Abstract

In this study, we have demonstrated the application of sodium manganese oxide for the chemisorption of toxic acidic gases at room temperature. The fabricated alkali ceramic has Na0.4MnO2, Na2Mn3O7, and NaxMnO2 phases with a surface area of 2.6 m2 g–1. Na-Mn oxide was studied for oxidation of H2S, SO2, and NO2 gases in the concentration range of 100–500 ppm. The material exhibited a high uptake capacity of 7.13, 0.75, and 0.53 mmol g–1 for H2S, SO2, and NO2 in wet conditions, respectively. The material was reusable when regenerated simply by soaking the spent oxide in a NaOH-H2O2 solution. While the H2S chemisorption process was accompanied by sulfide, sulfur, and sulfate formation, the SO2 chemisorption process yielded only sulfate ions. The NO2 chemisorption process was accomplished by its conversion to nitrite and nitrate ions. Thus, the present work is one of the first reports on alkali ceramic utilization for room-temperature mineralization of acidic gases.

Similar content being viewed by others

Introduction

The unprecedented rise in global energy requirements has triggered a massive climate imbalance around the globe. The emission from the combustion of fossil fuels (coal, petroleum, and natural gas) is the main reason behind the increasing concentration of acidic gases in the atmosphere. As per the study published in “The Lancet Planetary Health,” nearly 3 million global deaths in 2019 were associated with air pollution, making it one of the leading causes of death1. Moreover, these air pollutants are responsible for soil and water sources acidification, infrastructure corrosion, and loss of biodiversity2. Since it is impossible to switch from fossil fuels to green energy alternatives overnight, developing cleaner and more effective air decontamination technologies is more appropriate. These technologies are expected to clean fuel gases before combustion and flue gases originating from thermal power plants and industries.

The adsorption of acidic gases over porous materials like activated carbon3,4 or metal–organic frameworks (MOFs)5,6 is a go-to-response in the research community due to the availability of a large surface area for the gas to interact and the possibility of tuning these materials for better gas capture. MOFs exhibit a large surface area and specific interactions with acidic gas molecules, making them highly effective in gas capture. However, these materials are expensive and use toxic chemicals in their preparation7. Besides, these MOFs perform poorly at a low gas concentration (100–1000 ppm), making their role debatable in deep flue gas desulfurization and natural gas purification. The best MOF that has reached these requirements is Co-gallate, which could adsorb SO2 at a low pressure of 0.002 bar at 298 K8.

Previously, we developed MOF-derived Na-Mn oxides for room-temperature H2S mineralization at an ultra-low pressure of 0.0005 bar, where the derived oxide had a maximum adsorption capacity of 24.1 mmol g–1 with partial regenerability9. However, the method developed for synthesizing Na-Mn oxide was still expensive and involved toxic chemicals. To overcome these challenges, we have adopted a low-cost and eco-friendly approach to fabricating Na-Mn oxide, specifically, NaxMnO2. Na-Mn oxides in rechargeable Na-ion batteries are among the most explored materials for energy storage applications10,11,12. Other than that, these materials have found applications in radionuclides sequestration13,14 and heterogeneous catalysis15,16. However, these alkali ceramics are rarely explored for air decontamination applications, though these have better prospects of eliminating acid gases even at room temperature.

In this study, we have exploited the basic sites in NaxMnO2 for room-temperature oxidation of H2S, SO2, and NO2 gases in ambient conditions. The fabricated material was tested in column breakthrough configuration with 100–500 ppm of acidic gases to confirm its applicability in real-world problems involving flue gas purification17,18. The material exhibited a better gas chemisorption efficiency in wet conditions. The underlying mechanism driving the gas chemisorption process over the alkali ceramic was probed by various microscopic and spectroscopic techniques. The material possessed a high gas uptake behaviour even after three adsorption-regeneration cycles when regenerated by a green and inexpensive solution. We believe that the developed Na-Mn oxide ceramic is an affordable and green solution for tackling the rising concentrations of acidic gases in the atmosphere. With this work, we are opening a newer application of alkali ceramics in air decontamination applications.

Methods

Chemicals

Manganese(II) acetate tetrahydrate (Mn(CH3COO)2·4H2O) and Sodium acetate trihydrate (CH3COONa·3H2O) were procured from Samchun Pure Chemicals, Korea. Sodium hydroxide (2 mol L–1 NaOH) and hydrogen peroxide (28.0 Vol.% H2O2) solution were procured from Daejung Chemicals and Metals Co. Ltd, Korea. Highly pure H2S (Vol. 0.05%), SO2 (Vol. 0.01%), and NO2 (Vol. 0.01%) gas in N2 gas were procured from Union gas, Korea. All the chemicals were of analytical grade and used without any further purification.

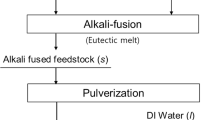

Fabrication of NaxMnO2

Mn(CH3COO)2·4H2O (12.25 g) and CH3COONa·3H2O (3.40 g) in a molar ratio of 2:1 were dissolved in a minimum volume of deionized water. The solution was dried at 130 °C overnight (paste-like composition) and pre-calcined at 300 °C for 2 h in a muffle furnace for acetate decomposition. The black powder was further calcined at 700 °C for 8 h to yield the resultant NaxMnO2 abbreviated as NMO.

Analytical instruments

The oxide morphology was probed through field emission scanning electron microscopy (FE-SEM, Hitachi S-4300, Hitachi, Japan) and field emission transmission electron microscopy (FE-TEM, JEM-2010F, JEOL Ltd., Japan). Elemental mapping was conducted using energy-dispersive X-ray spectroscopy (EDAX) (X-Maxn 80T, Oxford Instruments, United Kingdom) in TEM mode. The X-ray diffraction patterns were recorded at 298 °C between 2θ = 5–100°) on an Ultima IV (Rigaku, Japan) X-ray diffractometer with Cu Kα radiation (λ = 1.5406 Å) and a Ni filter. Fourier transform infrared (FT-IR) spectra were collected over a Cary670 FTIR spectrometer (Agilent Technologies, United States). The specific surface area and porosity of samples were determined by analysing the standard N2 adsorption–desorption isotherm at − 196 °C using a Gemini 2360 series (Micromeritics, United States) instrument after degassing at 150 °C for 8 h. X-ray photoelectron spectroscopy (XPS: Nexsa X-Ray Photoelectron Spectrometer System, Thermo Scientific, United Kingdom) was used to determine the chemical states of the elements in the samples. A monochromatic Al Kα X-ray source was used with a fixed pressure of 4.8 × 10−9 mbar. Spectra were charge corrected to the main line of the C 1s spectrum (aromatic carbon) set to 284.7 eV. Spectra were analysed using CasaXPS software (version 2.3.14) with GL(p) = Gaussian/Lorentzian product formula, where the mixing is determined by m = p/100, GL(100) is a pure Lorentzian, while GL(0) is a pure Gaussian. We used GL(30).

Breakthrough experiments

A 250 mg of the adsorbent was placed in a Pyrex tube between glass wool, and a gas flow of 200 mL min−1 was maintained. The samples were fully saturated with moisture by blowing water vapour (80% relative humidity) at 25 °C for 20 min through the adsorbent bed. The H2S concentration in the outflow gas was analysed by an H2S gas analyser (GSR-310, Sensoronic, Korea). The SO2 concentration in the effluent gas was analysed using GASTIGER 6000 SO2 analyser (Wandi, Korea). The material was tested for NO2 adsorption with a flow rate of 100 mL min−1. The NO2 concentration was analysed using GASTIGER 6000 NO2 analyser (Wandi, Korea). The adsorption capacity (q, mmol g−1) at the breakthrough point (20% of the input gas) was calculated by the following equation:

C0—initial concentration, Q—flow rate, m—the mass of oxide (g), Mw,g—gas molecular weight, and tb—breakthrough time.

Regeneration of spent oxide was done by soaking it in a binary solution (10 mL) of 0.25 mol L−1 of NaOH and 0.50 mol L−1 of H2O2 for 8 h. After phase separation, the material was dried and studied for gas adsorption experiments. The same solution was reused for the subsequent regeneration cycles. A mass loss during the regeneration process was expected, and normalized time was adopted to calculate the adsorption capacity.

Results and discussion

Characterization of NaxMnO2

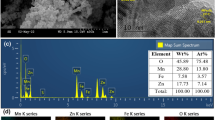

The SEM micrograph of NMO confirmed two different morphologies, a microrod-like feature (for Na0.4MnO2)19 and irregularly shaped microsheets (for Na2Mn3O7 and birnessite)20, for the synthesized material. The presence of different morphologies was due to the formation of different phases of NaxMnO2 (Fig. 1a)21. In the HR-TEM image, the microrod exhibited a fringe width of 0.55 nm corresponding to the 201 reflection of Na0.4MnO2, which further confirmed that the microrod feature was for the Na0.4MnO2 phase (Fig. 1b)19. The EDAX analysis confirmed the peaks for Mn, Na, and O at respective energy. Moreover, the Na: Mn ratio of 0.49 was nearly equal to the initial ratio of 0.5 for the metal precursors (Fig. 1c). The 2D elemental mapping showed a low and irregular distribution of ‘Na’ over the ‘Mn’ map, probably due to a low Na: Mn ratio in Na0.4MnO2 and a comparatively higher ratio of 0.7 in Na2Mn3O7 (Fig. 1d).

The Rietveld refinement of the XRD data was done to deduce the phases and structures in the prepared NMO sample. The observed and calculated diffraction patterns were in close agreement. The typical Rietveld refinement plot (Figure S1) and the refined structural parameters (Table S1) are available in the ESI file. The PXRD pattern of NMO and identified phases are presented in Fig. 2a. The first major phase was identified as Na0.4MnO2, crystallized in an orthorhombic lattice and space group Pbnm (a = 9.0741 Å, b = 26.4304 Å, c = 2.8240 Å)22. The second major phase was triclinic Na2Mn3O7 crystallized in P-1 space group (a = 6.604 Å, b = 6.851 Å, c = 7.527 Å, α = 106.29°, β = 106.63°, γ = 111.65°)23,24. A minor phase was identified as rhombohedral NaxMnO2 (Birnessite) crystallized in the P-3 space group (a = 2.8583 Å, c = 7.1108 Å)25. Thus, the analysis validated the presence of different Na-Mn oxide phases in the NMO sample.

The FTIR spectrum of NMO has a sharp high-intensity band at 3437 cm−1, which was assigned to the O–H stretching vibration of –OH/H2O. A low-intensity band at 1636 cm−1 was associated with the bending mode of adsorbed H2O molecules. The bands at 1449 and 751 cm−1 were attributed to the stretching Mn–OH and Na–O vibrations, respectively. Multiple sharp bands between 400–470 and 500–570 cm−1 were associated with the stretching vibrations of Mn–O/Na–O (Fig. 2b)9,26. The surface and pore characteristics of NMO were evaluated by N2 adsorption–desorption isotherms (Fig. 2c). The oxide exhibited type II isotherm behavior, generally observed for nonporous or macroporous materials27. The average pore diameter (Dp ~ 18 nm) and pore volume (Vp ~ 0.01 cm3 g–1) were calculated using the Brunauer–Emmett–Teller (BET) and Barrett–Joyner–Halenda method, respectively (Table S2). The surface area of 2.6 m2 g–1 was estimated using the BET method. The XPS survey of NMO has peaks for Na 1s, Mn 2p, and O 1s at respective binding energy. The C 1s peak was due to the adventitious carbon contamination (Fig. 2d)28.

The HRXPS Mn 2p spectrum of NMO has two peaks at 642.5 and 654.3 eV for 2p3/2 and 2p1/2, respectively (Fig. 3a, Table S3). The Mn 2p3/2 peak was deconvoluted into three contributions at 641.1 (14.1%), 642.4 (42.6%), and 643.5 eV (43.2%), which were assigned to the Mn2+, Mn3+, and Mn4+ oxidation states, respectively29,30. Previously reported studies on NaxMnO2-type materials have confirmed the existence of Mn ions exclusively in the + 4 and + 3 oxidation states19,30. However, the permanent existence of Mn2+ ions in these materials is a likely event, which has been observed for NaMnO2-type material31. Here, we have noticed a minor yet significant fraction of Mn ions in the + 2 oxidation state, following our reported study on NaMnxOy, where the oxide possessed 10.2% of Mn in the divalent state32. Thus, the analysis confirmed mixed valence states for Mn with an average oxidation state of + 3.3. The HRXPS Mn 3s spectrum could also shed light on the oxidation states of Mn in the material. The Mn 3s spectrum displayed two peaks at 84.3 and 89.0 eV with an energy separation value of 4.7 eV, which further indicated a major presence of Mn in the + 3 and + 4 oxidation states (Fig. 3b, Table S4)19. The HRXPS Na 1s spectrum has one peak at 1071.0 eV, which was associated with Na+ ions in the NMO structure (Fig. 3c)19. The HRXPS O 1s spectrum was deconvoluted into four contributions at 529.7, 531.4, 533.3, and 535.1 eV for lattice oxygen (OL), surface-bound hydroxyl groups (− OH), adsorbed H2O33, and Na Auger34, respectively (Fig. 3d, Table S5).

Gas breakthrough studies

The H2S and SO2 adsorption capacities of NMO were measured in dry and wet conditions (Fig. 4). The adsorption capacity of NMO was 0.41 and 3.90 mmol g−1 in dry and wet conditions, respectively (Fig. 4a). The SO2 adsorption capacity of NMO was 0.06 and 0.35 mmol g−1 in dry and wet conditions, respectively (Fig. 4b). These many-fold improvements in the adsorption capacity upon water vapour addition in the adsorbent bed suggested a strong involvement of the acidic gas dissolution process during the process. The dissolution of H2S \({(\mathrm{H}}_{2}\mathrm{S}(g)+{\mathrm{H}}_{2}\mathrm{O}(l)\to {\mathrm{HS}}^{-}(l)+{\mathrm{H}}_{3}{\mathrm{O}}^{+}(l))\)35 or SO2 (\({\mathrm{SO}}_{2}(g)+{\mathrm{H}}_{2}\mathrm{O}(l)\to {2\mathrm{H}}^{+}(l)+{\mathrm{SO}}_{3}^{2-}(l))\)36 in H2O layers to form reactive species is primarily responsible for a high H2S/SO2 uptake in wet oxides. The oxidation of sulfur (S0) and sulfide (S2−) species to sulfate (SO42−) in the presence of H2O and molecular O2 further enhances the H2S uptake capacity37. A similar effect is observed for SO2 adsorption, where the introduction of water to the adsorption system favours the SO2 uptake process by converting surface oxidized SO2 form (i.e., SO3) to sulfuric acid36. Water molecule dissociative adsorption over the metal oxide surface (to form –OH groups) improves the gas molecule interaction through reactive pathways35. Long et al. have reported significant improvement in the H2S and SO2 uptake gas over Na-MnOx xerogel and aerogel in humid conditions38. Even in our previously reported study on H2S adsorption over NaMnxOy, we witnessed ~ 5–6 fold improvement in the gas adsorption capacity when the adsorbent bed was saturated with water vapours9. Besides H2S and SO2, the NMO adsorbent was tested for NO2 gas as well (Figure S2). The oxide exhibited an uptake capacity of 0.53 mmol g−1 for NO2 gas, making it applicable to a broad spectrum of acidic gases.

In the literature, multiple Mn-based adsorbents have been reported to capture acidic gases in ambient conditions (Table 1). The Na-Mn oxide composite fabricated in this study outperforms many previously reported materials on efficacy and regenerability. However, some materials like Na-MnOx aerogel have demonstrated exceptionally high adsorption capacity with no regenerability38. Even MOF-derived NaMnxOy has shown a record-breaking capacity of 24.1 mmol g−19. However, these studies involved template-based synthesis approaches, which are tedious, energy-intensive, and environmentally unfriendly. Though adsorbent like Mn3O4/γ-Al2O3 has shown a high NO2 adsorption capacity39, we have demonstrated that Na-Mn oxide developed in this study could capture multiple acidic gases at low concentrations of 100–500 ppm.

The effect of column operational parameters like adsorbent mass and the gas flow rate was studied with SO2 as the target pollutant. The breakthrough experiments were carried out by varying the oxide mass between 0.25 and 0.45 g with a constant SO2 flow rate of 0.2 L min−1 (Fig. 4c). The SO2 adsorption capacity improved from 0.35 to 0.49 mmol g−1 with an increase in the oxide loading from 0.25 to 0.45 g. The increasing mass (increasing bed height) improves the gas retention time, which provides a better chance for a gas molecule to interact with the active sites. This increased adsorbate-adsorbent interaction enhances the gas adsorption capacity40. The effect of gas flow rate was studied between 0.1–0.3 L min−1 with a constant adsorbent mass of 0.25 g (Fig. 4d). The SO2 uptake capacity significantly dropped from 0.52 to 0.30 mmol g−1 with the rising flow rate from 0.1 to 0.3 L min−1. This inverse relationship is due to the decrease in the gas retention time and poor mass transfer with the increasing flow rate, which reduces the adsorbate-adsorbent interaction41.

One of the challenges for the reactive adsorption of acidic gases over metal oxides in ambient conditions is the regeneration of material for its judicious use. Metal oxide adsorbents are readily deactivated post-acidic gas adsorption and thermally treated at high temperatures for surface activation and subsequent reuse42,43,44. The idea of thermal regeneration severely limits the novelty of the room-temperature adsorption process as it is energy-intensive and forms secondary pollutants like SOx45. We are focused on developing affordable, zero-energy, and green regeneration strategies, which make the entire adsorption process lucrative. Previously, we have demonstrated partial regeneration of spent NaMnxOy by soaking it in an NH4OH solution. The material maintained ~ 47% (9.97 mmol g−1) of its initial capacity even after the fourth adsorption-regeneration cycle9. Even we have used an H2O2 solution in the partial regeneration of Ag–Cu-MOF post-H2S adsorption46.

Here, we have used a binary solution of NaOH and H2O2 for regenerating spent oxide by soaking it for 8 h, which is green, low-cost, and energy-free. We have demonstrated the applicability of the regeneration process for three cycles for H2S and SO2. The oxide exhibited an H2S adsorption capacity of 7.13 mmol g−1 in the first cycle, which dropped to 4.56 mmol g−1 (64% of initial capacity) in the third cycle (Fig. 4e). The gas removal capacity is still high even after the third cycle, which makes the entire process efficient for H2S uptake. The SO2 adsorption capacity of 0.75 mmol g−1 in the first cycle improved to 0.92 mmol g−1 in the third cycle (Fig. 4f). Thus, the alkali ceramic developed in this study is highly regenerative and effective for the chemisorption of various acidic gases.

Adsorption mechanism

The SEM micrographs of NMO before and after gas adsorption showed no significant morphological change in the material (Figure S3). The 2D elemental mapping of spent NMO samples is shown in Fig. 5. In all the samples, the ‘Mn’ and ‘Na” density was intact. In H2S- and SO2-adsorbed NMO samples, wide distribution of ‘S’ was confirmed (Fig. 5a,b). Similarly, for the NO2-adsorbed NMO sample, uniform distribution of ‘N’ over NMO was observed (Fig. 5c). The surface area and pore characteristics of water- and gas-exposed NMO samples are available in Table S2. There was no change in the shape of the N2 adsorption–desorption isotherms of these samples (Figure S4). The water-exposed-dried sample (hereafter denoted as NMO_H2O*) has a higher surface area and pore volume than the pristine sample, which could be one of the many reasons for higher gas adsorption. The surface area and pore volume of the H2S-exposed sample were the lowest due to the highest surface coverage with oxidized sulfur species. The Rietveld refinement plot of the NMO_H2O* sample remained unaltered with no compositional phases. Moreover, with an insignificant variation in the XRD plots of gas-exposed samples, a surface-driven delocalized chemisorption process was confirmed in this study (Figure S5).

The FTIR spectra of pristine NMO and NMO_H2O* overlapped with all bands intact (Fig. 6a). The FTIR spectrum of the H2S-adsorbed sample has new high-intensity bands at 1001 and 1126 cm−1 for the stretching vibration v1 and v3 modes of SO42− species, respectively (Fig. 6b)32,52. For the SO2-adsorbed NMO sample, the band at 993 cm−1 was related to the stretching vibration of the SO42− species (Fig. 6c). In the FTIR spectrum of NO2-adsorbed NMO, bands were observed at 1456, 1384, and 1271 cm−1. The band at 1384 cm−1 was associated with the stretching vibrations of nitrate (NO3−) ions. The bands at 1271 and 1456 cm−1 were due to the nitrite (NO2−) ions (Fig. 6d)53.

XPS spectroscopy was used to understand the adsorption behavior of NMO for various acidic gases. The peak at 1070.8 eV in the Na 1s spectrum of NMO_H2O* redshifted by 0.2 eV compared to the NMO sample. It was possibly due to the interaction of H2O molecules with the Na+ ions, which increased the electron density in the valence state of Na ions and redshifted the Na 1s peak. The binding energy of Na 1s peak shifted to a higher value upon acidic gas adsorption, which was associated with the removal of H2O molecules from Na+ ions and the interaction of oxidized sulfur or nitrogen species with the surface Na+ ions. This blue shift in the Na 1s binding energy has been witnessed for H2S chemisorption over NaMn0.6O3.2 (Fig. 7a)9. The HRXPS Mn 2p spectrum of NMO_H2O* has the same three contributions for + 2, + 3, and + 4 oxidation states, with their binding energy shifted to a lower value by 0.2–0.3 eV due to the interaction of H2O molecules and the formation of surface –OH groups (Fig. 7b)54. The surface hydroxyl formation was confirmed by the increased proportion of 531.7 eV peak in the O 1s spectrum of NMO_H2O*. This peak is associated with the hydroxyl group, which improved by 7.3% upon H2O exposure (Fig. 7d). This additional formation of Mn-anchored OH groups could serve as the binding sites and oxidation sites for acidic gas molecules9,32,55. In the HRXPS Mn 2p spectra of gas-exposed NMO samples, the binding energy for peaks corresponding to all three oxidation states reverted to the value of the fresh NMO sample. For NMO_H2S, the Mn2+ proportion increased to 24.0 from 17.4% in NMO_H2O*. The increased Mn2+/Mn4+ ratio upon H2S adsorption confirmed that Mn redox cycles oxidized S2− to S0 with the reduction of Mn4+ to Mn2+9,56. For the NMO_SO2 sample, the Mn2+ and Mn3+ proportion improved at the expense of Mn4+ ions. Previously, Quesne-Turin et al.reported the surface oxidation of SO2 gas molecules over Li2MnO3, where the gas probe molecule was oxidized to SO42− and a fraction of Mn4+ ions were reduced to Mn3+57. Here, the SO2 oxidation mechanism lowered the Mn oxidation state and formed SO42− species36. Like SO2, NO2 oxidizes on the NMO surface by reducing the Mn oxidation state. Because of this, the Mn3+ contribution increased at the expense of Mn4+ for the NMO_NO2 sample (Fig. 7b). The increased Mn2+ ion contribution in the samples could be identified qualitatively from the energy separation value in their respective Mn 3s spectrum. An increase from 4.6 eV (in NMO_H2O*) to 5.0 and 4.7 eV for H2S- and SO2-adsorbed NMO, respectively, further confirmed the increment in Mn2+ proportion. Since we did not observe any improvement in Mn2+ contribution for NMO_NO2, the energy separation value remained the same (Fig. 7c)58. One important thing to note here is that though the oxidation state variation is expected during these redox reactions, the proportional changes in the %Mnn+ ratio are not high. The possible reason for this is the role of adsorbed molecular O2, which could re-oxidize these low oxidation state Mn ions to a higher valency36,59. But, from the Mn 2p and Mn 3s analyses, it is confirmed that the Mn sites in NMO are the active sites for the adsorption and oxidation of acidic gas molecules.

The HRXPS O 1s spectrum could not be exploited for extracting new information as the peak for –OH groups at 531.7 eV in gas-adsorbed NMO samples coupled with the S–O bond contribution (from SO42−) at 531.8 eV60. The HRXPS S 2p spectrum of the H2S-adsorbed NMO sample showed a complex spectral shape, which after deconvolution, has three sets of doublets. The S 2p3/2 peak at 162.0, 164.1, and 168.1 eV were assigned to the S2− (34.1%)61, S0/polysulfide, Snn− (13.4%)62,63, and SO42− (52.5%) (Table S6)63, respectively. Thus, three sulfur species were confirmed as the by-products of the H2S chemisorption process. The adsorbed H2S molecules on the NMO surface dissociated to form S2− ions after chemically reacting with the OL sites or –OH groups. The S2− ions further oxidized to S0/Snn− by the Mn4+/Mn3+/Mn2+ redox cycle64. Finally, these species were oxidized by surface-adsorbed H2O and molecular O2 to SO42− ions41. The formation of these three sulfur species upon H2S adsorption is well-documented for NaMxOy-type materials9,41. The HRXPS S 2p spectrum of NMO_SO2 has only one doublet. The 2p3/2 peak at 168.8 eV was associated with SO42− species formed after the reactive adsorption of SO2. The adsorbed SO2 molecule could either be hydrolyzed in the surface H2O or directly react with the OL sites/–OH groups on the NMO surface to yield sulfite (SO32−) ions. These SO32− ions readily reacted with the molecular O2 on the NMO surface to yield SO42− ions38. Previously, the interaction of SO2 molecules with the LiMn2O3 surface has confirmed the preferential formation of SO42− over SO32− in ambient conditions57,65. Moreover, our previous work confirmed SO42− species formation over NaMnxOy after low-temperature SO2 adsorption (Fig. 7e)32. The HRXPS N 1s spectrum of NMO_NO2 has two well-defined peaks at 403.5 and 407.0 eV with a contribution of 32.9 and 67.1% (Table S7), which were assigned to NO2− and NO3− ions, respectively66. The direct interaction of NO2 with OL sites or a disproportionate reaction between NO2 molecules on Mn sites could form NO3− species on the NMO surface67. The disproportionate products NO3− and NO+ are located on adjacent Lewis acid (Mnn+) and Lewis base (O2−) sites, respectively, and formed through an intermolecular electron transfer process66. The second product of the disproportionate reaction, i.e., NO+, reacts readily with the OL sites to form NO2− species68. Another possible reaction pathway could be the interaction of NO2 molecules with the surface –OH group to form NO3− ions (Fig. 7f)69.

Conclusion

In this study, we have synthesized a novel and affordable sodium manganese oxide for the chemisorptive removal of low concentrations of toxic acidic gases at room temperature. The fabricated Na-Mn oxide has orthorhombic Na0.4MnO2, triclinic Na2Mn3O7, and rhombohedral NaxMnO2. The oxide possessed a surface area of 2.6 m2 g–1 with a dual rod-sheet morphology. The oxide showed a better acidic gas uptake capacity in wet conditions due to the formation of –OH groups on the NMO surface and the involvement of the gas dissolution process. The Na-Mn oxide exhibited a gas uptake capacity of 7.13, 0.75, and 0.53 mmol g–1 for H2S, SO2, and NO2, respectively, in wet conditions. The oxide was regenerable for multiple cycles after soaking in a binary NaOH-H2O2 solution. Insignificant changes in the PXRD pattern of gas-exposed samples confirmed the delocalized chemisorption process on two–three layers of the oxide surface. The spectroscopic analyses confirmed the formation of S2− (34.1%), S0 (13.4%), and SO42− (52.5%) species upon the H2S adsorption-oxidation process. While SO2 molecules oxidized to surface-bound SO42− ions, the NO2 oxidation process formed NO2− (32.9%) and NO3− (67.1%) ions. These surface reactions were mediated by the lattice oxygen, surface hydroxyl groups, and Mn redox cycles in H2O and O2 presence. Thus, we have demonstrated Na-Mn oxide as a robust and affordable material for removing lowly concentrated acid gases at room temperature. Moreover, the developed regeneration method could make these materials lucrative for air purification processes.

Data availability

The data will be made available by N.K. Gupta (guptan@kict.re.kr) only after a reasonable request.

References

Fuller, R. et al. Pollution and health: A progress update. Lancet Planet. Health 6, e535–e547 (2022).

Manisalidis, I., Stavropoulou, E., Stavropoulos, A. & Bezirtzoglou, E. Environmental and health impacts of air pollution: A review. Front. Public Health 8, 14 (2020).

Feng, W., Kwon, S., Borguet, E. & Vidic, R. Adsorption of hydrogen sulfide onto activated carbon fibers: Effect of pore structure and surface chemistry. Environ. Sci. Technol. 39, 9744–9749 (2005).

Severa, G., Head, J., Bethune, K., Higgins, S. & Fujise, A. Comparative studies of low concentration SO2 and NO2 sorption by activated carbon supported [C2mim][Ac] and KOH sorbents. J. Environ. Chem. Eng. 6, 718–727 (2018).

Martínez-Ahumada, E., Díaz-Ramírez, M. L., Velásquez-Hernández, M. J., Jancik, V. & Ibarra, I. A. Capture of toxic gases in MOFs: SO2, H2S, NH3 and NOx. Chem. Sci. 12, 6772–6799 (2021).

López, Y. C. et al. Transition metal-based metal–organic frameworks for environmental applications: A review. Environ. Chem. Lett. https://doi.org/10.1007/s10311-020-01119-1 (2021).

Kumar, P. et al. Regeneration, degradation, and toxicity effect of MOFs: Opportunities and challenges. Environ. Res. 176, 108488 (2019).

Chen, F. et al. Deep desulfurization with record SO2 adsorption on the metal–organic frameworks. J. Am. Chem. Soc. 143, 9040–9047 (2021).

Gupta, N. K., Bae, J. & Kim, K. S. Metal-organic framework-derived NaMnxOy hexagonal microsheets for superior adsorptive-oxidative removal of hydrogen sulfide in ambient conditions. Chem. Eng. J. 427, 130909 (2021).

Ortiz-Vitoriano, N., Drewett, N. E., Gonzalo, E. & Rojo, T. High performance manganese-based layered oxide cathodes: overcoming the challenges of sodium ion batteries. Energy Environ. Sci. 10, 1051–1074 (2017).

Pandit, B. et al. High stability and long cycle life of rechargeable sodium-ion battery using manganese oxide cathode: A combined density functional theory (DFT) and experimental study. ACS Appl. Mater. Interfaces 13, 11433–11441 (2021).

Chae, M. S., Elias, Y. & Aurbach, D. Tunnel-type sodium manganese oxide cathodes for sodium-ion batteries. ChemElectroChem 8, 798–811 (2021).

Bevara, S. et al. Synthetic Na/K-birnessite for efficient management of Sr(II) from nuclear waste. J. Environ. Chem. Eng. 6, 7200–7213 (2018).

Chakravarty, R. et al. Birnessite: A new-generation and cost effective ion exchange material for separation of clinical-grade 90Y from 90Sr/90Y mixture. ChemistrySelect 3, 10670–10676 (2018).

Escande, V., Lam, C. H., Coish, P. & Anastas, P. T. Heterogeneous sodium-manganese oxide catalyzed aerobic oxidative cleavage of 1,2-diols. Angew. Chem. Int. Ed. 56, 9561–9565 (2017).

Jia, X. et al. Alkali α-MnO2/NaxMnO2 collaboratively catalyzed ammoxidation–Pinner tandem reaction of aldehydes. Catal. Sci. Technol. 6, 7429–7436 (2016).

Zach, B. et al. The influence of SO2 and HCl concentrations on the consumption of sodium bicarbonate during flue gas treatment. Energy Fuels 35, 5064–5073 (2021).

Lin, Y., Li, Y., Xu, Z., Guo, J. & Zhu, T. Carbon consumption and adsorption-regeneration of H2S on activated carbon for coke oven flue gas purification. Environ. Sci. Pollut. Res. 28, 60557–60568 (2021).

Zhang, Y. et al. Rectangular tunnel-structured Na0.4MnO2 as a promising cathode material withstanding a high cutoff voltage for Na-ion batteries. ChemElectroChem 6, 1711–1721 (2019).

Sada, K., Senthilkumar, B. & Barpanda, P. Layered Na2Mn3O7 as a 3.1 V insertion material for Li-ion batteries. ACS Appl. Energy Mater. 1, 6719–6724 (2018).

Han, D.-W. et al. Aluminum manganese oxides with mixed crystal structure: High-energy-density cathodes for rechargeable sodium batteries. Chemsuschem 7, 1870–1875 (2014).

Sehrawat, D. et al. Alkali metal-modified P2 NaxMnO2: Crystal structure and application in sodium-ion batteries. Inorg. Chem. 59, 12143–12155 (2020).

Song, B. et al. Understanding the low-voltage hysteresis of anionic redox in Na2Mn3O7. Chem. Mater. 31, 3756–3765 (2019).

Adamczyk, E. & Pralong, V. Na2Mn3O7: A suitable electrode material for Na-ion batteries?. Chem. Mater. 29, 4645–4648 (2017).

Elmi, C., Post, J. E., Heaney, P. J. & Ilton, E. S. Effects of pH and Ca exchange on the structure and redox state of synthetic Na-birnessite. Am. Mineral. 106, 15–27 (2021).

Park, Y. et al. Understanding hydrothermal transformation from Mn2O3 particles to Na0.55Mn2O4·1.5H2O nanosheets, nanobelts and single crystalline ultra-long Na4Mn9O18 nanowires. Sci. Rep. 5, 18275 (2015).

Thommes, M. et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 87, 1051–1069 (2015).

Boumaiza, H. et al. A multi-technique approach for studying Na triclinic and hexagonal birnessites. J. Solid State Chem. 272, 234–243 (2019).

Bose, V. C. & Biju, V. Mixed valence nanostructured Mn3O4 for supercapacitor applications. Bull. Mater. Sci. 38, 865–873 (2015).

Sun, T. et al. Micron-sized Na0.7MnO2.05 as cathode materials for aqueous rechargeable magnesium-ion batteries. Ionics 25, 4805–4815 (2019).

Feng, X. & Cox, D. F. Oxidation of MnO(100) and NaMnO2 formation: Characterization of Mn2+ and Mn3+ surfaces via XPS and water TPD. Surf. Sci. 675, 47–53 (2018).

Gupta, N. K., Bae, J., Baek, S. & Kim, K. S. Metal-organic framework-derived NaMxOy adsorbents for low-temperature SO2 removal. Chemosphere 291, 132836 (2021).

Wu, T.-H. et al. Charge storage mechanism of activated manganese oxide composites for pseudocapacitors. J. Mater. Chem. A 3, 12786–12795 (2015).

Bradley, S. J. et al. Heterogeneity in the fluorescence of graphene and graphene oxide quantum dots. Microchim. Acta 184, 871–878 (2017).

Zhao, Y. et al. Critical role of water on the surface of ZnO in H2S removal at room temperature. Ind. Eng. Chem. Res. 57, 15366–15374 (2018).

Yang, W. et al. Heterogeneous reaction of SO2 on manganese oxides: The effect of crystal structure and relative humidity. Sci. Rep. 7, 4550 (2017).

Yang, C. et al. Bifunctional ZnO-MgO/activated carbon adsorbents boost H2S room temperature adsorption and catalytic oxidation. Appl. Catal. B 266, 118674 (2020).

Long, J. W., Wallace, J. M., Peterson, G. W. & Huynh, K. Manganese oxide nanoarchitectures as broad-spectrum sorbents for toxic gases. ACS Appl. Mater. Interfaces 8, 1184–1193 (2016).

Wang, L. et al. Nanodispersed Mn3O4/γ-Al2O3 for NO2 elimination at room temperature. Environ. Sci. Technol. 53, 10855–10862 (2019).

Akpasi, S. O. & Isa, Y. M. Effect of operating variables on CO2 adsorption capacity of activated carbon, kaolinite, and activated carbon—Kaolinite composite adsorbent. Water-Energy Nexus 5, 21–28 (2022).

Gupta, N. K., Bae, J. & Kim, K. S. Metal organic framework derived NaCoxOy for room temperature hydrogen sulfide removal. Sci. Rep. 11, 14740 (2021).

Yang, C., Florent, M., de Falco, G., Fan, H. & Bandosz, T. J. ZnFe2O4/activated carbon as a regenerable adsorbent for catalytic removal of H2S from air at room temperature. Chem. Eng. J. 394, 124906 (2020).

Chen, S., Guo, Y., Zhang, J., Guo, Y. & Liang, X. CuFe2O4/activated carbon adsorbents enhance H2S adsorption and catalytic oxidation from humidified air at room temperature. Chem. Eng. J. 431, 134097 (2022).

Dhage, P. et al. Copper-promoted ZnO/SiO2 regenerable sorbents for the room temperature removal of H2S from reformate gas streams. Ind. Eng. Chem. Res. 49, 8388–8396 (2010).

Huang, Y. Enhancement of hydrogen sulfide removal via polyoxometalate@biomass-based MCM-41 with hierarchical pore structures at room temperature. SSRN J. https://doi.org/10.2139/ssrn.4081354 (2022).

Gupta, N. K., Bae, J. & Kim, K. S. Bimetallic Ag–Cu-trimesate metal–organic framework for hydrogen sulfide removal. New J. Chem. 45, 22466–22477 (2021).

Gupta, N. K., Achary, S. N., Viltres, H., Bae, J. & Kim, K. S. Fabrication of Na0.4MnO2 microrods for room-temperature oxidation of sulfurous gases. ACS Omega 7, 37774–37781 (2022).

Xue, M., Chitrakar, R., Sakane, K. & Ooi, K. Screening of adsorbents for removal of H2S at room temperature. Green Chem. 5, 529–534 (2003).

Dhage, P., Samokhvalov, A., Repala, D., Duin, E. C. & Tatarchuk, B. J. Regenerable Fe–Mn–ZnO/SiO2 sorbents for room temperature removal of H2S from fuel reformates: performance, active sites, Operando studies. Phys. Chem. Chem. Phys. 13, 2179–2187 (2011).

Gupta, N. K., Kim, E. J., Baek, S., Bae, J. & Kim, K. S. Ternary metal oxide nanocomposite for room temperature H2S and SO2 gas removal in wet conditions. Sci. Rep. 12, 15387 (2022).

Ye, X. et al. Effect of manganese dioxide crystal structure on adsorption of SO2 by DFT and experimental study. Appl. Surf. Sci. 521, 146477 (2020).

Raabe, T. et al. Mechanistic study on H2S and subsequent O2 adsorption on iron oxides and hydroxides. Appl. Surf. Sci. 565, 150504 (2021).

Hadjiivanov, K., Bushev, V., Kantcheva, M. & Klissurski, D. Infrared spectroscopy study of the species arising during nitrogen dioxide adsorption on titania (anatase). Langmuir 10, 464–471 (1994).

Cherkashinin, G. & Jaegermann, W. Dissociative adsorption of H2O on LiCoO2 (00l) surfaces: Co reduction induced by electron transfer from intrinsic defects. J. Chem. Phys. 144, 184706 (2016).

Yuan, H., Yang, H., Hu, P. & Wang, H. Origin of water-induced deactivation of MnO2-based catalyst for room-temperature NO oxidation: A first-principles microkinetic study. ACS Catal. 11, 6835–6845 (2021).

Asaoka, S. et al. Regeneration of manganese oxide as adsorption sites for hydrogen sulfide on granulated coal ash. Chem. Eng. J. 254, 531–537 (2014).

Quesne-Turin, A. et al. Surface reactivity of Li2MnO3: First-principles and experimental study. ACS Appl. Mater. Interfaces 9, 44222–44230 (2017).

Ilton, E. S., Post, J. E., Heaney, P. J., Ling, F. T. & Kerisit, S. N. XPS determination of Mn oxidation states in Mn (hydr)oxides. Appl. Surf. Sci. 366, 475–485 (2016).

Gupta, N. K., Bae, J. & Kim, K. S. A novel one-step synthesis of Ce/Mn/Fe mixed metal oxide nanocomposites for oxidative removal of hydrogen sulfide at room temperature. RSC Adv. 11, 26739–26749 (2021).

Toupin, M., Brousse, T. & Bélanger, D. Charge storage mechanism of MnO2 electrode used in aqueous electrochemical capacitor. Chem. Mater. 16, 3184–3190 (2004).

Arul, N. S., Cavalcante, L. S. & In Han, J. Facile synthesis of ZnS/MnS nanocomposites for supercapacitor applications. J. Solid State Electrochem. 22, 303–313 (2018).

Shanthi, P. M. et al. Sulfonic acid based complex framework materials (CFM): Nanostructured polysulfide immobilization systems for rechargeable lithium–sulfur battery. J. Electrochem. Soc. 166, A1827–A1835 (2019).

Fantauzzi, M., Elsener, B., Atzei, D., Rigoldi, A. & Rossi, A. Exploiting XPS for the identification of sulfides and polysulfides. RSC Adv. 5, 75953–75963 (2015).

Sergienko, N. & Radjenovic, J. Manganese oxide-based porous electrodes for rapid and selective (electro)catalytic removal and recovery of sulfide from wastewater. Appl. Catal. B 267, 118608 (2020).

Quesne-Turin, A. et al. Surface reactivity of Li2MnO3: Structural and morphological impact. Appl. Surf. Sci. 542, 148514 (2021).

Vovk, E. I., Turksoy, A., Bukhtiyarov, V. I. & Ozensoy, E. Interactive surface chemistry of CO2 and NO2 on metal oxide surfaces: Competition for catalytic adsorption sites and reactivity. J. Phys. Chem. C 117, 7713–7720 (2013).

Baltrusaitis, J., Jayaweera, P. M. & Grassian, V. H. XPS study of nitrogen dioxide adsorption on metal oxide particle surfaces under different environmental conditions. Phys. Chem. Chem. Phys. 11, 8295 (2009).

Sivachandiran, L., Thevenet, F., Gravejat, P. & Rousseau, A. Investigation of NO and NO2 adsorption mechanisms on TiO2 at room temperature. Appl. Catal. B 142–143, 196–204 (2013).

Liu, C. et al. Structure–activity relationship of surface hydroxyl groups during NO2 adsorption and transformation on TiO2 nanoparticles. Environ. Sci. Nano 4, 2388–2394 (2017).

Acknowledgements

This work was supported by the UST Young Scientist Research Program 2021 through the University of Science and Technology, Korea [Grant number #20210672-001]. The authors are also grateful for the funds [Project #20230095-001] provided by the “Korea Institute of Civil Engineering and Building Technology” (KICT), Republic of Korea.

Author information

Authors and Affiliations

Contributions

N.K.G. oversaw data curation, methodology, and writing of the original draft. N.K.G., S.N.A., and H.V. oversaw formal analysis. N.K.G. and S.N.A. oversaw visualization and validation. K.S.K. and J.B. were responsible for funding acquisition, resources, and supervision. All the authors reviewed the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Gupta, N.K., Achary, S.N., Viltres, H. et al. Novel application of sodium manganese oxide in removing acidic gases in ambient conditions. Sci Rep 13, 2330 (2023). https://doi.org/10.1038/s41598-023-29274-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-023-29274-9

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.