Abstract

Production of methanol from electrochemical reduction of carbon dioxide is very attractive. However, achieving high Faradaic efficiency with high current density using facile prepared catalysts remains to be a challenge. Herein we report that copper selenide nanocatalysts have outstanding performance for electrochemical reduction of carbon dioxide to methanol, and the current density can be as high as 41.5 mA cm−2 with a Faradaic efficiency of 77.6% at a low overpotential of 285 mV. The copper and selenium in the catalysts cooperate very well for the formation of methanol. The current density is higher than those reported up to date with very high Faradaic efficiency for producing methanol. As far as we know, this is the first work for electrochemical reduction of carbon dioxide using copper selenide as the catalyst.

Similar content being viewed by others

Introduction

Electroreduction of carbon dioxide (CO2) is a potential strategy to transform the intermittent sources of energy into high-energy chemicals, which can potentially reduce our dependence on fossil fuels and alleviate atmospheric pollution1,2,3,4. Among the products formed upon electrochemical CO2 reduction, hydrocarbons, and alcohols with high energy density, like methanol, are compatible with existing infrastructures and can substitute for fossil fuels5,6,7. It is known that the electrocatalytic reduction of CO2 to methanol requires intricate six-electron/proton coupling steps and sluggish kinetics8,9,10,11. Therefore, the reaction usually suffers from low current density, poor selectivity and the large overpotential9,12,13,14. As a result, rational design of highly active and robust electrocatalysts that could generate high current density and high selectivity is critical for large-scale application.

Metal and metal-based catalysts have been used for electroreduction of CO2 to CO, hydrocarbons and alcohols15,16. To date, some electrocatalysts, such as precious metal and copper-based catalysts, have shown to be promising for electroreduction of CO2 to methanol9,10,11,12,14,17,18,19,20,21,22. Among these materials, Cu has been reported as the promising electrocatalyst that is active and selective for CO2 reduction to hydrocarbons and alcohols. However, the activity and selectivity of bulk Cu for producing methanol are usually low14,18,19,20. Metallic Pd or Pt, Pd-Cu and Mo complexes all have also been employed as catalysts for electrochemical synthesis of methanol10,12,19,21,22. In addition, Ru/Ti bimetallic oxide is another promising catalyst for production of methanol23. It was reported that Mo-Bi bimetallic chalcogenide (MoS2/Bi2S3) could be used as electrocatalyst to promote the reaction8. Nevertheless, achieving high current density and Faradaic efficiency (FE) simultaneously for conversion of CO2 to methanol remains to be a challenge, and only a few catalysts reported up to date could reach relatively high current density and selectivity, as shown in Supplementary Table 1. Therefore, designing efficient catalysts to enhance the activity and FE, and reduce the overpotential is very interesting from both scientific and practical viewpoints.

In recent years, nanoscale transition metal oxides (TMOs) and chalcogenides (TMCs) have attracted considerable attention, which have great potential of application in photo-electric devices, lithium-ion batteries, gas sensors, and electrocatalysis24,25. For electroreduction of CO2, it is known that metal-based oxides, and sulfides could have good performance8,26,27,28. However, only few studies have reported the use of TMCs, such as metal selenides and tellurides for CO2 electroreduction29,30. WSe2 nanoflakes were reported as an efficient catalyst for CO2 electroreduction to CO29. Density functional theory (DFT) calculation indicated that molybdenum sulfides and selenides were also possible catalysts for CO2 electroreduction30, which showed that the intermediates COOH and CHO were more easily adsorbed on the S and Se atoms at the edges than the intermediate CO. Therefore, transition-metal selenides may be a class of promising catalysts for CO2 electroreduction. Copper selenides are interesting materials that form nonstoichiometric (i.e., Cu2−xSe) as well as stoichiometric (i.e., CuSe, Cu2Se, Cu2Se3) phases31,32. They also have structure stability and composition-dependent optical/electrical properties33. In addition, they are low-cost materials compared with many other materials25, especially noble metals. The advantage of copper selenide is its multiple oxidation states and high electrical conductivity, which can deliver better electrochemical properties32. Moreover, the unsaturated Se atoms along its edges may enhance the number of exposed active sites, electrical conductivity and catalytic activity in CO2 reduction29,30.

Herein, we report a facile solvothermal synthesis of Cu2−xSe(y) nanocatalysts in diethylenetriamine (DETA, Supplementary Fig. 1 for the structure) and H2O binary solution, where y represents the volume ratio of DETA and water (VDETA/VH2O), and the value of x is in the range of 0.3 to 0.4, depending on the atom ratio of Cu and Se in the catalysts. The properties of the catalysts, such as size and morphology, are solvent-dependent. The catalysts synthesized in the mixed solvent with VDETA/VH2O of 1:3 can convert CO2 into methanol with a current density of 41.5 mA cm−2 at FE of 77.6%. The current density is higher than those reported up to date with very high methanol selectivity (Supplementary Table 1).

Results

Synthesis and characterization of Cu2−xSe(y) nanocatalysts

The Cu2−xSe(y) nanocatalysts were synthesized by solvent coordination molecular template method34,35, which is shown schematically in Supplementary Fig. 1. In the synthesis of the catalysts, the positively charged ammonium ions coordinated with Se to incorporate into the neighboring Cu2−xSe(y) nanoparticles. The protonated amine molecules then act as a template, resulting in the new morphology of the Cu2−xSe(y) nanocatalysts34,35.

It is clearly shown that the VDETA/VH2O affected the morphology of the Cu2−xSe(y) nanocatalysts considerably (Supplementary Fig. 2). The nanoparticles tended to be granular with increasing content of water in the solvent. In addition, the Cu1.63Se(1/3) nanoparticles synthesized at the VDETA/VH2O of 1/3 had the smallest size. The detailed characterization results of Cu1.63Se(1/3) nanocatalysts are shown in Fig. 1. The images of scanning electron microscopy (SEM) (Fig. 1a) and transmission electron microscopy (TEM) (Fig. 1b) reveal that the size of the Cu1.63Se(1/3) nanoparticles was ~50 nm, which is consistent with the results obtained from dynamic light scattering (DLS, inset of Fig. 1a). Elemental distribution mappings (inset images of Fig. 1b) analysis further indicated the uniform distribution of Cu (yellow) and Se (blue) atoms in the catalysts. Thermogravimetry (TG) curve is shown in Supplementary Fig. 3. The weight loss of DETA (if incorporated into the nanoparticles) should occur at 280–580°C36. It can be seen from the figure that there was no weight loss in the temperature range, indicating that there was no DETA in the catalysts. The high-resolution TEM (HR-TEM) image demonstrated the high crystallinity of nanoparticles (Fig. 1c). Furthermore, X-ray photoelectron spectroscopy (XPS) identified the valence states of Cu and Se in the nanocatalysts. The binding energies of Cu 2p3/2 and Cu 2p1/2 (Fig. 1d) were 932.1 and 952.0 eV respectively, and there was a peak at 916.9 eV in the Cu LMM spectrum (Fig. 1e), indicating the existence of Cu(I)37,38,39. In addition, the binding energies of Cu 2p3/2 and Cu 2p1/2 at 933.5 and 953.9 eV (Fig. 1d) along with the satellite lines can be assigned to Cu(II)40. The double peaks at 55.3 and 54.6 eV (Fig. 1f) in the XPS spectrum were the typical Se 3d binding energy for lattice Se2-37,41. The atomic ratio of Cu(I) to Cu(II) in the nanocrystal determined by XPS was 3.41. Meanwhile, the atomic ratio of Cu to Se determined by inductively coupled plasma-optical emission spectroscopy (ICP-OES) was 1.64, which is consistent with the value determined by XPS (1.63). In terms of the molecular formula, nonstoichiometric Cu2−xSe(y) could be considered as a mixture of stoichiometric Cu2Se and CuSe31 and thus the molecular formula can be estimated as Cu1.63Se(1/3). Similarly, the molecular formulae of the nanocatalysts prepared in the solvents at other VDETA/VH2O ratios were Cu1.64Se(0/1), Cu1.62Se(1/5), Cu1.63Se(1/1), Cu1.60Se(3/1), and Cu1.61Se(1/0) (Supplementary Table 2), and the HRTEM images and XPS spectra are shown in Supplementary Figs. 4–8. The diffraction peaks of the Cu1.63Se(1/3) nanocatalysts (Fig. 1g) can be assigned to (111), (200), (220), (311), (400), and (331) planes of cubic Cu2−xSe (JCPDS No. 06–0680)37,42, which is in agreement with the HR-TEM result (Fig. 1c). Meanwhile, the difference of XRD patterns of the catalysts synthesized at various VDETA/VH2O ratios was not noticeable (Supplementary Fig. 9). The results showed that the crystal structures of different samples were not changed with the VDETA/VH2O ratio notably. However, the size and morphology depended strongly on the composition of the solvents, which influenced the performances of CO2 electroreduction.

Characterization of Cu1.63Se(1/3) nanocatalysts. a SEM image of the Cu1.63Se(1/3) nanocatalysts and the inset is size distribution determined by DLS, scale bar = 200 nm; b TEM image of the Cu1.63Se(1/3) nanocatalysts and the inset is the corresponding elemental mappings, scale bar = 100 nm; c HR-TEM image of the Cu1.63Se(1/3) nanocatalysts, scale bar = 10 nm; XPS spectra of the Cu1.63Se(1/3) nanocatalysts: d Cu 2p, e Cu LMM, and f Se 3d; g XRD patterns of the Cu1.63Se(1/3) nanocatalysts

Electrocatalytic performance of CO2 reduction over Cu2−xSe(y) nanocatalysts

The linear sweep voltammetry (LSV) study was conducted to investigate the performances of the Cu2−xSe(y) nanocatalysts under the same conditions in [Bmim]PF6 (30 wt%)/CH3CN/H2O (5 wt%) ternary electrolyte, and the results are shown in Fig. 2a. The results indicate that Cu1.63Se(1/3) exhibited a more positive onset potential of −1.815 V vs. Ag/Ag+ than other Cu2−xSe(y) nanocatalysts, suggesting that Cu1.63Se(1/3) was favorable to the binding of CO2. In addition, the current density over Cu1.63Se(1/3) reached a high value of about 40 mA cm−2 at −2.1 V vs. Ag/Ag+, which exhibits higher activity than other Cu2−xSe(y) nanocatalysts. The much higher current density of the CO2-saturated than the N2-saturated on the Cu1.63Se(1/3) (around −2.1 V vs. Ag/Ag+) indicates the reduction of CO2.

CO2 reduction performance on Cu2−xSe(y) nanocatalysts. a LSV traces on different electrodes in CO2-saturated or N2-saturated electrolyte at scan rate of 20 mV s−1; b Total current density and c FE over Cu1.63Se(1/3) catalyst at different applied potentials; d Plots of particle size vs. FE of methanol on different catalysts (1) Cu1.61Se(1/0); (2) Cu1.60Se(3/1); (3) Cu1.63Se(1/1); (4) Cu1.63Se(1/3); (5) Cu1.62Se(1/5); (6) Cu1.64Se(0/1). Data were obtained at ambient temperature and pressure with CO2 stream of 10 sccm with 5 h electrolysis. All data in c and d are presented as mean ± s.d

Constant-potential electrolysis of CO2 over different catalysts was performed in a typical H-type cell8. Liquid-phase and gas-phase products were quantified by nuclear magnetic resonance spectroscopy (1H NMR) and gas chromatography (GC), respectively. The current density and FE are displayed in Fig. 2b, c. It can be found that all Cu2−xSe(y) nanocatalysts basically yielded a certain amount of methanol, HCOOH, CO, and H2 with a combined FE of around 100%, and no other product was detected (Supplementary Fig. 10). The Cu1.63Se(1/3) electrode had better performance than other Cu2−xSe(y) nanocatalysts. The maximum FE occurred at −2.1 V vs. Ag/Ag+, and it could reach 77.6% with a current density of 41.5 mA cm−2 (Fig. 2b, c). The equilibrium (thermodynamic) potential for CH3OH was −1.815 V vs. Ag/Ag+, which was obtained by extrapolation of partial current density vs. potential curve to zero partial current density (Supplementary Fig. 11)43,44,45. Therefore, the overpotential for CO2 electroreduction to methanol was 285 mV at −2.1 V vs. Ag/Ag+. This catalyst exhibits the highest current density with very high FE for producing methanol, as can be known in Supplementary Table 1. The cell voltage is an important factor for practical application, which depends mainly on the performances of the electrocatalysts. In this study, we calculated the cell voltage using the reported method46,47, and the cell voltage of our system was 2.67 V, which is in the range of reported values (2.2–3.7 V, Supplementary Table 3). In Supplementary Fig. 12, the FE for methanol production increased with the cell voltage to reach the maximum value of 77.6% at 2.67 V. We also calculated the energy efficiency (EE) for methanol production at different cell voltages using the reported method48, and the results are given in Supplementary Fig. 12. The EE exhibited a similar tendency to the FE of methanol with variation of the cell voltage. Furthermore, the highest EE was 61.7% at the optimized cell voltage of 2.67 V.

We also carried out the experiment using 13CO2 to replace CO2 in the electrolysis over Cu1.63Se(1/3). The 1H NMR spectra of the product indicated that only 13CH3OH was produced (Supplementary Fig. 13), confirming that the product methanol originated from CO2. Meanwhile, the electrolyte after different electrolysis times was also tested by IR8,49 in Supplementary Fig. 14, which can further confirm formation of methanol. In addition, FE and current density did not vary during 25 h of operation (Supplementary Fig. 15), which indicated exhibit long-term stability in the electrolysis. The composition and structure of the catalyst did not change after the reaction as characterized by XPS and XRD analysis (Supplementary Figs. 16 and 17), indicating the excellent stability of the Cu1.63Se(1/3).

The particle size and morphology of the materials can affect the number of exposed active sites. From Fig. 2d and Supplementary Fig. 1, we can see that the size of the catalysts synthesized at VDETA/VH2O = 1/3 was smallest and the current density and FE were largest. More active sites were exposed with more unsaturated Se atoms on the smaller particles may be one of the main reasons for high current density and FE29,30.

Discussion

The Tafel plots in Supplementary Fig. 18 and Supplementary Table 2 show the variation of overpotential with partial current density for methanol production over these catalysts. The resulting Tafel plots of various Cu2−xSe(y) electrodes are linear in the overpotential (η) range from 0.035 to 0.285 V. The Tafel slope of Cu1.63Se(1/3) was smaller than other Cu2−xSe(y) nanocatalysts, which leads to faster increment of CO2 reduction rate with increasing overpotential26,50. Combining with efficient and stable electrocatalytic CO2 conversion to methanol, the Cu1.63Se(1/3) nanocatalysts can be a promising catalyst in practical applications.

The excellent activity of Cu2−xSe(y) electrodes may also result partially from large electrochemical active surface area. According to the Randles–Sevcik equation, the current density at −1.85 V (vs. Ag/Ag+) plotted against the square root slope of scan rate is shown in Supplementary Fig. 19. The double-layer capacitances (Cdl) of various catalysts were then calculated and illustrated in Supplementary Table 2. The obvious difference in Cdl values (ranging from 0.00906 to 0.0183 Fcm−2) suggests that the Cu1.63Se(1/3) had the largest electrochemistry surface area, which is beneficial to the reaction.

Electrochemical impedance spectroscopy (EIS) also revealed an easier electron transfer process on the electrode interface. The Nyquist plot was conducted by running the experiment at an open circuit potential (Supplementary Fig. 20), and the equivalent circuit R(C(R(Q(RW)))) (Supplementary Fig. 21) is then used to fit the impedance data. The simulated results of charge transfer resistance (Rct) are given in Supplementary Table 2. The results confirm that the charge transfer could easily occur on the Cu1.63Se(1/3) electrode. It ensures a faster electron transfer to CO2 for stabilizing reduced CO2•− intermediate that is vital for electroreduction CO2. All the above results indicate that the particle sizes and morphologies of the catalysts played an important role for electroreduction CO2.

We also used [Bmim]PF6/CH3CN/H2O with different compositions as supporting electrolytes to perform the reaction over Cu1.63Se(1/3). Compared with aqueous electrolyte, combination of organic solvents and ionic liquids as electrolytes has obvious advantages. For example, they can accelerate catalytic performance of CO2 reduction by increasing the adsorption rate of CO251,52, and they provide more opportunity to produce various valuable products1,2,8,53,54. Meanwhile, the ionic liquids (ILs) with imidazolium cation and fluorine-containing anions can be the efficient supporting electrolytes for CO2 reduction53,54. From Supplementary Tables 4 and 5, we can find that the [Bmim]PF6 (30 wt%)/CH3CN/H2O (5 wt%) ternary electrolyte was most efficient for CO2 for the reaction, and the current density could reach 41.5 mA cm−2 with a Faradaic efficiency of 77.6%. To further understand the role of anions in the ILs, other ILs were also used, including [Bmim]PF6, [Bmim]BF4, [Bmim]TF2N, [Bmim]OAc, [Bmim]NO3, and [Bmim]ClO4 and acetonitrile systems for comparison (Supplementary Figs. 22 and 23). It can be observed that the anions of the ILs also influenced the electrochemical reaction significantly (Supplementary Fig. 23), which resulted partially from the difference of the interaction between CO2 and the anions of the ILs55. [Bmim]PF6 exhibited higher current density and Faradaic efficiency for methanol among all the ILs used. The separation of the reaction mixture is crucial for practical application. Although this is out of the scope of this work, we would like to discuss this very briefly. For this system, the boiling point of [Bmim]PF6 is much higher than that of CH3OH, CH3CN and H2O, and the IL in the system can be separated via distillation. Meanwhile, the method to separate ternary mixture consisting of CH3OH, CH3CN and H2O has been reported56.

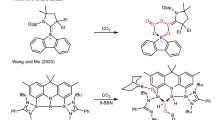

It is very interesting to investigate the reasons for the outstanding performance of the Cu1.63Se(1/3) electrocatalyst in the electrocatalytic reduction of CO2 to methanol. Therefore, we carried out a series of control experiments to investigate the crucial role of Se in the catalysts. CO2 electroreduction with Cu, CuO, Cu2O, CuS, Cu2S, CuSe, and Cu2Se as catalysts were studied. Both current density and FE for methanol over Se-free catalysts were obvious lower (Fig. 3 and Supplementary Fig. 24). The results suggest that the Cu and Se in the catalysts cooperated very well for the formation of methanol. In other words, the capacity of electroreduction of CO2 to methanol was enhanced when O or S atom was replaced by Se atom in the catalysts. Moreover, when commercial CuSe or Cu2Se was utilized as the catalysts, both current density and FE were much lower than that over Cu1.63Se(1/3). The catalytic performance was also evaluated using the electrochemical active surface areas (ECSA) determined by reported method57. Results in Supplementary Fig. 25 and Supplementary Table 6 show that the formation rate of methanol over Cu1.63Se(1/3) was intrinsically higher than that on the other catalysts. Thus, on the basis of above results, we can deduce that Se in the catalysts is crucial for efficient CO2 reduction to methanol.

We also carried out extended X-ray absorption fine structure spectroscopy (EXAFS) experiments to study Cu K-edge, which can disclose the local atomic arrangements of the catalysts. The Cu K-edge k2χ(k) oscillation curve for Cu1.63Se(1/3) was obviously different from that for CuSe and Cu2Se (Supplementary Fig. 26). It can be seen that the coordination number in Cu1.63Se(1/3) was smaller than that in CuSe and Cu2Se (Supplementary Figs. 27–30 and Supplementary Table 7). Thus, there existed unsaturated Se atom in the Cu1.63Se(1/3), which may enhance the performance for CO2 electroreduction.

To understand the reaction pathway for the formation of methanol, some control experiments were conducted in the presence of the possible reaction intermediates, such as formic acid, CO and formaldehyde (Supplementary Table 8). From the production rates of methanol, it can be seen that CO and formaldehyde clearly promoted the formation of methanol and thus they are possible intermediates in the formation of methanol. On the basis of the results above, we propose a possible reaction pathway over Cu2−xSe(y) nanocatalysts (Fig. 4a). In the initial stage of the reduction, the electrolyte containing ionic liquids can enhance the concentration of CO2 in electrolyte and transport of CO2 to the catalyst surface to improve further transform of CO2 into adsorbed CO2•−2,55. The adsorbed CO2•− could bind with the active sites on the surface of catalysts and accelerate the formation of adsorbed-CO species, which was a crucial intermediate for facilitating methanol production as reported20,58. Furthermore, the appropriate Cu active sites over the catalysts can enhance the initial intermediate of absorbed-CO to accept electrons and protons to form absorbed-CHO and then reduced to methanol.

The density functional theory (DFT) calculations were also conducted on the multiple elementary reaction steps, and the results are shown in Fig. 4b and Supplementary Figs. 31–33. Comparing with other two catalysts (Cu2Se and CuSe), the formation of intermediate (*COOH) on the Cu1.63Se(1/3) surfaces can reach a stable configuration with lower free energy via two neighboring Cu atoms through Cu-C and Cu-O bonds. The *COOH intermediate binds with the active sites on the surface of catalysts and accelerate the formation of adsorbed *CO species59. The Cu1.63Se(1/3) catalyst also has a moderate binding energy for *CO among the three catalysts, which is beneficial for CO2 transformation to more reduced products that require more than a two-electron reduction20,58. Based on the Brønsted–Evans–Polanyi (BEP) relationship60,61, the reaction barrier has a linear relationship to the reaction energy, and it can also be seen that the step of *CO reduction to *CHO was an endothermic and likely rate-limiting step since the highest energy potential (0.56 eV) is needed in this step. Compared with Cu2Se and CuSe, the free energy of *CHO over Cu1.63Se(1/3) catalyst is more negative, which may be mainly originated from the moderately strong binding energy for *CO intermediate. In addition, the C-Cu bond (Supplementary Fig. 34) between Cu1.63Se(1/3)-CHO is 1.926 Å, which is shorter than those of Cu2Se-CHO (2.188 Å) and CuSe-CHO (2.002 Å), indicating that *CHO is easier to adsorb on the surface of the catalyst to accept electrons and protons to form *OCH2 and *OCH3, and then is reduced to methanol. These results illustrate that the structure distortion of Cu1.63Se(1/3) was beneficial for CO2 electroreduction to methanol.

In summary, a series of Cu2−xSe(y) nanocatalysts were synthesized for selective electroreduction of CO2 to methanol. The Cu and Se in the catalysts had excellent cooperative effect for catalyzing the reaction. The size and morphology were crucial for the performance of the catalysts, which could be controlled by the VDETA/VH2O ratios. The Cu1.63Se(1/3) nanocatalysts yielded outstanding current density of 41.5 mA cm−2 with FE of 77.6% at −2.1 V vs. Ag/Ag+. Moreover, the catalyst was also very stable in the reaction. Despite the catalytic system is far from industrial production, it is still very interesting that Cu1.63Se(1/3) nanocatalysts can yield highest current density up to date at very high Faradaic efficiency. We believe that some other transition metal selenides can be designed as efficient electrocatalysts for CO2 reduction.

Methods

Materials

CuCl2⋅2H2O, sulfuric acid (95–98%), ethanol, acetone and acetonitrile (CH3CN) were obtained from Sinopharm Chem. Reagent Co. Ltd. Na2SeO3, diethylenetriamine (DETA), Cu, CuO, Cu2O, CuS, Cu2S, CuSe, Cu2Se, hydroxylamine, tetraethylammonium hexafluorophosphate (TEAPF6, purity > 98%), Toray carbon paper (CP, TGP-H-60, 19 × 19 cm), Nafion N-117 membrane (0.180 mm thick, ≥0.90 meg/g exchange capacity) and Nafion D-521 dispersion (5% w/w in water and 1-propanol, ≥0.92 meg/g exchange capacity) were purchased from Alfa Aesar China Co., Ltd. 1-butyl-3-methylimidazolium hexafluorophosphate ([Bmim]PF6, purity > 99%), 1-butyl-3-methylimidazolium tetrafluoroborate ([Bmim]BF4, purity > 99%), 1-butyl-3-methylimidazolium bis(trifluoromethylsulfonyl)imide ([Bmim]TF2N, purity > 99%), 1-butyl-3-methylimidazolium acetate ([Bmim]OAc, purity > 99%), 1-butyl-3-methylimidazolium nitrate ([Bmim]NO3, purity > 99%) and 1-butyl-3-methylimidazolium perchlorate ([Bmim]ClO4, purity > 99%) were obtained from the Centre of Green Chemistry and Catalysis, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences. N2, CO2 (99.999%) and 13CO2 (99.99%) were provided by Beijing Analytical Instrument Company.

Synthetic procedures for Cu2−xSe(y) nanocatalysts

The Cu2-xSe(y) nanocatalysts were prepared according to the procedures reported by other researcher35. In a typical procedure, 1 mmol CuCl2⋅2H2O, 1 mmol Na2SeO3, and 2 mL hydroxylamine were added into a mixed solvent (80 mL) including DETA and deionized water with a volume ratio of VDETA/VH2O = 1/3 (or 1/0, 3/1, 1/1, 1/5 and 0/1). After stirring for half an hour at room temperature, the blue solution was then transferred into a Teflon-lined autoclave. Subsequently, the sealed Teflon-lined autoclave was maintained at 180 °C for 15 h and then naturally cooled to room temperature. The resulting precipitates were obtained via the method of centrifugation and washed with distilled water and absolute ethanol five times, followed by drying at 80 °C overnight in a vacuum oven.

Physicochemical characterization

The microstructures of the catalysts were characterized by scanning electron microscope (SEM, HITACHI S-4800) and transmission electron microscopy (TEM, JEOL JEM-2100F) equipped with energy dispersive spectrometer (EDS). Dynamic light scattering (DLS) measurements in ethanol were performed on a Zetasizer Nano instrument (Malvern Instruments, Worcestershire, UK). X-ray photoelectron spectroscopy (XPS) study was carried out on the Thermo Scientific ESCALab 250Xi using a 200 W Al-Kα radiation. In the analysis chamber, the base pressure was about 3 × 10−10 mbar. Typically, the hydrocarbon C1s line at 284.8 eV from adventitious carbon was used for energy referencing. X-Ray diffraction (XRD) analysis of the samples were performed on a Rigaku D/max-2500 X-ray diffractometer with Cu-Kα radiation (y = 0.15406 nm) and the scan speed was 5 °/min. The elemental contents of the catalysts were detected using inductively coupled plasma optical emission spectroscopy (ICP-AES, Vista-MPX). The thermogravimetric (TG) curve was obtained using Pyris1 TGA under N2 atmosphere.

Electrode preparation

The electrode of Cu2-xSe(y)/CP was prepared as follow19. 10 mg Cu2-xSe(y) prepared above and 1 mg carbon black (Vulcan XC 72) were suspended in the solution with 3 mL acetone and 20 μL Nafion D-521 dispersion (5 wt%) via ultrasound. Then, 302 μL of the above solution was uniformly spread onto the CP (1 × 1 cm−2) surface assisted by a micropipette and then dried under room temperature. On each carbon paper, the loading of Cu2−xSe(y) catalyst was 1.0 mg cm−2. Before experiment, all the auxiliary electrodes were sonicated in acetone for 10 min and then washed with H2O and absolute ethanol, and then dried in N2 atmosphere.

Electrochemical study

All the electrochemical experiments were conducted on the electrochemical workstation (CHI 6081E, Shanghai CH Instruments Co., China). Linear sweep voltammetric (LSV) scans were conducted in a single compartment cell with a three electrodes configuration, including a working electrode, a counter electrode (Pt gauzes), and a reference electrode (Ag/Ag+ with 0.01 M AgNO3 in 0.1 M TBAP-CH3CN). The electrolytes were bubbled with CO2 or N2 at least 30 min to ensure formation of N2-saturated or CO2-saturated solution before experiments. LSV measurements in gas-saturated electrolytes were carried out in the potential range of −1.0 to −2.5 V versus Ag/Ag+ at a sweep rate of 20 mVs−1. Slight magnetic stirring was employed to acquire uniform electrolytes.

Electrochemical impedance spectroscopy (EIS) study

The EIS measurement was carried out in [Bmim]PF6-CH3CN-H2O that contents were 30 wt%, 65 wt%, 5 wt% at an open circuit potential (OCP) with an amplitude of 5 mV of 10−2 to 105 Hz. The data obtained from the EIS measurements were fitted using the software of Zview (Version 3.1, Scribner Associates, USA).

CO2 reduction electrolysis

The electrolysis experiments were measured at 25 °C in a commonly used H-type cell, including a working cathode (Cu2−xSe(y)/CP), a counter anode (platinum gauzes), and a reference electrode (Ag/Ag+ with 0.01 M AgNO3 in 0.1 M TBAP-CH3CN)8. In the experiments, Nafion-117 membrane was used as proton exchange membrane to separate the cathode and anode compartments. 0.5 M H2SO4 aqueous solution and [Bmim]PF6-CH3CN-H2O served as anodic and cathodic electrolytes, respectively. In each experiment, the amount of anodic and cathodic electrolytes was 30 mL. Before starting the electrolysis experiment, the electrolytes were bubbled with CO2 for 30 min under stirring and the electrolysis was carried out under a steady stream of CO2 (10 sccm).

Product analysis

After electrolysis reaction, the gaseous products were collected using a gas bag and then analyzed by an Agilent 4890 gas chromatograph equipped with a TCD detector with helium as internal standard. The liquid products were analyzed by 1H NMR measured on a Bruker Avance III 400 HD spectrometer in CD3CN with TMS as internal standard. The Faradaic efficiency of the products was calculated through GC and NMR analysis8.

Tafel analysis

The partial current densities for products under different potentials were measured and the equilibrium potential was obtained by extrapolation method. The overpotential was obtained from the difference between the equilibrium potential and the catalytic potential. Multiple electrolysis experiments were performed at each potential to obtain the current density versus overpotential data in the H-type electrolysis cell as described above. Tafel plots were constructed from these data.

Double-layer capacitance (C dl) measurements

The electrochemical active surface area is proportional to Cdl value. Cdl was determined in H-type electrolysis cell by measuring the capacitive current associated with double-layer charging from the scan-rate dependence of cyclic voltammogram (CV). The CV ranged from −1.8 to −1.9 V vs. Ag/Ag+. The Cdl was estimated by plotting the Δj (ja−jc) at −1.85 V vs. Ag/Ag+ against the scan rates, in which the ja and jc were the anodic and cathodic current density, respectively.

IR spectroscopy study

To further understand the process of CO2 electroreduction, a Bruker Tensor 27 IR spectrometer was used to analyze the species produced in the electrolyte. In the experiment, 100 μL electrolyte after desired electrolysis time was dropped on CaF2 disc window and then IR spectrum was obtained.

Electrochemical active surface areas (ECSA) measurement

The ECSA values of all electrodes were evaluated by cyclic voltammetry (CV) using the ferri-/ferrocyanide redox couple ([Fe(CN)6]3-/4-) as a probe57. The CV curves were obtained in a N2-saturated 5 mM K4Fe(CN)6/0.1 M KCl solution including a counter anode (platinum gauze), and a reference electrode (Ag/AgCl with saturated KCl). According to the Randles–Sevcik equation57, the values of ECSA were obtained.

The calculation of overpotential (η) and equilibrium potential (E 0)

Overpotential (η) is the difference between the equilibrium potential and the actual potential for the transformation of the substrate CO2 into the product methanol via Eq. (1):

Here, the E0CO2→methanol referred to the equilibrium potential for CO2 transformation to CH3OH, which can be obtained by extrapolation method43,44,45. Taking the Cu1.63Se(1/3) electrode as example, stepped potential electrolysis experiments between −1.8 and −2.0 V were carried out and the electrolysis products were collected and characterized. The current densities for CH3OH at each potential are shown in Supplementary Fig. 11, and the potential at jCH3OH = 0 by extrapolation method is the equilibrium potential. Therefore, the overpotential can be obtained. The method to calculate the overpotential over other electrodes was similar.

The calculation of cell voltage

In this study, we calculated the cell voltage using the method reported46,47. It is mainly from the half reaction potentials for water oxidation, CO2 reduction and the ohmic drop (EiR) from electrolyte resistance (Rs). The Rs stands for solution resistance which was determined by electrochemical impedance spectroscopy (EIS) at frequencies ranging from 10−2 to 105 Hz and the I represents for amps of average current. Therefore, we calculated EiR by Eq. (2). The applied potentials measured against Ag/Ag+ can be transformed to the reversible hydrogen electrode (RHE) scale by Eq. (3).

Cell efficiency

A characteristic cell energy efficiency (EE) of reduction CO2 to methanol was obtained by Eq. (4)48:

In the equation, ΔE° represents the difference between the standard half reaction potentials for water oxidation (1.23 V vs. RHE) and reduction CO2 to methanol (−0.89 V vs. RHE).

Extended X-ray absorption fine structure (EXAFS) experimental details

The homogeneously mixed samples (20 mg) and graphite (100 mg) sample were pressed into circular slices with a diameter of 10 mm which was used for further EXAFS measurement under ambient condition. The EXAFS measurements were carried out on the beamline 1W1B station of Beijing Synchrotron Radiation Facility, P.R. China (BSRF). A water-cooled Si (111) double-crystal monochromator (DCM) was utilized to monochromatize the X-ray beam and the detuning was done by 10% to remove harmonics. The electron storage ring of BSRF was operated at 2.5 GeV with a maximum current of 250 mA. The EXAFS data of Cu K-edge was obtained in the energy range from −200 to 1000 eV in transmission mode. The EXAFS oscillations were then extracted according to standard procedures via the ATHENA module implemented in the IFEFFIT software packages. With a Fourier transform k-space range of 2.2–12.8 Å−1, the quantitative curve-fittings were conducted in the R-space according to the module ARTEMIS of IFEFFIT software packages. The phase shift Φ(k) and backscattering amplitude F(k) were calculated by FEFF 8.0 code.

Computational method

The free energies of CO2 reduction states were performed using Vienna Ab-initio Simulation Package (VASP)62, taking advantage of the density functional theory (DFT) and the Projected Augmented Wave (PAW) method63. The revised Perdew–Burke–Ernzerhof (RPBE) functional was used to describe the exchange and correlation effects64,65. For all the geometry optimizations, the cutoff energy was set to be 450 eV. The (110) surface was chosen to represent the catalysis surface of CuSe; while the (220) surface was modeled to simulate the sites on Cu1.63Se(1/3) and Cu2Se. The Monkhorst-Pack grid66 of 2 × 2 × 1, 3 × 4 × 1, and 3 × 4 × 1 were used to carry out the surface calculations on CuSe, Cu1.63Se(1/3), and Cu2Se, respectively.

The reduction of CO2 to CH3OH could occur via a pathway involving six elementary steps67 by Eqs. (5–10):

where * denotes the active sites on the catalyst surface. Based on the above mechanism, the free energies of the corresponding intermediate states are important to identify the activity of a given material in catalyzing CO2 reduction. The computational hydrogen electrode (CHE) model68 proposed by Norskov et al. was used to calculate the free energies of CO2 reduction intermediates, based on which the free energy of an adsorbed species is defined as Eq. (11):

where ∆Eads is the electronic adsorption energy, ∆EZPE stands for the zero point energy difference between adsorbed and gaseous species, T∆Sads denotes the corresponding entropy difference between these two states, and ∫CPdT is the enthalpy correction. The electronic binding energy is referenced as graphene for each C atom, ½ H2 for each H atom, and (H2O − H2) for each O atom, plus the energy of the clean slab. The corrections of zero point energy, entropy, and enthalpy of adsorbed can be found in Supplementary Table 9.

Code availability

All code supporting the findings of this study are available from the corresponding author on request.

References

Medina-Ramos, J., DiMeglio, J. L. & Rosenthal, J. Efficient reduction of CO2 to CO with high current density using in situ or ex situ prepared Bi-based materials. J. Am. Chem. Soc. 136, 8361–8367 (2014).

Rosen, B. A. et al. Ionic liquid-mediated selective conversion of CO2 to CO at low overpotentials. Science 334, 643–644 (2011).

Medina-Ramos, J. et al. Efficient conversion of CO2 to CO using tin and other inexpensive and easily prepared post-transition metal catalysts. J. Am. Chem. Soc. 137, 5021–5027 (2015).

Ma, S. et al. Electroreduction of carbon dioxide to hydrocarbons using bimetallic Cu-Pd catalysts with different mixing patterns. J. Am. Chem. Soc. 139, 47–50 (2017).

Graciani, J. et al. Highly active copper-ceria and copper-ceria-titania catalysts for methanol synthesis from CO2. Science 345, 546–550 (2014).

Studt, F. et al. Discovery of a Ni-Ga catalyst for carbon dioxide reduction to methanol. Nat. Chem. 6, 320–324 (2014).

Wenjun, Z. et al. Progress and perspective of electrocatalytic CO2 reduction for renewable carbonaceous fuels and chemicals. Adv. Sci. 5, 1700275 (2018).

Sun, X. et al. Molybdenum-bismuth bimetallic chalcogenide nanosheets for highly efficient electrocatalytic reduction of carbon dioxide to methanol. Angew. Chem. Int. Ed. 55, 6771–6775 (2016).

Barton Cole, E. et al. Using a one-electron shuttle for the multielectron reduction of CO2 to methanol: kinetic, mechanistic, and structural insights. J. Am. Chem. Soc. 132, 11539–11551 (2010).

Yang, H.-P. et al. Organically doped palladium: a highly efficient catalyst for electroreduction of CO2 to methanol. Green. Chem. 17, 5144–5148 (2015).

Yang, H.-P. et al. Selective electrochemical reduction of CO2 to different alcohol products by an organically doped alloy catalyst. Green. Chem. 18, 3216–3220 (2016).

Lee, J. H. Q., Lauw, S. J. L. & Webster, R. D. The electrochemical reduction of carbon dioxide (CO2) to methanol in the presence of pyridoxine (vitamin B6). Electrochem. Comm. 64, 69–73 (2016).

Albo, J. et al. Production of methanol from CO2 electroreduction at Cu2O and Cu2O/ZnO-based electrodes in aqueous solution. Appl. Catal. B: Environ. 176, 709–717 (2015).

Albo, J. et al. Copper-based metal-organic porous materials for CO2 electrocatalytic reduction to alcohols. ChemSusChem 10, 1100–1109 (2017).

Hori, Y., Kikuchi, K. & Suzuki, S. Production of CO and CH4 in electrochemical reduction of CO2 at metal electrodes in aqueous hydrogencarbonate solution. Chem. Lett. 14, 1695–1698 (1985).

Han, Z. et al. CO2 reduction selective for C≥2 products on polycrystalline copper with N-substituted pyridinium additives. ACS Cent. Sci. 3, 853–859 (2017).

Popić, J. P., Avramov-Ivić, M. L. & Vuković, N. B. Reduction of carbon dioxide on ruthenium oxide and modified ruthenium oxide electrodes in 0.5 M NaHCO3. J. Electrochem. Soc. 421, 105–110 (1997).

Le, M. et al. Electrochemical reduction of CO2 to CH3OH at copper oxide surfaces. J. Electrochem. Soc. 158, 45–49 (2011).

Summers, D. P., Leach, S. & Frese, K. W. The electrochemical reduction of aqueous carbon dioxide to methanol at molybdenum electrodes with low overpotentials. J. Electroanal. Chem. Interfacial Electrochem. 205, 219–232 (1986).

Kuhl, K. P. et al. Electrocatalytic conversion of carbon dioxide to methane and methanol on transition metal surfaces. J. Am. Chem. Soc. 136, 14107–14113 (2014).

Lu, L. et al. Highly efficient electroreduction of CO2 to methanol on palladium-copper bimetallic aerogels. Angew. Chem. Int. Ed. 57, 14149–14153 (2018).

Giesbrecht, P. K. & Herbert, D. E. Electrochemical reduction of carbon dioxide to methanol in the presence of benzannulated dihydropyridine additives. ACS Energy Lett. 2, 549–555 (2017).

Qu, J. et al. Electrochemical reduction of CO2 on RuO2/TiO2 nanotubes composite modified Pt electrode. Electrochim. Acta 50, 3576–3580 (2005).

Wang, Q. H. et al. Electronics and optoelectronics of two-dimensional transition metal dichalcogenides. Nat. Nano 7, 699–712 (2012).

Gao, M.-R. et al. Nanostructured metal chalcogenides: synthesis, modification, and applications in energy conversion and storage devices. Chem. Soc. Rev. 42, 2986–3017 (2013).

Gao, S. et al. Ultrathin Co3O4 layers realizing optimized CO2 electroreduction to formate. Angew. Chem. Int. Ed. 55, 698–702 (2016).

Li, C. W. & Kanan, M. W. CO2 reduction at low overpotential on Cu electrodes resulting from the reduction of thick Cu2O films. J. Am. Chem. Soc. 134, 7231–7234 (2012).

Ren, D. et al. Selective electrochemical reduction of carbon dioxide to ethylene and ethanol on copper(I) oxide catalysts. ACS Catal. 5, 2814–2821 (2015).

Asadi, M. et al. Nanostructured transition metal dichalcogenide electrocatalysts for CO2 reduction in ionic liquid. Science 353, 467–470 (2016).

Chan, K. et al. Molybdenum sulfides and selenides as possible electrocatalysts for CO2 reduction. ChemCatChem 6, 1899–1905 (2014).

Zhang, S. et al. Ambient aqueous synthesis of ultrasmall PEGylated Cu2−xSe nanoparticles as a multifunctional theranostic agent for multimodal imaging guided photothermal therapy of cancer. Adv. Mater. 28, 8927–8936 (2016).

Li, D. et al. Design and growth of dendritic Cu2-xSe and bunchy CuSe hierarchical crystalline aggregations. CrystEngComm 12, 1856–1861 (2010).

Lee, J. et al. Graphene phototransistors sensitized by Cu2–xSe nanocrystals with short amine ligands. J. Phys. Chem. C. 121, 5436–5443 (2017).

Li, Y. et al. Solvothermal elemental direct reaction to CdE (E = S, Se, Te) semiconductor nanorod. Inorg. Chem. 38, 1382–1387 (1999).

Gao, M.-R. et al. Synthesis of unique ultrathin lamellar mesostructured CoSe2-amine (protonated) nanobelts in a binary solution. J. Am. Chem. Soc. 131, 7486–7487 (2009).

Wang, L. et al. Ga3(HPO3)4F4(H3DETA) (DETA = diethylenetriamine): a new open-framework fluorinated gallium phosphite with pentameric building unit. J. Solid State Chem. 179, 824–829 (2006).

Wang, Y. et al. Synthesis of ultrathin and thickness-controlled Cu2–xSe nanosheets via cation exchange. J. Phys. Chem. Lett. 5, 3608–3613 (2014).

Zhang, J. et al. Visible light photocatalytic H2-production activity of CuS/ZnS porous nanosheets based on photoinduced interfacial charge transfer. Nano. Lett. 11, 4774–4779 (2011).

White, S. L. et al. Co-operativity in a nanocrystalline solid-state transition. Nat. Chem. 4, 2933 (2013).

Radi, A. et al. Nanoscale shape and size control of cubic, cuboctahedral, and octahedral Cu-Cu2O core-shell nanoparticles on Si(100) by one-step, templateless, capping-agent-free electrodeposition. ACS Nano 4, 1553–1560 (2010).

Liu, Y. et al. Synthesis of Cu2–xSe nanocrystals by tuning the reactivity of Se. J. Phys. Chem. C 115, 9909–9916 (2011).

Wu, X.-J. et al. Two-dimensional CuSe nanosheets with microscale lateral size: synthesis and template-assisted phase transformation. Angew. Chem. Int. Ed. 53, 5083–5087 (2014).

Zhu, G. Z. et al. Curvature-dependent selectivity of CO2 electrocatalytic reduction on cobalt porphyrin nanotubes. ACS Catal. 6, 6294–6301 (2016).

Costentin, C., Guillaume, P. & Jean-Michel, S. Benchmarking of homogeneous electrocatalysts: overpotential, turnover frequency, limiting turnover number. J. Am. Chem. Soc. 137, 5461–5467 (2015).

Azcarate, I. et al. Through-space charge interaction substituent effects in molecular catalysis leading to the design of the most efficient catalyst of CO2-to-CO electrochemical conversion. J. Am. Chem. Soc. 138, 16639–16644 (2016).

Jiang, K. et al. Metal ion cycling of Cu foil for selective C-C coupling in electrochemical CO2 reduction. Nat. Catal. 1, 111 (2018).

Tatin, A. et al. Efficient electrolyzer for CO2 splitting in neutral water using earth-abundant materials. Proc. Natl Acad. Sci. USA 113, 5526–5529 (2016).

Lee, W. et al. Catholyte-free electrocatalytic CO2 reduction to formate. Angew. Chem. Int. Ed. 57, 6883–6887 (2018).

Liu, Y. et al. Efficient electrochemical reduction of carbon dioxide to acetate on nitrogen-doped nanodiamond. J. Am. Chem. Soc. 137, 11631–11636 (2015).

Lei, F. et al. Metallic tin quantum sheets confined in graphene toward high-efficiency carbon dioxide electroreduction. Nat. Commun. 7, 12697 (2016).

Hong, G. et al. Effect of acetonitrile on the solubility of carbon dioxide in 1-ethyl-3-methylimidazolium bis (trifluoromethylsulfonyl) amide. Ind. Eng. Chem. Res. 45, 8180–8188 (2006).

Matsubara, Y., Grills, D. C. & Kuwahara, Y. Thermodynamic aspects of electrocatalytic CO2 reduction in acetonitrile and with an ionic liquid as solvent or electrolyte. ACS Catal. 5, 6440–6452 (2015).

Zhu, Q. et al. Efficient reduction of CO2 into formic acid on a lead or tin electrode using an ionic liquid catholyte mixture. Angew. Chem. Int. Ed. 55, 9012–9016 (2016).

Sun, X. et al. MoP nanoparticles supported on indium-doped porous carbon: outstanding catalysts for highly efficient CO2 electroreduction. Angew. Chem. Int. Ed. 57, 2427–2431 (2018).

Cadena, C. et al. Why is CO2 so soluble in imidazolium-based ionic liquids? J. Am. Chem. Soc. 126, 5300–5308 (2004).

Wang, C. X. et al. A separation device and a separation method for acetonitrile-water-methanol mixture, CN103386211 (2013).

Zhou, Y. S. et al. Dopant-induced electron localization drives CO2 reduction to C2 hydrocarbons. Nat. Chem. 10, 974 (2018).

Kuhl, K. P. et al. New insights into the electrochemical reduction of carbon dioxide on metallic copper surfaces. Energy Environ. Sci. 5, 7050–7059 (2012).

Calle-Vallejo, F. & Koper, M. T. M. Theoretical considerations on the electroreduction of CO to C2 Species on Cu(100) Electrodes. Angew. Chem. Int. Ed. 52, 7282–7285 (2013).

Evans, M. G. & Polanyi, M. Inertia and driving force of chemical reactions. Trans. Faraday Soc. 34, 11–24 (1938).

Cheng, J. et al. Brønsted-Evans-Polanyi relation of multistep reactions and volcano curve in heterogeneous catalysis. J. Phys. Chem. C 112, 1308–1311 (2008).

Kresse, G. & Furthmüller, J. Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54, 11169–11186 (1996).

Blöchl, P. E. Projector augmented-wave method. Phys. Rev. B 50, 17953–17979 (1994).

Zhang, Y. & Yang, W. Comment on “Generalized gradient approximation made simple”. Phys. Rev. Lett. 80, 890–890 (1998).

Hammer, B., Hansen, L. B. & Nørskov, J. K. Improved adsorption energetics within density-functional theory using revised Perdew-Burke-Ernzerhof functionals. Phys. Rev. B 59, 7413–7421 (1999).

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Karamad, M. et al. Mechanistic pathway in the electrochemical reduction of CO2 on RuO2. ACS Catal. 5, 4075–4081 (2015).

Nørskov, J. K. et al. Origin of the overpotential for oxygen reduction at a fuel-cell cathode. J. Phys. Chem. B 108, 17886–17892 (2004).

Acknowledgements

The work was supported by National Key Research and Development Program of China (2017YFA0403102), National Natural Science Foundation of China (21773267, 21733011, 21533011), Beijing Municipal Science & Technology Commission (Z181100004218004), and the Chinese Academy of Sciences (QYZDY-SSW-SLH013). The EXAFS experiment was conducted at Beijing Synchrotron Radiation Facility.

Author information

Authors and Affiliations

Contributions

D.X.Y., Q.G.Z., and B.X.H. proposed the project, designed the experiments, and wrote the manuscript; D.X.Y. performed the whole experiments; C.J.C., H.Z.L., Z.M.L., Z.J.Z., X.Y.Z., and S.J.L. performed the analysis of experimental data; B.X.H. and Q.G.Z. supervised the whole project.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Journal peer review information: Nature Communications thanks the anonymous reviewers for their contribution to the peer review of this work. Peer reviewer reports are available.

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yang, D., Zhu, Q., Chen, C. et al. Selective electroreduction of carbon dioxide to methanol on copper selenide nanocatalysts. Nat Commun 10, 677 (2019). https://doi.org/10.1038/s41467-019-08653-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-019-08653-9

This article is cited by

-

Improved catalytic performance of CO2 electrochemical reduction reaction towards ethanol on chlorine-modified Cu-based electrocatalyst

Nano Research (2024)

-

Self-supporting BiCu/carbon hybrid nanofiber membrane promotes efficient CO2 electroreduction to formate

Science China Materials (2024)

-

The origins of catalytic selectivity for the electrochemical conversion of carbon dioxide to methanol

Nano Research (2024)

-

Electrochemical reduction of carbon dioxide into valuable chemicals: a review

Environmental Chemistry Letters (2023)

-

Active and conductive layer stacked superlattices for highly selective CO2 electroreduction

Nature Communications (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.