Abstract

A novel two-step approach consisting of hydrothermal process and subsequently selective etching has been developed to prepare flower-like three-dimensional porous Bi2Fe4O9 spheres with good uniformity and highly photocatalytic performance. XRD patterns and SEM images reveal that the Bi2Fe4O9 phase does not exhibit any changes after the etching process, and the crystal morphology evolves from micro-platelets to flower-like three-dimensional porous Bi2Fe4O9 spheres by controlling the experiment parameters. The change of morphology will lead to the significant increase of specific surface area, which would be beneficial to the enhancement of photocatalytic performance owing to prominent absorption in the ultraviolet and visible light region. As compared to Bi2Fe4O9 microplatelets, flower-like three-dimensional porous Bi2Fe4O9 spheres exhibit excellent photocatalytic degration rate of methyl orange (MO).

Similar content being viewed by others

Introduction

For the sustainable development of human society, the development of both pollution-free technologies for environmental remediation1 and alternative clean energy supplies is an urgent task. Moreover, visible-light-driven photocatalysts have been developed for efficient utilization of solar energy to address the increasing environmental pollution and energy problems. Among the extensive variety of green earth and renewable energy projects underway, semiconductor photocatalysis2,3,4 has emerged as one of the most promising technologies because it represents an easy way to utilize the energy of either natural sunlight or artificial indoor illumination, and is thus abundantly available everywhere in the world5,6,7,8,9.

It is believed that the properties of functional materials strongly depend on their morphology, microstructure, dimension, crystallinity, and so forth10,11,12,13,14,15. The ability to control particle morphology is an important objective in particle synthesis, since size and shape can significantly influence photocatalytic properties16,17,18. Liu et al.19 fabricated a magnetically separable photocatalyst based on nest-like γ-Fe3O4/ZnO double-shelled hollow structures with enhanced photocatalytic activity. Yu et al.20 prepared TiO2 solid spheres and hollow microspheres by typical hydrothermal processes in NH4F aqueous solution and investigated their visible-light-driven photocatalytic activities. It turns out that the photocatalytic activity of the samples prepared in the presence of NH4F is greatly higher than that of TiO2 sample prepared in pure water and commercial Degussa P25 (P25) powders. Porous cerium dioxide hollow spheres based on the Ostwald ripening process were fabricated by a simple solvothermal method in the absence of any templates. As compared to cerium dioxide nanoparticles, porous cerium dioxide hollow spheres have an enhancement for the light harvesting and provide activity sites in the photocatalytic process21. BiFeO3 nanoparticles ranging from 80 to 120 nm synthesized via a simple sol-gel method by Gao et al.22. It were demonstrated that its degradation was significantly more efficient than that of bulk BiFeO3 due to the higher surface area of nanosized BiFeO3. Besides, Reitz et al.23 studied the effect of porosity on the photocatalytic degradation of a common dye. In addition, some others previous studies also focused on the relationship between morphology and photocatalytic properties24,25,26,27. According to the above-mentioned studies, the enhancement of photocatalytic properties can be achieved by controlling the morphology of photocatalyst.

Bi2Fe4O9, as a typical semiconductor, is well-known for its catalytic performance for ammonia oxidation to NO28,29,30. It has orthorhombic structure with a space group of Pbam, which consists of two formula units per unit cell. The formula units can be described as columns of edge sharing FeO6 octahedra connected by corner sharing FeO4 tetrahedra and bismuth ions and the bismuth ions are surrounded by eight oxygen ions with mutually orthogonal shorter BiO3 and longer BiO5 units13, 31. In addition, Bi2Fe4O9 possesses the ability to photodegrade aqueous ammonia and MO under the ultraviolet light (UV-light) because of its relatively small bandgap for absorption of light13, 32. However, the photocatalytic degradation efficiency of the Bi2Fe4O9 with the regular shape is not high due to a prompt recombination of h+ and e− generated from light33,34,35,36,37.

In this work, the flower-like three-dimensional porous Bi2Fe4O9 spheres have been synthesized simply by etching Bi2Fe4O9 microplatelets. As compared to the unetched counterparts, the flower-like three-dimensional porous Bi2Fe4O9 spheres exhibit excellent photocatalytic degration rate of MO under ultraviolet and visible light irradiation.

Results and Discussion

The formation process of the three-dimensional flower-like Bi2Fe4O9 spheres was investigated by time-dependent evolution experiments. Intermediate products were collected at different stages, and their phase, morphology and structure informations were subjected to the following sections.

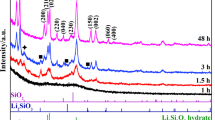

The phase purity of the prepared samples with different etching times was estimated by the XRD patterns (Fig. 1). As can be seen from the patterns, all the diffraction peaks can be perfectly indexed to the orthorhombic (space group: Pbam) structure of bulk Bi2Fe4O9 with lattice contants of a = 7.965 Å, b = 8.44 Å, c = 5.994 Å, which is consistent with the standard data (JSPDS 25-0090). As displayed in Fig. 1, the sharp peaks in the XRD patterns indicate that the bulk Bi2Fe4O9 powders prepared by the hydrothermal method are well-cystallized and have no any impurities. It can be also seen that the etched Bi2Fe4O9 still maintain the pure phase, but the intensity of characteristic peaks shows an obvious decrease with increasing the etching time. It may be ascribed to the porous structure of the etched Bi2Fe4O9 spheres, which contain nano-sized fragments and tiny miscrospheres.

The phase of the samples with the different etching times is also proved by Raman spectra (Figure S1, Supplementary Information). According to the group theory, the orthorhombic Bi2Fe4O9 possess 42 Raman active modes (12Ag + 12B1g + 9B2g + 9B3g)38, 39. As shown in Figure S1a, there are seven modes located at 202 cm−1, 279 cm−1, 318 cm−1, 357 cm−1, 416 cm−1, 537 cm−1, 643 cm−1 in bulk Bi2Fe4O9 phase. As etching time goes on, it can be found that some characteristic peaks tend to decrease and even disappear, and six modes located at 202 cm−1, 279 cm−1, 318 cm−1, 416 cm−1, 537 cm−1 and 643 cm−1 can be found in the Bi2Fe4O9 powder with 15 min etching time. When increasing the etching time to 30 min, five modes can be detected, which are located at 202 cm−1, 279 cm−1, 318 cm−1, 416 cm−1, and 537 cm−1, respectively. As further increasing the etching time to 45 min, only two modes located at 202 cm−1 and 279 cm−1 can be observed. In conjunction with the results of XRD phase identification, it can be confimed that the phase remains unchanged.

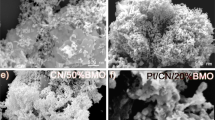

The morphology and microstructure of the as-prepared Bi2Fe4O9 spheres were analyzed by the field emission scanning electron microscopy (FESEM) and transmission electron microscopy (TEM). It can be seen from Fig. 2a that the bulk Bi2Fe4O9 microplatelets of 1~2 μm in edge length and 300~500 nm in thickness are well dispersed with a good monodispersity, and after being etched for 15 min, the small fragments of Bi2Fe4O9 are produced on the surface of the bulk Bi2Fe4O9, and the smooth surfaces have become rough (Fig. 2b). As increasing the etching time to 30 min, the bulk Bi2Fe4O9 are completely etched to the small fragments and gathered together to form the flower-like nanostructure constructed with separately intersected nanosheets (Fig. 2c), which is the reason why the etched samples seem to be amorphous from the XRD and Raman spectra. As shown in Fig. 2d, it can be found that the flowerlike spheres with diameters of about 1~2 μm can be clearly observed with increasing the etching time to 45 min. Correspondingly, several higher magnification SEM images demonstrate that these flowerlike structures consist of numerous Bi2Fe4O9 nanoplates of 200~300 nm in edge length and 4–7 nm in thickness or so. If the reaction time may be allowed to continue, the nanoplates will become shaper and more apparent in the flower-like structure but the phase constitution of Bi2Fe4O9 will transform to other bismuth oxides (Bi2O3, and a mixture of Bi2O3 and Bi2Fe4O9) (Figure S2, Supplementary Information).

Flower-like sphere structure was also demonstrated by TEM, as shown in Fig. 3. The typical TEM images of Bi2Fe4O9 spheres before and after etching are shown in Fig. 3a and b. It is shown that the evolution of morphology from microplatelets to flower-like spheres could be observed apparently after etching 45 min. Further, Fig. 3c confirms that the presence of ultrathin nanosheets in the etched Bi2Fe4O9 samples with a typical thickness of 4–7 nm. The structure of the as-obtained etched Bi2Fe4O9 spheres was investigated in more detail by high resolution transmission electron microscopy (HRTEM), as shown in Fig. 3d. The regular fringe spacing of the lattice planes is about 0.1581 nm, which is consistent with the separation of (121) plane of the orthorhombic Bi2Fe4O9. These observations lead to the conclusion that the bulk Bi2Fe4O9 crystals are exfoliated to ultrathin nanosheets by hydrazine together with methyl mercaptoacetate, which is gradually abraded from the surface of the bulk Bi2Fe4O9 and forms the flower-like nanostructures as the etching process continues.

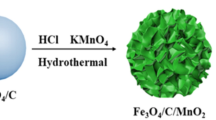

To analyze the changes in the Bi2Fe4O9 samples before and after etching, a plausible formation scheme of the Bi2Fe4O9 flowerlike structure spheres is illustrated in Fig. 4. Our tentative is that the evolution of ultrathin nanosheets of Bi2Fe4O9 may be attributed to the loss of surface Bi2Fe4O9 particles due to the reduction of ferric(III) to ferric(II) by hydrazine. Then, the ferric(II) is immediately coordinated with methyl mercaptoacetate in DMF, which results in the removing of Bi2Fe4O9. Thus, Bi2Fe4O9 ultrathin nanosheets are formed on surfaces of bulk Bi2Fe4O9. Finally, these formed nanosheets are abraded from the surfaces and gradually aggregated into flower-like spheres in virtue of the effect of surface tension. In addition, one can notice that as the amount of methyl mercaptoacetate or hydrazine changes in the reaction system, the evolution of the porous structure show a similar trend with that of the samples with different etching times (Figure S3, Supplementary Information), which confirms the above tentative.

To investigate the chemical state of elements and the surface defects, X-ray photoelectron spectroscopy (XPS) analysis was carried out on the surface of Bi2Fe4O9 and etched Bi2Fe4O9 samples and the results are shown in Fig. 5. The obtained binding energies in XPS analysis were corrected by specimen charging which was executed by referencing the C 1 s line to 284.6 eV. It can be found that the area ratios are basically suitable for the orbital lines of Bi 4 f and Fe 2p, which is consitent with the stoichiometry of Bi2Fe4O9.

The survey XPS spectrum in Fig. 5a clearly reveals that both the Bi2Fe4O9 samples mainly consist of Bi, Fe, and O. However, the ratio of the elements in the bulk of Bi2Fe4O9 is different from that of the etched sample, which seems to conflict with the arguments of XRD and Raman (Table 1). It is well known that XPS analysis is only applied on the surface of powder. Presumably, a small amount of non-magnetic powder are produced and covered on the surface of Bi2Fe4O9 flower-like spheres, as shown in the chemical reaction schemes of Fig. 4.

The Bi 4 f peaks of the samples are deconvoluted into the following peaks at around 158.2 eV, 159.4 eV, 163.7 eV and 164.8 eV, respectively (Fig. 5b). By comparison, the Bi 4 f peaks of Bi2Fe4O9 flower-like spheres shift slightly to higher binding energy with the formation of surface bismuth defects. In addition, the appearance of two additional peaks, located at 160.4 eV and 165.8 eV, may be attributed to the signal of S 2p due to the residual sulfydryl complex on the surface of Bi2Fe4O9 flower-like spheres40. Furthermore, Bi2Fe4O9 is an orthorhombic structure with the coexistence of [FeO6] octahedra and [FeO4] tetrahedra13, 31. And the peaks at around 710.8 and 724.6 eV (Fig. 5c) are related to the binding energies of Fe 2p3/2 and Fe 2p1/2 for the ferric(III), which is perfectly consistent with the data of unetched Bi2Fe4O9 powders41. After etching, the peaks at 708.2 eV and 722.7 eV of Fe 2p corresponded with ferric(II) are detected in the etched flower-like porous Bi2Fe4O9 sample besides the peaks of ferric(III)42, suggesting the reduction of ferric(III) to ferric(II) by hydrazine. From Fig. 5d, it can be seen that the O 1 s peak is deconvoluted into four Gaussian curves at the peak positions of around 528.9 eV, 530.3 eV, 531.3 eV and 532.8 eV for the unetched Bi2Fe4O9 sample, which are respectively assigned to oxygen vacancies, surface lattice oxygen, ordered lattice oxygen ions43,44,45 and absorbed H2O or surface carbonate46,47,48. When reacted with hydrazine and methyl mercaptoacetate, the peak located at 531.3 eV and related to lattice oxygen ions is strengthened in the etched sample, further confirming that ferric(III) is reduced to ferric(II), coordinated with methyl mercaptoacetate, and dissolved in DMF and thereby the lattice oxygen vacancies are formed. The other peaks at the same positions have almost no significant change apart from weakening of peak intensity, which may be ascribed to the low crystalline of Bi2Fe4O9 flower-like spheres. From the above results, it is concluded that only ferric(III) ions in the Bi2Fe4O9 are reduced to ferric(II) and coordinated with methyl mercaptoacetate, and bismuth(III) ions is not affected.

In order to verify the above inference, the supernatant after the etching process was studied. We found that some black powders were produced in addition to the etched samples. The XPS result of the black powders (Figure S4, Supplementary Information) shows that the Fe peaks are ferric(II) and S peaks are attributed to the H-S bond and the Fe-S bond49, 50, indicating that ferric(III) was indeed reduced to ferric(II), coordinated with sufhydryl to form a ferric(II) complex and dissolved in dimethyl formamide (DMF). In addition, the XRD pattern of the black powders (Figure S5, Supplementary Information) shows that the complex is amorphous. The above observations draw a conclusion that the Bi2Fe4O9 flower-like spheres is produced by the synergistic effect of hydrazine and methyl mercaptoacetate, peeling off the surface of Bi2Fe4O9 to achieve numerous nanoplates.

It has been reported that larger surface area endows higher photocatalytic activity for the increased reactive sites and the promoted electron-hole separation efficiency51,52,53. With increasing the etching time, the specific surface area of Bi2Fe4O9 particles become larger, which may be attributed to the changing of morphology. The nitrogen adsorption-desorption isotherms of the Bi2Fe4O9 samples are shown (Figure S6, Supplementary Information). It can be discovered that the etched Bi2Fe4O9 samples exhibit apparent hysteresis loops, which are powerful evidences of high porosities. According to Brunauer-Deming-Deming-Teller classification, the etched Bi2Fe4O9 samples are classified as Type H3, which are caused by the heterogeneous slit-like pores. A table shows the variation of surface area and pore volume which was calculated using the Brunauer-Emmet-Teller (BET) equation (Table S1, Supplementary Information). The surface area enlarges gradually with increasing the etching time, and reaches 41.04 m2/g after 45 min, which is significantly greater than that of bulk Bi2Fe4O9 (0.84 m2/g). It indicates that the formation of porous structure through etching process indeed could elevate the surface area of the bulk Bi2Fe4O9 effectively, achieving a marked improvement of Bi2Fe4O9 photocatalytic performance. Furthermore, the increased surface area would probably lead to band gap narrowing, enhancing its photocatalytic performance.

The diffuse reflection spectrum (DRS) of the as-prepared Bi2Fe4O9 samples are demonstrated to ensure the absorbance of light in the Bi2Fe4O9 particles before and after etching, as shown in Fig. 6a. It is shown that all the Bi2Fe4O9 samples can respond in the UV-vis light area. For the bulk Bi2Fe4O9, there are two distinct absorption edges at the wavelength of 610 nm and 850 nm in the visible region, which is consistent with the relevant literatures13, 26, however the absorption peaks disappear after etching. Theoretically, the movement of the absorption edge towards the lower energy visible light area may due to the narrowed bandgap width and improve visible light absorption performance. According to the results of XRD and Raman, it can be seen that the crystal structure of Bi2Fe4O9 are not affected by etching. Therefore, the speculation of bandgap narrowing is false. The etching process indeed leads to the enhancement of BET surface and thereby forms a porous structure to improve the light absorbance in the wavelength range from 200–800 nm compared with the unetched sample. The original absorption peak has been obscured completely by the light absorbance. It can be clearly observed that the powder color shows a tendency of darkening with increasing the etching time, as shown in Fig. 1. In addition, some mid-gap states resulted by the etching-introduced defects are beneficial for electron hopping and thus contribute to the ability of photodegradation54. Figure 6b shows plots of the Kubelka-Munk remission function (i.e., relationship of [αhν]2 versus photon energy) corresponding to each spectrum. Form Fig. 6b, it can be seen that the two bandgaps of the bulk Bi2Fe4O9 are calculated to be 2.01 and 1.57 eV, respectively, matching well with those of the previously reported Bi2Fe4O9 13, 30. After etching process, the curves of the flower-like Bi2Fe4O9 samples also reveal a very strong light absorbance, implying the possibility of utilizing more light as compared with the bulk Bi2Fe4O9.

In order to further account for the higher activity of Bi2Fe4O9 flower-like spheres, their photoelectrochemical response has been measured21, 55,56,57. As shown in Fig. 7, a fast and uniform photocurrent response is observed for each switch-on/off event in both photocatalysts-deposited electrodes under UV-light, and the response is entirely reversible. It also can be found that the etched Bi2Fe4O9 flower-like spheres exhibit much higher photoelectric current response than the unetched counterpart, which indicates that etching process endows materials higher ability of charge generate and separation. Nevertheless, there seem to be a downward trend for photocurrent densities of all the samples with increasing the test time, which may be ascribed to the weakness of Bi2Fe4O9 self-photoelectric translation properties.

In order to investigate the photocatalytic activity of the Bi2Fe4O9 samples with different morphologies, the absorption changes of MO in the presence of Bi2Fe4O9 with different etching times under UV-light irradiation are obtained (Figure S7, Supplementary Information). It is obvious that the as-prepared samples exhibit a clearly degradation phenomenon to MO solution under UV-light. In addition, the etched Bi2Fe4O9 samples exhibits a faster degradation rate than the unetched counterpart. Prior to illumination, the optical absorbance of all the samples has already reduced about 30%, which is ascribed to the adsorption of the dye molecules over Bi2Fe4O9, arising from the respectively specific surface area (BET area: 0.84, 12.56, 20.86, 41.04 m2/g). During the photodegradation process, the characteristic absorption peak at wavelength of 465 nm reduces significantly with the irradiation time. What is more, it can be observed that as increasing the etching time from 0 to 30 min, the maximum absorption peak decreases gradually from 0.51 to 0.18 after 3 h irradiation. When the etching time reaches 45 min, virtually MO in the presence of solution is degraded after 3 h illumination. However, the maximum absorption peak of the bulk Bi2Fe4O9 powders merely reaches 0.51 with the same irradiation time. That is to say, the porous structure may contribute to degradation of MO contaminant, which is corresponded with the previous inference.

According to the data of above absorbance curve, the photodegradation efficiencies of MO in the presence of Bi2Fe4O9 with different etching times under UV-light illumination are shown in Fig. 8a. As is well known, the bigger the specific surface area of Bi2Fe4O9 is, the larger the absorbing capacity is. Figure 8a shows the degradation rate of Bi2Fe4O9 with different specific surface areas after 3 h UV-light irradiation. Compared with the flower-like spheres, the bulk Bi2Fe4O9 exhibits a much poorer effect under the same condition. Hence, it is further proved that a larger BET surface is conducive to the enhancement of photodegradation rate. Meanwhile, the photodegradation efficiencies of MO in the presence of Bi2Fe4O9 samples with different etching times under visible light illumination are shown (Figure S8, Supplementary Information). It cannot be found that the Bi2Fe4O9 samples possess evident photocatalytic activity under visible light irradiation whether by etching process or not.

The kinetics of the photoreaction can be described as being of pseudo first-order ln(C/C0) = kt. C0 and C correspond to the concentrations at t = 0 and after time “h”, respectively. Figure 8b displays the first-order degradation rate constant k(h−1), determined from Fig. 8a, and of all the samples, are shown the first-rank photocatalytic activity efficiency. The calculated rate constant k (h−1) in the presence of Bi2Fe4O9 with different etching time (0, 15 min, 30 min, 45 min) are 0.07, 0.15, 0.49, 0.84 h−1, respectively, indicating that the photocatalytic activity of the etched Bi2Fe4O9 samples were evidently improved by dozens of times compared with the bulk Bi2Fe4O9 sample.

The stability of photocatalysts is also important for paractical application. To investigate the stability of the as-prepared photocatalysts, the repeatability experiments of MO degradation over the bulk Bi2Fe4O9 and the flower-like Bi2Fe4O9 spheres was conducted. The results are shown in Fig. 9 and no significant change is observed, indicating that the photocatalyst has an excellent stability after four recycling runs.

Method

Materials

Bismuth nitrate (Bi(NO3)3·5H2O), iron nitrate (Fe(NO3)3·9H2O), sodium hydroxide (NaOH), concentrated nitric acid (HNO3, 65%) methyl mercaptoacetate anhydrous ethanol and DMF were purchased from Sinopharm Chemical Reagent Corp (Shanghai, China) and used as received. Hydrazine (NH2NH2·H2O) and methyl orange were purchased from Aladdin (Shanghai, China) used as received. Anhydrous ethanol and deionized water were used in all the experiments. All the chemicals used in this study were analytical grade and were used without further purifications.

Synthesis of pure-phase Bi2Fe4O9

Bi2Fe4O9 microplatelets were synthesized via the hydrothermal reaction. Stoichiometric Bi(NO3)3·5H2O (1 mmol) and Fe(NO3)3·9H2O (2 mmol) were dissolved in 10 mL of diluted nitric acid to form an aqueous solution under vigorously magnetic stirring at room temperature. After 10 minutes, 12 mol/L of NaOH solution, was added dropwise into the solution under vigorous stirring continuously for 30 min and a brown suspension liquid was formed. Then, the solution was transferred to a 100 mL Teflon-lined steel autoclave and maintained at 200 °C for 12 h. After being cooled to room temperature, the obtained precipitate was centrifuged and washed with absolute alcohol and water several times, and then dried 60 °C for 12 h.

Synthesis of three-dimensional porous Bi2Fe4O9 spheres

Based on the Bi2Fe4O9 microplatelets, three-dimensional porous Bi2Fe4O9 spheres were synthesized by a facile etching process. Bi2Fe4O9 (500 mg) was dispersed ultrasonically in DMF (150 mL) in a 250 mL reagent bottle, and then a certain amount of hydrazine (6 mL) and methyl mercaptoacetate (1.5 mL) were added. After N2 protection for 30 min, the mixed solution reacted at 80 °C in a water-bath. The reaction time of etching process was 15 min, 30 min, 45 min for the preparation of samples. The reaction was terminated by cold ethanol and then the sediment was immediately washed by ethanol and deionized water several times respectively, followed by drying in vacuum for 12 h. For the synthesis of etching Bi2Fe4O9 samples with different amounts of hydrazine and methyl mercaptoactate, the reaction time was fixed at 45 min and the ratio of amounts of hydrazine and methyl mercaptoactate was also fixed at 4:1. A experiment that the amount of hydrazine and methyl mercaptoacetate was 4 mL and 1 mL respectively, has also been done.

Characterization

The phases of the samples were analyzed by X-ray diffraction (XRD, D/max-2200, Rigaku, Japan) using Cu Kα radiation (λ = 0.15418 nm) and Raman spectra recorded at room temperature using a micro-Raman spectrometer (ALMEGA-TM, Thermo Nicolet, American) in the backscattering geomitry with a 532 nm Ar+ laser as an excitation source. And the morphology and characterization of the samples were observed by field emission scanning electron microscopy (FE-SEM, Quanta 250FEG, FEI, USA) and transmission electron microscope (TEM, JEM-2100, JEOL, Japan). X-ray photoelectron spectroscopy (XPS) measurements were performed by using an ultrahigh vacuum VG Scientific Corp MK-II electron spectrometer equipped with a multichannel detector. The spectra were excited using Mg Ka (1253.6 eV) radiation (operated at 200 W) of a twin anode in the constant analyzer energy mode with a pass energy of 50 eV. The Brunner-Emmet-Teller (BET, ASAP 2020, Micromeritics, USA) was used to calculate the specific surface area. The ultraviolet-visible diffuse reflectance spectrum (DRS, Cary 5000, Agilent, USA) was used in the wavelength range of 200–800 nm to study the absorption range of the samples. The UV-vis absorption spectra were measured on a UV-vis spectrophotometer (UV-2600A, Unico Instrument Corp, China).

Measurements of photocatalytic activity

The photocatalytic behaviors of the as-prepared samples were evaluated by the degradation of MO under ultraviolet and visible light irradiation, respectively. The ultraviolet light source for catalytic reaction was a 300 W mercury lamp and the visible-light source was a 500 W xenon lamp positioned in a quartz cold trap which was in the middle of multiposition cylindrical reaction vessel. The system was cooled by wind and water at room temperature. In every run, 50 mg Bi2Fe4O9 was added to 50 mL MO solution (10−5 mol/L) in a Pyrex vessel. Before illumination, the suspensions were magnetically stirred in the dark for 40 min to ensure the establishment of an adsorption-desorption equilibrium between the photocatalyst and dye. During ultraviolet and visible light irradiation, a certain amount of mixed solution were withdrawn at regular time intervals and centrifuged to obtain the supematant which were analyzed the absorbance with a UV-vis spectrophotometer. Then, the repeatability experiments of MO degradation over the bulk Bi2Fe4O9 and the flower-like Bi2Fe4O9 spheres was measured under the same condition.

Conclusions

In summary, three-dimensional Bi2Fe4O9 flower-like spheres were successfully fabricated through two steps containing a hydrothermal process and subsequently etching. The bulk Bi2Fe4O9 slabs are coordinated with methyl mercaptoacetate and hydrazine through a series of oxidation-reduction reaction, transforming to spheres with a porous flower-like structure. XRD patterns and Raman spectra analysis show that the Bi2Fe4O9 still express purity phase before and after the etching process. SEM, TEM and BET analysis indicate the variations of morphology and BET surface area. The appropriate etching time exhibit a great influence on the morphology of the Bi2Fe4O9 samples. The etching process indeed leads to a porous structure and thereby achieve the enhancement of BET surface of Bi2Fe4O9, which would be beneficial to the enhancement of photocatalytic performance owing to the prominent absorption in the ultraviolet and visible light region. Furthermore, some mid-gap states resulted by the etching-introduced defects are beneficial to electron hopping and thus contribute to the photodegradation of MO contaminant. The etching strategy applied in this study provides an effective method through changing morphology to improve various properties of multiferroic materials.

References

Noubactep, C., Caré, S. & Crane, R. Nanoscale Metallic Iron for Environmental Remediation: Prospects and Limitations. Water Air Soil Poll. 223, 1363–1382, doi:10.1007/s11270-011-0951-1 (2012).

Wang, J., Huang, J. & Meng, J. et al. Double-hole Codoped Huge-gap Semiconductor ZrO2 For Visible-Light Photocatalysis. Phys. Chem. Chem. Phys. 18, 17517–17524, doi:10.1039/c6cp02047j (2016).

Xu, J., Wan, Y. & Huang, Y. et al. Layered Oxide Semiconductor In2Fe2CuO7: Optical Properties and Visible-Light Responsive Photocatalytic Abilities. Mater. Lett. 179, 175–178, doi:10.1016/j.matlet.2016.05.079 (2016).

Li, J., Fang, W. & Yu, C. et al. Ag-based Semiconductor Photocatalysts in Environmental Purification. Appl. Surf. Sci. 358, 46–56, doi:10.1016/j.apsusc.2015.07.139 (2015).

Tong, H., Ouyang, S. & Bi, Y. et al. Nano-photocatalytic Materials: Possibilities and Challenges. Adv. Mater. 24, 229–251, doi:10.1002/adma.201102752 (2012).

Liu, Y., Zuo, R. & Qi, S. Controllable Preparation of BiFeO3@carbon Core/Shell Nanofibers with Enhanced Visible Photocatalytic Activity. J. Mol. Catal. A Chem. 376, 1–6, doi:10.1016/j.molcata.2013.04.005 (2013).

Zhang, D. Effects of Deposited Metallic Silver on Nano-ZnO for the Environmental Purification of Dye Pollutants. S. Afr. J. Chem-S-Afr. T. 65, 98–103 (2012).

Sakthivel, S. & Kisch, H. Daylight Photocatalysis by Carbon-modified Titanium Dioxide. Angew. Chemie. 42, 4908–4911, doi:10.1002/anie.200351577 (2003).

Salameh, C., Nogier, J. & Launay, F. et al. Dispersion of Colloidal TiO2, Nanoparticles on Mesoporous Materials Targeting Photocatalysis Applications. Catal. Today. 257, 35–40, doi:10.1016/j.cattod.2015.03.025 (2015).

Sun, Y. & Xia, Y. Shape-Controlled Synthesis of Gold and Silver Nanoparticles. Science. 298, 2176–2179, doi:10.1126/science.1077229 (2002).

Wang, Z. L. & Song, J. H. Piezoelectric Nanogenerators Based on Zinc Oxide Nanowire Arrays. Science. 312, 242–246, doi:10.1126/science.1124005 (2006).

Wang, X., Zhuang, J. & Peng, Q. et al. A General Strategy for Nanocrystal Synthesis. Nature. 437, 121–124, doi:10.1038/nature03968 (2005).

Sun, S., Wang, W. & Zhang, L. et al. Visible Light-induced Photocatalytic Oxidation of Phenol and Aqueous Ammonia in Flowerlike Bi2Fe4O9 Suspensions. J. Phys. Chem. C. 113, 12826–12831, doi:10.1021/jp9029826 (2009).

Levratovsky, Y. & Gross, E. High Spatial Resolution Mapping of Chemically-active Self-assembled N-heterocyclic Carbenes on Pt Nanoparticles. Faraday Discuss. 188, 345–353, doi:10.1039/c5fd00194c (2016).

Xiang, Y. L. & Sawant, P. D. Micro/Nanoengineering of the Self-organized Three-dimensional Fibrous Structure of Functional Materials. Angew. Chem. Int. Ed. 41, 3641–3645, doi:10.1002/1521-3773(20021004)41:19<3641::AID-ANIE3641>3.0.CO;2-2 (2002).

Mclaren, A., Valdes-Solis, T. & Li, G. et al. Shape and Size Effects of ZnO Nanocrystals on Photocatalytic Activity. J. Am. Chem. Soc. 131, 12540–12541, doi:10.1021/ja9052703 (2009).

Ischenko, V., Polarz, S. & Grote, D. et al. Zinc Oxide Nanoparticles with Defects. Adv. Funct. Mater. 15, 1945–1954, doi:10.1002/(ISSN)1616-3028 (2005).

Gao, P. X., Ding, Y. A. & Wang, Z. L. Crystallographic Orientation-aligned ZnO Nanorods Grown by a Tin Catalyst. Nano Lett. 3, 1315–1320, doi:10.1021/nl034548q (2003).

Liu, Y., Yu, L. & Hu, Y. et al. A Magnetically Separable Photocatalyst Based on Nest-like γ-Fe2O3/ZnO Double-shelled Hollow Structures with Enhanced Photocatalytic Activity. Nanoscale. 4, 183–187, doi:10.1039/c1nr11114k (2011).

Yu, J. & Zhang, J. A Simple Template-free Approach to TiO2 Hollow Spheres with Enhanced Photocatalytic Activity. Dalton Trans. 39, 5860–5867, doi:10.1039/c0dt00053a (2010).

Yuan, S., Zhang, Q. & Xu, B. et al. Porous Cerium Dioxide Hollow Spheres and Their Photocatalytic Performance. Rsc Adv. 4, 62255–62261, doi:10.1039/c4ra12127a (2014).

Gao, F., Chen, X. & Yin, K. et al. Visible-Light Photocatalytic Properties of Weak Magnetic BiFeO3 Nanoparticles. Adv. Mater. 19, 2889–2892, doi:10.1002/(ISSN)1521-4095 (2007).

Reitz, C., Suchomski, C. & Weidmann, C. et al. Block Copolymer-Templated BiFeO3, Nanoarchitectures Composed of Phase-Pure Crystallites Intermingled with a Continuous Mesoporosity: Effective Visible-Light Photocatalysts. Nano Res. 4, 414–424, doi:10.1007/s12274-011-0096-y (2011).

Zhou, L., Wang, W. & Zhang, L. Single-crystalline BiVO4 Microtubes with Square Cross-sections: Microstructure, Growth Mechanism, and Photocatalytic Property. J. Phys. Chem. C. 111, 13659–13664, doi:10.1021/jp065155t (2007).

Zhou, L., Wang, W. & Xu, H. et al. Bi2O3 Hierarchical Nanostructures: Controllable Synthesis, Growth Mechanism, and Their Application in Photocatalysis. Chemistry (Germany) 15, 1776–1782, doi:10.1002/chem.200801234 (2009).

Shang, M., Wang, W. & Sun, S. et al. Bi2WO6 Nanocrystals with High Photocatalytic Activities under Visible Light. J. Phys. Chem. C. 112, 10407–10411, doi:10.1021/jp802115w (2008).

Lee, J., Park, H. & Choi, W. Selective Photocatalytic Oxidation of NH3 to N2 on Platinized TiO2 in Water. Environ. Sci. Technol. 36, 5462–5468, doi:10.1021/es025930s (2008).

Zakharchenko, N. I. Catalytic Properties of Bismuth Ferrite in Ammonia Oxidation. Russ. J. Appl. Chem. 73, 2047–2051, doi:10.1016/S1381-5148(00)00053-5 (2000).

Zakharchenko, N. I. Catalytic Properties of the Fe2O3-Bi2O3 System in Ammonia Oxidation to Nitrogen Oxides. Kinet. Catal. 43, 95–98, doi:10.1023/A:1014209415066 (2001).

Ruan, Q. J. & Zhang, W. D. Tunable Morphology of Bi2Fe4O9 Crystals for Photocatalytic Oxidation. J. Phys. Chem. C. 113, 4168–4173, doi:10.1021/jp810098f (2009).

Niizeki, N. & Wachi, M. The Crystal Structures of Bi2Mn4O10, Bi2Al4O9 and Bi2Fe4O9. Z. Kristallogr. 127, 173–187, doi:10.1524/zkri.1968.127.1-4.173 (1968).

Wang, J., Neaton, J. B. & Zheng, H. et al. Multiferroic Thin Film Heterostructures. Science. 299, 1719–1722, doi:10.1126/science.1080615 (2003).

Wu, T., Liu, L. & Pi, M. et al. Enhanced Magnetic and Photocatalytic Properties of Bi2Fe4O9 Semiconductor with Large Exposed (001) Surface. Appl. Surf. Science. 377, 253–261, doi:10.1016/j.apsusc.2016.03.140 (2016).

Singh, A. K., Kaushik, S. D. & Kumar, B. et al. Substantial Magnetoelectric Coupling Near Room Temperature in Bi2Fe4O9. Appl. Phys. Lett. 92, 132910, doi:10.1063/1.2905815 (2008).

Ressouche, E., Simonet, V. & Canals, B. et al. Magnetic Frustration in an Iron-Based Cairo Pentagonal Lattice. Phys. Rev. Lett. 103, 2725–2727, doi:10.1103/PhysRevLett.103.267204 (2009).

Iliev, M. N., Litvinchuk, A. P. & Hadjiev, V. G. et al. Phonon and Magnon Scattering of Antiferromagnetic Bi2Fe4O9. Phys. Rev. B. 81, 1718–1720, doi:10.1103/PhysRevB.81.024302 (2010).

Shamir, N., Gurewitz, E. & Shaked, H. The Magnetic Structure of Bi2Fe4O9-analysis of Neutron Diffraction Measurements. J. Magn. Magn. Mater. 7, 66–68, doi:10.1016/0304-8853(78)90152-X (1978).

Lin, Y., Kang, P. & Yang, H. B. et al. Preparation and Characterization of Bi2Fe4O9/NiFe2O4, Composite Powders. Powder Technol. 284, 143–148, doi:10.1016/j.powtec.2015.04.072 (2015).

Joshi, S., Kumar, M. & Chhoker, S. et al. Structural, Magnetic, Dielectric and Optical Properties of Nickel Ferrite Nanoparticles Synthesized by Co-precipitation Method. J. Mol. Struc.(Theochem). 1076, 55–62, doi:10.1016/j.molstruc.2014.07.048 (2014).

Grzybek, T., Pietrzak, R. & Wachowska, H. X-ray Photoelectron Spectroscopy Study of Oxidized Coals with Different Sulphur Content. Fuel Process. Technol. 77–78, 1–7, doi:10.1016/S0378-3820(02)00058-9 (2002).

Wang, M., Yang, H. & Xian, P. et al. A Facile Approach to Pure-phase Bi2Fe4O9 Nanoparticles Sensitive to Visible Light. Appl. Surf. Sci. 321, 144–149, doi:10.1016/j.apsusc.2014.09.166 (2014).

Liu, H., Cao, F. & Li, P. et al. The Formation of Discoid Hematite Particles from Al-doped Ferrihydrite: The Effect of Trace Fe(II) and the Introduction Procedures of Al(III). Chem. Eng. J. 157, 254–262, doi:10.1016/j.cej.2009.12.018 (2010).

Zhang, P., Gao, C. & Lv, F. et al. Hydrothermal Epitaxial Growth and Nonvolatile Bipolar Resistive Switching Behavior of LaFeO3-PbTiO3 Films on NbSrTiO3 (001) Substrate. Appl. Phys. Lett. 105, 152904, doi:10.1063/1.4898337 (2014).

Bogle, K. A., Bachhav, M. N. & Deo, M. S. et al. Enhanced Nonvolatile Resistive Switching in Dilutely Cobalt Doped TiO2. Appl. Phys. Lett. 95, 203502, doi:10.1063/1.3263713 (2009).

Lei, F. C., Sun, Y. F. & Liu, K. T. et al. Oxygen Vacancies Confined in Ultrathin Indium Oxide Porous Sheets for Promoted Visible-light Water Splitting. J. Am. Chem. Soc. 136, 6826–6829, doi:10.1021/ja501866r (2014).

Carley, A. F., Roberts, M. W. & Santra, A. K. Interaction of Oxygen and Carbon Monoxide with CsAu Surfaces. J. Phys. Chem. B 101, 9978–9983, doi:10.1021/jp971780+ (1997).

Deng, J., Zhang, L. & Dai, H. et al. Strontium-doped Lanthanum Cobaltite and Manganite: Highly Active Catalysts for Toluene Complete Oxidation. Ind. Eng. Chem. Res. 47, 8175–8183, doi:10.1021/ie800585x (2008).

Fierro, J. L. G. & Tejuca, L. G. Non-stoichiometric Surface Behaviour of LaMO3, Oxides as Evidenced by XPS. Appl. Surf. Sci. 27, 453–457, doi:10.1016/0169-4332(87)90154-1 (1987).

Shin, S. & Jang, J. Thiol Containing Polymer Encapsulated Magnetic Nanoparticles as Reusable and Efficiently Separable Adsorbent for Heavy Metal Ions. Chem. Commun. 41, 4230–4232, doi:10.1039/b707706h (2007).

Guan, G., Yang, L. & Mei, Q. et al. Chemiluminescence Switching on Peroxidase-like Fe3O4 Nanoparticles for Selective Detection and Simultaneous Determination of Various Pesticides. Anal. Chem. 84, 9492–7, doi:10.1021/ac302341b (2012).

Hamid, S. B. A. & Schlögl, R. The Impact of Nanoscience on Heterogeneous Catalysis. Science 299, 1688–1691, doi:10.1126/science.1083671 (2003).

Tang, J. W., Zou, Z. G. & Ye, J. H. Effects of Substituting Sr2+ and Ba2+ for Ca2+ on the Structural Properties and Photocatalytic Behaviors of CaIn2O4. Chem. Mater. 16, 1644–1649, doi:10.1021/cm0353815 (2004).

Yu, J., Xiong, J. & Bei, C. et al. Fabrication and Characterization of Ag-TiO2, Multiphase Nanocomposite Thin Films with Enhanced Photocatalytic Activity. Appl. Cata., B. 60, 211–221, doi:10.1016/j.apcatb.2005.03.009 (2005).

Lu, C., Li, G. & Mao, J. et al. Bandgap, Mid-gap States, and Gating Effects in MoS2. Nano Letters 14, 4628–4633, doi:10.1021/nl501659n (2014).

Allan-Wojtas, P., Hildebrand, P. D. & Braun, P. G. et al. Highly Active Oxide Photocathode for Photoelectrochemical Water Reduction. Nat. Mater. 10, 456–461, doi:10.1038/nmat3017 (2011).

Liu, Y., Xie, S. & Liu, C. et al. Facile Synthesis of Tungsten Oxide Nanostructures for Efficient Photoelectrochemical Water Oxidation. J. Power Sources. 269, 98–103, doi:10.1016/j.jpowsour.2014.07.012 (2014).

Wang, G. L., Liu, K. L. & Dong, Y. M. et al. A New Approach to Light up the Application of Semiconductor Nanomaterials for Photoelectrochemical Biosensors: Using Self-operating Photocathode as a Highly Selective Enzyme Sensor. Biosens. Bioelectron. 62, 66–72, doi:10.1016/j.bios.2014.06.033 (2014).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51572159), the Chinese Postdoctoral Science Foundation (Grant No. 2016M590916), the Scientific Research Foundation for the Returned Overseas Chinese Scholars, State Education Ministry, the Science and Technology Foundation of Weiyang District of Xi’an City (Grant No. 201605), the Industrialization Foundation of Education Department of Shaanxi Provincial Government (Grant No. 16JF002).

Author information

Authors and Affiliations

Contributions

H.B.Y. and J.J.D. wrote the main manuscript. H.B.Y., J.J.D. and L.W. designed all the research. H.B.Y. and J.J.D. performed the experiments. J.J.D., L.W., Y.L. F.W. and P.K. carried out some measurements and analyzed some data. All the authors reviewed and approved the manuscript.

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, H., Dai, J., Wang, L. et al. A novel approach to prepare Bi2Fe4O9 flower-like spheres with enhanced photocatalytic performance. Sci Rep 7, 768 (2017). https://doi.org/10.1038/s41598-017-00831-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-017-00831-3

This article is cited by

-

Optical properties of Bi2Fe4O9/Ag3PO4 for rapid degradation of Rhodamine B

Reaction Kinetics, Mechanisms and Catalysis (2024)

-

Structural, electrical, and magnetic properties of mullite-type Bi2Fe4O9 ceramic

Journal of Electroceramics (2020)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.