Abstract

The shape, size, and size distribution of nano- and microstructures formed by the self-assembly of small molecules are crucial factors that govern their chemical and physical properties. Understanding these factors can reveal the correlations between the supramolecular structure and the emergent properties and may realize innovative new materials. Hence, the formation processes and syntheses of nano- and microstructures consisting of various functional molecules have been actively studied. Herein, we report the bottom-up preparation and functions of nano- and microstructures formed by the self-assembly of cyclodextrins (CDs), which are cyclic oligosaccharides. Reprecipitation and electrospinning methods produce various supramolecular structures based on CDs. The assembly modes of CD molecules and their morphologies remarkably affect the properties and functions of the supramolecular structures. In particular, γ-CD-based supramolecular structures achieve the inclusion of guest molecules dissolved in oils, which is difficult to achieve with a single-CD molecule. Furthermore, cubic γ-CD structures show excellent dispersibility in oils, forming organogels in various oils, and organic solvents at ambient temperature. These studies indicate that the construction and morphological control of self-assembled CD structures can effectively realize the potential function of CD molecules and open new fields in oligosaccharide chemistry and supramolecular chemistry.

Similar content being viewed by others

Introduction

Self-assembly processes are ubiquitous in nature, providing not only precisely controlled structures but also rather complicated yet highly organized hierarchical structures [1]. Nano- and micrometer-sized self-assembled structures are essential in the construction of living systems. Inspired by nature, various artificial materials based on the self-assembly of small molecules and polymers have been developed [2, 3]. Tremendous efforts have been devoted to the development of bottom-up methods for controlling the shape, size, and size distribution of self-assembled structures [4, 5]. Although these materials are still simpler than the natural ones, such materials have provided significant insight into the correlation between self-assembled structures and their properties [6, 7]. However, morphological control of the self-assembled structures remains a great challenge in the field of supramolecular chemistry because the molecular components are easily trapped in kinetically stable arrangements with various topologies [8]. A deeper understanding of the self-assembly process and structure-dependent properties are required to generate self-assembled structures with desirable sizes and shapes, as well as to advance supramolecular chemistry to the next stage. Herein, we describe the preparation, structure-dependent properties, and functions of cyclodextrin (CD) self-assembled structures with various shapes and sizes.

CDs are a class of cyclic oligosaccharides consisting of several α-(1,4)-linked d-glucopyranose units (Fig. 1), which are produced from starch by an enzymatic reaction of CD glucanotransferase [9]. CDs composed of 6, 7, and 8 glucose units are called α-, β-, and γ-CDs, respectively, and have been extensively studied due to their unique inclusion properties. CDs can incorporate appropriately sized and shaped guest molecules into their subnanometer-sized cavities (Fig. 1) [10]. The inclusion ability of CDs toward guest molecules has been studied not only academically but also industrially. CDs have been applied in food, cosmetics, and pharmaceuticals [11, 12]. Inclusion into CD cavities increases the apparent aqueous solubility and oral availability of poorly soluble drugs, which is a promising strategy for improving drug efficacy [13, 14]. Moreover, CDs can form self-assembled nano- and microstructures through hydrogen bonding interactions between hydroxyl groups on the rim. CD-assembled structures have great potential as vehicles for drug and gene delivery to specific cells or tissues in the human body. Both CDs and CD-assembled structures have attracted considerable attention in the fields of supramolecular chemistry and materials science [15, 16]. This review highlights the formation behavior and functions of nano- and microstructures formed by the self-assembly of CDs.

Preparation of nano- and microstructures composed of CDs

CDs generally form three types of molecular packing modes in the crystalline state: cage, channel, and layer-type assemblies (Fig. 2) [17]. In cage-type assemblies, the CD molecules are arranged in a zig–zag fashion. The CD cavities are blocked by adjacent CD molecules, forming isolated cages. In channel-type assemblies, the CD molecules are stacked linearly through intermolecular hydrogen bonding interactions between the hydroxyl groups of the CD molecules, forming a columnar structure in a head-to-head or head-to-tail arrangement. In layer-type assemblies, CD molecules are arranged nearly parallel to the ring plane, forming molecular layers in which two adjacent layers are shifted by half a molecule. It is well known that the inclusion complexes of CDs and guest molecules tend to form channel-type assemblies, which CD itself rarely forms. Thus, channel-type assemblies without guest molecules should exhibit better inclusion capabilities toward guest molecules than other types of assemblies.

Tonelli and colleagues developed a facile method for preparing channel-type assemblies of CD molecules without guest molecules [18, 19]. The researchers successfully prepared channel-type assemblies of α- and γ-CD by dropping an aqueous CD solution into chloroform and acetone, respectively. Our studies using scanning electron microscopy (SEM) revealed that the channel-type assemblies of γ-CD prepared by Tonelli’s method form unique cubic microstructures (Fig. 3) [20, 21].

a Schematic representation of the preparation of nano- and microcubes and microrectangular particles. b–g SEM images of γ-CD microcubes formed by dropping aqueous γ-CD into (b–e) acetone, f 2-propanol, and g 2-butanol. The concentrations of the aqueous γ-CD solutions are (b, f, g) 0.17 M, c 1.7 × 10−2 M, d 3.5 × 10−3 M, and e 1.7 × 10−3 M

There are only a few reports of the fabrication and function of organic nano- and microcubes [22,23,24], although many studies have investigated cubic nano- and microstructures composed of inorganic compounds, such as metals and metal oxides [25,26,27,28,29,30,31,32,33,34,35,36]. Organic nano- and microcubes should function as unique molecular containers and drug carriers, which differ from spherical and rod-like aggregates. We subsequently prepared various CD-based microcubes by adjusting the fabrication conditions (e.g., the γ-CD concentration and the type of poor solvent) (Fig. 3). γ-CD microcubes with an average edge length of 7 µm were fabricated by dropping a saturated aqueous γ-CD solution into acetone at ambient temperature [21].

Our studies revealed some interesting behaviors. Decreasing the γ-CD concentration in the aqueous solution increases the size of γ-CD microcubes. Reducing the γ-CD concentration to one-hundredth of its original concentration induces a fourfold enhancement in the size of the γ-CD microcubes. Changing the type of poor solvent also affects the formation of the self-assembled structures. Using 2-propanol instead of acetone results in slightly larger γ-CD microcubes. In contrast, using 2-butanol decreases the size of the γ-CD microcubes (average edge length: 1 µm).

These size differences are derived from the solubility of γ-CD; the solubility of γ-CD in 2-propanol, acetone, and 2-butanol at 20 °C is 0.21, 0.16, and 0.11 mM, respectively. The decreasing order of the γ-CD microcube size is consistent with the order of solubility of γ-CD. A lower solubility of γ-CD in a poor solvent should increase the number of nuclei in the nucleation stage, leading to smaller-sized γ-CD microcubes.

We also examined the effects of guest ions on the morphologies of γ-CD microstructures using potassium iodide (KI) and sodium perchlorate (NaClO4) (Fig. 4) [37]. When an aqueous γ-CD solution (0.17 M) contained 1 equiv. of KI is dropped into 2-propanol, nanometer-sized cubes (average edge length: 300 nm), which are smaller than those produced without KI, are formed. In the presence of 0.1–0.8 equiv. of KI, rod-like microstructures are generated, and the shape becomes thinner as the amount of KI increases. On the other hand, NaClO4 shows the opposite effect as KI. Adding <0.9 equiv. of NaClO4 does not affect the morphologies of the γ-CD microcubes, whereas adding >1 equiv. of NaClO4 affords microsized rectangular structures. These results show that the anionic guests incorporated into the cavities can control the morphology of the γ-CD assembly. All the X-ray diffraction (XRD) patterns of these assemblies show a strong peak near 7.5°, which is derived from the well-known channel-type structure of γ-CD [18].

In the course of our studies on CD-assembled structures, we found that 1,1,1,3,3,3-hexafluoro-2-propanol (HFIP) is a good solvent for CDs [38]. HFIP solutions of CDs are a powerful tool for facilely preparing CD-assembled materials. Because HFIP has a relatively low boiling point (58 °C), it easily evaporates from the CD solution under mild conditions, and evaporating HFIP from a solution on a glass plate at ambient temperature gives crystalline CD solids composed of a channel-type assembly of γ-CD. The easy fabrication of a channel-type γ-CD assembly has great potential for realizing applications in various fields. Additionally, we successfully prepared fibrous CD structures by utilizing the high -CD-dissolving ability and high volatility of HFIP. The details are described in a later section.

CD microcubes as templates for fabricating hollow polymer structures

The obtained unique CD-assembled structures function as attractive templates for fabricating hollow polymer structures, which can be utilized as drug carriers, molecular containers, and nanoreactors [39]. Conventional inorganic core templates have been used to construct spherical polymer capsules [40]. However, template cores using organic nano- and microstructures have received less attention due to their lower stabilities. Templates composed of organic supramolecular structures should be easily removed from polymer film-template conjugates under milder conditions than those required for inorganic templates. This is a great advantage of organic templates relative to conventional inorganic templates. This property of organic templates should lead to the facile construction of polymer capsules with unique morphologies, including cubes and rods. Additionally, supramolecular structures composed of biocompatible building blocks such as oligo- and polysaccharides are ideal templates for fabricating polymer capsules for applications in the biomedical and pharmaceutical fields. For these reasons, we tried to fabricate hollow capsules using supramolecular CD microstructures as a core template [41].

The surface of γ-CD microcubes was coated with it-/st-poly(methyl methacrylate) (it-/st-PMMA) stereocomplex films by a layer-by-layer method. Simply washing with water removed the CD templates from the it-/st-PMMA stereocomplex film-coated particles to give hollow microcubes (Fig. 5). Considering that the morphology of the CD-assembled structures can be controlled as described above, this method should provide a powerful tool for constructing micrometer-sized hollow polymer structures with different morphologies. This method may realize a novel platform for fabricating DDS materials.

a Schematic representation of the fabrication of PMMA stereocomplex hollow cubes using γ-CD microcubes as a core template. b, c SEM images of the γ-CD microcubes (b) and PMMA-coated microstructures (c) obtained by the layer-by-layer method. d, e Phase-contrast (d) and fluorescence microscopy images (e) of hollow PMMA microcubes stained with rhodamine B

Preparation of CD-based fibrous structures by electrospinning

One-dimensional structures formed by the self-assembly of small molecules (i.e., supramolecular nanofibers) are applicable in numerous fields, including biotechnology, textiles, membranes/filters, electronics, sensors, and energy [42]. Uyar and co-workers reported that CD nanofibers can be fabricated by electrospinning [43,44,45,46]. Electrospinning is a very cost-effective technique for producing functional nanofibers from versatile materials such as polymers and polymer blends [47]. The researchers hypothesized that the fabrication of CD nanofibers can be realized by electrospinning highly concentrated CD solutions because CDs can form aggregates in such solutions via intermolecular hydrogen bonding. They obtained highly concentrated homogeneous solutions using 10 w/v% aqueous NaOH, DMSO-water, and 1-ethyl-3-methylimidazolium acetate (ionic liquid)–DMF solutions and successfully prepared nanofibers by electrospinning unmodified CDs.

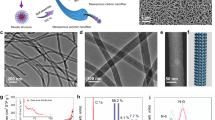

We also prepared CD fibers by electrospinning HFIP solutions of CDs (Fig. 6) [38]. XRD confirmed the assembly mode of the CD molecules in the resulting fibers. These fibers are not composed of crystalline CD assemblies but instead are amorphous. This result is in contrast to the case of the crystalline CD solids prepared by evaporating HFIP from CD/HFIP solutions at ambient temperature. These findings suggest that supramolecular CD materials composed of different CD assemblies can be prepared by appropriate treatment of the HFIP solution of CDs.

Formation of CD assemblies in aqueous solutions

In aqueous solutions, CDs form self-assemblies that range in size from nano- to micrometers, although the percentage of CD molecules participating in the formation of assemblies is very low, i.e., 0.8% and 0.02% in 12 mM aqueous solutions of α- and γ-CDs, respectively [48, 49], and 0.0011% in a 10 mM β-CD solution [50]. Dynamic and static light scattering measurements confirmed that the size of these CD assemblies increases with increasing concentration regardless of the type of CD [51, 52]. The largest CD assembly with a diameter of several micrometers forms from β-CD. Transmission electron microscopy (TEM) and cryo-TEM observations revealed the formation of spherical assemblies with diameters of 20–130 nm from β- and γ-CDs [50, 53]. Chemical modification (methylation) of the hydroxyl groups of the CDs, the addition of hydrogen bonding-disrupting agents such as urea, or the ionization of the CD hydroxyl groups (at pH 12 or higher) inhibits the formation of these assemblies. The driving force for the formation of these self-assemblies can be ascribed to hydrogen bonding between the hydroxyl groups of CDs. Hydrogen bonding plays an important role in the formation of assembled structures, even in aqueous solutions.

Inclusion complexes of CDs with guests also form assemblies in water. Inclusion complexes of trans-β-carotene with β- and γ-CDs form micellar assemblies in water [54]. The inclusion complex between hydrocortisone and γ-CD forms spherical structures with diameters of ~20 nm [55]. Micellar structures with hydrophobic drugs are important candidates for drug delivery carriers.

Function of CD assemblies: removal of polychlorinated biphenyls (PCBs) from oils by channel-type assemblies of γ-CD

Polychlorinated biphenyls (PCBs) are composed of 209 kinds of compounds with different degrees of substitution and substituent positions of chlorine atoms. Approximately 50 years ago [56], PCBs were widely used as insulating fluids in capacitors and transformers. Due to their high toxicity, environmental persistence, and bioaccumulation, the manufacture and commercial use of PCBs have been prohibited in many countries since the 1970s. However, large amounts of insulating oils contaminated with PCBs are still being used or stored without appropriate treatment [57,58,59]. Thus, a new technique for efficiently treating PCB-contaminated oils is strongly required.

Molecular modeling studies show that the molecular size of PCBs with lower degrees of substitution by chlorine atoms spatially fit into the cavity of γ-CD. A channel-type γ-CD assembly showing excellent oil dispersibility should be a promising material that can selectively remove PCBs, especially those with lower degrees of substitution by chlorine atoms, from insulating oil by the formation of inclusion complexes.

We examined the removal of PCBs from insulating oil using a γ-CD assembly as an adsorbent for PCBs with a relatively lower degree of chlorine atom substitution, such as 2-chlorobiphenyl (2-MCB), 4-chlorobiphenyl (4-MCB), 4,4′-dichlorobiphenyl (4,4′-DiCB), 3,4,4′-trichlorobiphenyl (3,4,4′-TrCB), and 3,3′,5,5′-tetrachlorobipheynyl (3,3′,5,5′-TeCB). For comparison, the adsorption capability of the γ-CD assembly toward trichlorobenzenes such as 1,2,4-trichlorobenzene (1,2,4-TrCBz) and 1,3,5-trichlorobenzene (1,3,5-TrCBz) was also examined [60]. A prescribed amount of the γ-CD assembly was added into the insulating oil (300 mg) containing PCBs or trichlorobenzenes (100 p.p.m.), and the resulting mixtures were shaken (60 min−1 frequency, 30 mm amplitude) for 24 h at 20 °C with a shaker. After removal of the γ-CD assembly solid by filtration using a syringe equipped with filter paper, the remaining PCB concentrations in the insulating oils were analyzed by gas chromatography mass spectrometry (GC–MS).

Figure 7 shows the removal percentages of 1,2,4-TrCBz and 3,4,4′-TrCB from the insulating oil. The removal percentages of 1,2,4-TrCBz and 3,4,4′-TrCB increase with increasing amount of γ-CD. It is noteworthy that 1,2,4-TrCBz and 3,4,4′-TrCB are completely removed when >150 mg of the channel-type γ-CD assembly is used (>50 wt% of insulating oil). On the other hand, the γ-CD assembly with a cage-type structure does not show adsorption of these PCBs from insulating oil, suggesting that the channel-type structure of the γ-CD is essential for adsorbing the PCBs.

The adsorption capability of γ-CD toward the other PCBs was also evaluated (Fig. 7). 1,3,5-TrCBz, 2-MCB, 4-MCB, 4,4′-DiCB, 1,2,4-TrCBz, and 3,4,4′-TrCB are completely removed from the insulating oil by the γ-CD channel-type assembly, but 3,3′,5,5′-TeCB is minimally removed. These results indicate that the molecular sizes of 1,3,5-TrCBz, 2-MCB, 4-MCB, 4,4′-DiCB, and 3,4,4′-TrCB are appropriate for fitting inside the cavity of the γ-CD channel; whereas, 3,3′5,5′-TeCB is too large to be incorporated into the cavity of the γ-CD assembly. The molecular size is responsible for the removal of PCBs from the insulating oil.

To obtain detailed information on the adsorption selectivity of γ-CD toward PCBs, competitive adsorption experiments using a PCB mixture were carried out. In the experiment using a mixture of 2- and 4-MCB, 4-MCB is adsorbed preferentially, indicating that the size and/or shape of 4-MCB is better fitted to the cavity of γ-CD. We also conducted a competitive experiment using 4-MCB, 4,4′-DiCB, and 3,4,4′-TrCB. The order of adsorption selectivity among 4-MCB, 4,4′-DiCB, and 3,4,4′-TrCB is 4-MCB > 4, 4′-DiCB > 3,4,4′-TrCB. This order is consistent with the molecular sizes, implying that steric hindrance is a crucial factor for adsorption by the γ-CD assembly. We now assume that PCB adsorption from oil is mainly caused by dipolar–dipolar interactions between the host cavity and the guest molecule, as well as by the steric fit of the guest in the host cavity.

Preliminary experiments on the recovery of the adsorbed PCBs from the channel-type γ-CD assembly reveals that >70% of the adsorbed PCBs are easily recovered by simple washing with n-hexane. Therefore, the γ-CD assembly has great potential as a practical adsorbent for removing and recovering harmful PCBs in oils.

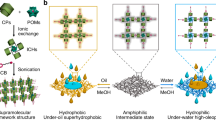

Functions of CD assemblies: organogelation ability of channel-type assemblies of γ-CD

In the course of our studies on inclusion complex formation between CD assemblies and guest molecules, we found that a channel-type assembly of γ-CD gelates some oils and organic solvents (Fig. 8) [20]. In sharp contrast to the channel-type γ-CD assembly, the cage-type packing structure of γ-CD does not show gelation capability toward any of the oils or organic solvents studied. In addition, neither the channel-type assembly of α-CD with a smaller cavity size than γ-CD nor the α-CD cage-type structure forms organogels.

a–d Photographs of mixtures of insulating oil and CD assemblies. a Channel-type γ-CD assembly, b cage-type α-CD assembly, c channel-type α-CD assembly, and d cage-type γ-CD assembly. e Critical gelation concentration of the channel-type γ-CD assembly in various oils and organic solvents at 20 °C. f–i SEM images of xerogels prepared from organogels with channel-type γ-CD microcubes. f Cyclohexane gel, g benzene gel, h 1,4-dioxane gel, and i ethanol gel. The insets show high-magnification images (scale bar: 5 µm). j Schematic illustration of three-dimensional network formed by self-assembly of microcubes composed of channel-type γ-CD assemblies in oils or organic solvents

The gelation capability of γ-CD is closely related to polarity of the organic solvent. γ-CD shows the highest gelation capability in tetradecane, which has a relatively low polarity among the organic solvents examined. On the other hand, when polar organic solvents that can form hydrogen-bonds, such as 1,4-dioxane and ethanol, are used, the gelation capability significantly decreases. These results imply that hydrogen bonding is key for constructing three-dimensional (3D) networks for organogelation.

The morphologies of the γ-CD assemblies in various organogels were confirmed by SEM observations. SEM images of the xerogels obtained from the cyclohexane and benzene gels clearly show microsized cubic structures. Direct in situ observation of the tetradecane gel with phase-contrast microscopy also supports the formation of a 3D network via the assembly of microcubes (Fig. 8). The tetradecane molecules are entrapped in the void spaces of the network. Their fluidity decreases, finally causing gelation. On the other hand, SEM images of the xerogel obtained from the 1,4-dioxane gel indicate that the microcubes are cleaved into smaller cubic fragments with an average edge length of 1 µm (Fig. 8). SEM images of the xerogel obtained from the ethanol gel show decomposed cubic structures and small particles, which likely broke off the original cubic structure. Polar solvents break the hydrogen bonding interactions in the self-assembled γ-CD structure and give distorted γ-CD assembly structures, which construct a weak 3D network that is insufficient for gelation. The main factor governing organogelation is the construction of 3D networks based on γ-CD microcubes through hydrogen bonding, van der Waals interactions, and London dispersion forces. We also clarified the relationship between the γ-CD morphologies and the gelation capability toward tetradecane, benzene, 1,4-dioxane, and soybean oil. The gelation capability tends to increase as the size of the γ-CD microcube decreases. Moreover, γ-CD microcubes show a better gelation capability than γ-CD microrectangular particles with a similar edge length in the base. These results suggest that organogel formation by γ-CD assemblies is greatly affected by their morphologies.

Perspective

In this review, we describe the preparation, properties, and functions of nano- and microstructures formed by the self-assembly of CDs. CDs adopt various types of assembly modes in aqueous solutions and crystal structures, which are formed mainly through hydrogen bonding between the hydroxyl groups on the upper and lower rims of the CD rings. Channel-type assemblies of γ-CD form micrometer-sized cubes, which exhibit emergent functions that cannot be achieved by a single-CD molecule. In general, inclusion complex formation with CDs has been achieved in aqueous media and in several kinds of polar organic media, as it was believed that inclusion complex formation in nonpolar organic media would be very difficult. We, however, found that the channel-type γ-CD assembly can capture guest molecules such as PCBs in oils. Using this assembly as an adsorbent should effectively remove and recover various harmful substances in oils. Channel-type assemblies of γ-CD possess excellent oil dispersion abilities and can form organogels in a variety of oils and organic solvents at ambient temperature. Organogels formed with drug-incorporated γ-CD assemblies will be useful as drug carriers. Studies on the nano- and microstructures formed by the self-assembly of CDs should become more active in a variety of fields, including supramolecular chemistry and materials science.

References

Alberts B, Johnson A, Lewis J, Raff M, Roberts K, Walter P. The cytoskeleton. Molecular Biology of the Cell. 5th edn. New York: Garland Science; 2008. p. 965–1052.

Tritschler U, Pearce S, Gwyther J, Whittell R, Manners I. 50th anniversary perspective: functional nanoparticles from the solution self-assembly of block copolymers. Macromolecules. 2017;50:3439–63.

Lutz J-F, Lehn J-M, Meijer EW, Matyjaszewski K. From precision polymers to complex materials and systems. Nat Rev Mater. 2016;1:16024.

Kang J, Miyajima D, Mori T, Inoue Y, Itoh Y, Aida T. Noncovalent assembly. A rational strategy for the realization of chain-growth supramolecular polymerization. Science. 2015;347:646–51.

Ogi S, Sugiyasu K, Manna S, Samitsu S, Takeuchi M. Living supramolecular polymerization realized through a biomimetic approach. Nat Chem. 2014;6:188–95.

Hollamby MJ, Karny M, Bomans PHH, Sommerdjik NAJM, Saeki A, Seki S, Minamikawa H, Grillo I, Pauw BR, Eastoe J, Mohwald H, Nakanishi T. Directed assembly of optoelectronically active alkyl-π-conjugated molecules by adding n-alkanes or π-conjugated species. Nat Chem. 2014;6:690–6.

Nguyen ST, Gin DL, Hupp JT, Zhang X. Supramolecular chemistry: functional structures on the mesoscale. Proc Natl Acad Sci USA. 2001;98:11849–50.

Feng H, Lu X, Wang W, Kang N, Mays JW. Block copolymers: synthesis, self-assembly, and applications. Polymers. 2017;3:494.

Saenger W, Jacob J, Gessler K, Steiner T, Hoffmann D, Sanbe H, Koizumi K, Smith SM, Takaha T. Structures of the common cyclodextrins and their larger analogues beyond the doughnut. Chem Rev. 1998;98:1787–802.

Saenger W. Cyclodextrin inclusion compounds in research and industry. Angew Chem Int Ed Engl. 1980;19:344–62.

Wenz G. Cyclodextrins as building blocks for supramolecular structures and functional units. Angew Chem Int Ed Engl. 1994;33:803–22.

Szejtli J, Osa T Comprehensive supramolecular chemistry, vol. 3. In: Atwood JL, Davies JED, MacNicol DD, Vogtle F, Lehn, editors. Pergamon: Oxford; 1996.

Ryzhakov A, Thi TD, Stappaerts J, Bertoletti L, Kimpe K, Couto AR, Saokham P, Mooter GV, Augustijns P, Somsen GW, Kurkov S, Inghelbrecht S, Arien A, Jimidar MI, Schrijinemakers K, Loftsson T. Self-assembly of cyclodextrins and their complexes in aqueous solutions. J Pharm Sci. 2016;105:2556–69.

Tiwari G, Tiwari R, Rai AK. Cyclodextrins in delivery systems: applications. J Pharm Bioallied Sci. 2010;2:72–9.

He Y, Fu P, Shen X, Gao H. Cyclodextrin-based aggregates and characterization by microscopy. Micron. 2008;39:495–516.

Messner M, Kurkov SV, Jansook P, Loftsson T. Self-assembled cyclodextrin aggregates and nanoparticles. Int J Pharm. 2010;387:199–208.

Harata K. Structural aspects of stereodifferentiation in the solid state. Chem Rev. 1998;98:1803–28.

Rusa CC, Bullions TA, Fox J, Porbeni FE, Wang X, Tonelli AE. Inclusion compound formation with a new columnar cyclodextrin host. Langmuir. 2002;18:10016–23.

Uyar T, Hunt MA, Gracz HS, Tonelli AE. Crystalline cyclodextrin inclusion compounds formed with aromatic guests: guest-dependent stoichiometries and hydration-sensitive crystal structures. Cryst Growth Des. 2006;6:1113–9.

Kida T, Marui Y, Miyawaki K, Kato E, Akashi M. Unique organogel formation with a channel-type cyclodextrin assembly. Chem Commun. 2009;25:3889–91.

Marui Y, Kida T, Akashi M. Facile morphological control of cyclodextrin nano- and microstructures and their unique organogelation ability. Chem Mater. 2010;25:282–4.

Wang Z, Li F, Stein A. Direct synthesis of shaped carbon nanoparticles with ordered cubic mesostructure. Nano Lett. 2007;7:3223–6.

Liu P, Cao YL, Wang CX, Chen XY, Yang GW. Micro- and nanocubes of carbon with C8-like and blue luminescence. Nano Lett. 2008;8:2570–5.

Wang Y, Fu H, Peng A, Zhao Y, Ma J, Ma Y, Yao J. Distinct nanostructures from isomeric molecules of bis(iminopyrrole) benzenes: effects of molecular structures on nanostructural morphologies. Chem Commun. 2007;16:1623–5.

Sun Y, Xia Y. Shape-controlled synthesis of gold and silver nanoparticles. Science. 2002;298:2176–9.

Murphy CJ. Nanocubes and nanoboxes. Science. 2002;298:2139–41.

Sosa IO, Noguez C, Barrera RG. Optical properties of metal nanoparticles with arbitrary shapes. J Phys Chem B. 2003;107:6269–75.

Sherry LJ, Chang S, Schatz GC, Van Duyne RP, Wiley BJ, Xia Y. Localized surface plasmon resonance spectroscopy of single silver nanocubes. Nano Lett. 2005;5:2034–8.

Tsung C, Kuhn JN, Huang W, Aliaga C, Hung L, Somorjai GA, Yang P. Sub-10 nm platinum nanocrystals with size and shape control: catalytic study for ethylene and pyrrole hydrogenation. J Am Chem Soc. 2009;131:5816–22.

Park JC, Kim J, Kwon H, Song H. Gram-scale synthesis of Cu2O nanocubes and subsequent oxidation to CuO hollow nanostructures for lithium-ion battery anode materials. Adv Mater. 2009;21:803–7.

Dumestre F, Chaudret B, Amiens C, Renaud P, Fejes P. Superlattices of iron nanocubes synthesized from Fe[N(SiMe3)2]2. Science. 2004;303:821–3.

Xiong Y, Chen J, Wiley B, Xia Y, Yin Y, Li Z. Size-dependence of surface plasmon resonance and oxidation for Pd nanocubes synthesized via a seed etching process. Nano Lett. 2005;5:1237–42.

Chen M, Kim J, Liu JP, Fan H, Sun S. Synthesis of FePt nanocubes and their oriented self-assembly. J Am Chem Soc. 2006;128:7132–3.

Xu R, Zeng HC. Self-generation of tiered surfactant superstructures for one-pot synthesis of Co3O4 nanocubes and their close-and non-close-packed organizations. Langmuir. 2004;20:9780–90.

Yang S, Gao L. Controlled synthesis and self-assembly of CeO2 nanocubes. J Am Chem Soc. 2006;128:9330–1.

Jung S, Oh M. Monitoring shape transformation from nanowires to nanocubes and size-controlled formation of coordination polymer particles. Angew Chem Int Ed. 2008;120:2079–81.

Matsui Y, Ono M, Tokunaga S. NMR spectroscopy of cyclodextrin-inorganic anion systems. Bull Chem Soc Jpn. 1997;70:535–41.

Kida T, Sato S, Yoshida H, Teragaki A, Akashi M. 1,1,1,3,3,3-Hexafluoro-2-propanol (HFIP) as a novel and effective solvent to facilely prepare cyclodextrin-assembled materials. Chem Commun. 2014;50:14245–8.

Fuji M, Takai C, Virudazo RVR. Development of new templating approach for hollow nanoparticles and their applications. Adv Powder Technol. 2014;25:91–100.

Ramli RA. Hollow polymer particles: a review. RSC Adv. 2017;7:52632–3650.

Kida T, Sato S, Akashi M. Supramolecular cyclodextrin microstructures as novel templates to fabricate hollow polymer cubes. Chem Lett. 2017;46:1616–9.

Webber MJ, Berns EJ, Stupp SI. Supramolecular nanofibers of peptide amphiphiles for medicine. Isr J Chem. 2013;53:530–54.

Celebioglu A, Uyar T. Cyclodextrin nanofibers by electrospinning. Chem Commun. 2010;46:6903–5.

Celebioglu A, Uyar T. Electrospinning of nanofibers from non-polymeric systems: polymer-free nanofibers from cyclodextrin derivatives. Nanoscale. 2012;4:621–31.

Celebioglu A, Uyar T. Electrospinning of nanofibers from non-polymeric systems. J Colloid Interface Sci. 2013;404:1–7.

Celebioglu A, Uyar T. Electrospinning of gamma cyclodextrin (γ-CD) nanofibers for entrapment of volatile organic compounds. RSC Adv. 2013;3:22891–5.

Zhang W, Chen M, Zha B, Diao G. Correlation of polymer-like solution behaviors with electrospun fiber formation of hydroxypropyl-β-cyclodextrin and the adsorption study on the fiber. Phys Chem Chem Phys. 2012;14:9729–37.

GonzAlz-Gaitano G, RodrIguez P, Isasi JR, Fuentes M, Tardajos G, Sanchez M. The aggregation of cyclodextrins as studied by photon correlation spectroscopy. J Incl Phenom Macrocycl Chem. 2002;44:101–5.

Szente L, Szejtli J, Kis GL. Spontaneous opalescence of aqueous γ-cyclodextrin solutions: complex formation or self-aggregation? J Pharm Sci. 1998;87:778–81.

Wu AH, Shen XH, He TK. Micrometer-sized rodlike structure formed by the secondary assembly of cyclodextrin nanotube. J Colloid Interf Sci. 2006;302:87–94.

Coleman AW, Nicolis I, Keller N, Dalbiez JP. Aggregation of cyclodextrins: an explanation of the abnormal solubility of β-cyclodextrin. J Incl Phenom Macrocycl Chem. 1992;13:139–43.

Bonini M, Rossi S, Karlsson G, Almgren M, Lo Nostro P, Baglioni P. Self-assembly of β-cyclodextrin in water. Part 1: Cryo-TEM and Dynamic and static light scattering. Langmuir. 2006;22:1478–84.

Wu AH, Shen XH, He TK. Investigation on gamma-cyclodextrin nanotube induced by N,N′-diphenylbenzidine molecule. J Colloid Interf Sci. 2006;297:525–33.

Mele A, Mendichi R, Selva A. Non-covalent associations of cyclomaltooligosaccharides (cyclodextrins) with trans-β-carotene in water: evidence for the formation of large aggregates by light scattering and NMR spectroscopy. Carbohydr Res. 1998;310:261–7.

Jansook P, Kurkov SV, Loftsson T. Cyclodextrins as solubilizers: formation of complex aggregates. J Pharm Sci. 2010;99:719–29.

Rouse TO. Mineral insulation oil in transformers. IEEE Electr Insul Mag. 1998;14:6–16.

Kim IS, Setford SJ, Saini S. Determination of polychlorinated biphenyl compounds in electrical insulating oils by enzyme immunoassay. Anal Chim Acta. 2000;422:167–77.

Kanbe H, Shibuya M. Solvent cleaning of pole transformers containing PCB contaminated insulating oil. Waste Manag. 2001;21:371–80.

Seok J, Seok J, Hwang KY. Thermo-chemical destruction of polychlorinated biphenyls (PCBs) in waste insulating oil. J Hazard Mater B. 2005;124:133–8.

Kida T, Nakano T, Fujino Y, Matsumura C, Miyawaki K, Kato E, Akashi M. Complete removal of chlorinated aromatic compounds from oils by channel-type γ-cyclodextrin assembly. Anal Chem. 2008;80:317–20.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Shigemitsu, H., Kida, T. Preparation of nano- and microstructures through molecular assembly of cyclic oligosaccharides. Polym J 50, 541–550 (2018). https://doi.org/10.1038/s41428-018-0040-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0040-z