Abstract

Strain engineering is widely used in material science to tune the (opto-)electronic properties of materials and enhance the performance of devices. Two-dimensional atomic crystals are a versatile playground to study the influence of strain, as they can sustain very large deformations without breaking. Various optical techniques have been employed to probe strain in two-dimensional materials, including micro-Raman and photoluminescence spectroscopy. Here we demonstrate that optical second harmonic generation constitutes an even more powerful technique, as it allows extraction of the full strain tensor with a spatial resolution below the optical diffraction limit. Our method is based on the strain-induced modification of the nonlinear susceptibility tensor due to a photoelastic effect. Using a two-point bending technique, we determine the photoelastic tensor elements of molybdenum disulfide. Once identified, these parameters allow us to spatially image the two-dimensional strain field in an inhomogeneously strained sample.

Similar content being viewed by others

Introduction

The properties of materials can be strongly influenced by strain. For example, local straining techniques are employed in modern silicon field-effect transistors to reduce the carrier effective mass and increase the carrier mobility1. In optoelectronics, strain can be used to transform indirect band gap semiconductors into direct gap materials with strongly enhanced radiative efficiencies, or to tune the emission wavelength of light emitters2,3,4,5. While silicon typically breaks at strain levels of ~1.5%, two-dimensional (2D) atomic crystals6 can withstand strain of >10%7,8, making them promising candidates for stretchable and flexible electronics9. Their high flexibility further allows for folding or wrapping them around (lithographically defined) nanostructures to induce spatially inhomogeneous atom displacements. This provides an opportunity to modify their electronic structure such that excitons can be funneled into a small region of a layered semiconductor10,11 to form exciton condensates, improve solar cell efficiencies, or realize single photon emitters12,13,14,15.

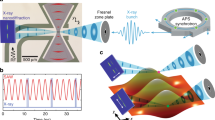

In order to better understand and improve the performance of devices, analytical tools are required that are capable of noninvasive strain imaging at the submicron scale. Traditionally, X-ray diffraction (XRD) is employed, but submicron spatial resolution can in most cases only be achieved by the use of coherent radiation, e.g., from a synchrotron16. High-resolution transmission electron microscopy (TEM) based techniques17 rely on precise measurements of atom column positions, but they offer only a small field of view and are invasive, as they require thin specimens. Electron backscatter diffraction (EBSD) techniques18 can overcome some of those limitations, but require flat surfaces and comparison of the experimental data with simulations to analyze the complex diffraction patterns. Optical techniques, such as micro-Raman19,20,21 and photoluminescence (PL)10,22,23 spectroscopy, offer an interesting alternative. They are noninvasive, allow for large-area imaging with submicron spatial resolution and are simple to set up.

Strain-induced second harmonic generation (SHG) has been investigated for decades24 and has been employed to generate frequency-doubled light in centrosymmetric materials, such as silicon25,26,27,28,29,30. The second harmonic response in these works is typically described by a phenomenological modification of the nonlinear susceptibility of the unstrained material31,32,33,34,35. In a more thorough theoretical investigation, Lyubchanskii et al. demonstrated that strain and nonlinear susceptibility are connected via a photoelastic tensor36,37.

Here, we adapt this theory and determine, to our knowledge for the first time, all photoelastic tensor elements of a material from SHG. Once identified, these parameters allow us to spatially map the full strain tensor in a mechanically deformed 2D material with a spatial resolution below the diffraction limit of the excitation light. As a representative example, we present results obtained from MoS2—a layered transition metal dichalcogenide (TMD) semiconductor38,39. Our technique, however, is not only limited to 2D materials, but is applicable to any thin crystalline film. It establishes a novel optical strain probing technique that provides an unprecedented depth of information.

Results

Theoretical description

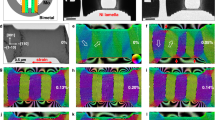

SHG is a nonlinear optical process in which two photons with the same frequency ω combine into a single photon with double frequency, as schematically depicted in Fig. 1a. As only non-centrosymmetric crystals possess a second-order nonlinear susceptibility, SHG in 2H-stacked TMDs requires odd layer thickness31,32,33,34,35. Figure 1b shows a microscope image of a mechanically exfoliated MoS2 flake on a Si/SiO2 (280 nm) wafer. The corresponding SHG signal amplitude in Fig. 1c shows the expected layer dependence and quadratic scaling behavior with excitation power (see Supplementary Fig. 2). The polarization dependence of the SHG intensity, plotted in Fig. 1d, reflects the underlying D3h symmetry of the TMD crystal31,32,33,34,35. The spatial resolution of our specific setup (280 nm full-width-at-half-maximum (FWHM)) was determined from a line scan across an edge of the MoS2 flake (Fig. 1e). Spatial features below the diffraction limit of the excitation wavelength can thus still be resolved, due to the nonlinear nature of the SHG process. Details of the experimental setup can be found in the Methods section and in Supplementary Fig. 1.

Second harmonic generation in MoS2. a Schematic illustration of the SHG process. b Micrograph of a mechanically exfoliated MoS2 flake on a Si/SiO2 wafer, and c corresponding SHG amplitude. Note that the SHG signal is absent in the bilayer region. Scale bars, 5 μm. d Linear polarization dependence of the SHG intensity from an MoS2 monolayer. e SHG line scan across an MoS2 edge. Symbols: experimental data. Line: fit of a function of the form \(1 - {\mathrm{erf}}\left( {\sqrt 2 x{\mathrm{/}}w} \right)\), where erf() is the error function and w is the waist, from which a spatial resolution of 280 nm (FWHM) is determined

We will now discuss how SHG can be used to measure strain in 2D TMDs, or thin crystals in general. Polarization resolved SHG reflects the lattice symmetry of the probed crystal, where the relation between SHG intensity and crystal lattice is given by the second-order nonlinear susceptibility tensor \({\boldsymbol{\chi }}_{{\mathrm{ijk}}}^{(2)}\). Strain deforms the crystal lattice and therefore also influences \({\boldsymbol{\chi }}_{{\mathrm{ijk}}}^{(2)}\), breaking the symmetry in the SHG polarization pattern, as illustrated in Fig. 2. This effect is described by an Ansatz which considers a linear strain dependence of the nonlinear susceptibility tensor36,37

with \({\bf{p}}_{{\mathrm{ijklm}}} = \partial {\boldsymbol{\chi }}_{{\mathrm{ijk}}}^{(2,0)}{\mathrm{/}}\partial {\bf{u}}_{{\mathrm{lm}}}.\) Here, \({\boldsymbol{\chi }}_{{\mathrm{ijk}}}^{(2,0)}\) describes the second-order nonlinear susceptibility of the unstrained crystal and \({\bf{p}}_{{\mathrm{ijklm}}}\) is the (fifth-rank) photoelastic tensor, which translates the strain tensor ulm into a nonlinear susceptibility contribution. The strain tensor is symmetric (ulm = uml) and the SHG process is dispersion free (\({\boldsymbol{\chi }}_{{\mathrm{ijk}}}^{(2)} = {\boldsymbol{\chi }}_{{\mathrm{ikj}}}^{(2)}\)). Therefore, the photoelastic tensor must feature the same symmetries: \({\bf{p}}_{{\mathrm{ijklm}}} = {\bf{p}}_{{\mathrm{ikjlm}}} = {\bf{p}}_{{\mathrm{ijkml}}} = {\bf{p}}_{{\mathrm{ikjml}}}\). These symmetries reduce the number of free parameters. Moreover, depending on the crystal symmetry class, there are a set of operations under which \({\bf{p}}_{{\mathrm{ijklm}}}\) is invariant. TMD monolayers have a trigonal prismatic D3h lattice symmetry. Considering all symmetries of the D3h class40, the 2D photoelastic tensor has 12 nonzero elements, with only two free parameters p1 and p2:

Polarization resolved SHG intensity \(I_{||}^{\left( {\mathrm{2}} \right)}\left( {2\omega } \right)\) pattern. The plot shows the component of the SHG signal with same polarization as the incident field. Blue line: unstrained TMD crystal; red line: with 1.0% tensile strain in horizontal (0°) direction (θ = −15°)

Depending on the coordinate system, the strain tensor ulm can have multiple representations. We chose a principal strain system by rotating the basis vectors by an angle θ so that the shear components vanish (uxy = uyx = 0) and chose, without loss of generality, \(\left| {u_{{\mathrm{xx}}}} \right| > \left| {u_{{\mathrm{yy}}}} \right|\). Under the consideration of Poisson’s ratio ν (the ratio of transverse to axial strain), we then obtain a 2D principal strain tensor

After rotating the principal strain tensor back into the coordinate system of the photoelastic tensor, where the x-direction is defined as the armchair (AC) direction of the hexagonal crystal lattice, we can calculate the polarization resolved SHG response of strained D3h crystals. The induced second-order polarization is given by the nonlinear susceptibility tensor and the incident electric fields, \({\bf{P}}_{\mathrm{i}}^{\left( 2 \right)}(2\omega ) \propto {\boldsymbol{\chi }}_{{\mathrm{ijk}}}^{\left( 2 \right)}{\bf{E}}_{\mathrm{j}}(\omega ){\bf{E}}_{\mathrm{k}}(\omega )\). In our polarization resolved SHG measurements we chose a linear polarized incident electric field under an angle ϕ and analyze the SHG signal with same polarization. \(P_\parallel ^{\left( 2 \right)}(2\omega )\) is the parallel polarization which corresponds to that signal and the square of it is proportional to the measured SHG intensity:

with A = (1 − ν)(p1 + p2)(εxx + εyy) + 2χ0 and B = (1 + ν)(p1 − p2)(εxx − εyy). p1 and p2 are the photoelastic parameters, εxx and εyy denote the principal strains, θ is the principal strain orientation, ϕ the polarization angle, and χ0 the nonlinear susceptibility parameter of the unstrained crystal lattice.

Photoelastic tensor measurement

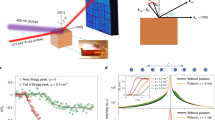

The effect of strain on SHG is determined by the photoelastic parameters, which depend on the specific material. We determine these parameters for monolayer MoS2 by applying different levels of uniaxial strain using a two-point bending method (Fig. 3a), and measuring the polarization resolved SHG signal. For that, MoS2 on a flexible substrate with length L and thickness d (see Methods for sample preparation) is clamped between two points and the distance a between them is controlled by a motorized linear actuator. At distances a < L the sample is bent, which causes tensile strain in the MoS2 layer. Assuming a circular bending profile of the flexible substrate, the resulting uniaxial strain εxx for a chosen distance a is then given by the relation sin(εxxL/d) = εxxa/d, which we solve numerically (see Supplementary Fig. 3).

Photoelastic parameters. a Schematic illustration of two-point bending method (top: side view; bottom: top view). AC armchair direction, ZZ zig-zag direction. b SHG patterns for applied tensile strains of 0.1, 0.5, and 0.95%. (symbols: measurement data; line: fit) c Photoelastic parameters p1 and p2 for monolayer MoS2 as determined from measurements on two different samples (plotted in different colors). Left panel: strain dependence; right panel: histogram of measurement data

Fitting the SHG patterns at different known strain levels with Eq. (4), allows us to determine the photoelastic parameters p1 and p2. Experimentally, we find that the SHG intensity under varying uniaxial strain is constant in the uniaxial strain direction (\(I_\parallel ^{\left( 2 \right)}\left( {\phi = \theta } \right)\) = constant), which indicates that the two photoelastic parameters are connected by Poisson’s ratio: p1 = νp2. This relation simplifies the nonlinear fitting procedure and, as shown in Fig. 3b, the measured polarization resolved SHG data from strained MoS2 flakes can be fitted accurately with the linear strain consideration in the nonlinear susceptibility tensor (1). In Fig. 3c the photoelastic tensor parameters are plotted for two different samples for tensile strain values up to ~1%. Both parameters are constant over this range, confirming the theoretically predicted linear relation between strain and nonlinear susceptibility (Eq. (1)). Using a Poisson ratio of νMoS2 = 0.2941 and an unstrained nonlinear susceptibility of χ0 = 4.5 nm/V32, we determine the photoelastic tensor parameters of MoS2 monolayers as p1 = −0.68 ± 0.07 nm/V/% and p2 = −2.35 ± 0.25 nm/V/%.

Strain imaging

Having extracted these parameters, we can now employ SHG spectroscopy to locally probe inhomogeneous strain fields in MoS2 monolayer samples. As discussed before, due to the nonlinear nature of SHG, the spatial resolution is higher than that obtained by linear optical strain mapping techniques, such as PL or Raman spectroscopy. However, recording a high-resolution strain map, where each strain value is determined by a full polarization scan, is extremely time consuming. We thus determine the strain from the SHG intensities at the three AC directions (ϕ = 0°, 60°, 120°) of the MoS2 crystal only. Using this method, we first record one complete polarization resolved measurement to determine the crystal orientation. Thereafter, for each location we acquire three SHG signals at the angles noted above, from which we determine the local strain. By taking the square root of the measured SHG intensity, being proportional to the second order polarization \(P_\parallel ^{\left( 2 \right)}\left( \phi \right) \propto \pm \left( {I_\parallel ^{\left( 2 \right)}\left( \phi \right)} \right)^{1/2}\), we obtain a system of equations with three unknowns—A, B, and θ, presented in the Methods section. This equation system is analytically solvable and yields:

with P0 > P60, P120.

A and B are directly related to the principal strain values εxx and εyy (see Eq. (4)), and θ is the rotation of the principal strain coordinate system relative to the crystal lattice. Uniaxial strain can then be determined as εua = εxx − εyy and biaxial strain as εbi = εyy, since we chose \(\left| {\varepsilon _{{\mathrm{xx}}}} \right| > \left| {\varepsilon _{{\mathrm{yy}}}} \right|\). The relative error of the photoelastic tensor elements p1 and p2 is directly connected to the error of the calculated strain \(\delta \varepsilon = \frac{{\delta p_1}}{{p_1}}\varepsilon = \frac{{\delta p_2}}{{p_2}}\varepsilon\). In our measurement, the relative error of the photoelastic tensor components is ~10%, which is also the uncertainty of the measured strain values. The uncertainty of p1 and p2 mainly stems from our two-point bending technique, which does not fix the strained samples as well as three-point or four-point bending methods. It could thus be improved by employing more sophisticated straining techniques.

We finally present an illustrative application example of the SHG strain mapping technique. Using a PC (polycarbonate) based pick-and-place technique, we transferred a mechanically exfoliated MoS2 monolayer flake onto a 115 nm high lithographically defined structure on a Si/SiO2 substrate, shown as scanning electron microscope (SEM) image in Fig. 4 (inset). The force applied during the transfer technique causes the MoS2 to be strained by the non-flat surface. A strain map is then recorded using the technique described above, and the resulting local uniaxial strains εua are plotted as vectors in Fig. 4. Since all uniaxial strain values are positive we conclude that only tensile strain is present, which makes sense because the relaxed MoS2 is spanned over the lithographic structure. Also contaminations on the substrate (e.g., in the lower right corner) lead to strained MoS2 areas.

Discussion

In summary, we have presented a method that allows to extract the full strain tensor by means of polarization resolved SHG measurements. Using a two-point bending technique, we determined the photoelastic tensor elements for monolayer MoS2. Once identified, these parameters allowed to spatially map the strain field in an inhomogeneously strained sample with 280 nm spatial resolution. Determination of the local strain tensor via three polarized SHG measurement points enables for efficient and fast strain field imaging over large sample areas, providing an unprecedented depth of information. Our method supplements and extends established optical strain measuring methods, such as Raman and PL spectroscopy. Due to the insensitivity of the SHG response to free carriers in TMD monolayers42, our technique is less prone to artefacts that arise from local doping. Moreover, using this technique, it may be possible to image transient crystal deformations on a sub-picosecond timescale.

Methods

Experimental SHG setup

For SHG measurements we use a femtosecond Ti:sapphire laser source (200 fs, 76 MHz) that is tuned to a wavelength of 800 nm, below the MoS2 band gap. A 100× confocal objective lens (NA = 0.9) is used to excite the sample with a diffraction-limited spot with ~1 mW average power. The SHG signal is collected in reflection geometry. In order to excite the sample with tunable linear polarization, a quarter-wave plate is first used to obtain light with circular polarization. Using a linear polarizer, mounted in a motorized rotation stage, the circularly polarized beam is then converted into a linear polarized one with polarization angle ϕ. The same linear polarizer is used to filter out SHG light with polarization angles other than ϕ. To suppress the excitation light, a dichroic mirror, that reflects wavelengths below 650 nm, as well as short-pass and band-pass filters are used, and the filtered SHG signal is detected with a sensitive photodetector. An additional beam splitter in the beam path allows to illuminate the sample with a white light source and capture the image with a CMOS camera. This allows to coarsely align the excitation laser spot on the sample. The beam splitter is removed during SHG measurements to avoid signal losses. To minimize the impact of background illumination (room light), we modulate the laser beam with a mechanical chopper and detect the photodiode signal with a lock-in amplifier. A schematic drawing of the setup is presented in Supplementary Fig. 1.

Sample preparation for two-point bending experiment

We use polyethylene naphthalate (PEN) with a thickness of d = 0.25 mm and a length of L = 18 mm as flexible substrate. First, a layer of SU-8 (MicroChem) photoresist is spun on top of the PEN substrate and the coating is cross-linked by UV light and heat. MoS2 monolayers are then selectively transferred using a pick-and-place technique. For that, MoS2 is mechanically exfoliated onto a Si/SiO2 wafer and a monolayer is picked up by using a Polydimethylsiloxane (PDMS) stamp covered by a polycarbonate (PC) layer. The stamp with the monolayer is then brought into contact with the SU-8 layer on the flexible substrate. After heating the sample to ~180 °C the stamp is lifted up, leaving the MoS2 monolayer and the PC layer on top of the SU-8 surface. The PC layer is then dissolved with chloroform. In order to clamp down the MoS2 monolayer, another SU-8 coating is spun on top. The SU-8 encapsulation is finally fully cross-linked by heating to a temperature of 200 °C for 30 min. This modifies the SU-8 layer such that it has the mechanical strength to reliably transfer strain from the substrate to the MoS2 monolayer.

Nonlinear polarizations along the AC directions

Data availability

The data that support the findings of this study are available from the corresponding author upon request.

References

Thompson, S. E. et al. A 90-nm logic technology featuring strained-silicon. IEEE Trans. Electron Devices 51, 1790–1797 (2004).

Liu, J. et al. Tensile-strained, n-type Ge as a gain medium for monolithic laser integration on Si. Opt. Express 15, 11272–11277 (2007).

Desai, S. B. et al. Strain-induced indirect to direct bandgap transition in multilayer WSe2. Nano. Lett. 14, 4592–4597 (2014).

Roldán, R. et al. Strain engineering in semiconducting two-dimensional crystals. Phys.: Condens. Matter 27, 313201 (2015).

Amorim, B. et al. Novel effects of strains in graphene and other two dimensional materials. Phys. Rep. 617, 1–54 (2016).

Novoselov, K. S. et al. Two-dimensional atomic crystals. Proc. Natl Acad. Sci. USA 102, 10451–10453 (2005).

Lee, C., Wei, X., Kysar, J. W. & Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 332, 385–388 (2008).

Bertolazzi, S., Brivio, J. & Kis, A. Stretching and breaking of ultrathin MoS2. ACS Nano 5, 9703–9709 (2011).

Akinwande, D., Nicholas, P. & Hone, J. Two-dimensional flexible nanoelectronics. Nat. Commun. 5, 5678 (2014).

Castellanos-Gomez, A. et al. Local strain engineering in atomically thin MoS2. Nano. Lett. 13, 5361–5366 (2013).

Hong, L. et al. Optoelectronic crystal of artificial atoms in strain-textured molybdenum disulphide. Nat. Commun. 6, 7381 (2015).

Kern, J. et al. Nanoscale positioning of single-photon emitters in atomically thin WSe2. Adv. Mater. 28, 7101–7105 (2016).

Palacios-Berraquero, C. et al. Large-scale quantum-emitter arrays in atomically thin semiconductors. Nat. Commun. 8, 15093 (2017).

Branny, A. et al. Deterministic strain-induced arrays of quantum emitters in a two-dimensional semiconductor. Nat. Commun. 8, 15053 (2017).

Feng, J., Qian, X., Huang, C.-W. & Li, J. Strain-engineered artificial atom as a broad-spectrum solar energy funnel. Nat. Photonics 6, 866–872 (2012).

Robinson, I. & Harder, R. Coherent X-ray diffraction imaging of strain at the nanoscale. Nat. Mater. 8, 291–298 (2009).

Hüe, F., Hytch, M., Bender, H., Houdellier, F. & Claverie, A. Direct mapping of strain in a strained silicon transistor by high-resolution electron microscopy. Phys. Rev. Lett. 100, 156602 (2008).

Wright, S. I., Nowell, M. M. & Field, D. P. A review of strain analysis using electron backscatter diffraction. Microsc. Microanal. 17, 316–329 (2011).

Mohiuddin, T. M. G. et al. Uniaxial strain in graphene by Raman spectroscopy: G peak splitting, Grüneisen parameters, and sample orientation. Phys. Rev. B 79, 205433 (2009).

Rice, C. et al. Raman-scattering measurements and first-principles calculations of strain-induced phonon shifts in monolayer MoS2. Phys. Rev. B 87, 081307R (2013).

Wang, Y., Cong, C., Qiu, C. & Yu, T. Raman spectroscopy study of lattice vibration and crystallographic orientation of monolayer MoS2 under uniaxial strain. Small 9, 2857–2861 (2013).

He, K., Poole, C., Mak, K. F. & Shan, J. Experimental demonstration of continuous electronic structure tuning via strain in atomically thin MoS2. Nano Lett. 13, 2931–2936 (2013).

Hui, Y. Y. et al. Exceptional tunability of band energy in a compressively strained trilayer MoS2 sheet. ACS Nano 7, 7126–7131 (2013).

Boyd, G. D., Nash, F. R. & Nelson, D. F. Observation of acoustically induced phase-matched optical harmonic generation in GaAs. Phys. Rev. Lett. 24, 1298–1301 (1970).

Govorkov, S. V. et al. Inhomogeneous deformation of silicon surface layers probed by second-harmonic generation in reflection. J. Opt. Soc. Am. B 6, 1117–1124 (1989).

Zhao, J.-H. et al. Enhancement of second-harmonic generation from silicon stripes under external cylindrical strain. Opt. Lett. 34, 3340–3342 (2009).

Schriever, C., Bohley, C. & Wehrspohn, R. B. Strain dependence of second-harmonic generation in silicon. Opt. Lett. 35, 273–275 (2010).

Cazzanelli, M. et al. Second-harmonic generation in silicon waveguides strained by silicon nitride. Nat. Mater. 11, 148–154 (2012).

Zhao, J.-J., Li, X.-B., Chen, Z.-G., Meng, X. & Jia, G. Precise measurement of weak strain by second-harmonic generation from silicon (111) surface. J. Opt. Soc. Am. B 30, 1200–1204 (2013).

Cho, Y. et al. Second-harmonic microscopy of strain fields around through-silicon-vias. Appl. Phys. Lett. 108, 151602 (2016).

Malard, L. M., Alencar, T. V., Barboza, A. P. M., Mak, K. F. & de Paula, A. M. Observation of intense second harmonic generation from MoS2 atomic crystals. Phys. Rev. B 87, 201401R (2013).

Li, Y. et al. Probing symmetry properties of few-layer MoS2 and h-BN by optical second-harmonic generation. Nano Lett. 13, 3329–3333 (2013).

Kumar, N. et al. Second harmonic microscopy of monolayer MoS2. Phys. Rev. B 87, 161403R (2013).

Seyler, K. L. et al. Electrical control of second-harmonic generation in a WSe2 monolayer transistor. Nat. Nanotechnol. 10, 407–411 (2015).

Wang, G. et al. Giant enhancement of the optical second-harmonic emission of WSe2 monolayers by laser excitation at exciton resonances. Phys. Rev. Lett. 114, 097403 (2015).

Lyubchanskii, I. L. et al. Second-harmonic generation from realistic film substrate interfaces: the effects of strain. Appl. Phys. Lett. 76, 1848 (2000).

Jeong, J.-W., Shin, S.-C., Lyubchanskii, I. L. & Varyukhin, V. N. Strain-induced three-photon effects. Phys. Rev. B 62, 13455 (2000).

Mak, K. F., Lee, C., Hone, J., Shan, J. & Heinz, T. F. Atomically thin MoS2: a new direct-gap semiconductor. Phys. Rev. Lett. 105, 136805 (2010).

Splendiani, A. et al. Emerging photoluminescence in monolayer MoS2. Nano Lett. 10, 1271–1275 (2010).

Zheludev, N. I., Popov, S. V. & Svirko, Y. P. Susceptibility Tensors for Nonlinear Optics. (Institute of Physics Publishing: Bristol, 1995).

Cooper, R. C. et al. Nonlinear elastic behavior of two-dimensional molybdenum disulfide. Phys. Rev. B 87, 035423 (2013).

Lee, J., Mak, K. F. & Shan, J. Electrical control of the valley Hall effect in bilayer MoS2 transistors. Nat. Nanotechnol. 11, 421–425 (2016).

Acknowledgements

We are grateful to Georg Reider, Juraj Darmo, and Tobias Korn for helpful discussions and to Karl Unterrainer for providing access to a Ti:Sapphire laser source. We acknowledge financial support by the Austrian Science Fund FWF (START Y 539-N16) and the European Union (grant agreement No. 696656 Graphene Flagship).

Author information

Authors and Affiliations

Contributions

L.M., M.M.F. and T.M. conceived and designed the experiment. L.M., M.M.F. and S.W. built the setup and carried out the measurements. M.M.F., L.M., S.W., M.P. and D.K.P. fabricated the samples. L.M. and M.M.F. analyzed the data. L.M., M.M.F. and T.M. prepared the manuscript. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mennel, L., Furchi, M.M., Wachter, S. et al. Optical imaging of strain in two-dimensional crystals. Nat Commun 9, 516 (2018). https://doi.org/10.1038/s41467-018-02830-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-018-02830-y

This article is cited by

-

Programmable nanowrinkle-induced room-temperature exciton localization in monolayer WSe2

Nature Communications (2024)

-

An anisotropic van der Waals dielectric for symmetry engineering in functionalized heterointerfaces

Nature Communications (2023)

-

Giant bulk piezophotovoltaic effect in 3R-MoS2

Nature Nanotechnology (2023)

-

Towards compact phase-matched and waveguided nonlinear optics in atomically layered semiconductors

Nature Photonics (2022)

-

Active pixel sensor matrix based on monolayer MoS2 phototransistor array

Nature Materials (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.