Abstract

Two polyhydroxyalkanoate (PHA) copolymers, poly(3-hydroxybutyrate-co-3-hydroxy-3-phenylpropioate) [P(3HB-co-3H3PhP)] and poly(3-hydroxybutyrate-co-3-hydroxy-4-phenylbutyrate) [P(3HB-co-3H4PhB)], both bearing aromatic side chains, were biosynthesized by recombinant Ralstonia eutropha fed with a respective precursor for the aromatic unit. As bacterial PHA copolymers generally exhibit broad comonomer compositional distribution, the as-biosynthesized samples, P(3HB-co-18 mol% 3H3PhP) and P(3HB-co-11 mol% 3H4PhB), were fractionated into several fractions with narrow comonomer compositional distribution using a chloroform/n-hexane mixed solvent. When the fractionated samples were aged under ambient conditions, the P(3HB-co-3H3PhP) fraction with 12 mol% 3H3PhP exhibited a melting temperature (Tm) of 132–148 °C, whereas the fractions with 15–21 mol% 3H3PhP did not exhibit melting behavior. As for P(3HB-co-3H4PhB), all fractions with a range of 4–15 mol% 3H4PhB exhibited Tm in the range 105–151 °C. The glass transition temperature (Tg) of these copolymers increased with increasing aromatic unit content, and the highest Tg of 20 °C was observed for the fraction with 21 mol% 3H3PhP. On the basis of the results presented here, the effects of aromatic comonomers on the thermal properties of the resulting copolymers are discussed.

Similar content being viewed by others

Introduction

Currently, plastics are predominantly derived from petroleum—a non-renewable resource. These petroleum-derived plastics cause problems such as emission of carbondioxide into the atmosphere when incinerated and generation of increased persistent plastic wastes. In this context, biodegradable plastics made from renewable biomass attract attention as alternatives to petroleum-derived plastics. Polyhydroxyalkanoates (PHAs) are biodegradable polyesters that are synthesized by bacteria as an intracellular carbon storage material from renewable biomass such as sugars and plant oils.1, 2 The most common type of PHA is poly(3-hydroxybutyrate) [P(3HB)], which has a melting temperature (Tm) and a glass transition temperature (Tg) of 177 and 4 °C, respectively.3 The thermal properties of P(3HB) are similar to those of polypropylene; however, P(3HB) is a highly crystalline material with poor elasticity. Therefore, 3HB-based PHA copolymers that are flexible and ductile due to reduced crystallinity are preferred for practical uses.4

A variety of comonomers for the synthesis of 3HB-based PHA copolymers have been reported, for example, 3-hydroxyvalerate (3HV) with an ethyl group side chain,1 3-hydroxyhexanoate (3HHx) with a propyl group1 and 3-hydroxy-4-methylvalerate (3H4MV) with an iso-propyl group.5 As the comonomer content of the copolymers increases, both Tm and Tg of the polymer decrease due to reduced lamellar thickness and the increased polymer-free volume. In a previous study,6 we synthesized a copolymer of 3HB and 3-hydroxy-3-phenylpropionate (3H3PhP), P(3HB-co-3H3PhP), by recombinant Ralstonia eutropha fed with precursors for the aromatic unit. The 3H3PhP unit has a phenyl group side chain, and unlike 3HV, 3HHx and 3H4MV comonomers, the Tg of the resulting copolymer tends to increase with increasing 3H3PhP content. Therefore, P(3HB-co-3H3PhP) is an interesting example of a PHA copolymer, which can be used to study the relationship between the structure and thermal properties of PHA polymers.

It has previously been reported that bacterial PHA copolymers often have broad distributions of comonomer composition due to various physiological factors during PHA biosynthesis.7 Thus, fractionation of PHA copolymers using a mixture of solvent/non-solvent is used to obtain fractionated samples for further investigation of the relationship between comonomer composition distributions and thermal properties.8, 9, 10, 11, 12 Thus far, how comonomer compositional distributions affect the thermal properties of various PHA copolymers such as P(3HB-co-3HV),8, 9 P(3HB-co-3HHx)10, 11 and P(3HB-co-3H4MV)12 has been studied using the fractionation technique.

In this study, the aromatic PHA copolymer, P(3HB-co-3H3PhP), was biosynthesized by recombinant R. eutropha and fractionated into several fractions with narrow comonomer composition using a chloroform/n-hexane mixed solvent. In addition, a new aromatic PHA copolymer, poly(3HB-co-3-hydroxy-4-phenylbutyrate) [P(3HB-co-3H4PhB)], was biosynthesized for the first time by recombinant R. eutropha fed with a 3H4PhB precursor, and was also fractionated into several fractions in the same manner as P(3HB-co-3H3PhP). The thermal properties of the fractionated copolymers were analyzed by differential scanning calorimetry (DSC), and the relationships between the thermal properties and comonomer composition were investigated. The present study reveals the effects of aromatic comonomer types on the thermal properties and the possible range of comonomer composition that allowed the aromatic copolymers to crystallize at room temperature.

Experimental procedure

Bacterial strains, plasmid construction and PHA biosynthesis

The bacterial strains and plasmids used in this study are listed in Table 1. R. eutropha PHB-4 (DSM541), a PHA-negative mutant of strain H16,13, 14 was used as a host strain for genetic modifications aiming PHA biosynthesis. The PHA synthase 1 gene (phaC1Ps) with two amino-acid mutations (S325T and Q481K, STQK) from Pseudomonas sp. 61-3 was amplified with XbaI and BglII sites from pGEM′′phaC1(STQK)AB15, 16 by PCR with a primer pair of 5′-tagtctagaaataatttaactttaagaagg-3′ (forward) and 5′-ctaagatctttaacgttcatgcacatacg-3′ (reverse). The 1.8-kbp phaC1PsSTQK fragment was digested by XbaI and BglII, and inserted into pGEM′′ABexII16 at the corresponding sites to obtain pGEM′′C1Ps(STQK)ABReII. A plasmid pBBR1′′C1Ps(STQK)ABJ4bRe was constructed as follows: first, a 4.5-kbp BamHI fragment of pGEM′′C1Ps(STQK)ABReII was ligated with the same site of pBBR1MCS-217 to obtain pBBR1′′C1Ps(STQK)ABReII. Next, the stereospecific enoyl-CoA hydratase gene (phaJ4bRe)18 was amplified with XbaI and EcoRI sites from R. eutropha H16 genomic DNA using a PCR primer set (forward: 5′-tagtctagataggaagagcaagcatgaaga-3′, reverse: 5′-ctagaattctcagggaaagcgccgcaggat-3′). A 0.5-kbp XbaI/EcoRI-restricted fragment of phaJ4bRe was inserted into pBBR1′′C1Ps(STQK)ABReII at the corresponding sites, resulting in the construction of pBBR1′′C1Ps(STQK)ABJ4bRe.

The recombinant R. eutropha PHB-4 strains were cultivated in 1.7 ml nitrogen-rich medium (10 g Bacto tryptone, 2 g yeast extract and 10 g meat extract per liter of distilled water)14 at 30 °C for 15 h as a seed culture. The seed culture was inoculated into a 500 ml shake flask with 100 ml mineral salt medium (pH 7.0) containing 9 g of Na2HPO4•2O, 1.5 g of KH2PO4, 0.5 g of NH4Cl, 2 ml of MgSO4 and 1 ml of trace element solution per liter of distilled water19 supplemented with 20 g l−1 fructose and an aromatic monomer precursor. For the biosynthesis of P(3HB-co-3H3PhP) and P(3HB-co-3H4PhB) by R. eutropha strains, racemic 3-hydroxy-3-phenylpropionic acid and 4-phenylbutyric acid were used, respectively, as aromatic monomer precursors. Kanamycin was added to the mineral salt medium to maintain the expression plasmids. The cells were cultivated at 30 °C for 72 h and washed with water or a water/hexane mixed solvent to remove the remaining precursors and medium components before lyophilization.

Polymer extraction and solvent fractionation

PHA polymers were extracted from dried cells by stirring in chloroform for 72 h at room temperature, and recovered by precipitation with methanol. After collection, the PHA polymers were purified by reprecipitation with hexane and then finally purified by reprecipitation with methanol.

P(3HB-co-3H3PhP) and P(3HB-co-3H4PhB) samples were fractionated by the following procedure:12 First, the PHA copolymer was dissolved in chloroform at a concentration of 5 g l−1, and a predefined amount of n-hexane was added to the PHA copolymer solution under agitation at room temperature. When a deposit was visually observed, the mixed solution was kept at room temperature for 12 h. Next, the deposit fraction was separated by filtration and dried at room temperature. This procedure was repeated until a large amount of n-hexane had been added. The residual PHA in the supernatant solution with an excess of n-hexane was recovered by evaporation.

PHA analyses

The P(3HB-co-3H3PhP) content of the dried cells and its copolymer composition were determined by high-performance liquid chromatography.20 The dried cells were hydrolyzed under alkaline conditions prior to high-performance liquid chromatography analysis as follows: Approximately 10 mg of the lyophilized cells was hydrolyzed by 2 ml of 1 n KOH at 100 °C for 3 h, and then neutralized with 0.4 ml of 5 n HCl. During the reaction with the alkaline solution, PHA was converted to monomeric 2-alkenoic acids.20 The cell hydrolysates were filtered using a 0.45 μm cellulose acetate filter prior to high-performance liquid chromatography analysis. The monomeric samples were analyzed by high-performance liquid chromatography using a LC-10Avp system (Shimadzu, Kyoto, Japan) with an ion-exclusion column Aminex HPX-87H (Bio-Rad, Hercules, CA, USA) at 60 °C using 0.014 n H2SO4 with 9% CH3CN as the mobile phase. The resulting chromatograms were produced by measuring absorption at 210 nm using a UV detector.

The P(3HB-co-3H4PhB) content of the dried cells and its copolymer composition was determined by gas chromatography (GC14B, Shimadzu) with a flame ionization detector. Approximately 20 mg dried cells were methanolyzed in the presence of methanol containing 15% sulfuric acid before GC analysis.19

For purified PHA samples, the copolymer compositions were analyzed by nuclear magnetic resonance (NMR) spectroscopy. Each polymer (30 mg) was dissolved in CDCl3 (0.7 ml) and subjected to 500 MHz 1H NMR and 125 MHz 13C NMR analyses. NMR spectra were recorded using a JNM-LA500 spectrometer (JEOL, Tokyo, Japan) as described previously.6

For thermal analysis, PHA films were prepared by solvent casting using Petri dishes. For this, the PHA copolymer obtained from solvent fractionation was dissolved in chloroform and the polymer solution was poured into Petri dishes. The solvent was evaporated in draft chamber over several days, followed by aging for at least 3 weeks at room temperature (kept at around 25 °C by air conditioner) to reach equilibrium crystallinity prior to analysis. To analyze the PHA copolymers by DSC, 3 mg of PHA film was weighed and encapsulated in aluminum pans, and heated under nitrogen with a Perkin-Elmer Pyris 1 DSC (Perkin-Elmer, Waltham, MA, USA) from −50 to 200 °C at a heating rate of 20 °C per minute (first heating scan). The melt samples were then maintained at 200 °C for 1 min, followed by rapid quenching at −50 °C. The samples were then heated from −50 to 200 °C at a heating rate of 20 °C per minute under nitrogen atmosphere (second heating scan).

Results and discussion

Biosynthesis of P(3HB-co-3H3PhP)

We previously reported the biosynthesis of P(3HB-co-3H3PhP) by R. eutropha PHB-4 expressing wild-type PHA synthase (PhaC1Ps) from Pseudomonas sp. 61-3,6 which is capable of polymerizing both 3HB units and medium chain length 3HA units, unlike typical synthases from Pseudomonas strains polymerizing only medium chain length 3HA units.21 A maximum of 9 mol% of 3H3PhP content (determined by 1H-NMR) was previously achieved;6 however, the 3H3PhP content needs to be increased to study the relationship between the structure and thermal properties of the polymers. Thus, in this study, the engineered PHA synthase, PhaC1PsSTQK,15, 16 was adopted to enhance the incorporation of aromatic units into the PHA polymer chains, because PhaC1PsSTQK has been demonstrated to possess improved capability for the polymerization of various monomers due to two amino-acid mutations (S325T and Q481K, STQK).15, 16

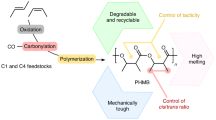

For P(3HB-co-3H3PhP) biosynthesis via the pathway shown in Figure 1, R. eutropha PHB-4 expressing PhaC1PsSTQK was cultured by feeding racemic 3-hydroxy-3-phenylpropionic acid as a 3H3PhP unit precursor. The 3-phenylpropionic acid was added at 0, 24 and 48 h to obtain a total concentration of 1.5 g l−1. The cultivation results are listed in Table 2.

Biosynthesis pathway for P(3HB-co-3H3PhP) and P(3HB-co-3H4PhB) copolymers. Subscripts ‘Re’ and ‘Ps’ denote R. eutropha and Pseudomonas sp. 61-3, respectively. PhaA, 3-ketothiorase; PhaB, acetoacetyl-CoA reductase; PhaC1, PHA synthase; PhaJ4b, stereospecific enoyl-CoA hydratase; 3HB, 3-hydroxybutyrate; 3H3PhP, 3-hydroxy-3-phenylpropionate; 3H4PhB, 3-hydroxy-4-phenylbutyrate.

By employing PhaC1PsSTQK, dry cell weight and PHA content were increased almost two-fold when compared with those of the previous strain expressing the wild-type enzyme. However, 3H3PhP content was only slightly increased from 13.9 to 15 mol%. It is known that 3HV and 3H4MV are incorporated into PHA copolymers when R. eutropha PHB-4 was employed as a production host.5, 6, 14 In the P(3HB-co-3H3PhP) synthesis, these minor comonomers were also detected; their contents were slightly decreased by changing the synthase from the wild-type enzyme to PhaC1PsSTQK.

To vary the 3H3PhP content, the effect of stereospecific enoyl-CoA hydratase (PhaJ4bRe), which catalyzes the enantioselective hydration reaction of trans-2-enoyl-CoA to 3-hydroxyacyl-CoA,18, 22, 23, 24, 25 on 3H3PhP unit supply was investigated (Figure 1). The reason why we selected PhaJ4bRe is because PhaJ4bRe showed higher hydration activity toward cinnamoyl-CoA than other several PhaJs in the preliminary tests (data not shown). The additional expression of PhaJ4bRe reduced the 3H3PhP fraction from 15 to 11.8 mol%. In an attempt to vary the relative 3H3PhP content by reducing the 3HB content, phaABRe genes were deleted from the plasmid. Contrary to our expectation, the 3H3PhP content was decreased from 11.8 to 9.4 mol% by this change. These results suggested that PhaJ4bRe might catalyze the reverse reaction from 3H3PhP-CoA to cinnamoyl-CoA in the P(3HB-co-3H3PhP) biosynthesis from racemic 3-phenylpropionic acid.

Biosynthesis of P(3HB-co-3H4PhB)

P(3HB-co-3H4PhB) biosynthesis, which has not been reported so far, was attempted by R. eutropha PHB-4 expressing PhaC1Ps fed with 4-phenylbutyric acid as a 3H4PhB precursor (Figure 1). 4-phenylbutyric acid was added at 0, 24 and 48 h with 1 g l−1 each to give a total concentration of 3 g l−1. The cultivation results are listed in Table 3.

Although the incorporation of 3H4PhB unit was observed even by the strain expressing the wild-type synthase from Pseudomonas sp. 61-3, the 3H4PhB content was too low. The use of PhaC1PsSTQK led to increase of the 3H4PhB content from 1.1 up to 6.2 mol%, accompanied by increase of the cellular content from 24 to 52 wt%. The 3HV and 3H4MV contents were again reduced to 0.2–0.3 mol% by the synthase replacement. Contrary to P(3HB-co-3H3PhP) biosynthesis, the 3H4PhB content was increased by the co-expression of PhaJ4bRe. This result implied that the flux from 4-phenylbutenoyl-CoA to 3H4PhB-CoA was reinforced by the function of PhaJ4bRe. Gene deletion of phaABRe from the plasmid slightly enhanced the 3H4PhB content, resulting in the highest 3H4PhB content of 11.7 mol%, whereas the PHA content was decreased by the expression of PhaJ4bRe and deletion of phaABRe genes.

Solvent fractionation of the aromatic copolymers

It is known that bacterial PHA copolymers occur as a mixture of various components of different compositions.7 Thus, the as-biosynthesized P(3HB-co-3H3PhP) and P(3HB-co-3H4PhB) with aromatic unit contents of 18 and 11 mol%, respectively, were subjected to fractionation treatment with a chloroform/n-hexane mixed solvent. As listed in Table 4, several fractions with different comonomer contents were obtained from the original samples. The aromatic unit content in the fractionated copolymers increased as the concentration of n-hexane used for fractionation increased. In contrast, the molecular weights of the fractionated copolymers decreased as the concentration of n-hexane increased. Thus, the solubility of these aromatic copolymers in chloroform/n-hexane mixed solvent would be the decisive factor in fractionation. The comonomer compositional and mass fractional distributions of copolymers after fractionation treatment are shown in Figure 2. The original samples were revealed to be composed of copolymer fractions with different comonomer compositions, and should, therefore, be considered natural polymer blends. The compositional distribution of the fractions in this study appeared to be narrower than those in previous studies.8, 9, 10, 11, 12 The diversity in compositional distribution is probably caused by changes in bacterial metabolism during PHA biosynthesis, induced by various factors such as availability of nutrients and dissolved oxygen, changes in pH and so on.

Randomness of the fractionated copolymers

Figure 3 shows the 13C NMR spectrum of the P(3HB-co-3H3PhP) copolymer with 21 mol% 3H3PhP, obtained by solvent fractionation (sample A-4). As shown in the expanded spectrum at 168–170 p.p.m., the carbonyl resonances of P(3HB-co-3H3PhP) were split into three peaks resulting from 3HB*−3HB, 3HB*−3H3PhP+3H3PhP*−3HB and 3H3PhP*−3H3PhP chain architectures. Using parameter D (=(3HB*−3HB) (3H3PhP*−3H3PhP)/(3HB*−3H3PhP) (3H3PhP*−3HB)26) for denoting the randomness of the copolymer, the chain architecture distribution was estimated from the ratios of carbonyl carbon resonance intensities. From the signal intensities, the values of D for the as-biosynthesized sample and fractionated sample A-4 were calculated as 2.0 and 1.1, respectively. The D value of the statistically random copolymer is 1.0; therefore, the fractionated sample was closer to a random copolymer than to the as-biosynthesized sample.

The P(3HB-co-3H4PhB) copolymer with 15 mol% 3H4PhB, obtained by solvent fractionation (sample B-3), was analyzed by 13C NMR. Each signal was assigned as shown in Figure 4 (unassigned signals at 27, 33, 35 and 142 p.p.m. may be from 3-hydroxy-6-phenylhexanoate unit biosynthesized by C2-elongation of 4-phenylbutyric acid). As shown in the expanded spectrum at 168–170 p.p.m., the carbonyl resonances of P(3HB-co-3H4PhB) were split into only two peaks, probably resulting from 3HB*−3HB+3HB*−3H4PhB and 3H4PhB*−3HB+3H4PhB*−3H4PhB chain architectures. Therefore, information about the 3HB*−3H4PhB and 3H4PhB*−3HB chain architectures was not obtained, resulting in a failure to determine the D value of the P(3HB-co-3H4PhB) copolymer.

Thermal properties of the fractionated aromatic copolymers

The solvent cast films of the as-biosynthesized and fractionated samples were aged at room temperature for at least 3 weeks. Subsequently, these samples were analyzed by DSC (Table 5). The first heating scan indicated that as-biosynthesized P(3HB-co-18 mol% 3H3PhP) was amorphous and did not exhibit a melting temperature (Tm) or enthalpy of fusion (ΔHm), whereas the as-biosynthesized P(3HB-co-11 mol% 3H4PhB) exhibited melting behavior. For fractionated copolymers during the first heating scan, melting behavior was observed for the fraction of P(3HB-co-3H3PhP) with 12 mol% 3H3PhP (A-1) and for all fractions of P(3HB-co-3H4PhB) (B-1 to 3). The Tm and ΔHm for the fractionated P(3HB-co-12 mol% 3H3PhP) (A-1) were detected to be 132–148 °C and 4 J g−1, respectively. Meanwhile, the fractionated P(3HB-co-3H4PhB) copolymers (B-1 to 3) exhibited Tm and ΔHm of 105–151 °C and 3–46 J g−1, respectively. These observations suggest that aromatic copolymers up to 12 mol% 3H3PhP and 15 mol% 3H4PhB still have a P(3HB) crystal phase when aged under ambient conditions.

Figure 5 shows the DSC thermograms of the aromatic copolymers during the second heating scan. The Tg of the fractionated P(3HB-co-3H3PhP) copolymers was in the range of 9–20 °C, whereas that of the fractionated P(3HB-co-3H4PhB) copolymers was in the range of 7–10 °C. By comparison with the Tg of P(3HB) (5 °C), the copolymers’ Tg was found to increase by the presence of aromatic side chains. During the second heating scan at 20 °C per minute, only two fractionated copolymers, 12 mol% 3H3PhP fraction (A-1) and 4 mol% 3H4PhB fraction (B-1), formed P(3HB) crystal phases. It is interesting to note that the 3H3PhP copolymer with 12 mol% 3H3PhP still exhibited crystallinity. However, because this sample was the first fraction obtained by the fractionation treatment, residual P(3HB) or low-content 3H3PhP copolymers coexisting in the fraction might facilitate the crystallization.

DSC thermogram (second scan) of as-biosynthesized and fractionated PHAs; (A) P(3HB-co-3H3PhP) copolymer; (B) P(3HB-co-3H4PhB) copolymer; (C) P(3HB). Copolymer compositions are listed in Table 4. DSC, differential scanning calorimetry; P(3HB), poly(3-hydroxybutyrate); PHA, polyhydroxyalkanoate; 3HB, 3-hydroxybutyrate; 3H3PhP, 3-hydroxy-3-phenylpropionate; 3H4PhB, 3-hydroxy-4-phenylbutyrate.

On the basis of the results obtained with the fractionated samples, the effects of aromatic side chains on Tm, ΔHm and Tg are compared with those of 3H4MV, which also has a bulky side chain structure (iso-propyl) and does not co-crystallize with 3HB.12 Figure 6 shows the dependency of the weight content of the comonomer units on thermal properties. Tm and ΔHm decreased as the 3H3PhP and 3H4PhB contents increased, which is a similar trend to that shown by 3H4MV. In contrast, Tg increased as the 3H3PhP and 3H4PhB contents increased, whereas Tg decreased as the 3H4MV content increased, which could be attributed to the rigidness of the 3H3PhP and 3H4PhB aromatic rings.

Melting temperature (Tm), glass transition temperature (Tg) and enthalpy of fusion (ΔHm) of P(3HB-co-3H3PhP), P(3HB-co-3H4PhB) and P(3HB-co-3H4MV). ▴, 3H3PhP; Δ, 3H4PhB; ●, 3H4MV. 3HB, 3-hydroxybutyrate; 3H3PhP, 3-hydroxy-3-phenylpropionate; 3H4MV, 3-hydroxy-4-methylvalerate; 3H4PhB, 3-hydroxy-4-phenylbutyrate.

Effects of the aromatic side group on Tg

Currently, P(3H3PhP) and P(3H4PhB) homopolymers cannot be biosynthesized; however, their Tg can be roughly estimated using the Fox equation27 and the Tg values of 3H3PhP and 3H4PhB copolymers. We estimated the Tg values of P(3H3PhP) and P(3H4PhB) to be 60 °C (333 K) and 27 °C (300 K), respectively, based on the Tg values of the fractionated copolymers with a high aromatic unit content (Table 5): P(3HB) (Tg=278 K, W3H3PhP or 3H4PhB=0), P(3HB-co-21 mol% 3H3PhP) (Tg=293 K, W3H3PhP=0.31) and P(3HB-co-15 mol% 3H4PhB) (Tg=283 K, W3H4PhB=0.25). The Tg of the P(3H3PhP) homopolymer estimated here is very close to a previous estimation (Tg=62 °C) using as-biosynthesized copolymers with up to 8.9 mol% 3H3PhP content.6 Our estimations suggest that the 3H3PhP unit would be more effective for increasing the Tg of biosynthesized PHA polymers than the 3H4PhB unit. However, it is worth noting that the fractionated copolymers with high aromatic unit contents had lower molecular weights than those with low aromatic unit contents (Table 4). The difference in the molecular weight should be considered for the accurate prediction of Tg, because the molecular weight of a polymer also influences its Tg.28

In general, an increase in the size of the side group in polymers causes steric hindrance and results in an increase in Tg. The thermal properties of as-biosynthesized PHA bearing bulky aromatic side chains have been studied previously.29, 30, 31, 32, 33 These results and our previous results6 suggest that increasing the alkyl chain length of the aromatic side group decreases the Tg of PHA, owing to the increase in the polymer-free volume. Therefore, Tg depends not only on the size of the side group but also on its rigidness. The side group rigidity would increase the hindrance to the main chain’s motion. In the present study, the phenyl side group of 3H3PhP is smaller in size than the benzyl side group of 3H4PhB, but the former is more rigid than the latter. Thus, 3H3PhP is more effective for increasing Tg than 3H4PhB.

Conclusions

Two PHA copolymers, P(3HB-co-3H3PhP) and P(3HB-co-3H4PhB), bearing aromatic side chains were biosynthesized by recombinant R. eutropha by feeding the corresponding aromatic precursors. This is the first report demonstrating P(3HB-co-3H4PhB) biosynthesis. In addition, 3H3PhP content in the P(3HB-co-3H3PhP) copolymer was increased from 9 mol% in a previous study to 18 mol% in this study by engineering the R. eutropha strain. The as-biosynthesized aromatic copolymers were fractionated into a series of fractions with different comonomer compositions. This suggested that the as-biosynthesized samples were natural blends of copolymers with different comonomer compositions. DSC analysis revealed that the copolymers with up to 12–15 mol% aromatic unit content exhibited melting behavior when aged under ambient conditions. Increasing the aromatic unit content increased the Tg, due to the rigidness of the side group in the copolymers. 3H3PhP was more effective in increasing Tg than 3H4PhB. The highest Tg of 20 °C was observed for a 21 mol% 3H3PhP copolymer. Because the as-biosynthesized PHAs were natural blends of copolymers with different compositional distributions, the solvent/non-solvent fractionation technique allowed for a more accurate evaluation of structure–thermal property relationships.

References

Sudesh, K., Abe, H. & Doi, Y. Synthesis, structure and properties of polyhydroxyalkanoates: biological polyesters. Prog. Polym. Sci. 25, 1503–1555 (2000).

Tsuge, T. Fundamental factors determining the molecular weight of polyhydroxyalkanoate during biosynthesis. Polym. J. 48, 1051–1057 (2016).

Tsuge, T. Metabolic improvements and use of inexpensive carbon sources in microbial production of polyhydroxyalkanoates. J. Biosci. Bioeng. 94, 579–584 (2002).

Noda, I., Green, P. R., Satkowski, M. M. & Schechtman, L. A. Preparation and properties of a novel class of polyhydroxyalkanoate copolymers. Biomacromolecules 6, 580–586 (2006).

Tanadchangsaeng, N., Kitagawa, A., Yamamoto, T., Abe, H. & Tsuge, T. Identification, biosynthesis, and characterization of polyhydroxyalkanoate copolymer consisting of 3-hydroxybutyrate and 3-hydroxy-4-methylvalerate. Biomacromolecules 10, 2866–2874 (2009).

Mizuno, S., Katsumata, S., Hiroe, A. & Tsuge, T. Biosynthesis and thermal characterization of polyhydroxyalkanoates bearing phenyl and phenylalkyl side groups. Polym. Degrad. Stab. 109, 379–384 (2014).

Feng, L., Yoshie, N., Asakawa, N. & Inoue, Y. Comonomer-unit compositions, physical properties and biodegradability of bacterial copolyhydroxyalkanoates. Macromol. Biosci. 4, 186–198 (2004).

Yoshie, N., Menju, H., Sato, H. & Inoue, Y. Complex composition distribution of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Macromolecules 28, 6516–6521 (1995).

Yamada, S., Wang, Y., Asakawa, N., Yoshie, N. & Inoue, Y. Crystalline structural change of bacterial poly(3-hydroxybutyrate-co-3-hydroxyvalerate) with narrow compositional distribution. Macromolecules 34, 4659–4661 (2001).

Watanabe, T., He, Y., Fukuchi, T. & Inoue, Y. Comonomer compositional distribution and thermal characteristics of bacterially synthesized poly(3-hydroxybutyrate-co-3-hydroxyhexanoate)s. Macromol. Biosci. 1, 75–83 (2001).

Feng, L., Watanabe, T., Wang, Y., Kichise, T., Fukuchi, T., Chen, G. Q., Doi, Y. & Inoue, Y. Studies on comonomer compositional distribution of bacterial poly(3-hydroxybutyrate-co-3-hydroxyhexanoate)s and thermal characteristics of their factions. Biomacromolecules 3, 1071–1077 (2002).

Tanadchangsaeng, N., Tsuge, T. & Abe, H. Comonomer compositional distribution, physical properties, and enzymatic degradability of bacterial poly(3-hydroxybutyrate-co-3-hydroxy-4-methylvalerate) copolyesters. Biomacromolecules 11, 1615–1622 (2010).

Raberg, M., Voigt, B., Hecker, M. & Steinbüchel, A. A closer look on the polyhydroxybutyrate-(PHB- negative phenotype of Ralstonia eutropha PHB-4. PLoS ONE 9, e95907 (2014).

Saika, A., Ushimaru, K., Mizuno, S. & Tsuge, T. Genome-based analysis and gene dosage studies provide new insight into 3-hydroxy-4-methylvalerate biosynthesis in Ralstonia eutropha. J. Bacteriol. 197, 1350–1359 (2015).

Takase, K., Taguchi, S. & Doi, Y. Enhanced synthesis of poly(3-hydroxybutyrate) in recombinant Escherichia coli by means of error-prone PCR mutagenesis, saturation mutagenesis, and in vitro recombination of the type II polyhydroxyalkanoate synthase gene. J. Biochem. 133, 139–145 (2003).

Takase, K., Matsumoto, K., Taguchi, S. & Doi, Y. Alteration of substrate chain-length specificity of type II synthase for polyhydroxyalkanoate biosynthesis by in vitro evolution: in vivo and in vitro enzyme assays. Biomacromolecules 5, 480–485 (2004).

Kovach, M. E., Elzer, P. H., Hill, D. S., Robertson, G. T., Farris, M. A., Roop, R. M. & Peterson, K. M. Four new derivatives of the broad-host-range cloning vector pBBR1MCS, carrying different antibiotic-resistance cassettes. Gene 166, 175–176 (1995).

Kawashima, Y., Cheng, W., Mifune, J., Orita, I., Nakamura, S. & Fukui, T. Characterization and functional analyses of R-specific enoyl coenzyme A hydratases in polyhydroxyalkanoate-producing Ralstonia eutropha. Appl. Environ. Microbiol. 78, 493–502 (2012).

Kato, M., Bao, H. J., Kang, C. K., Fukui, T. & Doi, Y. Production of a novel copolyester of 3-hydroxybutyric acid and medium-chain-length 3-hydroxyalkanoic acids by Pseudomonas sp. 61-3 from sugars. Appl. Microbiol. Biotechnol. 45, 363–370 (1996).

Watanabe, Y., Ichinomiya, Y., Shimada, D., Saika, A., Abe, H., Taguchi, S. & Tsuge, T. Development and validation of an HPLC-based screening method to acquire polyhydroxyalkanoate synthase mutants with altered substrate specificity. J. Biosci. Bioeng. 113, 286–292 (2012).

Matsusaki, H., Abe, H. & Doi, Y. Biosynthesis and properties of poly(3-hydroxybutyrate-co-3-hydroxyalkanoates) by recombinant strains of Pseudomonas sp. 61-3. Biomacromolecules 1, 17–22 (2000).

Sato, S., Nomura, C. T., Abe, H., Doi, Y. & Tsuge, T. Poly[(R-3-hydroxybutyrate] formation in Escherichia coli from glucose through an enoyl-CoA hydratase-mediated pathway. J. Biosci. Bioeng. 103, 38–44 (2007).

Tomizawa, S., Sato, S., Lan, J. C. W., Nakamura, Y., Abe, H. & Tsuge, T. In vitro evidence of chain transfer to tetraethylene glycols in enzymatic polymerization of polyhydroxyalkanoate. Appl. Microbiol. Biotechnol. 97, 4821–4829 (2013).

Thomson, N. M., Sangiambut, S., Ushimaru, K., Sivaniah, E. & Tsuge, T. Poly(hydroxyalkanoate) generation from nonchiral substrates using multiple enzyme immobilizations on peptide nanofibers. ACS Biomater. Sci. Eng. (2017). (in press). doi:10.1021/acsbiomaterials.6b00329

Tsuge, T., Taguchi, K., Taguchi, S. & Doi, Y. Molecular characterization and properties of (R-specific enoyl-CoA hydratases from Pseudomonas aeruginosa: metabolic tools for synthesis of polyhydroxyalkanoates via fatty acid β-oxidation. Int. J. Biol. Macromol. 31, 195–205 (2003).

Kamiya, N., Yamamoto, Y., Inoue, Y., Chujo, R. & Doi, Y. Microstructure of bacterially synthesized poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Macromolecules 22, 1676–1682 (1989).

Fox, T. G. Influence of diluent and of copolymer composition on the glass temperature of a polymer system. Bull. Am. Phys. Soc. 1, 123–135 (1956).

Fox, T. G. & Flory, P. J. Second-order transition temperatures and related properties of polystyrene. I. Influence of molecular weight. J. Appl. Phys. 21, 581–591 (1950).

Fritzsche, K., Lenz, R. W. & Fuller, R. C. An unusual bacterial polyester with a phenyl pendant group. Macromol. Chem. 191, 1957–1965 (1990).

Ward, P. G. & O’Connor, K. E. Bacterial synthesis of polyhydroxyalkanoates containing aromatic and aliphatic monomers by Pseudomonas putida CA-3. Int. J. Biol. Macromol. 35, 127–133 (2005).

Song, J., Choi, M., Yoon, S. & Huh, N. Cometabolism of ω-phenylalkanoic acids with butyric acid for efficient production of aromatic polyesters in Pseudomonas putida BMOl. J. Microbiol. Biotechnol. 11, 435–442 (2001).

Abraham, G. A., Gallardo, A., San Roman, J., Olivera, E. R., Jodra, R., García, B., Miñambres, B., García, J. L. & Luengo, J. M. Microbial synthesis of poly(β-hydroxyalkanoates) bearing phenyl groups from Pseudomonas putida: chemical structure and characterization. Biomacromolecules 2, 562–567 (2001).

Shen, R., Cai, L., Meng, D., Wu, L., Guo, K., Dong, G., Liu, L., Chen, J. C., Wu, Q. & Chen, G. Q. Benzene containing polyhydroxyalkanoates homo-and copolymers synthesized by genome edited Pseudomonas entomophila. Sci. China Life Sci. 57, 4–10 (2014).

Acknowledgements

This work was supported by a Grant-in-Aid for Scientific Research (KAKENHI 23658271) and partially supported by JST, CREST.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Mizuno, S., Hiroe, A., Fukui, T. et al. Fractionation and thermal characteristics of biosynthesized polyhydoxyalkanoates bearing aromatic groups as side chains. Polym J 49, 557–565 (2017). https://doi.org/10.1038/pj.2017.20

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2017.20

This article is cited by

-

Toward the production of block copolymers in microbial cells: achievements and perspectives

Applied Microbiology and Biotechnology (2024)

-

Biogeochemical properties of blue carbon sediments influence the distribution and monomer composition of bacterial polyhydroxyalkanoates (PHA)

Biogeochemistry (2023)

-

Biopolymer production in microbiology by application of metabolic engineering

Polymer Bulletin (2022)

-

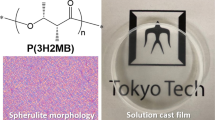

Thermal properties of poly(3-hydroxy-2-methylbutyrate-co-3-hydroxybutyrate) copolymers with narrow comonomer-unit compositional distributions

Polymer Journal (2021)

-

Established and Emerging Producers of PHA: Redefining the Possibility

Applied Biochemistry and Biotechnology (2021)