Abstract

The ability to manipulate the twisting topology of van der Waals structures offers a new degree of freedom through which to tailor their electrical and optical properties. The twist angle strongly affects the electronic states, excitons and phonons of the twisted structures through interlayer coupling, giving rise to exotic optical, electric and spintronic behaviours1,2,3,4,5. In twisted bilayer graphene, at certain twist angles, long-range periodicity associated with moiré patterns introduces flat electronic bands and highly localized electronic states, resulting in Mott insulating behaviour and superconductivity3,4. Theoretical studies suggest that these twist-induced phenomena are common to layered materials such as transition-metal dichalcogenides and black phosphorus6,7. Twisted van der Waals structures are usually created using a transfer-stacking method, but this method cannot be used for materials with relatively strong interlayer binding. Facile bottom-up growth methods could provide an alternative means to create twisted van der Waals structures. Here we demonstrate that the Eshelby twist, which is associated with a screw dislocation (a chiral topological defect), can drive the formation of such structures on scales ranging from the nanoscale to the mesoscale. In the synthesis, axial screw dislocations are first introduced into nanowires growing along the stacking direction, yielding van der Waals nanostructures with continuous twisting in which the total twist rates are defined by the radii of the nanowires. Further radial growth of those twisted nanowires that are attached to the substrate leads to an increase in elastic energy, as the total twist rate is fixed by the substrate. The stored elastic energy can be reduced by accommodating the fixed twist rate in a series of discrete jumps. This yields mesoscale twisting structures consisting of a helical assembly of nanoplates demarcated by atomically sharp interfaces with a range of twist angles. We further show that the twisting topology can be tailored by controlling the radial size of the structure.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data supporting the findings of this study are available within the paper.

References

Kim, C.-J. et al. Chiral atomically thin films. Nat. Nanotechnol. 11, 520–524 (2016).

Song, J. C. & Gabor, N. M. Electron quantum metamaterials in van der Waals heterostructures. Nat. Nanotechnol. 13, 986–993 (2018).

Cao, Y. et al. Correlated insulator behaviour at half-filling in magic-angle graphene superlattices. Nature 556, 80–84 (2018).

Cao, Y. et al. Unconventional superconductivity in magic-angle graphene superlattices. Nature 556, 43–50 (2018).

Liu, K. et al. Evolution of interlayer coupling in twisted molybdenum disulfide bilayers. Nat. Commun. 5, 4966 (2014).

Naik, M. H. & Jain, M. Ultraflatbands and shear solitons in moiré patterns of twisted bilayer transition metal dichalcogenides. Phys. Rev. Lett. 121, 266401 (2018).

Kang, P. et al. Moiré impurities in twisted bilayer black phosphorus: effects on the carrier mobility. Phys. Rev. B 96, 195406 (2017).

Shtukenberg, A. G., Punin, Y. O., Gujral, A. & Kahr, B. Growth actuated bending and twisting of single crystals. Angew. Chem. Int. Ed. 53, 672–699 (2014).

Jin, S., Bierman, M. J. & Morin, S. A. A new twist on nanowire formation: screw-dislocation-driven growth of nanowires and nanotubes. J. Phys. Chem. Lett. 1, 1472–1480 (2010).

Bierman, M. J., Lau, Y. A., Kvit, A. V., Schmitt, A. L. & Jin, S. Dislocation-driven nanowire growth and Eshelby twist. Science 320, 1060–1063 (2008).

Zhu, J. et al. Formation of chiral branched nanowires by the Eshelby twist. Nat. Nanotechnol. 3, 477–481 (2008).

Oaki, Y. & Imai, H. Amplification of chirality from molecules into morphology of crystals through molecular recognition. J. Am. Chem. Soc. 126, 9271–9275 (2004).

Feng, W. et al. Assembly of mesoscale helices with near-unity enantiomeric excess and light–matter interactions for chiral semiconductors. Sci. Adv. 3, e1601159 (2017).

Srivastava, S. et al. Light-controlled self-assembly of semiconductor nanoparticles into twisted ribbons. Science 327, 1355–1359 (2010).

Eshelby, J. The twist in a crystal whisker containing a dislocation. Philos. Mag. 3, 440–447 (1958).

Eshelby, J. Screw dislocations in thin rods. J. Appl. Phys. 24, 176–179 (1953).

Sutter, E. & Sutter, P. 1D wires of 2D layered materials: germanium sulfide nanowires as efficient light emitters. ACS Appl. Nano Mater. 1, 1042–1049 (2018).

Li, C., Yu, Y., Chi, M. & Cao, L. Epitaxial nanosheet–nanowire heterostructures. Nano Lett. 13, 948–953 (2013).

Kong, D. et al. Topological insulator nanowires and nanoribbons. Nano Lett. 10, 329–333 (2010).

Peng, H., Xie, C., Schoen, D. T. & Cui, Y. Large anisotropy of electrical properties in layer-structured In2Se3 nanowires. Nano Lett. 8, 1511–1516 (2008).

Zhang, L. et al. Three-dimensional spirals of atomic layered MoS2. Nano Lett. 14, 6418–6423 (2014).

Shearer, M. J. et al. Complex and noncentrosymmetric stacking of layered metal dichalcogenide materials created by screw dislocations. J. Am. Chem. Soc. 139, 3496–3504 (2017).

Ly, T. H. et al. Vertically conductive MoS2 spiral pyramid. Adv. Mater. 28, 7723–7728 (2016).

Tamura, N. in Strain and Dislocation Gradients from Diffraction: Spatially Resolved Local Structure and Defects (eds Barabash, R. & Ice, G) 125–155 (Imperial College Press, 2014).

Tan, D. et al. Anisotropic optical and electronic properties of two-dimensional layered germanium sulfide. Nano Res. 10, 546–555 (2017).

Akatyeva, E., Kou, L., Nikiforov, I., Frauenheim, T. & Dumitrica, T. Electrically active screw dislocations in helical ZnO and Si nanowires and nanotubes. ACS Nano 6, 10042–10049 (2012).

Albrecht, M., Lymperakis, L. & Neugebauer, J. Origin of the unusually strong luminescence of a-type screw dislocations in GaN. Phys. Rev. B 90, 241201 (2014).

Al-Ghalith, J., Ni, Y. & Dumitrică, T. Nanowires with dislocations for ultralow lattice thermal conductivity. Phys. Chem. Chem. Phys. 18, 9888–9892 (2016).

Ertekin E., Greaney, P. A., Chrzan, D. C. & Sands, T. D. Equilibrium limits of coherency in strained nanowire heterostructures. J. Appl. Phys. 97, 114325 (2005).

Hirth, J. P. & Lothe, Jen. Theory of Dislocations (Krieger, 1992).

Eshelby, J. D., Read, W. T. & Schockley, W. Anisotropic elasticity with applications to dislocation theory. Acta Metall. 1, 251–259 (1953).

Foreman, A. J. E. Dislocation energies in anisotropic crystals. Acta Metall. 3, 322–330 (1955).

de Jong, M. et al. Charting the complete elastic properties of inorganic crystalline compounds. Sci. Data 2, 150009 (2015).

Acknowledgements

Y.L. and J.Y. are supported by the Samsung Advanced Institute of Technology under the grant 037361-003. Work at the Molecular Foundry and the Advanced Light Source was supported by the Office of Science, Office of Basic Energy Sciences, of the US Department of Energy under contract no. DE-AC02-05CH11231. H.S. and D.C.C. are supported by the US Department of Energy, Office of Science, Office of Basic Energy Sciences, Materials Sciences and Engineering Division under contract no. DE-AC02-244 05CH11231 within the Electronic Materials Program (KC1201). This work was performed, in part, at the Center for Nanoscale Materials, a US Department of Energy Office of Science User Facility, and supported by the US Department of Energy, Office of Science, under contract no. DE-AC02-06CH11357. We thank C. So, C. Song, X. Wang, S. Yan, K. Bustillo and C. V. Stan for help with the experiments.

Reviewer information

Nature thanks Hua Zhang and the other anonymous reviewer(s) for their contribution to the peer review of this work.

Author information

Authors and Affiliations

Contributions

Y.L. and J.Y. conceived the project and designed the experiments. S.K., Z.F., Y.L. and M.W. synthesized the samples. N.T. performed the X-ray analysis. J. Wang, F.Y., Y.L. and D.J. prepared samples for TEM study. Y.L., J. Wang, J. Wen, K.B.T., X.S. and M.C.S. worked on the TEM measurements. R.Z., Q.Y., J.T., R.O.R. and A.M.M. performed the EBSD analysis. H.S., B.Z.X. and D.C.C. carried out the theoretical calculations. Y.L. and J.Y. wrote the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Furnace set-up for the growth.

a, Schematic diagram of the furnace used for the synthesis of the twisted GeS crystals. b, Temperature profiles of the furnace for heating temperatures of 350 °C, 400 °C, 450 °C, 500 °C and 550 °C at the source site.

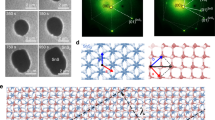

Extended Data Fig. 2 Additional chemical and structural analysis of mesoscale twisted GeS.

a–d, Chemical analysis of mesoscale twisted GeS using energy-dispersive X-ray spectroscopy (EDS). a, HAADF-STEM image of a cross-sectional lamellar sample with its normal perpendicular to the twist axis prepared by FIB milling. b, SEM image showing the crystal used to prepare the TEM sample. The dashed line represents the location of the cross-section. c, High-resolution TEM (HRTEM) image of the cross-section confirming that the twist axis is aligned with the [001] direction. d, STEM-EDS elemental map of the cross-section verifying that the structure is a compound consisting of Ge and S in an atomic ratio of 1:1. e, Additional X-ray microdiffraction analysis on a twisted GeS crystal with a period of about 15 μm. The orientation angle in the X-ray orientation map is defined by the angle between the b axis and the normal to the substrate. The large period, corresponding to a low crystallographic twist, facilitates the use of X-ray microdiffraction to determine the crystal orientation. The X-ray analysis also suggests that the widest portion in a period has its b axis aligned with the substrate normal while the narrowest portion in the period has its a axis aligned with the substrate normal. This growth phenomenon may result from the structural anisotropy of GeS. f, g, Handedness of mesoscale twisted GeS. f, Representative SEM micrographs showing twisted structures with opposite helicity. g, Histogram showing that the population of left-handed structures is approximately equal to the population of right-handed structures. The measured ratio of left-handedness to right-handedness is 74:67. h, Additional atomic-resolution HAADF-STEM image of a twist interface in a twisted GeS structure with the upper crystal oriented on the [110] zone axis. The inset shows the FFT pattern of the upper crystal.

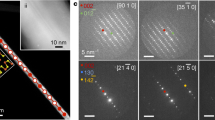

Extended Data Fig. 3 TEM image of the specimen on which diffraction patterns in Fig. 2c–e were obtained.

Using FIB, a lamellae sample containing two adjacent stacking nanoplates was prepared with the surface normal along the twist axis. After the thinning of the sample, the largest fraction of the sample consists of a single nanoplate (either the top or the bottom one), while a smaller fraction preserves the twist interface between the two nanoplates. The arrow shows the location of the twist interface. The red and blue dots show the locations that respectively contain the single upper plate and the single lower plate.

Extended Data Fig. 4 Electron backscattering diffraction analysis.

a, SEM image of a specimen used for EBSD. The lamellar sample is prepared by FIB milling with surface normal perpendicular to the twist axis of the structure. b, Representative EBSD orientation map of the nanoplates with the 2D projection of the unit cell superimposed. The unit cell projection shows the crystal orientation of the nanoplates at that point. The misorientations of the plates (that is, the differences between the crystal orientations of adjacent nanoplates) are quantified to be 10.2°, 14°, 6.7° and 8.7°. c, Unit cell of GeS viewed along the [100], [110] and [010] directions. d, Corresponding EBSD patterns acquired from five adjacent nanoplates. Note that 13 twist angles were measured on four mesoscale twisted structures using EBSD, and a representative measurement is shown in this figure. In addition, two twist angles were measured using the TEM (shown in Fig. 2). In total, 15 twist angles were measured on six twist structures. The values of the measured twist angles are 10.6°, 16°, 6.8°, 10.3°, 13.9°, 7.1°, 8.3°, 14°, 9.6°, 10.2°, 14°, 6.7°, 8.7°, 10.27° and 7.5°. This is a range from 6.8° to 16° with an average of 10.3° and standard deviation of 3°.

Extended Data Fig. 5 The effect of growth pressure on the growth of dislocated nanowires.

a, TEM image of a normal nanowire without a dislocation produced at a growth pressure of 5 Torr. b, Corresponding STEM image of the nanowire (left) and CBED patterns acquired from three different locations on the nanowire (right), showing the absence of the Eshelby twist. The white arrows in the STEM images show the locations where the CBED patterns are collected. c, HRTEM image of the normal nanowire showing that the growth direction of the nanowire is along the c axis. The inset is the FFT pattern of the HRTEM image suggesting the image is taken on the [110] zone axis (ZA). d, Areal number density (the number of twisted structures per unit area of the substrate) of twisted GeS structures as a function of the growth pressure. In this experiment, the flow rate of Ar/H2 carrier gas and the source temperature were fixed at 50 sccm and 450 °C, respectively. The growth of dislocated nanowires is achieved with typical growth pressures in the range 1–2 Torr and a flow rate of 20–50 sccm, whereas the yield of nanoscale and mesoscale twisted GeS drops when the growth pressure deviates from optimum.

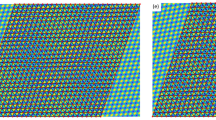

Extended Data Fig. 6 The invariance of the total twist rate in the radial growth of a pinned structure.

a, STEM image of a cross-sectional sample prepared from a twisted structure pinned on a substrate. This twist structure was formed by non-uniform radial growth on a twisted nanowire (similar to the structure shown in Fig. 4a), showing varying radial sizes for different portions of the structure. To verify the invariance of the total twist rate in the radial growth of a pinned structure, we used electron diffraction to measure the twist rates of different portions with varying radial sizes in the structure. b, Magnified STEM image of a thin portion highlighted by the dashed red box in a. c, CBED patterns for the [210] and [100] zone axes collected at locations marked by arrows in b. This suggests that the thin portion has a twist of 23° over a length of 970 nm, amounting to a twist rate of 0.4 rad mm−1. d, Magnified TEM image showing a thick portion highlighted by the dashed blue box in a. e, SAED patterns for the [010], [110] and [100] zone axes collected at locations marked by arrows in d. This suggests that the thick portion has a twist of 90° over a length of 4 μm, giving rise to a twist rate of 0.4 rad mm−1 as well. This electron diffraction analysis shows that twist rates at different portions with varying radial sizes in the structure are almost same, despite the significant difference in their radial size. Note that the thick portion has a radial size (about 450 nm) two times larger than that of the thin portion (about 150 nm). This result suggests that the overall twist rate of the structure is determined by the twist rate of the nanowire upon substrate pinning, and further radial growth does not result in untwisting that decreases the twist rate. The high twist rate of the initial nanowire with Eshelby twist is therefore preserved during radial growth.

Extended Data Fig. 7 Twisted GeS nanostructure in an intermediate twisting state.

a, Low-magnification STEM image of a nanostructure growing horizontally on a substrate. The nanowire had an approximate radial size of 200 nm and height of 150 nm with a twisting morphology that can be clearly observed by SEM imaging. We note that this nanostructure is the thin part of the sample shown in Extended Data Fig. 6. In contrast to free-standing nanowires (Fig. 3d) that have only a screw dislocation, the nanowire was segmented with the presence of both transverse boundaries and a dislocation line in the middle. b, HRTEM view of a boundary. The white arrow shows the boundary. c, d, FFT pattern of the two crystals across the boundary. The HRTEM imaging and the corresponding FFT patterns confirm that the crystals across the boundary have almost the same orientation and thus the boundary takes on a very small twist angle. e, HRTEM image of the screw dislocation. f, g, Burgers vector analysis, based on the g ∙ b contrast. To perform the analysis, the nanowire was first tilted to the [100] zone axis. Next, the sample was further tilted to create two-beam conditions for different diffraction spots in the diffraction pattern. Dark-field images of the dislocation were taken for g = (002) (f) and g = (020) (g). The insets show the excitation of reflections for the dark-field imaging in which the selected reflections are marked with red circles. For g = (002), high contrast of the dislocation is observed in the dark-field image (f), whereas for g = (020), the dislocation becomes invisible in the image (g). We have therefore determined the Burgers vector of the dislocation to be along the [001] direction, which is the same as for the dislocated nanowires that were grown vertical and free-standing. h, Low-magnification cross-sectional TEM image of the nanowire. i, j, CBED patterns for the [210] and [100] zone axes are collected at locations marked by circles in a, which were separated by 970 nm. This suggests a twist of 23° about the c axis within this length, amounting to a twist rate of 0.4 rad mm−1, which is comparable to the twist rate of mesoscale crystals. k, A series of dark-field TEM images showing that the [020] diffraction band progressively shifts when the sample is continuously rotated about its twist axis by tilting the TEM holder; this dark-field imaging verifies that the crystallographic twist of the nanowire is almost continuous. As such, the nanostructure has both twist boundaries with very small twist angles and an almost continuous twisting profile, exemplifying an intermediate twisting state at the onset of formation of the twist boundary.

Extended Data Fig. 8 Synthesis of mesoscale twisted GeSe using dislocated GeS nanowires as seeds.

a, Schematic showing the synthesis of mesoscale twisted GeSe structures. Twisted GeS nanowires were first grown via the VLS method. In a second growth, GeSe was deposited on the GeS nanowires using the chemical vapour transport method. b, Optical image of dislocated GeS nanowires. c, Optical image of mesoscale twisted structures synthesized through depositing GeSe on those twisted GeS nanowires. d, e, SEM images of twisted GeSe structures at low magnification (d) and at high magnification (e). f, SEM image (left) and corresponding EDS elemental maps of the structure. Quantitative chemical analysis using EDS suggests an almost 1:1 atomic ratio of Ge to Se.

Extended Data Fig. 9 Transfer of twisted GeS crystals to other substrates.

a, Schematic showing a facile processing scheme to transfer twisted GeS crystals to other substrates. i, Twisted crystals were first grown on a thermally oxidized Si/SiO2 substrate. These crystals adhered well to the substrate. ii, Polymethyl methacrylate (PMMA) was applied on the substrate. iii, The SiO2 layer was etched using hydrofluoric acid, and the crystals were transferred to the PMMA film. iv, The PMMA film with the crystals was brought into contact with another substrate. v, The GeS crystals were transferred to the substrate by dissolving PMMA in acetone. b, SEM images of the GeS crystals after the transfer. Scale bar, 4 μm.

Extended Data Fig. 10 Change in energy.

The total change in energy upon introduction of one dislocation pair into a nanowire of radius R (dimensionless), given that the initial twist rate of the wire is set at Ri = 100. Note that for these conditions there is a critical value of R necessary to introduce misfit dislocations, as well as a critical thickness. Note also that the energy is only reduced over a range of ∆l. See Methods for details.

Supplementary information

Video 1 Three-dimensional architecture of a mesoscale GeS structure

The video was created by combining cross-sectional SEM images that are sequentially acquired in the course of FIB milling of a mesoscale GeS structure along its twist axis.

Rights and permissions

About this article

Cite this article

Liu, Y., Wang, J., Kim, S. et al. Helical van der Waals crystals with discretized Eshelby twist. Nature 570, 358–362 (2019). https://doi.org/10.1038/s41586-019-1308-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-019-1308-y

This article is cited by

-

Reconfiguring nucleation for CVD growth of twisted bilayer MoS2 with a wide range of twist angles

Nature Communications (2024)

-

Creating chirality in the nearly two dimensions

Nature Materials (2024)

-

Conversion of chirality to twisting via sequential one-dimensional and two-dimensional growth of graphene spirals

Nature Materials (2024)

-

Vapour-phase deposition of two-dimensional layered chalcogenides

Nature Reviews Materials (2023)

-

Enantioselectivity of discretized helical supramolecule consisting of achiral cobalt phthalocyanines via chiral-induced spin selectivity effect

Nature Communications (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.