Abstract

In recent years, high-entropy alloys (HEAs) have developed a lot as the new style of materials, which have become a research focus in the materials fields. It breaks the normal procedure of traditional alloy design (based on one/two elements as the main component, and adds some other elements to improve the microstructure and required related performance of the alloy), and consists of five or more equal or nearly equal elements, with multiple principal elements. Therefore, HEAs have many excellent mechanical properties compared with traditional alloys, which have aroused great research interest of researchers. The rapid development of high-pressure technology makes it a powerful tool to modulate the structures of HEAs, and brings new chance for the study and optimization of mechanical properties of HEAs. In this paper, the application of high-pressure technology in exploring and improving the mechanical properties of HEAs is reviewed, which could deepen the understanding of high-pressure technology and provide a new avenue for further exploration of HEAs’ mechanical properties.

reproduced with permission from Ref. [4]. Copyright 2017 Elsevier. The above part of high strength is reproduced with permission from Ref. [5]. Copyright 2021 Elsevier. The below part of high strength is reproduced with permission from Ref. [6]. Copyright 2019 Elsevier. The part of high hardness is reproduced with permission from Ref. [7]. Copyright 2019 Elsevier. The part of superconductivity is reproduced with permission from Ref. [8]. Copyright 2022 Elsevier. The part of superplasticity is reproduced with permission from Ref. [9]. Copyright 2020 Springer Nature

Reproduced with permission from Ref. [42]. Copyright 2018 Elsevier. b Two-dimensional contour map of hardness of samples treated with different HPT; c IPF maps of samples with monotonic 100°, cyclic 100°, monotonic 360°, and cyclic 360° HPT-treated. Reproduced with permission from Ref. [43]. Copyright 2019 Springer Nature. d The Vickers hardness of nanocrystals CoCrFeNiMn after different HPT treatment as a function of the distance from the center of the disk; e simulation diagram of nanocrystalline CoCrFeNiMn torsional stress with disk center distance after compression and 1/5 HPT treatment. The distribution of torsional stress on the surface of semicircular disk was shown in different colors. Reproduced with permission from Ref. [44]. Copyright 2015 Springer Nature. f The Vickers microhardness evolution of nanocrystalline CoCrFeMnNi as a function of center distance after 1/4, 1/2, 1, and 2 turns of HPT treatment. Reproduced with permission from Ref. [45]. Copyright 2017 Elsevier

Reproduced with permission from Ref. [45]. Copyright 2017 Elsevier. c Vickers microhardness versus distance from disk center; SEM–EDS analysis of d the initial AlCrFeCoNiNb high entropy alloy and e 1/4 turns HPT-treated and f 4 turns HPT-treated samples to check the element distribution map. Reproduced with permission from Ref. [46]. Copyright 2021 Elsevier. g The Vickers microhardness of Al0.1CoCrFeNi at 6 GPa after 1 and 2 cycles of hot-isostatic pressed (HIPed) and HPT treatments as a function of the distance from the center of the disk. Reproduced with permission from Ref. [47]. Copyright 2016 Elsevier

Reproduced with permission from Ref. [51]. Copyright 2019 Elsevier. c Vickers hardness of isochronous (1 h) treated samples at different annealing temperatures; d Vickers hardness of samples treated for unequal time at the same annealing temperature (450 °C). Reproduced with permission from Ref. [52]. Copyright 2015 Elsevier

Reproduced with permission from Ref. [9]. Copyright 2020 Springer Nature

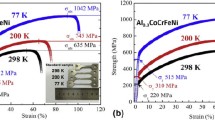

Reproduced with permission from Ref. [9]. Copyright 2020 Springer Nature. b Engineering stress–strain curves of CoCrFeMnNi HEA powder billet after 4 HPT and post-HPT annealed; EBSD-IPF diagrams of the post-HPT annealed samples at c 700 °C for 15 min; d 700 °C for 60 min; e 800 °C for 15 min; f 800 °C for 60 min. Reproduced with permission from Ref. [5]. Copyright 2021 Elsevier. g Engineering stress–strain curves of V10Cr15Mn5Fe35Co10Ni25 HEA under different conditions. Reproduced with permission from Ref. [63]. Copyright 2020 Elsevier

Reproduced with permission from Ref. [63]. Copyright 2020 Elsevier

Reproduced with permission from Ref. [64]. Copyright 2021 Elsevier

Reproduced with permission from Ref. [66]. Copyright 2021 MDPI. c HRTEM image of quenched Al0.3CoCrFeNi sample from 53 GPa. Reproduced with permission from Ref. [72]. Copyright 2019 AIP Publishing. d XRD patterns of CrMnFeCoNi at different pressures; e XRD patterns of quenched CrMnFeCoNi from different pressures. Reproduced with permission from Ref. [74]. Copyright 2017 Springer Nature

Similar content being viewed by others

References

Feng R, Zhang CA, Gao MC, Pei ZR, Zhang F, Chen Y, Ma D, An K, Poplawsky JD, Ouyang LZ, Ren Y, Hawk JA, Widom M, Liaw PK. High-throughput design of high-performance lightweight high-entropy alloys. Nat Commun. 2021;12:1.

Shi PJ, Li RG, Li Y, Wen YB, Zhong YB, Ren WL, Shen Z, Zheng TX, Peng JC, Liang XL, Hu PF, Min N, Zhang Y, Ren Y, Liaw PK, Raabe D, Wang YD. Hierarchical crack buffering triples ductility in eutectic herringbone high-entropy alloys. Science. 2021;373:912.

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT, Tsau CH, Chang SY. Nanostructured high-entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater. 2004;6:299.

Miracle DB, Senkov ON. A critical review of high entropy alloys and related concepts. Acta Mater. 2017;122:448.

Asghari-Rad P, Sathiyamoorthi P, Nguyen NTC, Zargaran A, Kim TS, Kim HS. A powder-metallurgy-based fabrication route towards achieving high tensile strength with ultra-high ductility in high-entropy alloy. Scripta Mater. 2021;190:69.

Lee DH, Park JM, Yang GH, He JY, Lu ZP, Suh JY, Kawasaki M, Ramamurty U, Jang J. Nano-graining a particle-strengthened high entropy alloy. Scripta Mater. 2019;163:24.

Gubicza J, Hung PT, Kawasaki M, Han JK, Zhao YK, Xue YF, Labar JL. Influence of severe plastic deformation on the microstructure and hardness of a CoCrFeNi high-entropy alloy: a comparison with CoCrFeNiMn. Mater Charact. 2019;154:304.

Uporov SA, Ryltsev RE, Sidorov VA, Estemirova SK, Sterkhov EV, Balyakin IA, Chtchelkatchev A. Pressure effects on electronic structure and electrical conductivity of TiZrHfNb high-entropy alloy. Intermetallics. 2022;140:107394.

Nguyen NTC, Asghari-Rad P, Sathiyamoorthi P, Zargaran A, Lee CS, Kim HS. Ultrahigh high-strain-rate superplasticity in a nanostructured high-entropy alloy. Nat Commun. 2020;11:1.

Guo J, Wang HH, Rohr FV, Wang Z, Cai S, Zhou YZ, Yang K, Li AG, Jiang S, Wu Q, Cava RJ, Sun LL. Robust zero resistance in a superconducting high-entropy alloy at pressures up to 190 GPa. P Natl Acad Sci USA. 2017;50:13144.

Zhang WR, Liaw PK, Zhang Y. Science and technology in high-entropy alloys. Sci China Mater. 2018;61:2.

Zhang Y, Zou TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP. Microstructures and properties of high-entropy alloys. Prog Mater Sci. 2014;61:1.

Lu ZP, Wang H, Chen MW, Baker I, Yeh JW, Liu CT, Nieh TG. An assessment on the future development of high-entropy alloys: summary from a recent workshop. Intermetallics. 2015;66:67.

Zhang F, Lou HB, Cheng BY, Zeng ZD, Zeng QS. High-pressure induced phase transitions in high-entropy alloys: a review. Entropy. 2019;21:239.

Miracle DB, Miller JD, Senkov ON, Woodward C, Uchic MD, Tiley J. Exploration and development of high entropy alloys for structural applications. Entropy. 2013;16:494.

Dong WQ, Zhou Z, Zhang MD, Ma YM, Yu PF, Liaw PK, Li G. Applications of high-pressure technology for high-entropy alloys: a review. Metals. 2019;9:867.

Chen TK, Shun TT, Yeh JW, Wong MS. Nanostructured nitride films of multi-element high-entropy alloys by reactive dc sputtering. Surf Coat Tech. 2004;188:193.

Hsu CY, Yeh JW, Chen SK, Shun TT. Wear resistance and high-temperature compression strength of fcc CuCoNiCrAl0.5Fe alloy with boron addition. Metall Mater Trans A. 2004;35:1465.

Huang PK, Yeh JW, Shun TT, Chen SK. Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv Eng Mater. 2004;6:74.

Yeh JW, Chen SK, Gan JY, Lin SJ, Chin TS, Shun TT, Tsau CH, Chang SY. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall Mater Trans A. 2004;35:2533.

Gludovatz B, Hohenwarter A, Catoor D, Chang EH, George EP, Ritchie RO. A fracture-resistant high-entropy alloy for cryogenic applications. Science. 2014;345:1153.

Yeh JW. Recent progress in high entropy alloys. Ann Chim Sci Mat. 2006;31:633.

Zhang Y, Zhou YJ, Lin JP, Chen GL, Liaw PK. Solid-solution phase formation rules for multi-component alloys. Adv Eng Mater. 2008;10:534.

Zhang Y, Yang X, Liaw PK. Alloy design and properties optimization of high-entropy alloys. Jom. 2012;64:830.

Tsai MH, Yeh JW. High-entropy alloys: a critical review. Mater Res Lett. 2014;2:107.

Singh S, Wanderka N, Murty BS, Glatzel U, Banhart J. Decomposition in multi-component AlCoCrCuFeNi high-entropy alloy. Acta Mater. 2011;59:182.

Tsai KY, Tsai MH, Yeh JW. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high-entropy alloys. Acta Mater. 2013;61:4887.

Senkov ON, Wilks GB, Scott JM, Miracle DB. Mechanical properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 refractory high-entropy alloys. Intermetallics. 2011;19:698.

Hsu CY, Juan CC, Wang WR, Sheu TS, Yeh JW, Chen SK. On the superior hot hardness and softening resistance ofAlCoCrxFeMo0.5Ni high-entropy alloys. Mater Sci Eng A. 2011;528:3581

Cheng KH, Lai CH, Lin SJ, Yeh JW. Recent progress in multi-element alloy and nitride coatings sputtered from high-entropy alloy targets. Ann Chim. 2006;31:723.

Ranganathan S. Alloyed pleasures: multimetallic cocktails. Curr Sci India. 2003;85:1404.

Hemley RJ, Ashcroft NW. The revealing role of pressure in the condensed matter sciences. Phys Today. 1998;51:26.

Mao HK, Chen B, Chen JH, Li K, Lin JF, Yang W, Zheng HY. Recent advances in high-pressure science and technology. Matter Radiat Extrem. 2016;1:59.

Bridgman PW. Effects of high shearing stress combined with high hydrostatic pressure. Phys Rev. 1935;48:825.

Zhilyaev AP, Langdon TG. Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci. 2008;53:893.

Edalati K, Horita Z. A review on high-pressure torsion (HPT) from 1935 to 1988. Mater Sci Eng A. 2016;652:325.

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer MJ, Zhu YT. Producing bulk ultrafine-grained materials by severe plastic deformation: ten years later. Jom. 2016;68:1216.

Bundy FP, Hall HT, Strong HM, Wentorf RH. Man-made diamonds. Nature. 1955;176:51.

Bassett WA. Diamond anvil cell, 50th birthday. High Pressure Res. 2009;29:163.

Dubrovinsky L, Dubrovinskaia N, Bykova E, Bykov M, Prakapenka V, Prescher C, Glazyrin K, Liermann HP, Hanfland M, Ekholm M, Feng Q, Pourovskii LV, Katsnelson MI, Wills JM, Abrikosov IA. The most incompressible metal osmium at static pressures above 750 gigapascals. Nature. 2015;525:226.

Buras B, Olsen JS, Gerward L, Will G, Hinze E. X-ray energy-dispersive diffractometry using synchrotron radiation. J Appl Crystallogr. 1977;10:431.

Stepanov ND, Yurchenko NY, Gridneva AO, Zherebtsov SV, Ivanisenko YV, Salishchev GA. Structure and hardness of B2 ordered refractory AlNbTiVZr0.5 high entropy alloy after high-pressure torsion. Mater Sci Eng A. 2018;716:308.

Sonkusare R, Khandelwal N, Ghosh P, Biswas K, Gurao NP. A comparative study on the evolution of microstructure and hardness during monotonic and cyclic high pressure torsion of CoCuFeMnNi high entropy alloy. J Mater Res. 2019;34:1.

Lee DH, Choi IC, Seok MY, He JY, Lu ZP, Suh JY, Kawasaki M, Langdon TG, Jang JI. Nanomechanical behavior and structural stability of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. J Mater Res. 2015;30:2804.

Heczel A, Kawasaki M, Labar JL, Jang JI, Langdon TG, Gubicza J. Defect structure and hardness in nanocrystalline cocrfemnni high-entropy alloy processed by high-pressure torsion. J Alloy Compd. 2017;711:143.

Edalati P, Mohammadi A, Ketabchi M, Edalati K. Ultrahigh hardness in nanostructured dual-phase high-entropy alloy AlCrFeCoNiNb developed by high-pressure torsion. J Alloy Compd. 2021;884:161101.

Yu PF, Cheng H, Zhang LJ, Zhang H, Jing Q, Ma MZ, Liaw PK, Li G, Liu RP. Effects of high pressure torsion on microstructures and properties of an Al0.1CoCrFeNi high-entropy alloy. Mater Sci Eng A. 2016;655:283.

Edalati K, Li HW, Kilmametov A, Floriano R, Borchers C. High-pressure torsion for synthesis of high-entropy alloys. Metals. 2021;11:1263.

Taheriniya S, Davani FA, Hilke S, Hepp M, Gadelmeier C, Chellali MR, Boll T, Rosner H, Peterlechner M, Gammer C, Divinski SV, Butz B, Glatzel U, Hahn H, Wilde G. High entropy alloy nanocomposites produced by high pressure torsion. Acta Mater. 2021;208:116714.

Tang QH, Huang Y, Huang YY, Liao XZ, Langdon TG, Dai PQ. Hardening of an Al0.3CoCrFeNi high entropy alloy via high-pressure torsion and thermal annealing. Mater Lett. 2015;151:126.

Kilmametov A, Kulagin R, Mazilkin A, Seils S, Boll T, Heilmaier M, Hahn H. High-pressure torsion driven mechanical alloying of cocrfemnni high entropy alloy. Scripta Mater. 2019;158:29.

Schuh B, Mendez-Martin F, Volker B, George EP, Clemens H, Pippan R, Hohenwarter A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015;96:258.

Kawasaki M, Langdon TG. Principles of superplasticity in ultrafine-grained materials. J Mater Sci. 2007;42:1782.

Langdon TG. Seventy-five years of superplasticity: historic developments and new opportunities. J Mater Sci. 2009;44:5998.

Shahmir H, He JY, Lu ZP, Kawasaki M, Langdon TG. Evidence for superplasticity in a CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Mater Sci Eng A. 2017;685:342.

Nguyen NTC, Moon J, Sathiyamoorthi P, Asghari-Rad P, Kim GH, Lee CS, Kim HS. Superplasticity of V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy processed using high-pressure torsion. Mater Sci Eng A. 2019;764:138198.

Ma E, Wu XL. Tailoring heterogeneities in high-entropy alloys to promote strength–ductility synergy. Nat Commun. 2019;10:1.

Sathiyamoorthi P, Kim HS. High-entropy alloys with heterogeneous microstructure: processing and mechanical properties. Prog Mater Sci. 2020;2:100709.

Li WD, Xie D, Li DY, Gao YF, Liaw PK. Mechanical behavior of high-entropy alloys. Prog Mater Sci. 2021;2:100777.

Pan QS, Zhang LX, Feng R, Lu QH, An K, Chuang AC, Poplawsky JD, Liaw PK, Lu L. Gradient cell–structured high-entropy alloy with exceptional strength and ductility. Science. 2021;2:8114.

Valiev RZ, Sergueeva AV, Mukherjee AK. The effect of annealing on tensile deformation behavior of nanostructured SPD titanium. Scripta Mater. 2003;49:669.

Shahmir H, He JY, Lu ZP, Kawasaki M, Langdon TG. Effect of annealing on mechanical properties of a nanocrystalline CoCrFeNiMn high-entropy alloy processed by high-pressure torsion. Mater Sci Eng A. 2016;676:294.

Asghari-Rad P, Sathiyamoorthi P, Nguyen NTC, Bae JW, Shahmir H, Kim HS. Fine-tuning of mechanical properties in V10Cr15Mn5Fe35Co10Ni25 high-entropy alloy through high-pressure torsion and annealing. Mater Sci Eng A. 2020;771:138604.

Zhang CY, Yue BB, Bhandari U, Starovoytov ON, Yang Y, Ypung DP, Yan JY, Hong F, Yang SZ. In situ study on the compression deformation of MoNbTaVW high-entropy alloy. J Alloy Compd. 2021;871:159557.

Zhang CY, Bhandari U, Zeng CY, Ding H, Guo SM, Yan JY, Yang SZ. Carbide formation in refractory Mo15Nb20Re15Ta30W20 alloy under a combined high-pressure and high-temperature condition. Entropy. 2020;22:718.

Zhang CY, Bhandari U, Lei JL, Zeng CY, Guo SM, Choi H, Nam S, Yan JY, Yang SZ, Gao F. Performance of carbide alloy compounds in carbon doped MoNbTaW. Curr Comput-Aided Drug Des. 2021;11:1073.

Yusenko KV, Khandarkhaeva S, Fedotenko T, Pakhomova A, Gromilov SA, Dubrovinsky L, Dubrovinskaia N. Equations of state of rhodium, iridium and their alloys up to 70 GPa. J Alloy Compd. 2019;788:212.

Yusenko KV, Riva S, Carvalho PA, Yusenko MV, Arnaboldi S, Sukhikh AS, Hanfland M, Gromilov SA. First hexagonal close packed high-entropy alloy with outstanding stability under extreme conditions and electrocatalytic activity for methanol oxidation. Scripta Mater. 2017;138:22.

Ahmad AS, Su Y, Liu SY, Stahl K, Wu YD, Hui XD, Ruett U, Gutowski O, Glazyrin K, Liermann HP, Franz H, Wang H, Wang XD, Cao QP, Zhang DX, Jiang JZ. Structural stability of high entropy alloys under pressure and temperature. J Appl Phys. 2017;121:235901.

Yu PF, Zhang LJ, Ning JL, Ma MZ, Zhang XY, Li YC, Liaw PK, Li G, Liu RP. Pressure-induced phase transitions in HoDyYGdTb high-entropy alloy. Mater Lett. 2017;196:137.

Fakirov S. On the application of the “rule of mixture” to microhardness of complex polymer systems containing a soft component and/or phase. J Mater Sci. 2007;42:1131.

Wang CX, Tracy CL, Park S, Liu J, Ke F, Zhang FX, Yang TF, Xia SQ, Li CY, Wang YG, Zhang Y, Mao WL, Ewing RC. Phase transformations of Al-bearing high-entropy alloys AlxCoCrFeNi (x= 0, 0.1, 0.3, 0.75, 1.5) at high pressure. Appl Phys Lett. 2019;114:091902.

Li XY, Wei YJ, Lu L, Lu K, Gao HJ. Dislocation nucleation governed softening and maximum strength in nano-twinned metals. Nature. 2010;464:877.

Tracy CL, Park S, Rittman DR, Zinkle SJ, Bei HB, Lang M, Ewing RC, Mao WL. High pressure synthesis of a hexagonal close-packed phase of the high-entropy alloy CrMnFeCoNi. Nat Commun. 2017;8:1.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 62104090, 11604133, and 11874174), the Natural Science Foundation of Shandong Province (Grant Nos. ZR2017QA013, ZR2021QA087, and ZR2021QA092 ), the Science and Technology Plan of Youth Innovation Team for Universities of Shandong Province (Grant No. 2019KJJ019), the Introduction and Cultivation Plan of Youth Innovation Talents for Universities of Shandong Province, Fundamental Research Funds for the Central Universities (buctrc 202122), the Research Funding of Liaocheng University (318012016, 318051610, and 318051612), and the Special Construction Project Fund for Shandong Province Taishan Scholars.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, SC., Wang, QL., Yao, Y. et al. Application of high-pressure technology in exploring mechanical properties of high-entropy alloys. Tungsten 5, 50–66 (2023). https://doi.org/10.1007/s42864-021-00132-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42864-021-00132-3