial grown, doped with P, with a resistivity of 2.0–2.6 Ω cm, and a doping concentration of 1.6–2.5 × 1015/cm3. The top electrode is AlCu alloy with Schottky contact. Ohmic contact shall be made on the bottom surface, and the electrode shall be paved on the bottom surface. The basic electrical properties of the fabricated device are tested by I–V curve.

High temperature annealing

The introduction of defects through high-temperature annealing is essentially to simulate the long-term degradation of material or device performance through a short time test by introducing a temperature stress field6. First of all, according to different materials and devices, the temperature selected is different. For example, the white LED is 85–125 ℃7, 8, the GaN based device is 85 ℃9, the In Pb material is 150 ℃10, the erbium ytterbium co doped fiber amplifier is 85 ℃11, the organic material fluorosilicone rubber is 200 ℃12, the InGaAs photodiode is 100–300 ℃13, and the MEMS gyroscope is 125 ℃14. In general, the influence of high temperature treatment on devices is mainly reflected in the influence of temperature stress on electron mobility, which leads to the formation of voids or metal compounds in materials, which changes the electrical properties, the oxidation of metals caused by the presence of air oxygen, and the degradation of electrical and thermal properties caused by the denaturation of packaging materials. In this test, three ranges of 150 ℃, 200 ℃ and 300 ℃ are used for 1200 h high temperature treatment.

We used SEM (Scanning Electron Microscope) and surface morphology scanning to observe the changes of device surface morphology, as shown in Fig. 2. High-temperature annealing at 150 ℃, 200 ℃, and 300 ℃ for 1200 h is compared with the ground state, in which there is no obvious change at 150 ℃ and 200 ℃, and there are some micro visible changes at 300 ℃. The number of peaks in Fig. 3(left) explains the reason for surface morphology changes under electron microscopy. Then use the source table to test the I–V curve of the device after high-temperature treatment, as shown in Fig. 3(right).

The structure of Schottky diode is relatively simple for this test, because there is no effect on other packaging structures and materials. Generally the anode AlCu alloy used in this test has obvious oxidation phenomenon above 650 ℃ for a short time, and the structure of Schottky diode can be significantly changed after high-temperature annealing at 500 ℃ for 120 h15. Considering its Si substrate, the diffusion of Si atoms is obvious only when the temperature is above 900 ℃16. When Al Cu Si composite structure is formed, the eutectic reaction can only occur in the Al rich area at 548 °C, while no atomic diffusion phenomenon is found in the 350 °C short-term aging test17. Combined with the fact that there is no obvious phenomenon in the 250 ℃ aging test of InGaAs diodes with the same simple structure13, it can be considered that the basic electrical properties of Schottky bare chips have not been significantly affected under the aging conditions of 150 ℃, 200 ℃ and 300 ℃.

Transient photocurrent test

We set up the device as shown in Fig. 4 to test the transient photocurrent of Schottky diode sample. A laser pulse from a high-energy single pulse nanosecond laser (the single pulse energy is greater than 1 J/cm2) first enters the beam expander through the shutter, reflector and attenuator, and expands the original 10 mm spot to 20 mm, which is convenient for full coverage of the test sample. The energy meter is used to monitor the energy of the test beam in real time, and the microlens array is used to homogenize the beam, which can improve the beam uniformity to more than 80%. At the same time, the sampling resistance method is used to test the transient photocurrent. As shown in Fig. 5, the sample is in reverse bias state, the reverse bias voltage provided by the power supply is 3 V, and the sampling resistance R = 1000 Ω.

The test results of the transient dose rate are shown in Fig. 6. It is obvious that defects are introduced at 150 ℃, 200 ℃ and 300 ℃. Compared with the ground state, although the electrical performance of the device has not changed, it has significantly affected the transient photocurrent at 300 ℃, and the transient photocurrent has increased significantly.

Discussion

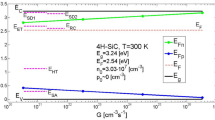

To explore the causes of the above phenomena, the DLTS technology is used to test the defects of the samples as shown in Fig. 7. Under the reverse bias condition, DLTS did not detect an obvious defect peak in the samples treated with high-temperature annealing at ground state, 150 ℃ and 200 ℃, but a significant defect peak appeared in the 300 ℃ high-temperature treated samples.

It can be seen that there are slight inconspicuous multi carrier traps in the ground state, at 150 ℃ and 200 ℃, while a huge carrier trap appears at 300 ℃. The formula is used to calculate energy level status18:

where, \(E_{Ta}\) is the activation energy, \(\left\langle V \right\rangle\) is the thermal motion rate of electrons, \(N_{v,c}\) is the density of states, \(k\) is the Boltzmann constant, and \(T\) is the temperature. It can be obtained that, \(E_{Ta}\) = + 0.41 eV, the capture cross section of minority carrier trap \(\sigma\) = 8.5 \(\times\) 1017. According to the following formula,

The energy level concentration of the multi carrier defect is 2.8 \(\times\) 1013 /cm2.

Generally speaking, when a short pulse laser irradiates a semiconductor material, a large number of non-equilibrium photogenerated carriers will be generated in a short time19. The Si–P material in this test is an N-type semiconductor, and its electrons are multi carriers, in which the minority carrier trap plays a role usually. At the same time, Si is also an indirect transition semiconductor material, which the conduction band bottom and valence band top are not at the same position in the Brillouin zone. The carrier recombination process requires assistant of phonon. The recombination center is the determinant of lifetime of minority carrier20. The minority carrier trap introduced by high temperature treatment promotes the recombination of unbalanced carriers, shortens the lifetime of unbalanced carriers and improved the transient photocurrent.

It is speculated that the change of interface state between AlCu Si leads to the generation of defects. The interface state is a heterojunction formed near the interface when two different materials contact. The interface maintains lattice continuity, but a large number of interface states or dangling bonds are generated on the interface. Generally, the greater the density of interface states, the greater the lattice mismatch, and the more mismatched dislocations21. Dislocation defects play the role of recombination center, which will reduce minority carrier lifetime and minority carrier diffusion length. For heterostructures, the reverse current is significantly increased22.

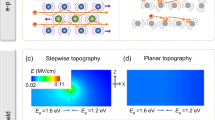

TCAD simulation is used to model the device to prove the above assumption as shown in Fig. 8 (Fig. 8b is a three-dimensional display, not applicable to coordinate axis dimensions). The validity of the model is proved by comparing the simulated IV curve with the measured IV curve. As shown in Fig. 9, the deviation of the simulated and measured current under the same voltage is less than 20% on average.

The model is used to study the influence of interface state density on the transient photocurrent. As shown in Figs. 10 and 11, TCAD simulates that interface state density, aluminum atom diffusion and trap concentration affect the transient photocurrent. The interface state density increases from 1 \(\times\) 1010/cm2 to 1 \(\times\) 1013/cm2 as shown in Fig. 10a. It can be seen that with the increase of interface state density, the transient photocurrent has an obvious downward trend, which is consistent with the previous test results (Due to the reverse bias condition during transient photocurrent testing, the positive current during simulation is called negative current during testing). The increase in trap concentration in the body region leads to a significant decrease in transient photocurrent. Figure 10b and c show a strong correlation between the diffusion of aluminum atoms and the effect of trap concentration on transient photocurrent, which is due to the increase in trap concentration and interface density of states caused by aluminum atom diffusion. Among them, the diffusion of aluminum atoms mainly afftects the peak of transient photocurrent, while the concentration of bulk defects shows a certain degree of influence in the long term. The influence of aluminum atom diffusion and bulk defect density is different, and the reasons for this need to be further studied.

Conclusions

DLTS and TCAD simulation technology are used to prove that the influence mechanism of defects introduced by high temperature annealing treatment do not lead to changes in basic electrical properties on transient photocurrent. It is that the interface state formed between AlCu-Si is a minority carrier trap defect, which reduces minority carrier lifetime and leads to the improve of transient photocurrent. Therefore, some deep-level defects of materials cannot be detected by general electrical performance tests, which lead to unknown devices problems for the scene requiring high reliability (such as space radiation effects). In this paper, the deep level transient spectrum defect detection technology may be used as a test method for the reinforcement of space radiation effect.

Data availability

The datasets generated and/or analysed during the current study are not publicly available, because the samples and laser experimental setup involve special test items which is not convenient for disclosure. However, these are available from the corresponding author on reasonable request.

References

Sidel, V. W. The effects of nuclear weapons. Am. J. Public Health 97, 1589–1594 (2007).

Chen, Q. et al. Characteristics of latch-up current of dose rate effect by laser simulation. Acta Phys. Sin. 68, 12 (2019).

Yan, G. et al. Accumulative total ionizing dose (TID) and transient dose rate (TDR) effects on planar and vertical ferroelectric tunneling-field-effect-transistors (TFET). Microelectron. Reliab. 114(9), 113855 (2020).

Gromov, D. V., Maltsev, P. P. & Polevich, S. A. Laser-assisted simulation of transient radiation effects in heterostructure components based on AIIIBV semiconductor compounds. Semiconductors 50(2), 222–227 (2016).

Cardoso, A. S. et al. Single-event transient and total dose response of precision voltage reference circuits designed in a 90-nm SiGe BiCMOS technology. IEEE Trans. Nucl. Sci. 61(6), 3210–3217 (2014).

Gao, Y. et al. High-temperature mechanical properties of carbon fiber reinforced polyimide resin matrix composites MT300/KH420(I)–tensile and interlaminar shear properties. Acta Mater. Compos. Sin. 33, 1206 (2016).

Wen-wen, S. U. N. et al. Effect of preparation layer temperature on photoelectric properties and aging properties of yellow light-emitting diode. Chin. J. Luminesc. 41(4), 461–467 (2020).

Hsu, Y. C., Lin, Y. K. & Tsai, C. C. et al. Failure mechanisms associated with lens shape of high-power LED modules in aging test. In LEOS 2007—IEEE Lasers and Electro-Optics Society Annual Meeting Conference Proceedings (2007).

Zhou, Z. The aging characteristics of high-power GaN-based white light-emitting diodes. Chin. J. Luminesc. 32(10), 1046–1050 (2011).

Yang, S. & Yang, X. Microstructure and mechanical properties of SnAgCu/Cu solder joint during isothermal aging. Trans. China Weld. Inst. 34(5), 83–86 (2013).

Harun, S. W., Moghaddam, M. R. A. & Ahmad, H. High output power Erbium-Ytterbium doped cladding pumped fiber amplifier. Laser Phys. 20(10), 1899–1901 (2010).

Qi, M. et al. Research on high temperature friction properties of PTFE/fluorosilicone rubber/silicone rubber. Polym. Test. 2020, 106817 (2020).

Ishihara, H. et al. High temperature aging test of planar InGaAs/InP PIN phototransistors in Ti/Pt and Ti/Au contact. Semiconductor Optoelectronics. (1985).

Liu, W. M. et al. Research on vacuum packaging of micro-gyroscope with vacuum reflow furnace. Microfabric. Technol. 2, 61 (2006).

FALTUS et al. Aluminium alloy with good machinability. Patent Number: EP0828008A3

Kagadey, V. A. et al. The enhanced outdiffusion and its influence on the impurity behavior in the implanted Si at rapid electron beam annealing. MRS Proc. 279, 219 (1992).

Zhang, D. F. et al. Effect of silicon phase on copper diffusion speed in the Al-Si-Cu alloys. Heat Treat. Metals 31(6), 13–16 (2006).

Duenas, S. et al. The electrical-interface quality of as-grown atomic-layer-deposited disordered HfO2 on p- and n-type silicon. Semicond. Sci. Technol. 19(9), 1–8 (2004).

Wang, Y. H. et al. Study of non-equilibrium thermal transport in Ge2Sb2Te5 thin films under ultrafast laser excitation using a photo-excited carrier integrated semiconductor model. J. Appl. Phys. 122(4), 043104 (2017).

He, Q. et al. Improvement of the minority carrier lifetime of Fe contaminated UMG-Si ingot by Sn doping. Mater. Rev. 2016, 8 (2016).

Wunderlich, W., Fujimoto, M. & Ohsato, H. Molecular dynamics calculations about misfit dislocations at the BaTiO3/SrTiO3-interface—ScienceDirect. Thin Solid Films 375(1), 9–14 (2000).

Jian, R. et al. Comparison of electrical characteristics between AlGaN/GaN and lattice-matched InAlN/GaN heterostructure Schottky barrier diodes. Microelectron. Reliab. 61, 82–86 (2016).

Acknowledgements

This research was funded by the National Natural Science Foundation of China (No. U2241280) and the Study Encouragement to Youth Innovation Promotion Association Outstanding Member of Chinese Academy of Sciences (No. Y2022057).

Author information

Authors and Affiliations

Contributions

Y.H.W. wrote the main manuscript. Others provide assistance to complete tests in this paper.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, Y.H., Su, J.H., Wang, T.W. et al. Study on transient photocurrent induced by energy level defect of schottky diode irradiated by high power pulsed laser. Sci Rep 13, 14487 (2023). https://doi.org/10.1038/s41598-023-40983-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-40983-z

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.