Abstract

Random copolymers (P(M100-m/T m )) composed of 2-methacryloyloxyethyl phosphorylcholine (MPC), which suppresses protein adsorption, and 3-(triethoxysilyl)propyl methacrylate (MTEOS), which can be covalently fixed on a glass surface, were prepared via photoinitiated radical polymerization. When P(M100-m/T m ) was coated on a glass surface, a protein antifouling effect could be observed because of the presence of MPC units on the glass surface. To confirm the coating of the glass surface with P(M100-m/T m ) by fluorescence microscopy, pyrene-labeled P(M100-m/T m ) was also prepared. An ethanol solution of P(M100-m/T m ) was spin-coated on the glass, which was exposed to NH3 vapor to promote the reaction of the pendant triethoxysilyl groups in P(M100-m/T m ) with silanol groups on the glass. The coating of the glass with MPC was confirmed by fluorescence microscopy. The protein antifouling effects of the P(M100-m/T m )-coated glass were confirmed using fluorescence-labeled proteins. It is expected that P(M100-m/T m ) can be applied as a surface-coating agent on glass containers for protein formulations.

Similar content being viewed by others

Introduction

Recently, many protein-based drugs have been developed because of advances in biotechnology. However, denaturation of proteins in glass containers induced by their absorption on the glass container wall is a problem [1]. When biomedical devices made of inorganic materials come into contact with biological components for a long period, the function of the device decreases [2, 3]. These problems arise from nonspecific protein adsorption on the inorganic materials. Surface modification solves this problem by endowing the surfaces of the inorganic material with protein antifouling properties.

Poly(ethylene glycol) [4,5,6] and 2-methacryloyloxyethyl phosphorylcholine (MPC) polymers [7,8,9] are already widely used for surface modification of biomedical devices because these polymers reduce nonspecific protein fouling. In particular, the MPC polymer shows excellent biocompatibility when it is implanted in the living system for a long period [10].

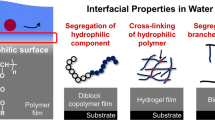

Recently, graft polymerization has been widely used for surface modification. This is mainly achieved by “grafting from” and “grafting to” methods. In the “grafting from” method, polymerization-initiation points are immobilized on the surface. In general, monomers are polymerized from the initiation points via controlled living radical polymerization methods, such as atom transfer radical polymerization and reversible addition-fragmentation chain transfer radical polymerization [11,12,13,14,15,16]. The “grafting from” method can produce a high-density grafted surface. However, immobilization of the initiation points on the surface is time-consuming. In the “grafting to” method, polymers possessing functional groups that attach to the surface are initially prepared [17]. The polymers are attached to the surface to be modified. The surface graft density produced by the “grafting to” method tends to be low compared to that of the “grafting from” method because of the steric hindrance of the grafted polymer chains.

Coating a surface with a polymer film by physical adsorption is more technically reliable than surface grafting techniques. In the film coating method, the surface is initially covered with a polymer solution via dip, spin, or spray-coating methods. A polymer thin film forms and physically adsorbs on the surface as the solvent evaporates [18,19,20]. However, a polymer film coating that is physically adsorbed on a surface tends to readily exfoliate.

To avoid the detachment of the polymer film from the substrate, polymers possessing a pendant silane coupling agent that can covalently attach to the surface have been prepared [21, 22]. Ordinary hydroxyl groups exist on the surface of many inorganic compounds, such as glass, metal oxides, and ceramics. Vinyl polymers containing 3-(triethoxysilyl)propyl methacrylate (MTEOS) units covalently attach to the hydroxyl groups on the surface of inorganic materials by a condensation reaction of the pendant triethoxysilyl groups with the hydroxyl groups [23]. The condensation reactions are catalyzed by acids and bases [24]. The hydrolysis and condensation reactions of triethoxysilyl groups are also promoted by heating [25]. Therefore, conventional heat-initiated radical polymerization of MTEOS sometimes induces unfavorable side reactions, such as the hydrolysis and condensation of the pendant triethoxysilyl groups.

Photoinitiated radical generation methods can polymerize vinyl monomers without heating. To generate primary radicals by photoirradiation, various wavelengths are selected in the UV and visible region. Side reactions can be prevented by choosing an irradiation wavelength that is not absorbed by the monomer. When MTEOS is polymerized by a photoinitiated radical polymerization, the hydrolysis and condensation side reactions are reduced to obtain a vinyl polymer containing pendant triethoxysilyl groups [26].

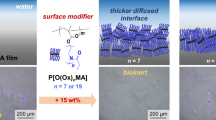

In this study, we prepared random copolymers (P(M100-m/T m )) composed of MPC and MTEOS via a photoinitiated radical polymerization (Fig. 1). To suppress protein fouling on the glass surface, the MPC units were covalently immobilized on the glass. The glass surface was spin-coated with P(M100-m/T m ) ethanol solutions, and then, the polymer film was immobilized by a condensation of the pendant triethoxysilyl groups with silanol on the glass surface. To confirm the immobilization of the polymers on the glass surface using fluorescence microscopy, we prepared pyrene-labeled random copolymers (P(M100-m-n/T m /Py n )). The adsorption behaviors of fluorescence-labeled proteins, bovine serum albumin (BSA), and fibrinogen (Fbg) on the polymer-coated glass were evaluated using fluorescence microscopy.

Experimental procedure

Materials

MPC was purchased from NOF (Tokyo, Japan) and recrystallized from acetonitrile [27]. MTEOS (98%, Tokyo Chemical Industry, Tokyo, Japan) was passed through an inhibitor removal column (Sigma-Aldrich, St Louis, MO, USA). N-(1-Pyrenylmethyl)methacrylamide (1-PyMAm) was synthesized according to a previously reported method [28]. n-Butyl methacrylate (BMA, 99.0%, Tokyo Chemical Industry) was dried over 4 Å molecular sieves and distilled under reduced pressure. The preparation method and characterization of a random copolymer (P(M78/B22)) composed of MPC and BMA are described in the Supplementary Information (Figure S1 and S2). Phenyl-bis(2,4,6-trimethylbenzoyl)phosphine oxide (BAPO, 96%, Tokyo Chemical Industry, Tokyo, Japan), Rhodamine 6 G (97%, Kanto Chemical, Tokyo, Japan), sodium dodecyl sulfate (SDS, 95%, Wako Pure Chemical, Osaka, Japan), bovine serum albumin Alexa Fluor 488 conjugate (488-BSA, Thermo Fisher Scientific, Kanagawa, Japan), fibrinogen from human plasma Alexa Fluor 488 conjugate (488-Fbg, Thermo Fisher Scientific, Kanagawa, Japan), and phosphate-buffered saline (PBS, Thermo Fisher Scientific, Kanagawa, Japan) were used without further purification. Ethanol and methanol were dried over 3 Å molecular sieves and then distilled. Water was purified with an ion-exchange column. Other reagents were used as received. The glass substrate (Okabe Co., Fukui, Japan), which was conventional float glass, was cut into 10 mm × 10 mm pieces with a thickness of 2 mm.

Synthesis of random copolymers (P(M100-m-n/T m /Py n ))

P(M50/T50) was prepared by the following method. MPC (5.90 g, 0.020 mol), MTEOS (5.81 g, 0.020 mol), and BAPO (45.1 mg, 0.108 mmol) were dissolved in ethanol (27.0 mL). The solution was deoxygenated with Ar gas for 30 min. It was then irradiated with a light-emitting diode (LED) lamp (LED-EXHD, Opto Code Corp., Tokyo, Japan) at λ = 420 nm and 1.72 mW/cm2 for 2 h with stirring at 25 °C. After the polymerization, the solution was dialyzed against methanol for 18 h. The dialyzed solution was poured into a large excess of mixed solvent of THF/n-hexane (1/9, v/v). The resulting polymer (P(M50/T50)) was dried under vacuum overnight (7.15 g, 61.1%). The MTEOS content in P(M50/T50), which was estimated from 1H NMR in methanol-d4, was 50.1 mol%. The number-average molecular weight (Mn) and molecular weight distribution (Mw/Mn) estimated from gel-permeation chromatography (GPC) for P(M50/T50) were 8.20 × 103 and 3.29, respectively. The synthetic route for the polymer is shown in Figure S3. P(M91/T9) with 9.0 mol% MTEOS was prepared by the method described above. Mn and Mw/Mn for P(M91/T9) were 2.83 × 104 and 2.10, respectively.

Pyrene-labeled polymers (P(M50/T49/Py1): Mn = 1.41 × 104 and Mw/Mn = 2.03, and P(M99/Py1): Mn = 3.36 × 104 and Mw/Mn = 3.85, were also prepared by the same method using 1-PyMAm. The MTEOS content in P(M50/T49/Py1) was 49.1 mol%. The 1-PyMAm contents for P(M50/T49/Py1) and P(M99/Py1), which were estimated from the UV–vis absorption spectra in ethanol, were both 1.0 mol%.

Surface coating of a glass substrate with random copolymers

The glass substrate (15 × 15 × 2 mm) was sonicated for 10 min in an aqueous solution containing Cleanace detergent (As One Co., Osaka, Japan) to remove surface impurities. The glass was rinsed with pure water and dried under a reduced pressure. The polymers were dissolved in ethanol at a concentration (Cp) of 10 g/L. The polymer solution (40 μL) was spin-coated on the glass substrate using a Mikasa (Tokyo, Japan) spin coater MS-A150. The spin speed was increased to 500 rpm over 10 s, increased from 500 to 2500 rpm over 30 s, and then kept constant at 2500 rpm for 30 s. Finally, the spinning was stopped for 15 s. To accelerate the reaction between the MTEOS unit and the glass substrate, the sample was exposed to NH3 vapor for 10 min. The polymers that were not attached to the glass substrate were rinsed off with methanol. The sample was dried under reduced pressure for 1 day at room temperature.

To confirm the presence of MPC units on the glass surface, an aqueous solution of Rhodamine 6 G (0.01 g/L, 40 µL) was dropped on the glass substrates with and without a polymer coating; the excess Rhodamine 6 G was washed off with water. The stained, glass substrates were observed with a fluorescence microscope.

Protein antifouling test

PBS solutions of 488-BSA and 488-Fbg (0.01 g/L, 40 µL) were dropped on glass substrates with and without a polymer coating. The glass substrate was allowed to stand for 2 h, washed, and immersed in PBS buffer for 5 min at 25 °C. The PBS buffer was replaced three times. The glass substrates that were in contact with the fluorescently labeled protein were observed using a fluorescence microscope.

Measurements

GPC measurements were performed using a Tosoh (Tokyo, Japan) DP-8020 pump and RI-8020 refractive index detector equipped with a Shodex (Tokyo, Japan) GF-1G guard column and GF-7 M HQ column (exclusion limit ~107) operating at 40 °C with a flow rate of 0.6 mL/min. Phosphate buffer (50 mM, pH 9) containing 10 vol% acetonitrile was used as the eluent. The sample solutions were filtered with a 0.2 µm pore size filter. The values of Mn and Mw/Mn were calibrated with standard sodium poly(styrenesulfonate) samples. The 1H NMR spectra were obtained using a Bruker (Karlsruhe, Germany) DRX-500 spectrometer operating at 500 MHz. The UV-vis absorption spectra were recorded on a Jasco (Tokyo, Japan) V-630 BIO spectrophotometer. The fluorescence spectra of P(M50/T49/Py1) and P(M99/Py1) in ethanol were recorded on a Hitachi (Tokyo, Japan) F-2500 fluorescence spectrophotometer. The excitation wavelength was 344 nm, and the slit widths for the emission and excitation were both 2.5 nm. Dynamic light scattering (DLS) measurements were performed using a Malvern (Worcestershire, UK) Zetasizer Nano ZS ZEN3600 instrument equipped with a He-Ne laser (632.8 nm, 4.0 mW) at 25 °C. The hydrodynamic radius (Rh) was obtained from the Stokes–Einstein relation: Rh = kBT/(6πηD), where kB is the Boltzmann constant, T is the absolute temperature, and η is the solvent viscosity. The water contact angles were measured using a sessile drop technique combined with a half-angle method. A 10 µL drop of water was placed on the glass substrate. An image of the drop was captured 10 s after the drop deposition. X-ray photoelectron spectroscopy (XPS) was performed using a Thermo Fisher Scientific (Kanagawa, Japan) ESCALab 250 spectrometer equipped with monochromatic AlK X-ray radiation (1486.6 eV) to investigate the elemental composition of the glass surface coated with the polymer. The XPS spectra were recorded at a take-off angle of 90°, and the system was operated at 15 kV and 200 W. Information about a 5–6 nm depth from the surface was obtained under these conditions. The background was removed using Thermo Fisher Scientific (Kanagawa, Japan) Advantage Analysis software. Atomic force microscopy (AFM) was conducted using a scanning force microscope equipped with an environment control scanner (Cypher ES; Asylum Research, Santa Barbara, USA). Topographic images were obtained in a contact mode at 25 °C with a back-side Au-coated silicon nitride triangular cantilever (OMCL-TR800PSA, Olympus Corporation, Tokyo, Japan; spring constant: 0.57 Nm−1, tip radius: less than 20 nm) under ambient conditions (25 °C, approximately 40% RH) or in a PBS buffer. The ambient and swollen thicknesses were determined from the height gap at a scratch track on the thin film. The scratch track was produced by scratching the film with a sharp needle. Fluorescence micrographs were obtained using a Keyence (Osaka, Japan) Biorevo BZ-8000 instrument equipped with a Nikon (Tokyo, Japan) Plan Fluor ELWD DM 20 × NAO 0.45 objective lens and dichroic mirror with excitation/emission = 480/510 nm and 540/605 nm, respectively.

Results and discussion

Condensation reactions of the pendant triethoxysilyl groups in MTEOS are promoted by heating. Condensation of MTEOS may occur between the pendant chains during heat-induced radical polymerization. In fact, when MTEOS was polymerized in ethanol at 60 °C for 15 h, the obtained polymer was not always soluble in ethanol, presumably because of the condensation reactions of the pendant triethoxysilyl groups.

P(M100-m-n/T m /Py n ) with different MTEOS and pyrene contents were prepared by photoinitiated radical polymerization at 25 °C to avoid thermally induced condensation reactions of the pendant triethoxysilyl groups in the MTEOS units. The polymerization was performed in ethanol with light irradiation at a wavelength of 420 nm for 2 h. Although BAPO can generate radicals upon light irradiation at a wavelength of 420 nm, the monomers are not affected because they do not absorb at this wavelength.

The GPC elution curves for P(M50/T50), P(M91/T9), and P(M50/T49/Py1) were unimodal (Figure S4), which indicated that the condensation reactions between the pendant triethoxysilyl groups in MTEOS units did not occur. The composition, Mn, and Mw/Mn of the random copolymers are summarized in Fig. 1.

Typical examples of the 1H NMR spectra for P(M50/T50), P(M91/T9), and P(M50/T49/Py1) in methanol-d4 are shown in Fig. 2. The composition was calculated from the integral intensity ratios of the pendant methylene protons in the MPC unit at 3.7 ppm to those of MTEOS at 0.7 ppm. The 1H NMR signals attributed to pyrene at approximately 8.0–8.5 ppm should be observed for P(M50/T49/Py1); however, these signals cannot be observed clearly due to their low intensities (Fig. 2c). Hence, the pyrene contents were estimated from the UV–vis absorption spectra. The pyrene contents of P(M50/T49/Py1) and P(M99/Py1) were both 1.0 mol%, as determined from the absorption spectra using the molar absorption coefficient of pyrene in ethanol (ε344 = 43,000 M−1 cm−1) [29]. The shape of the absorption and the fluorescence spectra of P(M50/T49/Py1) and P(M99/Py1) were the same as those before irradiation (Figure S5), which showed that 1-PyMAm was not affected by photoinitiated radical polymerization when light with a wavelength of 420 nm was used.

The glass substrate was spin-coated using an ethanol solution with the Cp = 10 g/L. DLS measurements were performed to confirm that no interpolymer aggregation occurred in ethanol (Figure S6). The Rh distributions for P(M50/T50), P(M91/T9), P(M50/T49/Py1), and P(M99/Py1) were measured in ethanol at Cp = 10 g/L. The Rh values for the copolymers were 8–9 nm with unimodal distributions. The MPC homopolymer is soluble in ethanol as a unimer. Interpolymer aggregation of P(M99/Py1) may not occur in ethanol because the hydrophobic unit content is low (1 mol%). Interpolymer aggregation of all the random copolymers may not occur in ethanol at Cp = 10 g/L because the Rh values for all the copolymers are 8–9 nm, which are close to the Rh (9 nm) for P(M99/Py1).

The contact angles of pure water were measured on the glass surfaces that were spin-coated with P(M100-m/T m ) and uncoated to study the surface properties (Fig. 3). The contact angle on the glass coated with P(M50/T50) is 26.3°, indicating that P(M50/T50)-coated glass is more hydrophobic than bare glass. This observation suggests that hydrophilic MPC and hydrophobic MTEOS, which cannot react with the glass surface, are exposed at the film-air interface. The contact angle on the glass coated with P(M91/T9) was small (15.0°) and similar to that on the bare glass. The small contact angle may be due to the low content of hydrophobic MTEOS in P(M91/T9). Fukazawa et al. [30] reported contact angles for poly(MPC-co−2-methacryloyloxy-4-azidobenzoate) and poly(MPC-co-n-butylmethacrylate) films on glass substrates of approximately 60° and 50°, respectively. Xu et al. [31] reported that the contact angle for a film on a glass substrate prepared with a random copolymer composed of MPC, n-butylmethacrylate, potassium methacryloyloxypropylsulfonate, and MTEOS was 13.4°. The contact angle of the P(M91/T9) film on the glass substrate was similar to that reported by Xu and co-workers.

The thickness of the polymer films on the glass substrate was measured using AFM (Figure S7). After spin-coating the polymers on the glass substrate, half the area of the polymer film was scratched off with a razor. The thicknesses of the P(M50/T50) and P(M91/T9) films were 241 and 145 nm, respectively (Table S1). The spin-coated P(M100-m/T m ) films exhibited a flat topography without large aggregates and defects. P(M50/T50) produced a thicker coating film than P(M91/T9), probably because of the high solution viscosity. The main target of this study is the preparation of protein antifouling polymer films in PBS. Protein antifouling studies were performed in PBS; these will be discussed later. Therefore, the polymer films in PBS were studied by AFM. Both films swelled in PBS due to the hydration of the charged groups in the MPC units [32]. The excluded volume of the surface-bound P(M100-m/T m ) chains increased with the hydration to promote thickening. The P(M91/T9) film showed more significant thickening than the P(M50/T50) films. The P(M91/T9) film thickness more than doubled from the ambient thickness, whereas the P(M50/T50) film thickness expanded to approximately 1.3 times the ambient thickness (Figure S7 and Table S1). The contrast in the degree of thickening is simply attributed to the composition of the copolymer. A higher MPC composition increases the thickening in the PBS buffer. The interface roughness in the topographic AFM image increased in the PBS buffer. The distribution of the molecular weight and monomer composition as well as the geometry of the siloxane network produced by the condensation of the pendant triethoxysilane groups led to interfacial roughening. The differences in the roughness between P(M50/T50) and P(M91/T9) were small in the PBS buffer compared with that in the dry state, presumably because the polymer chains were hydrated.

The surface elemental analysis of the bare glass, P(M91/T9), and P(M50/T50)-coated glass was performed by XPS (Fig. 4). The peaks attributed to nitrogen (N) and phosphorus (P) were observed at 403 and 133 eV, respectively for the polymer-coated glasses (Figs. 4b, c). These peaks were not observed for bare glass (Fig. 4a). Therefore, the glass was coated with P(M100-m/T m ). The take-off angle of the XPS measurements was fixed at 90° so that the composition of a region 5–6 nm from the surface could be analyzed. The thickness of the polymer film was more than 100 nm (Table S1). Therefore, the XPS data indicated only the composition of the polymer film, which was not affected by the glass substrate. The P and N contents attributed to the pendant phosphorylcholine group of the MPC units in P(M91/T9) and P(M50/T50) were close to the theoretical values calculated based on the chemical structure (Table 1). For example, the P contents of the P(M91/T9) film estimated from XPS and theory were 4.9 and 4.8 mol%, respectively. The silicon (Si) contents of the P(M91/T9) and P(M50/T50) films estimated from XPS measurements were larger than those predicted from the chemical structures. These results suggest that the hydrophobic MTEOS units tend to be localized at the air interface. When the polymer film was prepared, the MTEOS units tended to localize at the polymer film surface due to the hydrophobicity of the air-film interface [33].

The glass substrates were covered with P(M99/Py1) without MTEOS by a spin-coating method, rinsed with water several times, and subjected to fluorescence microscopy (Figure S8). Blue fluorescence from pyrene was not observed, showing that P(M99/Py1) did not exist in the glass surface. Therefore, the MTEOS unit that contains the pendant triethoxysilyl group is important for attaching the polymer to the glass. The glass was then covered with P(M50/T49/Py1) and rinsed. Half of the polymer film on the substrate was peeled off with a razor blade. Blue fluorescence from pyrene could be observed from the coated area (Fig. 5a), showing that P(M50/T49/Py1) remained on the glass surface.

Half of the films were peeled off the glass substrates that were coated with random copolymers with no fluorescence label, i.e., P(M50/T50) and P(M91/T9). The polymer-coated glass substrates that were stained with Rhodamine 6 G were observed with a fluorescence microscope (Figs. 5b, c). Rhodamine 6 G specifically adsorbs to MPC [34]. The presence of P(M100-m/T m ) on half of the glass substrates was confirmed by red fluorescence from the polymer-coated area. The fluorescence intensities of Rhodamine 6 G from the P(M50/T50) and P(M91/T9) films were almost independent of the MPC content. The differences in the number of MPC units on the glass surface cannot be evaluated from the Rhodamine 6 G fluorescence. A random copolymer (P(M78/B22)) composed of MPC and BMA was prepared via thermal-initiated conventional radical polymerization. P(M78/B22) was spin-coated on the glass substrate, and then, the polymer film was stained with Rhodamine 6 G. Excess Rhodamine 6 G was washed off with water and then observed using a fluorescence microscope (Figure S9). The P(M78/B22) film on the glass substrate cannot be observed because the polymer film may peel off. This observation indicates that the MTEOS unit, which acts as an anchoring part, should be introduced to the polymer to fix the film.

The durability of the polymer film on the glass substrate was evaluated. After spin-coating P(M50/T49/Py1) on the glass substrate, half the area of the film was scraped with a razor. The glass substrate was then soaked in a 0.01 M aqueous SDS solution for 3 days. The pyrene fluorescence intensity observed with a fluorescence microscope was compared to that before soaking (Figure S10). The relative fluorescence intensities before and after soaking were 65 and 79, respectively, under the same observation conditions. These fluorescence intensities were almost the same. Therefore, the polymer coating was stable against an aqueous SDS solution for at least 3 days because the pendant triethoxysilyl groups in MTEOS were covalently attached to the glass substrate.

BSA as a general protein and Fbg as a coagulation factor were used for adsorption experiments on the polymer-coated glass substrate. The glass substrates were covered with P(M50/T50) and P(M91/T9) by a spin-coating method, and half the polymer film was peeled off with a razor blade. PBS solutions of fluorescently labeled BSA and Fgb were dropped on the polymer-coated glass substrates and allowed to stand for 2 h. The glass was rinsed by immersion in PBS for 5 min. After washing three times, fluorescence microscopic measurements were performed (Fig. 6). Although no green fluorescence from the fluorescently labeled BSA and Fgb was observed for the halves coated with P(M100-m/T m ), it was observed in the uncoated areas. Therefore, the protein antifouling effect was confirmed for the polymer-coated area. The protein antifouling effects for P(M100-m/T m ) with different MPC contents may be similar because fluorescence from BSA was not observed for each area. Therefore, more than 50 mol% of MPC in the random copolymer is sufficient to prevent protein adsorption.

Conclusions

Random copolymers (P(M100-m/T m )) were prepared by a photoinitiated radical polymerization at room temperature without condensation of the pendant triethoxysilyl groups. MPC moieties were introduced to the glass surface using P(M100-m/T m ). The polymer-coated area on the glass substrate suppressed protein fouling. Similar protein antifouling properties were observed regardless of the MPC content of P(M100-m/T m ). The polymer film was stable on a glass surface even when soaked in an aqueous surfactant solution for 3 days. P(M100-m/T m ) is considered to be a suitable surface coating agent for glass substrates for biomedical applications.

References

Mathes J. Protein adsorption to vial surfaces - quantification, structural and mechanistic studies. Göttingen, Germany: Cuvillier Verlag; 2010.

Xu Y, Takai M, Konno T, Ishihara K. Microfluidic flow control on charged phospholipid polymer interface. Lab Chip. 2007;7:199–206.

Kihara T, Yoshida N, Mieda S, Fukazawa K, Nakamura C, Ishihara K, Miyake J. Nanoneedle surface modification with 2-methacryloyloxyethyl phosphorylcholine polymer to reduce nanospecific protein adsorption in a living cell. Nanobiotechnol. 2007;3:127–34.

Yang Z, Galloway JA, Yu H. Protein interactions with poly(ethylene glycol) self-assembled monolayers on glass substrates: diffusion and adsorption. Langmuir. 1999;15:8405–11.

Wazawa T, Kasturan YI, Nishikawa S, Iwane AH, Aoyama S. Grafting of poly(ethylene glycol) onto poly(acrylic acid)-coated glass for a protein-resistant surface. Anal Chem. 2006;78:2549–56.

Li M, Neoh KG, Xu LQ, Wang R, Kang ET, Lau T, Olszyna DP, Chiong E. Surface modification of silicone for biomedical applications requiring long-term antibacterial, antifouling, and hemocompatible properties. Langmuir. 2012;28:16408–22.

Ishihara K & Fukazawa K. In Phosphorus-based polymers: from synthesis to applications. (eds) Monge S & David G, Ch. 5, London: RSC; 2014. p. 68–96.

Ishihara K, Mu M, Konno T, Inoue Y, Fukazawa K. The unique hydration state of poly(2-methacryloyloxyethyl phosphorylcholine). J Biomat Sci Polym Ed. 2017;28:884–99.

Ishihara K, Mu M & Konno T. Water-soluble and amphiphilic phospholipid copolymers having 2-methacryloyloxyethyl phosphorylcholine units for the solubilization of bioactive compounds. J. Biomat. Sci. Polym. Ed. 1–19. https://doi.org/10.1080/09205063.2017.1377023).

Ueda T, Oshida H, Kurita K, Ishihara K, Nakabayashi N. Preparation of 2-methacryloyloxyethyl phosphorylcholine copolymers with alkyl methacrylates and their blood compatibility. Polym J. 1992;24:1259–69.

Iwata R, Suk-In P, Hoven VP, Takahara A, Akiyoshi K, Iwasaki Y. Control of nanobiointerfaces generated from well-defined biomimetic polymer brushes for protein and cell manipulations. Biomacromolecules. 2004;5:2308–14.

Feng W, Brash J, Zhu S. Atom-transfer radical grafting polymerization of 2-methacryloyloxyethyl phosphorylcholine from silicon wafer surfaces. J Polym Sci, Part A: Polym Chem. 2004;42:2931–42.

Feng W, Zhu S, Ishihara K, Brash JL. Adsorption of fibrinogen and lysozyme on silicon grafted with poly(2-methacryloyloxyethyl phosphorylcholine) via surface-initiated atom transfer radical polymerization. Langmuir. 2005;21:5980–7.

Inoue Y, Onodera Y, Ishihara K. Preparation of a thick polymer brush layer composed of poly(2-methacryloyloxyethyl phosphorylcholine) by surface-initiated atom transfer radical polymerization and analysis of protein adsorption resistance. Colloid Surf B. 2016;141:507–12.

Sakata S, Inoue Y, Ishihara K. Molecular interaction forces generated during the protein adsorption to well-defined polymer brush surfaces. Langmuir. 2015;31:3108–14.

Pereira AS, Sheikh S, Blaszykowski C, Pop-Georgievski O, Fedorov K, Thompson M, Rodriguez-Emmenegger C. Antifouling polymer brushes displaying antithrombogenic surface properties. Biomacromolecules. 2016;17:1179–85.

Yuan B, Chen Q, Ding WQ, Liu PS, Wu SS, Lin SC, Shen J, Gai Y. Copolymer coatings consisting of 2-methacryloyloxyethyl phosphorylcholine and 3-methacryloxypropyl trimethoxysilane via ATRP to improve cellulose biocompatibility. ACS Appl Mater Interfaces. 2012;4:4031–9.

Futamura K, Matsumoto R, Konno T, Takai M, Ishihara K. Rapid development of hydrophilicity and protein adsorption resistance by polymer surfaces bearing phosphorylcholine and naphthalene groups. Langmuir. 2008;24:10340–4.

Iwasaki Y, Takami U, Shinohara Y, Kurita K, Akiyoshi K. Selective biorecognition and preservation of cell function on carbohydrate-immobilized phosphorylcholine polymers. Biomacromolecules. 2007;8:2788–94.

Bi H, Zhong W, Meng S, Kong J, Yang P, Liu B. Construction of a biomimetic surface on microfluidic chips for biofouling resistance. Anal Chem. 2006;78:3399–405.

Razunguzwa TT, Warrier M, Timperman AT. ESI-MS compatible permanent coating of glass surfaces using poly (ethylene glycol)-terminated alkoxysilanes for capillary zone electrophoretic protein separations. Anal Chem. 2006;78:4326–33.

Sung D, Park S, Jon S. Facile immobilization of biomolecules onto various surfaces using epoxide-containing antibiofouling polymers. Langmuir. 2012;28:4507–14.

Gong M, Dang Y, Wang YB, Yang S, Winnik FM, Gong YK. Cell membrane mimetic films immobilized by synergistic grafting and crosslinking. Soft Matter. 2013;9:4501–8.

Brinker CJ, Scherer GW. Sol-Gel Science: The Physics and Chemistry of Sol-Gel Processing. San Diego, USA: Academic Press; 1990.

Jiang H, Zheng Z, Li Z, Wang X. Effects of temperature and solvent on the hydrolysis of alkoxysilane under alkaline conditions. Ind Eng Chem Res. 2006;45:8617–22.

Yagci Y, Jockusch S, Turro NJ. Photoinitiated polymerization: advances, challenges, and opportunities. Macromolecules. 2010;43:6245–60.

Ishihara K, Ueda T, Nakabayashi N. Preparation of phospholipid polylners and their properties as polymer hydrogel membranes. Polym J. 1990;22:355–60.

Yusa S, Sakakibara A, Yamamoto T, Morishima Y. Fluorescence studies of pH-responsive unimolecular micelles formed from amphiphilic polysulfonates possessing long-chain alkyl carboxyl pendants. Macromolecules. 2002;35:10182–8.

Yip J, Duhamel J, Qiu XP, Winnik FM. Long-range polymer chain dynamics of pyrene-labeled poly(N-isopropylacrylamide)s studied by fluorescence. Macromolecules. 2011;44:5363–72.

Fukazawa K, Ishihara K. Synthesis of photoreactive phospholipid polymers for use in versatile surface modification of various materials to obtain extreme wettability. Acs Appl Mater Interfaces. 2013;5:6832–6.

Xu Y, Takai M, Ishihara K. Protein adsorption and cell adhesion on cationic, neutral, and anionic 2-methacryloyloxyethyl phosphorylcholine copolymer surfaces. Biomaterials. 2009;30:4930–8.

Kobayashi M, Terayama Y, Kikuchi M, Takahara A. Chain dimensions and surface characterization of superhydrophilic polymer brushes with zwitterion side groups. Soft Matter. 2013;9:5138–48.

Krasowska M, Zawala J, Malysa K. Air at hydrophobic surfaces and kinetics of three phase contact formation. Adv Colloid Interface Sci. 2009;147-148:155–69.

Wang JH, Bartlett JD, Dunn AC, Small S, Willis SL, Driver MJ, Lewis AL. The use of rhodamine 6G and fluorescence microscopy in the evaluation of phospholipid‐based polymeric biomaterials. J Microsc. 2005;217:216–24.

Acknowledgements

This work was financially supported by a Grant-in-Aid for Scientific Research (17H03071 and 16K14008) from the Japan Society for the Promotion of Science (JSPS), JSPS Bilateral Joint Research Projects, and the Cooperative Research Program of “Network Joint Research Center for Materials and Devices (20174031).”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Rights and permissions

About this article

Cite this article

Honda, T., Nakao, A., Ishihara, K. et al. Polymer coating glass to improve the protein antifouling effect. Polym J 50, 381–388 (2018). https://doi.org/10.1038/s41428-018-0026-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-018-0026-x