Abstract

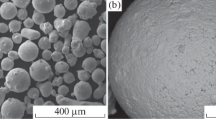

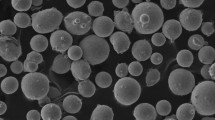

Multilayer of laser direct metal deposition (DMD) was prepared by depositing a gas atomized pre-alloyed powder with a composition close to Inconel 718 alloy on Inconel 718 high temperature alloy substrate. The effects of the DMD parameters on the build-up rate and the structure of the deposited layer were studied. The laser DMD sample was further processed by a solution treatment. The microstructure and property of the laser DMD zone before and after heat treatment were investigated as well. The results show that the laser parameters of actual laser power of 650 W, scanning speed of 5. 8 mm/s, beam diameter of 1 mm, powder feed rate of 6. 45 g/min, with a corresponding specific energy of 90–130 J/mm2, can be recommended as optimum parameters for high build-up rate of Inconel 718 alloy. Under the condition of optimized parameters, a directional solidification microstructure was obtained and the average distance between the columnar crystals was 5–10 μm. The microcomposition segregation was found between the columnar crystal trunk and columnar crystal. The elements of Nb, Mo, Ti concentrated in the columnar crystal trunk. After the heat treatment, the segregation was greatly minimized, and the segregation ratios were close to 1. The hardness of the laser deposited layer did not show obvious difference along the height of the layer either for the as-deposited layer or for the heat treated layer. However, the microhardness of the laser DMD zone after heat treatment was obviously higher than that after the as-deposited treatment. During the heat treatment process, some Nb- and Mo-rich phases precipitated and strengthened DMD layer.

Similar content being viewed by others

References

Strondl A, Fischer R, Frommeyer G, et al. Investigations of MX and γ′/γ′ Precipitates in the Nickel-Based Superalloy 718 Produced by Electron Beam Melting [J]. Materials Science and Engineering, 2008, 480A(1/2): 138.

Vander Voort G F, Lucas G M, Manilova E P. Metallography and Microstructures of Heat-Resistant Alloys [J]. Metallography and Microstructures, 2004, 9: 820.

Elliott A J, Pollock T M, Tin S, et al. Directional Solidification of Large Superalloy Castings With Radiation and Liquid-Metal Cooling: A Comparative Assessment [J]. Metallurgical and Materials Transactions, 2004, 35A(10): 3221.

YANG Sen, HUANG Wei-dong, LIU Wen-jin, et al. Research on Laser Rapid Directional Solidification With Ultra High Temperature Gradient [J]. Chinese Journal of Lasers, 2002, 29A(5): 475 (in Chinese).

ZHAO Xiao-ming, CHEN Jing, LIN Xin, et al. Study on Microstructure and Mechanical Properties of Laser Rapid Forming Inconel 718 [J]. Materials Science and Engineering, 2008, 478A(1/2): 119.

Qi H, Mazumde J, Green L, et al. Laser Beam Analysis in Direct Metal Deposition Process [J]. Journal of Laser Applications, 2005, 17(3): 136.

Mazumder J, Dutta D, Kikuchi N, et al. Closed Loop Direct Metal Deposition; Art to Part [J]. Optics and Lasers in Engineering, 2000, 34(4): 397.

Sexton L, Lavin S, Byrne G, et al. Laser Cladding of Aerospace Materials [J]. Journal of Materials Processing Technology, 2002, 122(1): 63.

Gaumann M, Bezencon C, Canalis P, et al. Single-Crystal Laser Deposition of Superalloys: Processing-Microstructure Maps [J]. Acta Materialia, 2001, 49(6): 1051.

FENG Li-ping, HUANG Wei-dong, LI Yan-min, et al. Investigation on the Microstructure and Composition Segregation of the Laser Metal Forming Directional Solidification [J]. Acta Metallurgica Sinica, 2002, 38(5): 501 (in Chinese).

Safari J, Nategh S. On the Heat Treatment of Rene-80 Nickel-Base Superalloy [J]. Journal of Materials Processing Techpology, 2000

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Ql., Yao, Jh. & Mazumder, J. Laser Direct Metal Deposition Technology and Microstructure and Composition Segregation of Inconel 718 Superalloy. J. Iron Steel Res. Int. 18, 73–78 (2011). https://doi.org/10.1016/S1006-706X(11)60054-X

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1016/S1006-706X(11)60054-X