Abstract

The deformation behavior of the dual phase steel (DP1000 steel) was studied by the quasi-static tensile experiment and the dynamic tensile experiment. The experiments were carried out at strain rates ranging from 10−4 to 2 000 s−1 at room temperature. Then the stress-strain curves of DP1000 steel in the strain rate range of 10−4–2000 s−1 were measured. By introducing the strain rate sensitivity factor m, Zerilli-Armstrong model was optimized. The constitutive equation parameters which formulate the mechanical behavior of DP1000 steel were fitted based on the Johnson-Cook (JC) constitutive model and the optimized Zerilli-Armstrong (ZA) constitutive model, respectively. By comparing indicators of “accuracy-of-fit”, R2 terms, for the two models, the optimized Zerilli-Armstrong constitutive model can reflect plastic deformation behavior both at the low and high strain rates more accurately. The reasons why the optimized Zerilli-Armstrong constitutive model is more advantageous than the Johnson-Cook model were discussed by using the yield strength and ultimate tensile strength (UTS) versus strain rates, and strain hardening rate versus effective plastic strain analytical methods.

Similar content being viewed by others

References

Hayat F, Uzun H. Effect of Heat Treatment on Microstructure Mechanical Properties and Fracture Behaviour of Ship and Dual Phase Steels [J]. Journal of Iron and Steel Research, International, 2011, 18(8): 65.

LIU Ji-yuan, ZHANG Zi-cheng, ZHU Fu-xian, et al. Effect of Cooling Method on Microstructure and Mechanical Properties of Hot-Rolled C-Si-Mn TRIP Steel [J]. Journal of Iron and Steel Research, International, 2012, 19(1): 41.

Huseyin A, Havva K Z, Ceylan K. Effect of Intercrical Annealing Parameters on Dual Phase Behavior of Commercial Low-Alloyed Steels [J]. Journal of Iron and Steel Research, International, 2010, 17(4): 73.

HAN Qi-hang, KANG Yong-n, ZHAO Xian-meng, et al. Mcrostructure and Properies of Mo Microalloyed Cold Rolled DP1000 Steels [J]. Journal of Iron and Steel Research, International, 2011, 18(5): 52.

Meng Q G, Li J, Wang J, et al. Effect of Water Quenching Process on Microstructure and Tensile Properties of Low Alloy Cold Rolled Dual-Phase Steel J]. Materals and Design, 2009, 30(7): 2379.

Qu J B, Dabbouss W, Hassani F, et al. Effect of Microstructure on the Dynamic Deformation Behavior of Dual Phase Steel [J]. Materials Science and Engineering, 2008, 479A: 93.

Oliver S, Jones T B, Fourlaris G Dual Phase Versus TRIP Strip Steels: Microstructural Changes as a Consequence of Quasi-Static and Dynamic Tenile Testing [J]. Materials Characterization, 2007, 58: 390.

Oliver S, Jones T B, Fourlaris G Dual Phase Versus TRIP Strip Steels: Comparison of Dynamic Properties for Automotive Crash Performance [J]. Materials Science and Technology, 2007, 23(4): 423.

Hwang B C, Cao T Y, Shin S Y, et al. Effects of Ferrite Grain Size and Martensite Volume Fraction on Dynamic Deformation Behaviour of 0. 15C-2. 0Mn-0. 2Si Dual Phase Steels [J]. Materials Science and Technology, 2005, 21(8); 967.

Yang H S, Seong B S, Han S H, et al. Texture Evolution of Monolithic-Phase and Dual-Phase Steel Sheets During a Deep-Drawing Process [J]. Metals and Materials International, 2011, 17(3): 403.

Curtze S, Kuokkala V T, Hokka M, et al. Deformation Behavior of TRIP and DP Steels in Tension at Different Temperatures Over a Wide Range of Strain Rates [J]. Materials Science and Engineering, 2009, 507A: 124.

Vedantam K, Baaj D, Brar N S, et al. Johnson-Cook Strength Models for Mild and DP 590 Steels [C]// Michael D F, Elert M, Thomas P R, et al. Proc of the Conference of the American Physical Society Topical Group on Shock Compression of Condensed Matter. Baltimore, USA: AIP, 2005: 775.

Boyce B L, Dilmore M F The Dynamic Tenle Behavior of Tough, Ultrahigh-Strength Steels at Strain-Rates From 0. 000 2 s−1 to 200 s−1 [J]. International Journal of Impact Engineering, 2009, 362): 263.

Peixinho N, Pinho A Study of Viscoplastity Models for the Impact Behavior of High-Strength Steels [J]. Journal of Computational and Nonlinear Dynamics, 2007, 2(2); 114.

Bodner S R, Partom Y. Consitutive Equaions for Elasc-Vis co-plastic Strain-Hardening Materals [J]. Journal of Applied Mechanics, 1975, 42(1): 385.

Johnson G R, Cook W H A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures [C]// Proceedings of the Seventh International Symposium on Bllistic. Hague, Netherlands: International Ballistics Committee, 1983: 541.

Zerlli F J, Armtrong R W. Dio cation-Mechans-Based Consitutive Relations for Material Dynamics Calculations [J]. Journal of Applied Physics, 1987, 61(5): 1816.

Khan A S, Huang S. Experimental and Theoretical Study of Mechanical Behavior of 1100 Aluminum in the Strain Rate Range 10−5–10−4 s1 [J]. International Journal of Plastcity, 1992, 8: 397.

Liang R Q, Khan A S. A Cical Review of Experimental Results and Constitutive Models for BCC and FCC Metals Over a Wide Range of Strain Rates and Temperatures [J]. International Journal of Plasticity, 1999, 15: 963.

Kolsky H. An Investigation of the Mechanical Properies of Materials at Very High Rates of Loading [J]. Proceedings of the Physical Society. Section B, 1949, 62: 676.

Hopkinson B. A Method of Measuring the Pressure Produced in the Detonation of High Explosives or by the Impact of Bullets [J]. Philosophical Transactions, 1914, 213A: 437.

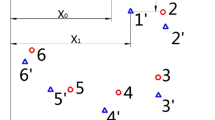

Huh H, Kang W J, Han S S. A Tenion Split Hopkinson Bar for Investigating the Dynamic Behavior of Sheet Metals [J]. Experimental Mechanics, 2002, 42(1): 8.

Staab G H, Glat A. A Direct-Tension Split Hopkinson Bar for High Strain-Rate Testing [J]. Journal of Experimental Mechanics, 1991, 31: 232.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation Item: Item Sponsored by National High Technology Research and Development Program (863 Program) of China (2009AA03Z518); Basic Theory Research Fund of Engineering Research Institute of USTB of China (YJ2010-006)

Rights and permissions

About this article

Cite this article

Song, Rb., Dai, Qf. Dynamic Deformation Behavior of Dual Phase Ferritic-Martensitic Steel at Strain Rates From 10−4 to 2000 s−1. J. Iron Steel Res. Int. 20, 48–53 (2013). https://doi.org/10.1016/S1006-706X(13)60140-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(13)60140-5