Abstract

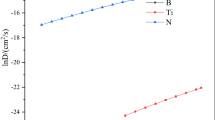

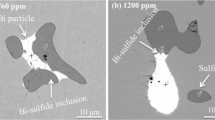

B2O3 was added to tire cord steel during refining in a carbon tube furnace. The influence of boron on the deformability of oxide inclusions was studied by metallographic and scanning electron microscope (SEM) observations. The melting points of boron-bearing compound oxide inclusions were calculated using Factsage software. The results showed that the main inclusion was a boron-bearing compound oxide and the deformation properties of the inclusions were clearly improved by adding B2O3. As the boron content was increased from 0.004 6% to 0.039%, the proportion of long strip type inclusions changed slightly and the number of inclusions decreased. The low-melting point areas of the MnO-SiO2-Al2O3 and CaO-SiO2-Al2O3 ternary system increased with the addition of B2O3. Moreover, the area increased with the increase of B2O3 content. Clear improvements in the deformation ability of the inclusions occurred when the B2O3 mass percent rose to 5% in the CaO-SiO2-Al2O3 inclusion system and to 10% in the MnO-SiO2-Al2O3 inclusion system.

Similar content being viewed by others

References

Central Iron and Steel Research Institute. Boron Steel Research Works Collection [M]. Beijing: Metallurgical Press, 1981 (in Chinese).

LI Wen-ying, CHEN Wei-qing, YUAN Hui. Investigation on Strain Aging of Boron Containing Low Carbon Steel Wire Rod [J]. Iron and Steel, 2006, 41(5), 78 (in Chinese).

YUAN Hui, LI Yong-dong, CHEN Wei-qing. Developmental History and Present Situation of Low-Carbon Steel With Boron [J]. Shougang Keji, 2005 (6), 21 (in Chinese).

XIAO Li-jun, QIU Sheng-tao, LIU Jia-qi, et al. Softening Mechanism of Low-Carbon Al-Killed Steel Strip Produced by TSCR Route [J]. Iron and Steel, 2006, 41(4): 66 (in Chinese).

FAN Ding-dong, ZHANG Jian-ping, XIAO Li-jun. Effect of Boron Micro-Alloying on Microstructure Precipitates and Yield Strength of SPHC Steel [J]. Iron and Steel, 2006, 41(9): 60 (in Chinese).

Fujimoto H, Soejima T, Matsumoto H. Development of ladle Arc Refining Process [J]. Iron and steel, 1988, 74(10): 74 (in Chinese).

Mimure T, Ogawa K, Maeda S. Shape Control of Inclusions in Wire Rods for Steel Tire Cord [J]. R and D Kobe Steel Technical Report, 1989, 39(4): 77.

YE Fei, CHEN Wei-qing, ZHOU Xin-long. Effect of Boron on Inclusion Morphology in Low Carbon Steel [J]. Iron and Steel, 2007, 42(10): 76 (in Chinese).

Ridal K A, Hughes J D H. Occurrence of Boron in Oxide Inclusions in Steel [J]. Journal of the Iron and Steel Institute, 1967, 205(2): 183.

Bernard G, Ribound P V, Urbain G. Oxide Inclusions Plasticity [J]. La Revue de Metallurgie-CTT, 1981, 78(5): 421.

Louis Rohl. The Manufacture and Use of Boron Steels in the U. S. A [J]. Journal of the Iron and Steel Institute, 1954, 176: 173.

ZU Rong-xiang. Influence of Carbon and Alloying Elements on the Properties of Spring Steel [J]. Journal of the Iron and Steel Institute, 1986, 6(4), 59 (in Chinese).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cui, Hz., Chen, Wq. Effect of Boron on Morphology of Inclusions in Tire Cord Steel. J. Iron Steel Res. Int. 19, 22–27 (2012). https://doi.org/10.1016/S1006-706X(12)60082-X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(12)60082-X