Abstract

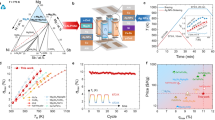

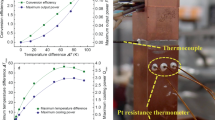

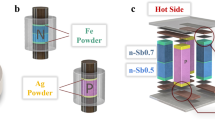

To facilitate the development of thermoelectric modules for various operating temperature ranges, a connection technology that is suitable for heat-sensitive thermoelectric materials and capable of realizing both low-temperature connections and high-temperature service is required. Here we use low-temperature sintering of silver nanoparticles as an approach to connect the electrode and metallization layer of low- (Bi2Te3-based), medium- (PbTe-based) and high-temperature (half-Heusler-based) thermoelectric modules. Owing to the low melting point of Ag nanoparticles and the high stability in the sintered bulk, the processing temperature of the module is decoupled from the operating temperature, avoiding welding thermal stress. We demonstrate a conversion efficiency of ~11% at the temperature difference of 550 K for the PbTe-based module. Additionally, the module’s performance remains nearly unchanged throughout thermal cycling between hot-side temperatures of 593 and 793 K for 50 cycles. Our work accelerates the development of advanced modules for thermoelectric power generation.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in the article, its Supplementary Information and the Source data provided with this paper.

References

DiSalvo, F. J. Thermoelectric cooling and power generation. Science 285, 703–706 (1999).

Bell, L. E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 321, 1457–1461 (2008).

Wang, X. et al. Band modulation and strain fluctuation for realizing high average zT in GeTe. Adv. Energy Mater. 12, 2201043 (2022).

Zhu, H. et al. Discovery of ZrCoBi based half Heuslers with high thermoelectric conversion efficiency. Nat. Commun. 9, 2497 (2018).

Zhao, L.-D. et al. Ultrahigh power factor and thermoelectric performance in hole-doped single-crystal SnSe. Science 351, 141–144 (2016).

Mao, J. et al. High thermoelectric cooling performance of n-type Mg3Bi2-based materials. Science 365, 495–498 (2019).

Zhang, Q. et al. Deep defect level engineering: a strategy of optimizing the carrier concentration for high thermoelectric performance. Energy Environ. Sci. 11, 933–940 (2018).

Yin, L. et al. Reliable n-type Mg3.2Sb1.5Bi0.49Te0.01/304 stainless steel junction for thermoelectric applications. Acta Mater. 198, 25–34 (2020).

Manikam, V. R. & Cheong, K. Y. Die attach materials for high temperature applications: a review. IEEE Trans. Compon. Packag. Manuf. Technol. 1, 457–478 (2011).

Lu, G.-Q., Calata, J. N., Lei, G. & Chen, X. Low-temperature and pressureless sintering technology for high-performance and high-temperature interconnection of semiconductor devices. In 2007 International Conference on Thermal, Mechanical and Multi-Physics Simulation Experiments in Microelectronics and Micro-Systems 1–5 (IEEE, 2007).

Li, M., Xiao, Y., Zhang, Z. & Yu, J. Bimodal sintered silver nanoparticle paste with ultrahigh thermal conductivity and shear strength for high temperature thermal interface material applications. ACS Appl. Mater. Interfaces 7, 9157–9168 (2015).

Jood, P., Ohta, M., Yamamoto, A. & Kanatzidis, M. G. Excessively doped PbTe with Ge-induced nanostructures enables high-efficiency thermoelectric modules. Joule 2, 1339–1355 (2018).

Brinkfeldt, K. et al. Sintered nano-Ag as joining material for thermoelectric modules. In Proc. 11th European Conference on Thermoelectrics (eds Amaldi, A. & Tang, F.) 71–82 (Springer, 2014).

Funahashi, R. et al. Relationship between tensile strength and durability of oxide thermoelectric modules. J. Electron. Mater. 50, 3996–4005 (2021).

Li, H. et al. Interface evolution analysis of graded thermoelectric materials joined by low temperature sintering of nano-silver paste. J. Alloys Compd. 659, 95–100 (2016).

Paknejad, S. A. & Mannan, S. H. Review of silver nanoparticle based die attach materials for high power/temperature applications. Microelectron. Reliab. 70, 1–11 (2017).

Peng, P. et al. Self-oriented nanojoining of silver nanowires via surface selective activation. Part. Part. Syst. Charact. 30, 420–426 (2013).

Paknejad, S., Dumas, G., West, G., Lewis, G. & Mannan, S. Microstructure evolution during 300 °C storage of sintered Ag nanoparticles on Ag and Au substrates. J. Alloys Compd. 617, 994–1001 (2014).

Lu, L., Shen, Y., Chen, X., Qian, L. & Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 304, 422–426 (2004).

Crocker, A. & Wilson, M. Microhardness in PbTe and related alloys. J. Mater. Sci. 13, 833–842 (1978).

Hu, X. et al. Power generation from nanostructured PbTe-based thermoelectrics: comprehensive development from materials to modules. Energy Environ. Sci. 9, 517–529 (2016).

Jiang, B. et al. Realizing high-efficiency power generation in low-cost PbS-based thermoelectric materials. Energy Environ. Sci. 13, 579–591 (2020).

Jiang, B. et al. High-entropy-stabilized chalcogenides with high thermoelectric performance. Science 371, 830–834 (2021).

Jia, B. et al. Realizing high thermoelectric performance in non-nanostructured n-type PbTe. Energy Environ. Sci. 15, 1920–1929 (2022).

Ben-Ayoun, D., Sadia, Y. & Gelbstein, Y. Compatibility between Co-metallized PbTe thermoelectric legs and an Ag–Cu–In brazing alloy. Materials 11, 99 (2018).

Hori, Y. & Ito, T. Fabrication of 500°C class thermoelectric module and evaluation of its high temperature stability. In 25th International Conference on Thermoelectrics 642–645 (IEEE, 2006).

Tan, G. et al. Subtle roles of Sb and S in regulating the thermoelectric properties of n‐type PbTe to high performance. Adv. Energy Mater. 7, 1700099 (2017).

Wang, X. et al. Organic/inorganic hybrid design as a route for promoting the Bi0.5Sb1.5Te3 for high-performance thermoelectric power generation. Adv. Funct. Mater. 32, 2200307 (2022).

Zhang, Q. et al. High thermoelectric performance by resonant dopant indium in nanostructured SnTe. Proc. Natl Acad. Sci. USA 110, 13261–13266 (2013).

Zhu, J. et al. AgNi alloy as a suitable barrier layer material for NbFeSb-Based half-Heusler thermoelectric modules. J. Electron. Mater. 48, 6815–6822 (2019).

Sun, Y. et al. Low contact resistivity and excellent thermal stability of p-type YbMg0.8Zn1.2Sb2/Fe-Sb junction for thermoelectric applications. Acta Mater. 235, 118066 (2022).

Joshi, G. et al. NbFeSb-based p-type half-Heuslers for power generation applications. Energy Environ. Sci. 7, 4070–4076 (2014).

Liu, Y. et al. Demonstration of a phonon-glass electron-crystal strategy in (Hf,Zr)NiSn half-Heusler thermoelectric materials by alloying. J. Mater. Chem. A 3, 22716–22722 (2015).

Zhu, B. et al. Realizing record high performance in n-type Bi2Te3-based thermoelectric materials. Energy Environ. Sci. 13, 2106–2114 (2020).

Zhang, Q. et al. Realizing a thermoelectric conversion efficiency of 12% in bismuth telluride/skutterudite segmented modules through full-parameter optimization and energy-loss minimized integration. Energy Environ. Sci. 10, 956–963 (2017).

Liang, Z. et al. High thermoelectric energy conversion efficiency of a unicouple of n-type Mg3Bi2 and p-type Bi2Te3. Mater. Today Phys. 19, 100413 (2021).

Zhu, Q. & Ren, Z. A double four-point probe method for reliable measurement of energy conversion efficiency of thermoelectric materials. Energy 191, 116599 (2020).

Gao, B., Sun, X., Yao, C. & Mao, L. A new strategy to obtain thin ZrO2–Al2O3 composite aerogel coating with prominent high-temperature resistance and rapid heat dissipation. J. Solid State Chem. 314, 123384 (2022).

Knoerr, M., Kraft, S. & Schletz, A. Reliability assessment of sintered nano-silver die attachment for power semiconductors. In 12th Electronics Packaging Technology Conference 56–61 (IEEE, 2010).

Watanabe, T., Yanagisawa, A. & Sasaki, T. Development of Ag based brazing filler metal with low melting point. Sci. Technol. Weld. Join. 16, 502–508 (2011).

Buhl, S., Leinenbach, C., Spolenak, R. & Wegener, K. Microstructure, residual stresses and shear strength of diamond–steel-joints brazed with a Cu-Sn-based active filler alloy. Int. J. Refract. Met. Hard Mater. 30, 16–24 (2012).

Ambrose, J., Nicholas, M., Young, N. & Jenkins, S. Wetting and spreading of Ni–P brazes: effects of workpiece and braze composition. Mater. Sci. Technol. 6, 1021–1031 (1990).

Yang, T., Shiue, R. & Wu, S. Infrared brazing of Ti50Ni50 shape memory alloy using pure Cu and Ti–15Cu–15Ni foils. Intermetallics 12, 1285–1292 (2004).

Weng, W. & Chuang, T. Interfacial characteristics for brazing of aluminum matrix composites with Al-12Si filler metals. Metall. Mater. Trans. A 28, 2673–2682 (1997).

Rowe, D. M. CRC Handbook of Thermoelectrics (CRC Press, 2018).

Brož, P. et al. Study of thermal stability of CoSb3 skutterudite by Knudsen effusion mass spectrometry. Calphad 65, 1–7 (2019).

Zhang, J. et al. Mechanical properties and thermal stability of the high-thermoelectric-performance Cu2Se compound. ACS Appl. Mater. Interfaces 13, 45736–45743 (2021).

Shang, H. et al. n-Type Mg3Sb2–xBix with improved thermal stability for thermoelectric power generation. Acta Mater. 201, 572–579 (2020).

Zhang, F. & Saxena, S. Phase stability and thermal expansion property of FeSi2. Scr. Mater. 54, 1375–1377 (2006).

Jiang, C. et al. Thermal stability of p-type polycrystalline Bi2Te3-based bulks for the application on thermoelectric power generation. J. Alloys Compd. 692, 885–891 (2017).

Shi, D.-l et al. Thermal stability study of Cu1.97Se superionic thermoelectric materials. J. Mater. Chem. C 8, 10221–10228 (2020).

Tan, G. et al. High thermoelectric performance of p-type SnTe via a synergistic band engineering and nanostructuring approach. J. Am. Chem. Soc. 136, 7006–7017 (2014).

Yin, K. et al. Thermal stability of Mg2Si0.3Sn0.7 under different heat treatment conditions. J. Mater. Chem. C 3, 10381–10387 (2015).

Mi, J.-L. et al. Elaborating the crystal structures of MgAgSb thermoelectric compound: polymorphs and atomic disorders. Chem. Mater. 29, 6378–6388 (2017).

Hou, S. et al. High performance wearable thermoelectric generators using Ag2Se films with large carrier mobility. Nano Energy 87, 106223 (2021).

Singh, A. et al. Development of low resistance electrical contacts for thermoelectric devices based on n-type PbTe and p-type TAGS-85 ((AgSbTe2)0.15(GeTe)0.85). J. Phys. D 42, 015502 (2009).

Hsieh, H.-C. et al. Joint properties enhancement for PbTe thermoelectric materials by addition of diffusion barrier. Mater. Chem. Phys. 246, 122848 (2020).

Liu, W. et al. Understanding of the contact of nanostructured thermoelectric n-type Bi2Te2.7Se0.3 legs for power generation applications. J. Mater. Chem. 1, 13093–13100 (2013).

Wu, X. et al. A general design strategy for thermoelectric interface materials in n-type Mg3Sb1.5Bi0.5 single leg used in TEGs. Acta Mater. 226, 117616 (2022).

Xing, T. et al. High efficiency GeTe-based materials and modules for thermoelectric power generation. Energy Environ. Sci. 14, 995–1003 (2021).

Bu, Z. et al. Realizing a 14% single-leg thermoelectric efficiency in GeTe alloys. Sci. Adv. 7, eabf2738 (2021).

Gu, M., Xia, X., Li, X., Huang, X. & Chen, L. Microstructural evolution of the interfacial layer in the Ti-Al/Yb0.6Co4Sb12 thermoelectric joints at high temperature. J. Alloys Compd. 610, 665–670 (2014).

Acknowledgements

This work was supported by the Shenzhen Science and Technology Program (KQTD20200820113045081). Q.Z. acknowledges financial support from the National Natural Science Foundation of China (52172194 and 51971081), the Natural Science Foundation for Distinguished Young Scholars of Guangdong Province of China (2020B1515020023) and the Shenzhen Science and Technology Program (RCJC20210609103733073). J.M. acknowledges financial support from the National Natural Science Foundation of China (52101248), Shenzhen Fundamental Research Projects (JCYJ20210324132808020) and Shenzhen Stable Support Plan for Higher Education Institutions (GXWD20220818151757003).

Author information

Authors and Affiliations

Contributions

Q.Z., Z.R., J.M. and L.Y. designed this work. L.Y., X.W., J.C. and X.B. synthesized the samples and conducted the transport property measurements. F.Y. and Z.D. synthesized the Ag NP paste. L.Y. conducted the experimental study on sintered connection and characterization of the junctions. Y.W. and W.X. performed the TEM observations. L.Y. and X.B. conducted the experimental study on module fabrication and characterization. Q.Z., L.Y., Z.R., J.M., F.C., H.J., J.S., X.L. and M.L. discussed the results. L.Y., Q.Z., J.M. and Z.R. wrote this paper, and all authors edited it.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Energy thanks Johannes de Boor, Michihiro Ohta and Qingyu Yan for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–33 and Tables 1–6.

Source data

Source Data Fig. 1

Statistical source data.

Source Data Fig. 2

Statistical source data.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yin, L., Yang, F., Bao, X. et al. Low-temperature sintering of Ag nanoparticles for high-performance thermoelectric module design. Nat Energy 8, 665–674 (2023). https://doi.org/10.1038/s41560-023-01245-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41560-023-01245-4

This article is cited by

-

CALPHAD accelerated design of advanced full-Zintl thermoelectric device

Nature Communications (2024)

-

Enhanced thermoelectric properties of Bi2Sr2Co2Oy ceramics by dispersing B2O3 additive

Applied Physics A (2024)

-

On-Chip Micro Temperature Controllers Based on Freestanding Thermoelectric Nano Films for Low-Power Electronics

Nano-Micro Letters (2024)

-

Pressure Sintering of Micro-Silver Joints in SiC Power Devices: Optimization of Processing Parameters and FEM Analysis

Journal of Electronic Materials (2024)

-

Design of efficient thermoelectric generators

Science China Materials (2024)