Abstract

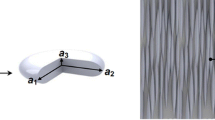

High energy synchrotron diffraction is introduced as a new method for residual stress analysis in the bulk of materials. It is shown that energy dispersive measurements are sufficiently precise so that strains as small 10−4 can be determined reliably. Due to the high intensity and the high parallelism of the high energy synchrotron radiation the sample gauge volume can be reduced to approximately 50 μm × 1 mm × 1 mm compared to gauge volume of one mm3 up to several mm3 achievable by neutron diffraction. The benefits of the high penetration depth and the small gauge volume are demonstrated by the results of stress studies performed on a fiber reinforced ceramic, a functional gradient material and a metal–ceramic compound. Furthermore, it is shown that in case of a cold extruded metal specimen the energy dispersive measurement technique yields simultaneous information about texture and residual stresses and thus allows a detailed investigation of elastic and plastic deformation gradients.

Similar content being viewed by others

REFERENCES

H. Ruppersberg and I. Detemple, Mater. Sci. Eng. A161: 41–44 (1993).

H. Ruppersberg, Adv. X-Ray Anal. 35: 481–487 (1992).

G. Brusch and W. Reimers, Proceedings of the ICRS 5, Linköping, Sweden, 1997, pp. 557–562.

M. Hutchings, Neutron News 3: 14–19 (1992).

L. Pintschovius, in Measurement of Residual and Applied Stress Using Neutron Diffraction, M. Hutchings and A. Krawitz, eds. (Kluwer Academic Publisher Dordrecht, Boston, London, 1989), pp. 115–128.

C. J. Bechtoldt, R. C. Placious, W. J. Boettinger, and M. Kuriyama Adv. X-Ray Anal. 25: 330–338 (1981).

R. D. Black, C. J. Bechtoldt, R. C. Placious, and M. Kuriyama, J. Nondestr. Eval. 5(1): 21–25 (1985).

J. Neuefeind and H. F. Poulsen, Phys. Scripta T57: 112–116 (1995).

H. F. Poulsen, S. Garbe, T. Lorentzen, D. J. Jensen, F. W. Poulsen, N. H. Andersen, T. Frello, R. Feidenhans, and H. Graafsma, preprint (submitted to J. Synchr. Radiat.).

M. R. Daymond and P. J. Withers, Scripta Mater. 35(10): 1229–1234 (1996).

P. J. Webster, X. D. Wang, and G. Mills, Mater. Sci. Forum 228–321: 227–232 (1996).

C. G. Windsor, in Measurement of Residual and Applied Stress Using Neutron Diffraction, M. Hutchings and A. Krawitz, eds. (Kluwer Academic Publisher Dordrecht, Boston, London, 1989), pp. 285–296.

T. Tschentscher and P. Suortti, J. Synchr. Radiat. (submitted).

P. Suortti and T. Tschentscher, Rev. Sci. Instr. 66(2): 1798–1801 (1995).

J. Chakrabarty, Theory of Plasticity (McGraw-Hill Book Company, New York, 1987), p. 129.

R. Ostertag and T. Haug, in Advanced Structural Inorganic Composites, P. Vincenzini, ed. (Elsevier Science Publishers, London, New York, 1991), pp. 469–477.

Y. M. Chiang, D. P. Birnie, and W. D. Kingery, Physical Ceramics-Principles for Ceramic Science and Engineering (John Wiley & Sons, New York, 1997), pp. 26–33.

P. Müller and E. Macherauch, Z. Angew. Phy. 13: 305–312 (1961).

G. Arlt and G. R. Schodder, J. Acoust. Soc. Am. 37: 384 (1965).

R. M. Martin, Phys. Rev. B 6: 4546 (1972).

B. H. Rabin, R. L. Williamson, and S. Suresh, MRS Bull. 20(1): 37–39 (1995).

G. Faninger and U. Hartmann, Härterei Technische Mitteilungen 27: 233–244 (1972).

Landolt-Börnstein, Numerical Data and Functional Relationships in Science and Technology, New Series Group III, Vol. 11, K. Hellwege, ed. (Springer Verlag, Berlin, Heidelberg, New York, 1979), p. 50.

U. Baron, T. Cosack, R. Elsing, P. Izquierdo, W. Reimers, G. Schäfer, T. Schmackers, C. Schwaminger, and M. Wildau, Abschlußbericht des BMBF-Projektes: Charakterisierung des Spannungs-Dehnungsverhaltens in Metall-keramischen Schichtverbunden, Fördernummer: 03M 2114 B.

O. T. Iancu and D. Munz, J. Am. Ceram. Soc. 73: 1144–1149 (1990).

G. Wassermann and J. Grewen, Texturen metallischer Werkstoffe (Springer Verlag, Berlin, 1962).

A. E. Tekkaya, Ermittlung von Eigenspannungen in der Kaltmasssivumformung, Thesis, Universität Stuttgart (1986).

A. Pyzalla and W. Reimers, in Competitive Advantages by Near-Net-Shape Manufacturing, H.-D. Kunze, ed. (DGM—Informationsgesellschaft Verlag, Oberursel, 1997), pp. 175–180.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Reimers, W., Broda, M., Brusch, G. et al. Evaluation of Residual Stresses in the Bulk of Materials by High Energy Synchrotron Diffraction. Journal of Nondestructive Evaluation 17, 129–140 (1998). https://doi.org/10.1023/A:1022607030355

Issue Date:

DOI: https://doi.org/10.1023/A:1022607030355