Abstract

In the present study, a sensitive microfluidic paper-based analytical device (μ-PADs) integrated with adsorption enrichment procedure was developed to analyze Cr(VI) in water samples. The affecting factors, including pH and amounts of reagents were optimized. The limit of detection of 0.0015 mg L−1 and linear range of 0.005–2 mg L−1 were achieved with good intra- and inter-day precision of 5.1 and 7.6% RSD, respectively. The results obtained by the proposed method were validated by inductively coupled plasma-optical emission spectrometry (ICP-OES). The recoveries of the present method and ICP-OES were ranged from 96.3 to 109.0% and 106.0 to 109.7%, respectively. The two sets of (μ-PADs and ICP-OES) results were in a good agreement as paired t-test indicated no significant differences. The proposed method could be utilized for analyzing trace levels of Cr(VI) in water samples in the absence of conventional analytical instruments.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Aquatic systems have been contaminated by heavy metals over the past few decades [1]. The presence of heavy metal in the aquatic system is of great concern due to its toxicity and carcinogenic effects on human health and aquatic organism. Because heavy metals persist in nature, they can be dispersed in water, accumulated in plants and animals, and finally reached in human beings throughout the food chain or by drinking polluted water, causing several health problems [2]. Cr dissipates into the ecosystem from a variety of industrial activities such as electroplating, leather tanning, paint, paper, mining, textile dyeing, wood preserving, chromate preparation, dye industries, and metal finishing [3,4,5,6].

Cr species typically exist in natural ecosystems as Cr(III) and Cr(VI). However, these Cr species are drastically different in charge, physicochemical properties as well as in chemical and biochemical reactivity. Cr(III) is an essential micronutrient and generally absorbed by soil and precipitates in soil solutions, which may hamper its mobility and subsequent phytoaccumulation in the environment [2, 7, 8]. Conversely, Cr(VI) poses several environmental and health risks due its high toxicity, teratogenicity, carcinogenicity, and mutagenicity [9, 10]. Cr(VI) forms oxyanions, namely chromate (HCrO4−) and dichromate (Cr2O72−) which display high solubility, mobility, and strong oxidation tendencies [11,12,13]. Cr(VI) is thus highly dynamic in terrestrial and aquatic environments and has the potential to persist and remain concealed for longer duration in the natural environment [14, 15]. Thus, Cr(VI) poses a great threat to human health and the ecosystem and it is important to develop simple, sensitive, and cost-effective methods to detect trace levels of Cr(VI) in water, mainly in developing countries and remote areas.

Microfluidic paper-based analytical devices (μ-PADs) have a promising potential to address the aforementioned demands for environmental monitoring of heavy metals in developing countries [16,17,18]. The California Environmental Protection Agency has set the maximum contaminant levels of Cr(VI) at 0.010 mg L−1 in drinking water. However, the paper-based devices that have been so far developed have limitations for quantitative determination of Cr(VI) at 0.010 mg L−1 because of low sensitivity [18,19,20]. Therefore, the use of an enrichment procedure is substantially essential prior to Cr(VI) analysis using paper-based devices to enhance its analytical sensitivity. Previously, Alahmad et al. (2018, 2019) demonstrated paper-based methods coupled with liquid-phase microextraction and electro-membrane microextraction for quantitative determination of Cr(VI) at and below 0.010 mg L−1 [21, 22]. However, the use of liquid-phase microextraction and electro-membrane microextraction procedures would incur complexity, time, and cost.

Adsorption-based processes using aluminum hydroxide (Al(OH)3) has been reported for the Cr(VI) concentration determined by ICP-MS in the supernatant [23]. Cr(VI) is present as chromate anions in water so that it can be adsorbed on aluminum hydroxide precipitate [24, 25] due to the presence of aluminum species as AlOH2+ and Al8(OH)204+ in acidic solutions [26]. Al(OH)3 has a higher enrichment factor which can be prepared from readily available and low-cost chemicals, Al(NO3)3, and Na2CO3 [27]. The enrichment procedure can be associated with chromate anions adsorption on the Al(OH)3 precipitate surface [28]. Centrifugation process provides the separation of the adsorbent from the supernatant, and the adsorbent precipitate can be then dissolved in acids [27,28,29] to release Cr(VI). In paper-based methods, adsorption-based processes with Al(OH)3 has not been previously demonstrated for Cr(VI) assay. Recently, we have demonstrated the assay of Cu and Ni ions via combining colorimetric µ-PADs with co-precipitation [30, 31].

In the present study, we demonstrate detection of Cr(VI) using colorimetric µ-PADs coupled with adsorption enrichment technique. The adsorption enrichment under optimized conditions enabled quantitative detection of Cr(VI) in water samples with LOD and LOQ values of 0.0015 and 0.005 mg L−1, respectively. The results obtained by the proposed method were found to be in a good agreement with the ICP-OES measurements.

Experimental

Equipment and apparatus

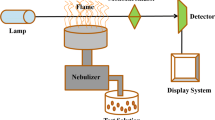

The pH meter (model D-52, HORIBA, Kyoto, Japan) was used for precise pH measurements. The centrifugal machine (Model 3740, KUBOTA, Tokyo, Japan) was employed to separate the adsorbent part from the supernatant. The μ-PADs were fabricated on a sheet of filter paper (200 × 200 mm, Chromatography Paper 1CHR, WhatmanTM, GE Healthcare Lifesciences, UK) by printing with a wax printer (ColorQube 8580N, Xerox, CT, USA). The printed sheets were heated using a drying machine (ONW-300S, AS ONE, Tokyo, Japan) to penetrate wax to the backside of the sheets. The desktop scanner (Canon MG 6300 Series, Tokyo, Japan) was employed to capture images of the μ-PADs that were dried before scanning. Inductively coupled plasma-optical emission spectrometry (ICP-OES) (Model VISTA-PRO, Seiko Electronics, Tokyo, Japan) was also used to determine Cr.

Reagents and chemicals

All reagents used in this study were of analytical grade and used as received. All solutions were prepared with deionized water purified by means of an Elix water purification system (Millipore Co., Ltd., Molsheim, France). Sodium carbonate and nitric acid were obtained from Kanto chemical co. Inc. (Tokyo, Japan). Potassium dichromate (K2Cr2O7) and 1,5-diphenylcarbazide (DPC) were obtained from Nacalai Tesque (Kyoto, Japan). Methanol and Iron(III) chloride anhydrous were obtained from Sigma-Aldrich (MO, USA) and Alfa Aesar (WH, USA), respectively. Cobalt(II) nitrate hexahydrate, magnesium sulfate, barium chloride dehydrate, aluminum nitratenonahydrate, sodium acetate, acetic acid, sodium hydroxide, hydrochloric acid, phosphate buffer, and standard solution of copper, zinc, and calcium were obtained from Wako Pure Chemical Industries (Osaka, Japan). The standard solutions of nickel and manganese were obtained from Kishida Chemicals (Osaka, Japan). The mineral water sample was purchased from a local store at the Okayama University, Japan. The tap water samples were obtained from an outlet at the Analytical Chemistry Group, Department of Chemistry, Graduate School of Natural Science and Technology, Okayama University, Okayama, Japan.

Cr(VI) adsorption enrichment process

As shown in Fig. 1, the adsorption enrichment procedure was developed for enhancing the sensitivity of Cr(VI) detection using µ-PADs. Thus, 14 mL of sample/standard solution was used in this procedure. As per optimized experimental conditions, the same volume (40 μL) and concentration (1 M) of Al(NO3)3 and Na2CO3 were added to the 15 mL centrifuge tube containing aliquots of sample solution (Fig. 1A, B). The resulted mixture of Al(NO3)3 and Na2CO3 adjusted the pH to 4.55 and showed a cloudy suspension of Al(OH)3 (Fig. 1B). The resulting solution was turned up and down for mixing, followed by centrifugation at 4000 rpm for 5 min and the light orange precipitate settled at the bottom of the clear supernatant (Fig. 1C). The adsorbent, white Al(OH)3 precipitate, turned to light orange due to adsorption of Cr(VI). The supernatant was decanted, and any residual water was removed with a micropipette. The precipitate was dissolved with 8 µL of 6 M HNO3 followed by pH adjustment with 8 µL of 6 M sodium acetate. For Cr(VI) assay (Fig. 1D), 10 µL of sample solution was loaded on the sample zone of the µ-PADs.

Cr(VI) enrichment procedure via adsorption on Al(OH)3 precipitate and its subsequent analysis, A sample solution containing Al(NO3)3 with no change in clarity, B carbonate addition resulted in cloudy suspension, C centrifugation resulted in light orange adsorbent with clear supernatant, D sample introduction on pre-loaded μ-PADs with reagents, E development of visual signal on detection zones, and F image analysis using ImageJ software

Design and fabrication of the μ-PAD

The μ-PAD design and dimensions are described in Fig. 1D, and our previously reported design, dimensions, and techniques were used for device fabrication [30]. The pattern of the μ-PADs was drawn using Microsoft Office PowerPoint 2010. The μ-PADs consisted of a sample zone attached to three channels that led to three detection zones for triplicate measurements and one control zone as a visual control (Fig. 1D). The μ-PADs have a height of 17 mm, a width of 20 mm, and a sample zone diameter of 6 mm at the center; there are also channels with a width of 2 mm and a length of 3 mm along with detection zones with diameters of 4 mm. The designed μ-PADs were printed using a wax printer on a sheet of filter paper (200 × 200 mm), followed by heating at 120 °C for 2 min in a drying machine to melt the wax ink to create a hydrophobic barrier as described in previous studies [16, 32,33,34,35]. The bottom of the printed paper was covered with clear packing tape to avoid leakage of the solutions through the bottom of the μ-PADs during the analysis.

Cr(VI) assay and image processing

The Cr(VI) assay is based on the formation of a complex compound between Cr(VI) with DPC at acidic pH [33, 36]. As per optimized experimental conditions, the μ-PADs were prepared by adding 0.25 µL of 50 mM DPC in methanol twice and 0.5 µL of pH 6 acetate buffer diluted with 0.1 M NaOH once on detection zones of µ-PADs. After drying the reagent solutions on the μ-PADs (Fig. 1D), 10 μL of a sample/standard solution was introduced to the sample zone. When the solution reached the detection zones by capillary action, the immediate appearance of a purple color was visible to the naked eye (Fig. 1E). The devices were then allowed to dry at room temperature and then a desktop scanner was used to capture images developed on the μ-PADs for quantitative analysis. The scanned images of the μ-PADs were stored in JPG format at 600 dpi resolution. The mean color intensity was measured using ImageJ software according to a method reported by Henry’s group [33, 34]. Accordingly, the background color and the blank signal were removed by adjusting the hue and brightness window in the image color threshold until only the purple color was visible. The images were then converted to a grayscale and inverted to achieve greater intensity, and the mean color intensity was measured. The mean color intensity values were proportional to the analyte concentrations.

Results and discussion

Effect of pH on the intensity

The colorimetric reaction between Cr(VI) and DPC is pH dependent [37] as the complex forms and is stable only in an acidic environment [38, 39]. De Andrade et al. (1984) recommend nitric acid (HNO3) to enhance the yield of the chromium complex [39]. In the present study, HNO3 was used for dissolving the adsorbent and hence, further application of HNO3 on μ-PADs could decrease intensity as demonstrated in our previous study [18]. Furtherly, our preliminary study showed that use of acetate buffer increased intensity higher than HNO3. Therefore, the effect of pH was investigated using acetate and phosphate buffers. pH levels ranging from 2 to 8 were investigated and showed that the mean color intensity of the complex was increased at pH 6 and then decreased with increasing pH (Fig. 2). Thus, acetate buffer diluted with 0.1 M NaOH to pH 6 was chosen as optimum and 0.5 µL of this buffer solution was deposited after DPC on detection zones of μ-PADs. 0.25 µL of the chromogenic reagent, DPC (50 mM in 1 mL methanol), was twice deposited on each detection zones. The concentration of DPC (50 mM) with twice deposition was the optimum condition as demonstrated in our previous study of Cr speciation [18].

Cr(VI) adsorption enrichment optimization

The paper-based devices that have been so far developed have limitations for quantitative determination of Cr(VI) at and below 0.010 mg L−1 in drinking water because of low sensitivity. Therefore, in the present study, trace detection of Cr(VI) using µ-PADs coupled with adsorption enrichment technique was investigated. Important parameters affecting the formation and performance of the adsorbent (Al(OH)3), such as volumes of reagents and pH adjustment, were optimized to attain the best experimental conditions with optimum intensity.

Effect of volume of carbonate on intensity

The adsorbent, Al(OH)3 precipitate, is simple, convenient, and easily coagulated when sodium carbonate (Na2CO3) is used as a hydroxide ion source and pH gradient controlling [27].

In the present study, it was observed that the adsorbent settled rapidly and easily separated from the matrix solution after centrifugation for a short time. The volumes of 1 M Na2CO3 ranging from 25 to 200 µL were preliminarily investigated at a constant 50 µL of 1 M Al(NO3)3 using a sample containing 0.5-mg L−1 Cr(VI) to assess its effect on intensity. As shown in Fig. 3, intensity increased with increasing volume to 50 µL and then rapidly decreased at higher volumes. The rapid declining in intensity at higher volumes was due to the increase in pH even though adsorbent amount increased nearly proportionally with volumes of Na2CO3 (Fig. 3). The observed results showed that Cr(VI) adsorption is not favored at pH values higher than weak acidic conditions which is consistent with reported results [26].

Figure 3 furtherly demonstrates that equal volumes of Na2CO3 and Al(NO3)3 associated with the highest intensity of Cr-DPC complex. Therefore, equal volumes of Na2CO3 and Al(NO3)3 at different levels ranging from 20 to 80 µL were investigated using a sample containing 0.5 mg L−1 Cr(VI) in order to achieve optimum color intensity. The largest and smallest adsorbent amount were observed at 80 and 20 µL of Na2CO3 and Al(NO3)3, respectively. However, due to pH effect, intensity was not linearly proportional with adsorbent amount. In addition to pH, dilution effect could also decrease intensity associated with larger amount of adsorbent as larger amount of adsorbent required higher volumes of HNO3 and sodium acetate for dissolution and pH adjustment (partial acid neutralization), respectively. Therefore, the increase in the volume of HNO3 and sodium acetate diluted the sample solution in the subsequent µ-PAD assays, so that a decrease in the color intensity was observed associated with larger amount of adsorbent. As shown in Fig. 4, the intensity of Cr-DPC complex increased with increasing volumes of Na2CO3 and Al(NO3)3, peaking at 40 µL (pH 4.55) and then dropped progressively at higher volumes. The maximum color intensity was obtained at 40 µL (pH 4.55) of Na2CO3 and Al(NO3)3 and hence, these volumes were used for the subsequent experiments.

Adsorbent dissolution and pH adjustment

The adsorbent obtained after centrifugation at 4000 rpm for 5 min at 25 °C and removal of supernatant was dissolved in the minimum amount of 8 µL of 6 M HNO3 to get a higher enrichment factor. The high concentration of HNO3 (6 M) completely suppressed Cr-DPC complex formation on the detection zones of µ-PADs. Thus, pH adjustment of the resulted sample solution was carried out using sodium acetate to achieve the desired Cr-DPC interaction. Accordingly, volumes of 4 M sodium acetate ranging from 4 to 16 µL were investigated using a sample solution containing 0.5 mg L−1 Cr(VI) to identify a volume with optimum intensity. The intensity steadily increased with increasing volume to 8 µL and then decreased at higher volumes (Fig. 5). Therefore, 8 µL of 4 M sodium acetate was chosen for the subsequent experiments to partially neutralize the acid used for adsorbent dissolution with optimum intensity. Thus, minimum volumes of 6 M HNO3 (8 µL) and 4 M sodium acetate (8 µL) were added to the adsorbent for adsorbent dissolution and pH adjustment, respectively, to optimize the enrichment factor (EF).

Cr(VI) adsorption enrichment factor (EF)

In the present study, 0.5 mg L−1 Cr(VI) showed a very weak visual signal when it was analyzed using our previously reagent optimized procedure [18] and without the present enrichment procedure (Fig. 6A). However, analysis of 0.5 mg L−1 Cr(VI) via the present developed enrichment procedure showed a very strong visual signal (Fig. 6B). Therefore, µ-PADs analysis for Cr(VI) analysis need to be accompanied by enrichment procedure to detect quantitatively Cr(VI) at lower concentration levels to comply with the environmental guideline. Thus, the enrichment procedure developed in this study substantially improved the analytical sensitivity for μ-PAD assay of Cr(VI) at trace levels with enrichment factor (EF) of 100. The EF was defined as the ratio of the concentration without enrichment (10 mg L−1) to the concentration with enrichment (0.1 mg L−1) where their color intensity is closely equivalent. Thus, the 0.1 mg L−1 Cr(VI) sample with enrichment (Fig. 6C) showed a color intensity nearly equivalent to 10 mg L−1 Cr(VI) without enrichment (Fig. 6D), giving a 100 fold EF.

Analytical features

A calibration curve was established by analyzing a series of working standard solutions of Cr(VI) (0.005, 0.01, 0.05, 0.1, 0.5, and 2 mg L−1) using the optimized experimental conditions. The working standard solutions were prepared from a stock of 1000 mg L−1 Cr(VI) standard solution. The linearity of log intensity was studied with the increasing log Cr(VI) concentration and the intensities of working standards were proportional with their corresponding concentrations as shown by the images of the detection zones in Fig. 7. The relationship between the logarithm of Cr(VI) concentration and the logarithm of the color intensity was linear in the range of 0.005–2 mg L−1 with a correlation coefficient of 0.9990 (Fig. 7). The upper end of the range was 2 mg L−1 and additional complexation at higher concentrations did not result in additional increasing in color intensity as expected which could be attributed to saturation of the paper with the complex.

The limit of quantification (LOQ) and limit of detection (LOD) were determined by the concentration equivalent to ten times the standard deviation of replicate intensity measurements of spiked blank (n = 3) and LOQ/3.3, respectively. Therefore, the LOD and LOQ of the present developed method were 0.0015 and 0.005 mg L−1. The low LOD obtained demonstrates that enrichment prior to paper-based assay could improve analytical sensitivity considerably. The reproducibility of the present method was also evaluated using the relative standard deviation (%RSD) for 9 replicate measurements of a standard solution at a concentration of 0.05 mg L−1. The relative standard deviations for intra-day and inter-day precision were 5.1 and 7.6%, respectively.

The analytical features obtained in this study were compared with the reported values [18,19,20,21,22] as presented in Table 1. The LOD was lower than most of the previous studies. The present enrichment technique decreased the measurable concentration to 0.005 mg L−1 which is by far lower than most of the reported values. The results of the present study showed that the coupling of µ-PADs with enrichment technique is useful for trace-level determination of Cr(VI) in water samples.

Interference study of µ-PADs

In the present study, an interference study was conducted under optimized experimental conditions to evaluate the effects of other ions and the analytical applications of the adsorption enrichment procedure for Cr(VI) assay in water samples. The selectivity of the proposed adsorption procedure was evaluated under optimized conditions by adding metal ions at 2.5, 5, and 10 mg L−1 (25 to 100-times) to 0.1-mg L−1 Cr(VI) solution (Table 2). Fe(III) showed weak signal on the µ-PADs; however, the imageJ adjustment used for Cr(VI) mean color intensity analysis was able to remove Fe(III) signal leaving Cr(VI) signal alone. Because of this advantage, 100-times higher concentrations of Fe(III) did not show interference effect in the detection of Cr(VI). Generally, 25-time higher concentrations of foreign ions showed no interference in the present analytical method. The criterion for interference was an intensity value varying by more than 5% from the expected value for a 0.1-mg L−1 Cr(VI) solution [40]. Thus, the tolerance limit is the largest interfering ion concentration causing a relative error smaller than ± 5%.

Recovery study

The proposed method was applied to detect Cr(VI) in spiked tap and mineral water samples to evaluate its potential application and reliability. Thus, aliquots of tap and mineral water samples were spiked at 0.05- and 0.1 mg L−1 Cr(VI) and subjected to the adsorption procedure for the subsequent determination of Cr(VI) using the µ-PADs. The spiked Cr(VI) was quantitatively recovered from the samples using the developed method with recovery values of 96.3–109.0% (Table 3). The reliability of the results obtained by the proposed method was validated by inductively coupled plasma-optical emission spectroscopy (ICP-OES). ICP-OES exhibited recoveries of 106–109.7%, which is in good agreement with the results of the µ-PADs as paired t-tests showed no significant differences between them. The proposed method could be applicable for the analysis of Cr(VI) in water samples at trace levels, particularly in resource-limited settings.

Conclusion

In this study, a simple, low-cost, fast, selective, and sensitive method was presented to detect trace levels of Cr(VI) in water samples. Cr(VI) enrichment via adsorption was successfully demonstrated prior to Cr(VI) assay using μ-PADs. The enrichment factor as high as 100-fold was achieved and resulted in a significant improvement in the sensitivity of the μ-PADs. The Cr(VI) enrichment technique coupled with µ-PADs permitted lower LOD and LOQ of 0.0015 and 0.005 mg L−1, respectively, with a wider linear dynamic range of 0.005–2 mg L−1. The proposed method was successfully applied to spiked water samples and the results obtained were in a good agreement with ICP-OES results. Therefore, the combination of μ-PADs with the enrichment technique has great potential to extend the applications of μ-PADs in environmental monitoring without need for sensitive conventional analytical instruments, particularly in developing countries.

Data availability

The authors declare that the data supporting the findings of this study are available within the paper.

References

U. Khalil, M.B. Shakoor, S. Ali, S.R. Ahmad, M. Rizwan, A.A. Alsahli, M.N. Alyemeni, Water 13, 263 (2021)

J. Valentín-Reyes, R. García-Reyes, A. García-González, E. Soto-Regalado, F. Cerino-Córdova, J. Environ. Manag. 236, 815 (2019)

L. Hu, Y. Cai, G. Jiang, Chemosphere 156, 14 (2016)

R. Shan, Y. Shi, J. Gu, J. Bi, H. Yuan, B. Luo, Y. Chen, J. Environ. Chem. Eng. 8, 103885 (2020)

K.E. Ukhurebor, U.O. Aigbe, R.B. Onyancha, W. Nwankwo, O.A. Osibote, H.K. Paumo, O.M. Ama, C.O. Adetunji, I.U. Siloko, J. Environ. Manag. 280, 111809 (2021)

S.O. Owalude, A.C. Tella, Beni-Suef Univ. J. Basic appl. Sci. 5, 377 (2016)

S. Xia, Z. Song, P. Jeyakumar, S.M. Shaheen, J. Rinklebe, Y.S. Ok, N. Bolan, H. Wang, Crit. Rev. Environ. Sci. Technol. 49, 1027 (2019)

J. Geng, Y. Yin, Q. Liang, Z. Zhu, H. Luo, J. Chem. Eng. 361, 1497 (2019)

N. Zhao, C. Zhao, D.C. Tsang, K. Liu, L. Zhu, W. Zhang, J. Zhang, Y. Tang, R. Qiu, J. Hazard. Mater. 404, 124162 (2021)

T.U. Han, J. Kim, K. Kim, Sep. Purif 250, 117233 (2020)

A. Ashraf, I. Bibi, N.K. Niazi, Y.S. Ok, G. Murtaza, M. Shahid, A. Kunhikrishnan, D. Li, T. Mahmood, Int. J. Phytoremediat. 19, 605 (2017)

L. Reale, F. Ferranti, S. Mantilacci, M. Corboli, S. Aversa, F. Landucci, C. Baldisserotto, L. Ferroni, S. Pancaldi, R. Venanzoni, Chemosphere 145, 98 (2016)

A.U. Rajapaksha, M.S. Alam, N. Chen, D.S. Alessi, A.D. Igalavithana, D.C. Tsang, Y.S. Ok, Sci. Total. Environ. 625, 1567 (2018)

V. Antoniadis, A.A. Zanni, E. Levizou, S.M. Shaheen, A. Dimirkou, N. Bolan, J. Rinklebe, Chemosphere 195, 291 (2018)

R. Jobby, P. Jha, A.K. Yadav, N. Desai, Chemosphere 207, 255 (2018)

A.W. Martinez, S.T. Phillips, G.M. Whitesides, Anal. Chem. 82, 3 (2010)

A. Muhammed, A. Hussen, M. Redi, T. Kaneta, Anal. Sci. 20, 325 (2020)

A. Muhammed, A. Hussen, T. Kaneta, Anal. Bioanal. Chem. 413, 3339 (2021)

H. Asano, Y. Shiraishi, Anal. Sci. 34, 71 (2018)

H.-M. Zhai, T. Zhou, F. Fang, Z.-Y. Wu, Talanta 210, 120635 (2020)

W. Alahmad, N. Tungkijanansin, T. Kaneta, P. Varanusupakul, Talanta 190, 78 (2018)

W. Alahmad, P. Varanusupakul, T. Kaneta, P. Varanusupakul, Anal. Chim. Acta 1085, 98 (2019)

O. Ajouyed, C. Hurel, M. Ammari, L.B. Allal, N. Marmier, J. Hazard. Mater. 174, 616 (2010)

E. Pehlivan, S. Cetin, J. Hazard. Mater. 163, 448 (2009)

S. Kaneko, M. Ogawa, Appl. Clay Sci. 75, 109 (2013)

A.J. Rubin, P.L. Hayden, Studies on the Hydrolysis and Precipitation of Aluminum (III), Ohio State University. Water Resour. Res. (1973)

G. Doner, A. Ege, Anal. Chim. Acta 547, 14 (2005)

N. Bader, A.A. Benkhayal, B. Zimmerman, Int. J. Chem. Sci. 12, 519 (2014)

S. Saracoglu, U. Divrikli, M. Soylak, L. Elci, J. Food Drug Anal. 10, 188 (2002)

A. Muhammed, A. Hussen, T. Kaneta, Anal. Sci. 21, 215 (2021)

A. Muhammed, A. Hussen, T. Kaneta, S. Afr, J. Chem. 77, 01 (2023)

W. Alahmad, K. Uraisin, D. Nacapricha, T. Kaneta, Anal. Methods 8, 5414 (2016)

M.M. Mentele, J. Cunningham, K. Koehler, J. Volckens, C.S. Henry, Anal. Chem. 84, 4474 (2012)

P. Rattanarat, W. Dungchai, D.M. Cate, W. Siangproh, J. Volckens, O. Chailapakul, C.S. Henry, Anal. Chim. Acta 800, 50 (2013)

D.M. Cate, Development of Paper-Based Analytical Devices for Particulate Metals in Welding Fume (Colorado State University, Fort Collins, 2015)

E. Carrilho, A.W. Martinez, G.M. Whitesides, Anal. Chem. 81, 7091 (2009)

L.V. Mulaudzi, J.F. van Staden, R.I. Stefan, Anal. Chim. Acta 467, 51 (2002)

K.A. Stancheva, B.I. Bogdanov, D.P. Georgiev, Y.H. Hristov, I.G. Markovska, Eurasian. J. Anal. Chem. 8, 10 (2012)

J.C. de Andrade, J.C. Rocha, N. Baccan, Analyst 109, 645 (1984)

C.B. Ojeda, A.G. De Torres, F.S. Rojas, J.C. Pavon, Analyst 112, 1499 (1987)

Acknowledgements

The authors gratefully thank the Division of Instrumental Analysis, Department of Instrumental Analysis & Cryogenics, Advanced Science Research Center, Okayama University for the ICP-OES measurements.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muhammed, A., Hussen, A. & Kaneta, T. Adsorption enrichment integrated with paper-based devices for detection of trace levels of hexavalent chromium in water samples. ANAL. SCI. 40, 709–717 (2024). https://doi.org/10.1007/s44211-023-00504-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s44211-023-00504-4