Abstract

Rapid progress has been made in realizing battery electrode materials with high capacity and long-term cyclability in the past decade. However, low first-cycle Coulombic efficiency as a result of the formation of a solid electrolyte interphase and Li trapping at the anodes, remains unresolved. Here we report LixSi–Li2O core–shell nanoparticles as an excellent prelithiation reagent with high specific capacity to compensate the first-cycle capacity loss. These nanoparticles are produced via a one-step thermal alloying process. LixSi–Li2O core–shell nanoparticles are processible in a slurry and exhibit high capacity under dry-air conditions with the protection of a Li2O passivation shell, indicating that these nanoparticles are potentially compatible with industrial battery fabrication processes. Both Si and graphite anodes are successfully prelithiated with these nanoparticles to achieve high first-cycle Coulombic efficiencies of 94% to >100%. The LixSi–Li2O core–shell nanoparticles enable the practical implementation of high-performance electrode materials in lithium-ion batteries.

Similar content being viewed by others

Introduction

Rechargeable lithium-ion batteries are widely used for consumer electronics and exhibit great potential for electrical vehicle and grid-scale energy storage1,2,3,4. The first charging process, in which lithium ions and electrons move from cathode to anode, is critical for lithium-ion battery operation. When the potential of the anode is below ~1 V versus Li metal, the organic electrolyte is reduced on the anode surface to form a layer of solid electrolyte interphase (SEI) that consists of a complex composition of inorganic and organic lithium compounds5,6,7,8. In addition, some lithium may be trapped in the electrode upon lithiation9. As a result, the first charging process irreversibly consumes a fraction of the lithium ions, giving rise to a net loss of storage capacity. Such first-cycle irreversible capacity loss is usually compensated by additional loading of cathode materials in current lithium-ion batteries. However, lithium metal-oxide cathodes have much lower specific capacity (mostly less than ~200 mAh g−1) than anodes3,10. Excessive loading of cathode material causes appreciable reduction of battery specific energy and energy density. It is therefore attractive to develop an alternative method that suppresses this loss and consequently increases the first-cycle Coulombic efficiency.

Addressing first-cycle capacity loss is an important step forward in the success of commercial graphite anodes. With graphite anodes, 5–20% of the lithium from the cathode is consumed to form the SEI, corresponding to an appreciable amount of inactivated cathode material. In the past two decades, the first-cycle Coulombic efficiency of graphite anodes has increased from <80% to 90–95% through optimization of material quality, electrolyte and additives11,12,13,14. Further improvement is likely to result from pre-compensation or prelithiation of the electrodes15.

Besides graphite anodes, prelithiation presents exciting opportunities for next-generation high-capacity anode materials such as Si, Ge and Sn, which have a large first-cycle capacity loss16,17. For example, Si is a particularly attractive anode material, owing to its high specific capacity of ~4,200 mAh g−1, excellent material abundance and well-developed industrial infrastructure for manufacturing16,18. In the past several years, there has been exciting progress in addressing the issues associated with large volume change (>300%) during lithium insertion and extraction by designing nanostructured Si including nanowires and core–shell nanowires19,20,21,22, hollow particles and tubes23,24,25, porous materials26,27, Si/C nanocomposites28,29,30 and by using novel binders31,32,33,34. One of the remaining issues for Si anodes is the large capacity loss in the first cycle. The first-cycle Coulombic efficiency is typically very low, in the range of 50–80%31,35,36,37, in spite of a few reports with higher values of ~85%38,39.

The first-cycle Coulombic efficiency can be improved by prelithiation. Anode prelithiation has been previously achieved by inducing electrical shorting between anode materials and lithium metal foil40,41. It requires a temporary battery to be fabricated, a process that is difficult to scale up. In addition, prelithiation of a thick electrode with Li foil is time consuming, as it requires the diffusion of Li ions across the entire anode. Another approach is to use stabilized lithium metal powder (SLMP), which is effective to pre-compensate the first-cycle irreversible capacity loss of different anode materials, such as graphite and silicon-carbon nanotube (Si–CNT) composite15,42,43,44. It is thus far the only prelithiation reagent in the powder form that can potentially be adopted during battery manufacturing, although practical challenges still exist to be addressed45. It is therefore highly desirable to develop alternative microparticles or nanoparticles (NPs) for prelithiation.

Herein, we demonstrate that chemically synthesized core–shell NPs of LixSi–Li2O (Fig. 1) as an excellent prelithiation reagent, which can be mixed with various anode materials during slurry processing. LixSi NPs exhibit multiple attractive properties for prelithiation: (1) fully lithiated LixSi alloy has a sufficiently low potential of around 10 mV versus Li/Li+ to prelithiate all types of anodes including graphite, Si, Ge and Sn16,18,46; (2) LixSi has very high specific capacity (4,200 mAh g−1 of Si, 2,000 mAh g−1 of Li4.4Si) for pre-storing lithium, so only a small percentage of material is needed for prelithiation; (3) nanoscale LixSi–Li2O particles (100~200 nm) are helpful for distributing pre-stored Li uniformly across the anodes. Furthermore, using nanoscale LixSi–Li2O particles as prelihitation reagent is less likely to disturb the whole structure of the electrode47; (4) nanoscale LixSi particles provide a localized lithium source to realize fast prelithiation of anode materials, compared with the process of inducing electrical shorting between anode materials and lithium metal foil; (5) potentially, LixSi can be benefit from the mature manufacturing infrastructure of the Si industry for scale-up and low-cost manufacturing.

A dense passivation layer is formed on the LixSi NPs after exposure to trace amounts of oxygen, preventing the LixSi alloy from further oxidation in dry air. As-synthesized LixSi–Li2O core–shell NPs, compatible with the existing battery-manufacturing environment, can be mixed with various anode materials during slurry processing and serve as an excellent prelithiation reagent.

Another challenge associated with anode prelithiation is the high chemical reactivity of prelithiation reagents, which make them difficult to survive multiple processing steps (exposure to air and solvents, slurry mixing, coating and baking) during battery electrode fabrication. A protective coating is therefore needed. However, this coating needs to be activated later to ensure quick lithium-ion diffusion for prelithiation. LixSi is a very reactive prelithiation reagent. In this paper, we also studied how to protect and de-protect it using a LixSi–Li2O core–shell nanostructure. The following findings in this paper are important to enable successful prelithiation: (1) The core–shell NPs rapidly react with solvents containing active protons such as water and alcohol. The slow reaction with oxygen, however, allows the formation of a dense Li2O shell that protects the LixSi core in dry-air environments over the long term. This is exciting since these NPs are compatible with the low-humidity environment of a dry room, commonly used in existing battery manufacturing; (2) for solvents without active protons, we found that LixSi can survive in low-polarity solvents such as ether and toluene during slurry processing. Highly polar solvents such as N-methyl-2-pyrrolidinone and organic carbonate can weaken the protection of the Li2O shell and react with the LixSi core, making them poor candidates for solvents in slurry processing. At the end of the battery assembly process, carbonate electrolyte is injected, directly resulting in the activation of the facile lithium diffusion into anode materials. To the best of our knowledge, this is the first report on prelithiation of anode materials with stabilized LixSi NPs.

Results

Synthesis and characterizations of LixSi–Li2O NPs

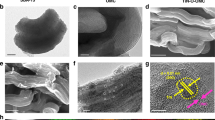

LixSi NPs were synthesized by mechanical stirring of a stoichiometric mixture (1:4.4) of Si NPs (~50 nm in diameter) and Li metal foil at 200 °C for 6 h in a glove box (Ar-atmosphere, H2O level <0.1 p.p.m. and O2 level <3 p.p.m.). In the process, the colour of the powder changes from brown to black, indicating the formation of the LixSi alloy. Owing to trace oxygen in the glove box, a dense Li2O passivation layer will form outside the LixSi NPs, resulting in the formation of LixSi–Li2O core–shell NPs and preventing LixSi from further oxidizing. The Li2O passivation layer was evidenced by extensive characterization. Transmission electron microscopy (TEM) images were taken immediately after exposure of the samples to the electron beam to minimize the impact of the electron beam on the NPs. The TEM image (Fig. 2a) and scanning electron microscopy (SEM) image (Supplementary Fig. 1a) show that the size of the LixSi NPs range from 100 to 200 nm, which is larger than the Si NPs (50 nm) due to volume expansion and some aggregation of particles during the alloying process. The magnified TEM image (Fig. 2b) shows a thin passivation layer (~10 nm thick) on the surface of the LixSi NPs.

(a) TEM image of LixSi–Li2O NPs. Scale bar, 200 nm. (b) Magnified TEM image reveals the core–shell nanostructure. (c) STEM image of LixSi–Li2O NPs, and (d) the corresponding EELS map of O distribution. Scale bar, 100 nm (b–d). (e) STEM image of LixSi–Li2O NPs. Corresponding EELS maps of (f) Li distribution and (g) Si distribution. Scale bar, 200 nm (e–g). (h) XRD pattern reveals the core–shell nanoparticles consisting of crystalline Li21Si5 and Li2O.

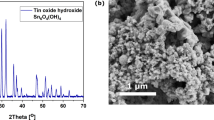

Compositional analysis of the LixSi NPs was acquired by electron energy loss spectroscopy (EELS) in the TEM. EELS is ideal for Li mapping, since the shallow Li K-edge has a high-ionization cross-section, which is about 10–100 times greater than that of other light elements such as oxygen48. Oxygen mapping is therefore performed with longer exposure time per step. Compared with the scanning transmission electron microscopy (STEM) image in Fig. 2c, the corresponding EELS oxygen map (Fig. 2d) reveals that oxygen is concentrated in the passivation layer of the core–shell NPs. To avoid possible beam damage through consecutive scans, a different region is selected for Li and Si mapping. STEM image (Fig. 2e) and corresponding EELS elemental mapping reveal the spatial distribution of Li (Fig. 2f) and Si (Fig. 2g), respectively. The specific electron energy loss spectra of Li, Si and O are shown in Supplementary Fig. 2. According to the elemental maps, Li is distributed throughout the entire nanoparticle, whereas Si is distributed in the internal part of the nanoparticle. Both images and elemental maps suggest that the NPs form a core–shell structure, consisting of a core of LixSi and a shell of Li2O. Furthermore, X-ray diffraction (XRD) of the product (Fig. 2h) reveals the crystalline nature of the core–shell NPs formed by Li21Si5 (PDF# 00-018-747) and Li2O (PDF# 04-001-8930). The broad background comes from the Kapton tape used to protect the samples from moisture in the air. Li21Si5, a variation of the Li22Si5 phase with ordered vacancies, is the most thermally stable phase among the crystalline lithium silicides46,49.

Electrochemical performance

To study the electrochemical properties of the LixSi–Li2O NPs, half cells were fabricated with Li metal as a counter electrode. LiPF6 (1.0 M) in a mixture of 1:1 w/w ethylene carbonate/diethyl carbonate, 10 vol% fluoroethylene carbonate and 1 vol% vinylene carbonate was used as the electrolyte. To find a proper solvent for the slurry process, LixSi–Li2O NPs were mixed with carbon black (Super P) and polyvinylidene fluoride (PVDF) (65:20:15 by weight) in different solvents to form a slurry, which was then drop cast on copper foil and dried under vacuum. The entire battery electrode preparation process from the slurry formation to drop casting and drying were performed in a dry-air glove box (dew point=−50 °C). The capacities of the resulting electrodes were studied by delithiating the samples to 1 V directly. Figure 3a shows that there is almost no Li capacity extracted from the LixSi–Li2O NPs processed with N-methyl-2-pyrrolidinone solvent. With diethyl carbonate solvent, the LixSi–Li2O NPs show a small Li extraction capacity of ~300 mAh g−1, indicating that most of the stored Li is not active. Excitingly, LixSi–Li2O NPs are compatible with 1,3-dioxolane (DOL) and toluene (Fig. 3a), showing high extraction capacities of 1,200–1,400 mAh g−1, which is sufficient to qualify it as a prelithiation reagent. It appears the highly polar functional groups can be attacked by free electrons in LixSi acting as a nucleophile. The detailed reaction mechanism is shown in Supplementary Fig. 3. Notice that PVDF binder does not dissolve in toluene to form a uniform slurry, so DOL is selected in the following experiments.

(a) First-cycle delithiation capacity of LixSi–Li2O NPs, using different solvents to form the slurry. (b) Galvanostatic discharge/charge profiles of LixSi–Li2O NPs in first and second cycles. (c) First-cycle voltage profiles of Si NPs/LixSi–Li2O and Si NPs show that the incorporation of LixSi–Li2O additive compensates the first-cycle capacity loss of Si NPs. (d) Cycling performance of LixSi–Li2O NPs, Si NPs/LixSi–Li2O and the control Si NPs at C/20 (1C=4.2 A g−1 Si, the capacity is based on the total mass of Si in the electrodes). The purple line is the Coulombic efficiency of Si NPs/LixSi–Li2O composite. (e) First-cycle voltage profiles of MCMB/LixSi–Li2O (81:9 by weight) show LixSi–Li2O NPs improve the first-cycle Coulombic efficiency of MCMB. The table shows that the first-cycle Coulombic efficiency is tuned by the amount of LixSi–Li2O additives. (f) Cycling performance of MCMB/LixSi–Li2O composites with different weight ratios at C/20 for first three cycles and C/5 for the following cycles (1C=0.372 A g−1 C, the capacity is based on the mass of the total active materials, including MCMB and Si in LixSi–Li2O NPs). The purple line is the Coulombic efficiency of MCMB/LixSi–Li2O composite (80:10 by weight).

To evaluate the electrochemical behaviour of the LixSi–Li2O NPs, normal deep galvanostatic lithiation/delithiation was used. Figure 3b shows the voltage profiles of the first and second cycles. LixSi–Li2O NPs were first lithiated to 0.01 V, and then delithiated to 1 V at a rate of C/20 (the specific capacity is calculated based on the mass of Si in the electrode. 1C=4.2 A g−1 Si). The open-circuit voltage (OCV) of LixSi–Li2O NPs was <0.2 V, which is significantly lower than that of crystalline Si NPs. The capacity preloaded into Si NPs is 1,310 mAh g−1, determined by subtracting the first lithiation capacity from the delithiation capacity. After the first cycle, the voltage profile is similar to normal Si anodes, but the second-cycle Coulombic efficiency of the LixSi–Li2O NPs is 96%, still higher than that of Si NPs (93%) (Supplementary Fig. 5a). During the slurry process, we believe that DOL will decompose on the surface of the LixSi–Li2O core–shell NPs to form a thin coating due to the strong reducing power of LixSi (Supplementary Fig. 1b). The reaction only consumes part of the Li stored in the LixSi–Li2O NPs, and a significant amount of electrochemically active Li is left to be used as the prelithiation reagent.

Figure 3c demonstrates that LixSi–Li2O NPs can be used as a prelithiation reagent to improve the first-cycle Coulombic efficiency of normal Si NP anodes. The anodes were made by forming a slurry of Si NPs, LixSi–Li2O NPs, carbon black and PVDF binder with a mass ratio of 50:15:20:15. The dimensions of the LixSi–Li2O NPs are the same as that of Si NPs, so the LixSi–Li2O NPs were more uniformly distributed in the electrode compared with large-size prelithiation reagent. After a coin cell was fabricated, 6 h was needed for the anode to reach equilibrium. The first-cycle voltage profile reveals an OCV of 0.27 V, much lower than that of the control cell, which indicates partial prelithiation of the Si NPs. The capacity of the LixSi–Li2O NPs compensates the irreversible capacity loss of the Si NPs in the first cycle. Therefore, the first-cycle Coulombic efficiency increased from 76 to 94%. In addition, the lithiation capacity due to SEI formation decreases, due to the pre-formation of SEI during the prelithiation process. The electrochemical cycling performance was evaluated using deep lithiation/delithiation cycling from 1 to 0.01 V. The LixSi–Li2O NPs exhibited improved cycling performance over Si NPs at C/20 as displayed in Fig. 3d. Using LixSi–Li2O NPs as anode material, enough void space formed during the delithiation will be pre-built into the electrode structure to accommodate the volume expansion during the next lithiation process. Accordingly, the introduction of LixSi–Li2O NPs into Si NP anodes did not affect the cycling performance of Si NPs (the specific capacity was based on the total mass of Si in the electrode. 1C=4.2 A g−1 Si). The cyclic voltammetry (CV) measurement of Si/LixSi–Li2O NPs (Supplementary Fig. 4b) also demonstrates the performance of Si anode is negligibly affected by the addition of prelithiation reagents.

LixSi–Li2O NPs can also be used to compensate the irreversible capacity loss of existing graphite anodes as shown in the first-cycle voltage profiles (Fig. 3e). Graphite anodes consisting of mesocarbon microbeads (MCMB) graphite and a PVDF binder (90:10 by weight) were measured in a voltage window from 0.005 to 2 V as a control. In Fig. 3e, the blue voltage profile reveals a sloping region between 0.7 and 0.2 V, corresponding to SEI formation during first-cycle lithiation. As a result, the apparent first lithiation capacity of MCMB graphite is higher than the theoretical capacity of graphite (372 mAh g−1), whereas the first-cycle Coulombic efficiency is just 75%. Prelithiation of the MCMB graphite by LixSi–Li2O NPs (mass ratio 81:9, red line) yields a first-cycle Coulombic efficiency of 99%. The electrochemical potential of the electrode is close to 0.3 V, indicating partial prelithiation of MCMB graphite. The incorporation of LixSi–Li2O NPs decreases the typical lithiation capacity, due to the pre-formation of SEI during the prelithiation process. CV of MCMB/LixSi–Li2O composites (blue) and MCMB graphite (red) shows consistent results (Supplementary Fig. 4c). As shown in the table in Fig. 3e, the first-cycle Coulombic efficiency of MCMB anodes can be adjusted by tuning the amount of LixSi–Li2O additive. The first-cycle Coulombic efficiency ranges from 96 to 104% by varying the mass ratio of MCMB to LixSi–Li2O NPs from 83:7 to 80:10. The MCMB/LixSi–Li2O composites (mass ratio of 83:7 and 80:10) exhibited stable cycling performance at C/20 for the first three cycles and C/5 for the following cycles (1C=372 mA g−1 C) as displayed in Fig. 3f. The specific capacity was based on the mass of MCMB graphite and Si in the LixSi–Li2O additives. The capacities of MCMB/LixSi–Li2O composites are slightly higher than that of the control graphite cell, contributed by the capacity stored in the LixSi–Li2O NPs. The incorporation of LixSi–Li2O NPs into the MCMB graphite electrode does not damage the structure of the electrode during cycling. As a result, the cycling performance of MCMB graphite is not affected. Furthermore, LixSi–Li2O additives also improve the second-cycle Coulombic efficiency of MCMB, and Coulombic efficiency of the subsequent cycles is comparable to cells without additives (Supplementary Fig. 5b). Prelithiation of graphite flakes by LixSi–Li2O NPs (mass ratio 83:7) shows consistent results, increased first-cycle coulombic efficiency from 87 to 99% (Supplementary Fig. 6a). Graphite/LiFePO4 full cells are used to investigate the effect of LixSi–Li2O particles on full cell performance. The SEM image and half-cell study of LiFePO4 are shown in Supplementary Fig. 7. One full cell consists of graphite flake anode prelithiated with LixSi–Li2O particles (graphite flakes:LixSi–Li2O:PVDF=83:7:10), whereas another one consists of an anode with regular graphite flakes (graphite flakes: PVDF=90:10). The cells are measured in the voltage window from 2.5 to 3.8 V at C/10 (Supplementary Fig. 8a). The rate and cell capacity are both presented based on the mass of LiFePO4 in the cathode. The blue voltage profile reveals a plateau between 2.6 and 3.2 V, corresponding to the SEI formation in the anode during charging. After incorporating LixSi–Li2O particles into the anode, the OCV before cycling is about 2.3 V, significantly higher than 0.8 V for regular full cell. As shown by the red voltage profile, the incorporation of LixSi–Li2O NPs compensates the irreversible Li consumption resulting from SEI formation. Accordingly, the first-cycle Coulombic efficiency increases from 77.6 to 90.8%. In the following cycles, the cell with LixSi–Li2O NPs consistently shows a higher capacity than the regular cell (Supplementary Fig. 8b).

Stability of LixSi–Li2O NPs

Figure 4a is a TEM image to show that the LixSi–Li2O core–shell nanostructure remains after 3 days of exposure to dry air (dew point=−50 °C), although a thicker passivation layer of ~20 nm is observed, as compared with the original 10-nm-thick layer. XRD (Fig. 4b) analysis confirms that the sample exposed to dry air for 3 days is still composed of crystalline Li21Si5 and Li2O. There is no obvious change in the XRD pattern as compared with the sample without exposure to dry air. The capacities of the LixSi–Li2O NPs exposed to dry air for different numbers of days were studied by delithiating the LixSi–Li2O NPs to 1 V directly (Fig. 4c). After exposure to dry air for 1 day, there is 1,175 mAh g−1 capacity, only a 9% decay from time zero. After 5 days of exposure, the LixSi–Li2O NPs still exhibit a capacity of 880 mAh g−1 (red line in Fig. 4c), showing high capacity retention of 70%. The capacity of the LixSi–Li2O NPs decays slowly with exposure time. The LixSi–Li2O NPs stored in dry air for various durations were added into MCMB graphite to optimize the first-cycle Coulombic efficiency (MCMB:LixSi–Li2O NPs=8:1 by weight). The corresponding cells were tested in the voltage window of 0.005–2 V. The first-cycle voltage profiles of the MCMB/LixSi–Li2O composites (Supplementary Fig. 9b) indicate that LixSi–Li2O NPs stored in dry air for 5 days are still active enough to prelithiate MCMB graphite, yielding a 20% improvement in the first-cycle Coulombic efficiency. More attractively, LixSi–Li2O NPs exhibit excellent dry-air stability even at elevated temperatures. MCMB/LixSi–Li2O composites baked at 45°C for 1 h in dry air exhibit a first-cycle Coulombic efficiency of 101.6%. LixSi–Li2O NPs after baking at 65 °C can still effectively prelithiate MCMB graphite to counteract the first-cycle capacity loss as shown in Supplementary Fig. 10. To test humidity stability, the LixSi–Li2O NPs were stored in an air box with different dew points for 6 h. The capacity of the samples in air with different humidities was studied by discharging the samples to 1 V directly (Fig. 4d). The electrochemical performance demonstrates that 6 h of exposure to air with dew point of −30 °C does not affect the capacity. Even in air with a dew point of −10 °C, the LixSi–Li2O NPs still exhibit a capacity of 819 mAh g−1. However, the LixSi–Li2O NPs were completely converted to LiOH under high humidity, as confirmed by the XRD pattern in Fig. 4b.

(a) TEM image of LixSi–Li2O NPs after 3 days of exposure to dry air. Scale bar, 100 nm. (b) XRD patterns of LixSi–Li2O NPs without exposure to dry air, exposed to dry air for 3 days and under ambient conditions. (c) The capacity retention of LixSi–Li2O NPs exposed to dry air with varying durations. The inset shows the trend of capacity decay. (d) The capacity retention of LixSi–Li2O NPs exposed to air at different humidity levels.

Discussion

Electrochemical characterization (Fig. 3b) shows that the amount of Li preloaded into the Si NPs is 1,310 mAh g−1 for Si. Li is partially consumed to form a Li2O passivation layer to protect LixSi from further oxidation. During the slurry process, DOL decomposes on the surface of the NPs to form a thin layer due to the strong reducing power of LixSi, further consuming a fraction of the Li. However, the remaining capacity of the LixSi–Li2O NPs is still sufficient as a prelithiation reagent, higher than most Li-rich cathode materials. Compared with the conventional approach of extra loading of cathode materials, prelithiation using LixSi–Li2O NPs more effectively increases the specific energy and energy density of batteries. LixSi–Li2O core–shell NPs can be mixed with various anode materials in the slurry process to achieve high first-cycle Coulombic effieiency. Nanoscale LixSi particles provide uniform and localized Li distribution to realize fast prelithiation of anode materials. Cycling performance of anode materials is negligibly affected by the addition of prelithiation reagents. The low material loading and particle dimensions are less likely to disturb the structure of the electrode. In addition, void spaces will be formed through delithiaion of the LixSi additive, which accommodates the volume expansion during the next lithiation process.

As shown in Fig. 4c, the capacity retention is 91% after exposure to dry air for 1 day indicating that the LixSi–Li2O NPs are sufficiently stable to go through the battery fabrication process in a dry room. LixSi–Li2O NPs exposed to dry air for 5 days are still active enough to prelithiate MCMB graphite, which yields a 20% improvement in the first-cycle Coulombic efficiency (red curve in Supplementary Fig. 9b), indicating the potential for long-term storage. We attribute the dry-air stability to the unique core–shell nanostructure. The dense Li2O passivation layer has a remarkable effect in preventing LixSi NPs from thermally oxidizing in dry air. The stabilized LixSi NPs are still sensitive to moisture. Increasing the stability of the LixSi alloy in moisture is an important field for future investigations.

In summary, we have demonstrated a one-step thermal alloying process to synthesize LixSi–Li2O core–shell NPs without using specialized capital equipment. These NPs exhibit high capacity under dry-air conditions with the protection of the Li2O passivation shell, indicating that LixSi–Li2O NPs are potentially compatible with industrial battery fabrication processes in a dry room. Both commercial Si NPs and graphite are prelithiated with LixSi–Li2O NPs, thereby remarkably increasing the first-cycle Coulombic efficiency. It suppresses the undesired consumption of Li from cathode materials during SEI formation. The approach is generally applicable to various anode materials involving complex nanostructures. In addition, the LixSi alloy also serves as a new anode material with the potential to pair with all high-capacity lithium-free cathodes for next-generation high-energy-density lithium-ion batteries.

Methods

Synthesis of LixSi–Li2O NPs

Si NPs (~50 nm, MTI Inc.) were dried under vacuum for 24 h to remove trapped water. Si NPs (140 mg) were mixed with 154 mg of Li metal foil (99.9%, Alfa Aesar). The LixSi NPs were synthesized by mixing the Si NPs and lithium foil at 200 °C under mechanical stirring for 6 h in a glove box (Ar-atmosphere, H2O level <0.1 p.p.m. and O2 level <3 p.p.m.).

Characterization

SEM and TEM images were taken using a FEI XL30 Sirion SEM and a FEI Tecnai G2 F20 X-TWIN, respectively. A FEI Titan 80–300 environmental TEM was employed for EELS mapping collection at an acceleration voltage of 300 kV. The energy resolution of the EELS spectrometer is about 0.9 eV as measured by the full width at half-maximum of the zero-loss peak. EELS mapping data was acquired using a C2 aperture size of 50 mm and a camera length of 48 mm. To minimize sample drift during the STEM EELS mapping, the mapping drift was corrected every 30 pixels. The energy window of the EELS was 40–145 eV for Li (Li K-edge, 54.7 eV) and Si (Si L2, 3 edge 99.2 eV) peaks and 510–615 eV for O (O K-edge, 532 eV) peak. XRD patterns were obtained on a PANalyticalX’Pert, Ni-filtered Cu Kα radiation. LixSi NPs are sensitive to ambient moisture so the samples were sealed with Kapton tape (DuPont) in the glove box before XRD characterization.

Electrochemical measurements

Si NPs (~50 nm, MTI Inc.), MCMB graphite (MTI Inc.), carbon black (Super P, TIMCAL, Switzerland) and PVDF binder (Kynar HSV 900) were dried under vacuum for 24 h to remove trapped water. To prepare the working electrodes, various materials were dispersed uniformly in DOL to form a slurry. (Anode materials and mass ratio are based on specific cells.) The slurry was then cast onto a thin copper foil and dried under vacuum. Coin-type cells (2,032) were assembled in an Ar-filled glove box using a Li metal foil as counter/reference electrode. The electrolyte is 1.0 M LiPF6 in 1:1 w/w ethylene carbonate/DEC (EMD Chemicals), 1 vol % vinylene carbonate and 10 vol% fluoroethylene carbonate (Novolyte Technologies). CV measurements were carried out on a BioLogic VMP3 system. Galvanostatic cycling was carried out using an MTI 8 Channel battery tester. The total mass loading of the Si-based anode was 0.7–1.0 mg cm−2 and a typical total mass loading of the graphite-based anode was 2.0–2.5 mg cm−2.

Additional information

How to cite this article: Zhao, J. et al. Dry-air-stable lithium silicide–lithium oxide core–shell nanoparticles as high-capacity prelithiation reagents. Nat. Commun. 5:5088 doi: 10.1038/ncomms6088 (2014).

References

Bruce, P. G., Freunberger, S. A., Hardwick, L. J. & Tarascon, J. M. Li-O2 and Li-S batteries with high energy storage. Nat. Mater. 11, 19–29 (2012).

Tarascon, J. M. & Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 414, 359–367 (2001).

Whittingham, M. S. Lithium batteries and cathode materials. Chem. Rev. 104, 4271–4301 (2004).

Choi, N. S. et al. Challenges facing lithium batteries and electrical double-layer capacitors. Angew. Chem. Int. Ed. 51, 9994–10024 (2012).

Aurbach, D. et al. The study of electrolyte-solutions based on ethylene and diethyl carbonates for rechargeable Li batteries. 2. Graphite-electrodes. J. Electrochem. Soc. 142, 2882–2890 (1995).

Verma, P., Maire, P. & Novak, P. A review of the features and analyses of the solid electrolyte interphase in Li-ion batteries. Electrochim. Acta 55, 6332–6341 (2010).

Zhang, X. R., Kostecki, R., Richardson, T. J., Pugh, J. K. & Ross, P. N. Electrochemical and infrared studies of the reduction of organic carbonates. J. Electrochem. Soc. 148, 1341–1345 (2001).

Downie, L. E., Nelson, K. J., Petibon, R., Chevrier, V. L. & Dahn, J. R. The impact of electrolyte additives determined using isothermal microcalorimetry. ECS Electrochem. Lett. 2, 106–109 (2013).

Liu, N. et al. A pomegranate-inspired nanoscale design for large-volume-change lithium battery anodes. Nat. Nanotech. 9, 187–192 (2014).

Armand, M. & Tarascon, J. M. Building better batteries. Nature 451, 652–657 (2008).

Arakawa, M. & Yamaki, J. I. The cathodic decomposition of propylene carbonate in lithium batteries. J. Electroanal. Chem. 219, 273–280 (1987).

Matsumura, Y., Wang, S. & Mondori, J. Mechanism leading to irreversible capacity loss in Li ion rechargeable batteries. J. Electrochem. Soc. 142, 2914–2918 (1995).

Xu, K. Nonaqueous liquid electrolytes for lithium-based rechargeable batteries. Chem. Rev. 104, 4303–4417 (2004).

Wang, D. Y., Sinha, N. N., Petibon, R., Burns, J. C. & Dahn, J. R. A systematic study of well-known electrolyte additives in LiCoO2/graphite pouch cells. J. Power Sources 251, 311–318 (2014).

Jarvis, C. R., Lain, M. J., Yakovleva, M. V. & Gao, Y. A prelithiated carbon anode for lithium-ion battery applications. J. Power Sources 162, 800–802 (2006).

Wu, H. & Cui, Y. Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today 7, 414–429 (2012).

Zhang, W. J. Lithium insertion/extraction mechanism in alloy anodes for lithium-ion batteries. J. Power Sources 196, 877–885 (2011).

McDowell, M. T., Lee, S. W., Nix, W. D. & Cui, Y. 25th Anniversary article: understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries. Adv. Mater. 25, 4966–4984 (2013).

Chan, C. K. et al. High-performance lithium battery anodes using silicon nanowires. Nat. Nanotech. 3, 31–35 (2008).

Xie, J., Yang, X. G., Zhou, S. & Wang, D. W. Comparing one- and two-dimensional heteronanostructures as silicon-based lithium ion battery anode materials. ACS Nano 5, 9225–9231 (2011).

Jeong, S. et al. Etched graphite with internally grown Si nanowires from pores as an anode for high density Li-ion batteries. Nano Lett. 13, 3403–3407 (2013).

Sim, S., Oh, P., Park, S. & Cho, J. Critical thickness of SiO2 coating layer on core@shell bulk@nanowire Si anode materials for Li-ion batteries. Adv. Mater. 25, 4498–4503 (2013).

Wu, H. et al. Stable cycling of double-walled silicon nanotube battery anodes through solid-electrolyte interphase control. Nat. Nanotech. 7, 309–314 (2012).

Yao, Y. et al. Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett. 11, 2949–2954 (2011).

Liu, N. et al. A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes. Nano Lett. 12, 3315–3321 (2012).

Liu, N. A., Huo, K. F., McDowell, M. T., Zhao, J. & Cui, Y. Rice husks as a sustainable source of nanostructured silicon for high performance Li-ion battery anodes. Sci. Rep. 3, 1919–1925 (2013).

Ge, M. Y. et al. Large-scale fabrication, 3D tomography, and lithium-ion battery application of porous silicon. Nano Lett. 14, 261–268 (2014).

Jung, D. S., Hwang, T. H., Park, S. B. & Choi, J. W. Spray drying method for large-scale and high-performance silicon negative electrodes in Li-ion batteries. Nano Lett. 13, 2092–2097 (2013).

Hwang, T. H., Lee, Y. M., Kong, B. S., Seo, J. S. & Choi, J. W. Electrospun core-shell fibers for robust silicon nanoparticle-based lithium ion battery anodes. Nano Lett. 12, 802–807 (2012).

Magasinski, A. et al. High-performance lithium-ion anodes using a hierarchical bottom-up approach. Nat. Mater. 9, 353–358 (2010).

Wu, H. et al. Stable Li-ion battery anodes by in-situ polymerization of conducting hydrogel to conformally coat silicon nanoparticles. Nat. Commun. 4, 1943–1948 (2013).

Koo, B. et al. A highly cross-linked polymeric binder for high-performance silicon negative electrodes in lithium ion batteries. Angew. Chem. Int. Ed. 51, 8762–8767 (2012).

Wu, M. Y. et al. Toward an ideal polymer binder design for high-capacity battery anodes. J. Am. Chem. Soc. 135, 12048–12056 (2013).

Liu, G. et al. Polymers with tailored electronic structure for high capacity lithium battery electrodes. Adv. Mater. 23, 4679–4683 (2011).

Wu, H. et al. Engineering empty space between Si nanoparticles for lithium-ion battery anodes. Nano Lett. 12, 904–909 (2012).

Hu, L. B. et al. Silicon-conductive nanopaper for Li-ion batteries. Nano Energy 2, 138–145 (2013).

Yi, R., Dai, F., Gordin, M. L., Chen, S. R. & Wang, D. H. Micro-sized Si-C composite with interconnected nanoscale building blocks as high-performance anodes for practical application in lithium-ion batteries. Adv. Energy Mater. 3, 295–300 (2013).

Cui, L. F., Ruffo, R., Chan, C. K., Peng, H. L. & Cui, Y. Crystalline-amorphous core-shell silicon nanowires for high capacity and high current battery electrodes. Nano Lett. 9, 491–495 (2009).

Yao, Y., Liu, N., McDowell, M. T., Pasta, M. & Cui, Y. Improving the cycling stability of silicon nanowire anodes with conducting polymer coatings. Energy Environ. Sci. 5, 7927–7930 (2012).

Liu, N. A., Hu, L. B., McDowell, M. T., Jackson, A. & Cui, Y. Prelithiated silicon nanowires as an anode for lithium ion batteries. ACS Nano 5, 6487–6493 (2011).

Hassoun, J. et al. A contribution to the progress of high energy batteries: a metal-free, lithium-ion, silicon-sulfur battery. J. Power Sources 202, 308–313 (2012).

Forney, M. W. et al. Pre-lithiation of silicon-carbon nanotube anodes using stabilized lithium metal powder. Nano Lett. 13, 4158–4163 (2013).

Wang, Z. H. et al. Application of stabilized lithium metal powder (SLMP (R)) in graphite anode—a high efficient prelithiation method for lithium-ion batteries. J. Power Sources 260, 57–61 (2014).

Xiang, B., Wang, L., Liu, G. & Minor, A. M. Electromechanical probing of Li/Li2CO3 core/shell particles in a TEM. J. Electrochem. Soc. 160, 415–419 (2013).

Wang, L., Fu, Y. B., Battaglia, V. S. & Liu, G. SBR-PVDF based binder for the application of SLMP in graphite anodes. RSC Adv. 3, 15022–15027 (2013).

Wang, C. M. et al. In situ TEM Investigation of congruent phase transition and structural evolution of nanostructured silicon/carbon anode for lithium ion batteries. Nano Lett. 12, 1624–1632 (2012).

Harris, S. J. & Lu, P. Effects of inhomogeneities-nanoscale to mesoscale-on the durability of Li-ion batteries. J. Phys. Chem. C 117, 6481–6492 (2013).

Wang, F. et al. Chemical distribution and bonding of lithium in intercalated graphite: identification with optimized electron energy loss spectroscopy. ACS Nano 5, 1190–1197 (2011).

Nesper, R. & Vonschnering, H. G. Li21Si5, a zintl phase as well as a hume-rothery phase. J. Solid State Chem. 70, 48–57 (1987).

Acknowledgements

Y.C. acknowledges the support from the Assistant Secretary for Energy Efficiency and Renewable Energy, Office of Vehicle Technologies of the US Department of Energy. H.-W.L. acknowledges support from the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology under NRF-2012R1A6A3A03038593. M.T.M. acknowledges the National Science Foundation Graduate Fellowship Program and the Stanford Graduate Fellowship Program. We thank Dr Zheng Chen, Dr Zhidan Zeng, Dr Hongwei Zhou, Dr Kai Yan, Jian He, Dr Desheng Kong and Denys Zhuo for helpful discussion.

Author information

Authors and Affiliations

Contributions

J.Z. and Y.C. conceived the concept. J.Z. carried out the synthesis and performed materials characterizations and electrochemical measurements. N.L., Z.L. and H.-W.L. conducted XRD, TEM and EELS mapping, respectively. M.T.M. inspired the synthesis method. J.Z., Z.L. and Y.C. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing financial interests.

Supplementary information

Supplementary Information

Supplementary Figures 1-10 (PDF 1077 kb)

Rights and permissions

About this article

Cite this article

Zhao, J., Lu, Z., Liu, N. et al. Dry-air-stable lithium silicide–lithium oxide core–shell nanoparticles as high-capacity prelithiation reagents. Nat Commun 5, 5088 (2014). https://doi.org/10.1038/ncomms6088

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/ncomms6088

This article is cited by

-

Dual function high efficiency silicon electrode prelithiation strategy

Ionics (2023)

-

Solid-state corrosion of lithium for prelithiation of SiOx-C composite anode with carbon-incorporated lithium phosphorus oxynitride

Nano Research (2023)

-

Li2S as a cathode additive to compensate for the irreversible capacity loss of lithium iron phosphate batteries

Ionics (2022)

-

Sandwich-like structure C/SiOx@graphene anode material with high electrochemical performance for lithium ion batteries

International Journal of Minerals, Metallurgy and Materials (2022)

-

Exploring the practical applications of silicon anodes: a review of silicon-based composites for lithium-ion batteries

Ionics (2022)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.