Abstract

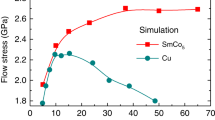

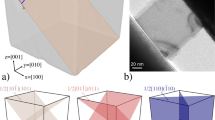

Nanocrystalline solids, in which the grain size is in the nanometre range, often have technologically interesting properties such as increased hardness and ductility. Nanocrystalline metals can be produced in several ways, among the most common of which are high-pressure compaction of nanometre-sized clusters and high-energy ball-milling1,2,3,4. The result is a polycrystalline metal with the grains randomly orientated. The hardness and yield stress ofthe material typically increase with decreasing grain size, a phenomenon known as the Hall–Petch effect5,6. Here we present computer simulations of the deformation of nanocrystalline copper, which show a softening with grain size (a reverse Hall–Petch effect3,7) for the smallest sizes. Most of the plastic deformation is due to a large number of small ‘sliding’ events of atomic planes at the grain boundaries, with only a minor part being caused by dislocation activity in the grains; the softening that we see at small grain sizes is therefore due to the larger fraction of atoms at grain boundaries. This softening will ultimately impose a limit on how strong nanocrystalline metals may become.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Siegel, R. W. in Encyclopedia of Applied PhysicsVol. 11, 173–199 (VCH, New York, 1994).

Siegel, R. W. What do we really know about the atomic-scale structure of nanophase materials? J. Phys. Chem. Solids 55, 1097–1106 (1994).

Siegel, R. W. & Fougere, G. E. in Nanophase Materials: Synthesis — Properties — Applications (eds Hadjipanayis, G. C. & Siegel, R. W.) 233–261 (NATO-ASI Ser. E, Vol. 260, Kluwer, Dordrecht, 1994).

Gleiter, H. in Mechanical Properties and Deformation Behavior of Materials Having Ultra-Fine Microstructures (ed. Nastasi, M.) 3–35 (Kluwer, Dordrecht, 1993).

Hall, E. O. The deformation and ageing of mild steel: III Discussion of results. Proc. Phys. Soc. Lond. B 64, 747–753 (1951).

Petch, N. J. The cleavage of polycrystals. J. Iron Steel Inst. 174, 25–28 (1953).

Chokshi, A. H., Rosen, A., Karch, J. & Gleiter, H. On the validity of the Hall–Petch relationship in nanocrystalline materials. Scripta Metall. 23, 1679–1684 (1989).

Voronoi, G. Z. Reine Angew. Math. 134, 199 (1908).

Jacobsen, K. W., Nørskov, J. K. & Puska, M. J. Interatomic interactions in the effective-medium theory. Phys. Rev. B 35, 7423–7442 (1987).

Jacobsen, K. W., Stoltze, P. & Nørskov, J. K. Asemi-empirical effective medium theory for metals and alloys. Surf. Sci. 366, 394–402 (1996).

Jónsson, H. & Andersen, H. C. Icosahedral ordering in the Lennard–Jones liquid and glass. Phys. Rev. Lett. 60, 2295–2298 (1988).

Clarke, A. S. & Jónsson, H. Structural changes accompanying densification of random-sphere packings. Phys. Rev. E 47, 3975–3984 (1993).

Gschneidner, K. A. Physical properties and interrelationships of metallic and semimetallic elements. Solid State Phys. 16, 275–426 (1964).

Shen, T. D., Koch, C. C., Tsui, T. Y. & Pharr, G. M. On the elastic moduli of nanocrystalline Fe, Cu, Ni, and Cu-Ni alloys prepared by mechanical milling/alloying. J. Mater. Res. 10, 2892–2896 (1995).

Kluge, M. D., Wolf, D., Lutsko, J. F. & Phillpot, S. R. Formalism for the calculation of local elastic constants at grain boundaries by means of atomistic simulation. J. Appl. Phys. 67, 2370–2379 (1990).

Phillpot, S. R., Wolf, D. & Gleiter, H. Molecular-dynamics study of the synthesis and characterization of a fully dense, three-dimensional nanocrystalline material. J. Appl. Phys. 78, 847–860 (1995).

Chokshi, A. H., Mukherjee, A. K. & Langdon, T. G. Superplasticity in advanced materials. Mater. Sci. Eng. R 10, 237–274 (1993).

Ridley, N. (ed.) Superplasticity: 60 years after Pearson (Institute of Metals, London, 1995).

Nieman, G. W., Weertman, J. R. & Siegel, R. W. Mechanical behavior of nanocrystalline Cu and Pd. J.Mater. Res. 6, 1012–1027 (1991).

Nieh, T. G. & Wadsworth, J. Hall–Petch relation in nanocrystalline solids. Scripta Met. Mater. 25, 955–958 (1991).

Lian, J., Baudelet, B. & Nazarov, A. A. Model for the prediction of the mechanical behaviour of nanocrystalline materials. Mater. Sci. Eng. A 172, 23–29 (1993).

Langdon, T. G. The significance of grain boundaries in the flow of polycrystalline materials. Mater. Sci. Forum 189–190;31–42 (1995).

Suryanarayanan, R. et al. Mechanical properties of nanocrystalline copper produced by solution-phase synthesis. J. Mater. Res. 11, 439–448 (1996).

Weertman, J. R. Hall–Petch strengthening in nanocrystalline metals. Mater. Sci. Eng. A 166, 161–167 (1993).

Van Swygenhoven, H. & Caro, A. Plastic behavior of nanophase Ni: A molecular dynamics computer simulation. Appl. Phys. Lett. 71, 1652–1654 (1997).

Acknowledgements

We thank J. K. Nørskov, T. Leffers, O. B. Pedersen, A. E. Carlsson and J. P. Sethna for discussions. The Center for Atomic-scale Materials Physics is sponsored by the Danish National Research Foundation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Schiøtz, J., Di Tolla, F. & Jacobsen, K. Softening of nanocrystalline metals at very small grain sizes. Nature 391, 561–563 (1998). https://doi.org/10.1038/35328

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1038/35328

This article is cited by

-

The reformation of catalyst: From a trial-and-error synthesis to rational design

Nano Research (2024)

-

Local chemical ordering coordinated thermal stability of nanograined high-entropy alloys

Rare Metals (2023)

-

Investigation of Microstructure and Mechanical Properties of Cast Al–10Zn–3.5Mg–2.5Cu Nanocomposite Reinforced with Graphene Nano Sheets Produced by Ultrasonic Assisted Stir Casting

International Journal of Metalcasting (2023)

-

Evidence of twinning-induced plasticity (TWIP) and ultrahigh hardness in additively-manufactured near-eutectic Ni–Nb

Journal of Materials Science (2023)

-

Atomistic study on high temperature creep of nanocrystalline 316L austenitic stainless steels

Acta Mechanica Sinica (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.