Abstract

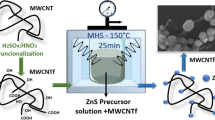

Carbon fibers of polyacrylonitrile (PAN) type were coated with nickel nanoparticles using a chemical reduction method in alkaline hydrazine bath. The carbon fibers were firstly heated at 400 °C and then chemically treated in hydrochloric acid followed by nitric acid to clean, remove any foreign particles and functionalized its graphitic surfaces by introducing some functional groups. The functionalized carbon fibers were coated with nickel to produce 10 wt% Cf/Ni nanocomposites. The uncoated heat treated and the nickel coated carbon fibers were investigated by SEM, EDS, FTIR and XRD to characterize the particle size, morphology, chemical composition and the crystal structure of the investigated materials. The nickel nanoparticles were successfully deposited as homogeneous layer on the surface of the functionalized carbon fibers. Also, the deposited nickel nanoparticles have quazi-spherical shape and 128–225 nm median particle size. The untreated and the heat treated as well as the 10 wt% Cf/Ni nanocomposite particles were further reinforced in ethylene vinyl acetate (EVA) polymer separately by melt blending technique to prepare 0.5 wt% Cf-EVA polymer matrix stretchable conductive composites. The microstructures of the prepared polymer composites were investigated using optical microscope. The carbon fibers as well as the nickel coated one were homogenously distributed in the polymer matrix. The obtained samples were analyzed by TGA. The addition of the nickel coated carbon fibers to the EVA was improved the thermal stability by increasing the thermal decomposition temperature Tmax1 and Tmax2. The electrical and the mechanical properties of the obtained 10 wt% Cf/Ni nanocomposites as well as the 0.5 wt% Cf-EVA stretchable conductive composites were evaluated by measuring its thermal stability by thermogravimetric analysis (TGA), electrical resistivity by four probe method and tensile properties. The electrical resistivity of the fibers was decreased by coating with nickel and the 10 wt% Cf/Ni nanocomposites has lower resistivity than the carbon fibers itself. Also, the electrical resistivity of the neat EVA is decreased from 3.2 × 1010 to 1.4 × 104 Ω cm in case of the reinforced 0.5 wt% Cf/Ni-EVA polymer composite. However, the ultimate elongation and the Young’s modulus of the neat EVA polymer was increased by reinforcing with carbon fibers and its nickel composite.

Similar content being viewed by others

References

Kim KW, Kim DK, Kim BS, An KH, Park SJ, Rhee KY et al (2017) Cure behaviors and mechanical properties of carbon fiber-reinforced nylon6/epoxy blended matrix composites. Compos Part B Eng 112:15–21

Park SJ (2018) History and structure of carbon fibers. In: Carbon fibers. Springer Series in Materials Science, p 210

Hung P, Lau K, Fox B, Hameed N, Lee J, Hui D (2018) Surface modification of carbon fiber using graphene-related materials for multifunctional composites. Compos B Eng 133:240–257

Zhang Y, Wang H, Lu H, Li S, Zhang Y (2021) Electronic fibers and textiles: recent progress and perspective. Science 24(7):102716

Navalon S, Dhakshinamoorthy A, Alvaro M, Garcia H (2014) Carbocatalysis by graphene-based materials. Chem Rev 114(12):6179–6212

Rane A, Thomas S (2018) Methods for synthesis of nanoparticles and fabrication of nanocomposites. Synth Inorgan Nanomater 2018:121–139

Lee P, Chen D, Pui D (2003) Experimental study of a nanoparticle virtual impactor. J Nanopart Res 5:269–280

Sun L, Mao J, Pan Z et al (1999) Growth of straight nanotubes with a cobalt–nickel catalyst by chemical vapor deposition. Appl Phys Lett 74(5):644–646

Daoush WM, Alkhuraiji TS, Khamis MA et al (2020) Microstructure and electrical properties of carbon short fiber reinforced copper composites fabricated by electroless deposition followed by powder metallurgy process. Carbon Lett 30:247–258

Daoush WM, Albogmy TS, Khamis MA, Inam F (2020) Syntheses and step-by-step morphological analysis of nano-copper-decorated carbon long fibers for aerospace structural applications. Crystals 10:1090

Sayam A, Rahman ANMM, Rahman M, Smriti SA, Ahmed F, Rabbi MF, Hossain M, Faruque MO (2022) A review on carbon fiber-reinforced hierarchical composites: mechanical performance, manufacturing process, structural applications and allied challenges. Carbon Lett 32:1173–1205

Irina M, Azmi A, Tan C, Lee C, Khalil A (2015) Evaluation of mechanical properties of hybrid fiber reinforced polymer composites and their architecture. Proc Manuf 2:236–240

Tehrani M, Boroujeni A, Hartman T, Haugh T, Case S, Al-Haik M (2013) Mechanical characterization and impact damage assessment of a woven carbon fiber reinforced carbon nanotube–epoxy composite. Compos Sci Technol 75:42–48

Lin G, CINTE21 (2022) Global carbon fiber composites market report. Text Sci Res Z1:46–66

Zheng H, Zhang W, Li B, Zhu J, Wang C, Song G, Wu G, Yang X, Huang Y, Ma L (2022) Recent advances of interphases in carbon fiber-reinforced polymer composites: a review. Compos Part B Eng 233:109639

Zakaria MR, Md Akil H, Abdul Kudus MH, Ullah F, Javed F, Nosbi N (2019) Hybrid carbon fiber-carbon nanotubes reinforced polymer composites: a review. Compos Part B Eng 176:107313

Lamorinière S, Jones MP, Ho K, Kalinka G, Shaffer MSP, Bismarck A (2022) Carbon nanotube enhanced carbon fibre-poly(ether ether ketone) interfaces in model hierarchical composites. Compos Sci Technol 221:109327

Yousefi N, Fisher SJ, Burgstaller C, Shaffer MSP, Bismarck A (2022) Hierarchical carbon fiber composites incorporating high loadings of carbon nanotubes. Compos Sci Technol 222:109369

Hu Y, Wei Y, Han G, Zhang J, Sun G, Hu X, Cheng F (2022) Comparison of impact resistance of carbon fibre composites with multiple ultra-thin CNT, aramid pulp, PBO and graphene interlayers. Compos Part A Appl Sci Manuf 155:106815

Pawlik M, Le H, Lu Y (2019) Effects of the graphene nanoplatelets reinforced interphase on mechanical properties of carbon fibre reinforced polymer—a multiscale modelling study. Compos Part B Eng 177:107097

Sánchez-Romate XF, Del Bosque A, Artigas-Arnaudas J, Muñoz BK, Sánchez M, Ureña A (2021) A proof of concept of a structural supercapacitor made of graphene coated woven carbon fibers: EIS study and mechanical performance. Electrochim Acta 370:137746

Wu Y, Wang LX, Xu H, Wang S, Peng L, Zheng Z et al (2021) Preparation of silver-plated carbon nanotubes/carbon fiber hybrid fibers by combining freeze-drying deposition with A sizing process to enhance the mechanical properties of carbon fiber composites. Compos Part A Appl Sci Manuf 146:106421

Liu L, Du M, Liu F (2023) Recent advances in interface microscopic characterization of carbon fiber-reinforced polymer composites. Front Mater 10:1124338

Tang Z, He C, Tian H, Ding J, Hsiao BS, Chu B, Chen X (2016) Polymeric nanostructured materials for biomedical applications. Prog Polym Sci 60:86–128

Okubo M, Tahara M, Kurok T, Hibimo T, Saeki N (2008) Plating technology for fluorocarbon polymer films using atmospheric-pressure nonthermal plasma graft polymerization. J Photopolym Sci Technol 21:219–224

Daoush W, Imae T (2015) Fabrication of PtNi bimetallic nanoparticles supported on multi-walled carbon nanotubes. J Exp Nanosci 10(5):392–406

Daoush W, Lim B, Nam D, Hong S (2014) Microstructure and mechanical properties of CNT/Ag nanocomposites fabricated by spark plasma sintering. J Exp Nanosci 9(6):588–596

Sun X, Gutierrez A, Yacaman MJ, Dong X, Jin S (2000) Investigations on magnetic properties and structure for carbon encapsulated nanoparticles of Fe Co, Ni. Mater Sci Eng A 286(1):157–160

Daoush W, Elkady O (2014) Microstructure, physical properties and hardness of Al2O3 short fibres/Ni matrix composites fabricated by powder technology. J Compos Mater 48(30):3735–3746

Cai Y, Hu Y, Song L, Lu H, Chen Z, Fan W (2006) Preparation and characterizations of HDPE–EVA alloy/OMT nanocomposites/paraffin compounds as a shape stabilized phase change thermal energy storage material. Thermochim Acta 451:44–51

Horrocks A, Price D (2001) Fire retardant materials. Woodhead Publishing, London

Duquesne S, Le Bras M, Bourbigot S, Delobel R, Camino G, Eling B, Lindsay C, Roels T, Vezin H (2001) Mechanism of fire retardancy of polyurethanes using ammonium polyphosphate. J Appl Polym Sci 82:3262–3274

Huang G, Yang J, Gao J, Wang X (2012) Thin films of intumescent flame retardant–polyacrylamide and exfoliated graphene oxide fabricated via layer-by-layer assembly for improving flame retardant properties of cotton fabric. Ind Eng Chem Res 51(38):12355–12366

Jyoti J, Kumar A, Dhakate S, Singh BP (2018) Dielectric and impedance properties of three-dimension graphene oxide–carbon nanotube acrylonitrile butadiene styrene hybrid composites. Polym Testing 68:456–466

Jamali AR, Bhatti J, Khan W, Akther F, Batool M, Batool R, Daoush WM (2022) Synthesis and characterization of silver nanoparticle–polydimethylsiloxane (Ag-NP-PDMS) stretchable conductive nanocomposites. Crystals 12(8):1098

Wang Z, Zhao GL (2013) Microwave absorption properties of carbon nanotubes-epoxy composites in a frequency range of 2–20 GHz. Open J Compos Mater 3(2):17–23

Chrissafis K, Bikiaris D (2011) Can nanoparticles really enhance thermal stability of polymers? Part I: an overview on thermal decomposition of addition polymers. Thermochim Acta 523(1–2):1–24

Chung DD (2001) Electromagnetic interference shielding effectiveness of carbon materials. Carbon 39:279–285

Singh B, Singh D, Mathur R et al (2008) Influence of surface modified MWCNTs on the mechanical, electrical and thermal properties of polyimide nanocomposites. Nanoscale Res Lett 3:444–453

Li M, Feng Y, Wang J (2023) Asymmetric conductive structure design for stabilized composites with absorption dominated ultra-efficient electromagnetic interference shielding performance. Compos Sci Technol 236:110006

Yang S, Chen CY, Parng SH (2002) Effects of conductive fibers and processing conditions on the electromagnetic shielding effectiveness of injection molded composites. Polym Compos 23(6):1003–1013

Oehler D, Seegert P, Wetzel T (2021) Modeling the thermal conductivity of porous electrodes of Li-ion batteries as a function of microstructure parameters. Energ Technol 9:2000574

Abdel Rafea M, Eid A, Daoush W (2023) Synthesis and characterization of carbon nanotube/copper oxide nanocomposite as an enhanced absorber for solar radiation. Opt Mater 138:113643

Wang C, Wan W, Huang Y (2014) Hierarchical MoS2 nanosheet/active carbon fiber cloth as a binder-free and free-standing anode for lithium-ion batteries. Nanoscale 6:5351–5358

Tadjine R, Houimi A, Alim M, Oudini N (2022) Oxygen flow rate effect on copper oxide thin films deposited by radio frequency magnetron sputtering. Thin Solid Films 741:139013

Murali D, Kumar S, Choudhary R, Wadikar A, Jain M, Subrahmanyam A (2015) Synthesis of Cu2O from CuO thin films: optical and electrical properties. AIP Adv 5:047143

Ribeiro Y, Pereira J, David D, da Silv M (2022) Growth, characterization, and photovoltaic application of copper oxide thin films. Thin Solid Films 757:139381

Chevallier C, Bose S, Hamady S, Horwat D, Pierson J, Boulet P, Fressengeas N (2022) Effect of temperature and d-sorbitol reducing agent content on the structural and optical properties of copper oxide thin films deposited by ultrasonic spray pyrolysis. Thin Solid Films 758:139435

Abdel Rafea M, Roushdy N (2009) Determination of the optical band gap for amorphous and nanocrystalline copper oxide thin films prepared by SILAR technique. J Phys D Appl Phys 42:015413

Daoush W, Lim B, Mo C, Nam D, Hong S (2009) Electrical and mechanical properties of carbon nanotube reinforced copper nanocomposites fabricated by electroless deposition process. Mater Sci Eng 513–514:247–253

Geeth M, Maury M, Al-Maadeed S, Muthalif A, Sadasivuni K (2022) High-precision nonenzymatic electrochemical glucose sensing based on CNTs/CuO nanocomposite. J Electron Mater 51:4905–4917

Zhang X, Fan X, Yan C (2012) Interfacial microstructure and properties of carbon fiber composites modified with graphene oxide. ACS Appl Mater Interfaces 4:1543–1552

Feng M, Wang S, Yu Y, Feng Q, Yang J, Zhang B (2017) Carboxyl functionalized carbon fibers with preserved tensile strength and electrochemical performance used as anodes of structural lithium-ion batteries. Appl Surf Sci 392:27–35

Schlesinger M (2000) Electroless deposition of nickel. Modern Electroplat 4:667–684

García-Cerda LA, Bernal-Ramos KM, Montemayor SM, Quevedo-López MA, Betancourt-Galindo R, Bueno-Báques D (2011) Preparation of hcp and fcc Ni and Ni/NiO nanoparticles using a citric acid assisted pechini-type method. J Nanomater 2011:162495

Eluri R, Paul B (2012) Synthesis of nickel nanoparticles by hydrazine reduction: mechanistic study and continuous flow synthesis. J Nanopart Res 14:800

El-Sabbagh SH, Ahmed NM, Daoush W (2006) Colored rubber vulcanizates with some magnetic properties. J Appl Polym Sci 102:494–505

Mansour SH, Ahmed NM, Daoush W (2007) Studies on magnetic pigmented polyester composites. Polym Plast Technol Eng 46:85–96

Maria HJ, Lyczko N, Nzihou A et al (2013) Transport of organic solvents through natural rubber/nitrile rubber/organically modified montmorillonite nanocomposites. J Mater Sci 48:5373–5386. https://doi.org/10.1007/s10853-013-7332-7

Costache MC, Jiang DD, Wilkie CA (2005) Thermal degradation of ethylene–vinyl acetate coplymer nanocomposites. Polymer 46(18):6947–6958. https://doi.org/10.1016/j.polymer.2005.05.084

Sobhy M et al (2022) Thermal properties of nano tungsten-ethylene vinyl acetate (EVA) composites. 2020 IOP Conf Ser Mater Sci Eng 975:012003

Daoush WM, Imae T (2012) Syntheses and characterizations of multi-walled carbon nanotubes-supported palladium nanocomposites. J Mater Res 27(13):1680–1687

Daoush WM, Hong SH (2013) Synthesis of multi-walled carbon nanotube/silver nanocomposite powders by chemical reduction in aqueous solution. J Exp Nanosci 8(5):578–587

Lu H, Li Z, Qi X, Xu L, Chi Z, Duan D, Islam MDZ, Wang W, Jin X, Zhu Y, Fu Y, Cui L, Zhuang Y, Dong Y (2021) Flexible, electrothermal-driven controllable carbon fiber/poly(ethylene-co-vinyl acetate) shape memory composites for electromagnetic shielding. Compos Sci Technol 207:108697

Faga MG, Duraccio D, Di Maro M, Pedraza R, Bartoli M, d’Ayala GG, Torsello D, Ghigo G, Malucelli G (2022) Ethylene-vinyl acetate (EVA) containing waste hemp-derived biochar fibers: mechanical, electrical, thermal and tribological behavior. Polymers 14:4171. https://doi.org/10.3390/polym14194171

Zubkiewicz A, Szymczyk A, Franciszczak P, Kochmanska A, Janowska I, Paszkiewicz S (2020) Comparing multi-walled carbon nanotubes and halloysite nanotubes as reinforcements in EVA nanocomposites. Materials 13:3809. https://doi.org/10.3390/ma13173809

Gan X (2009) Effect of interface structure on mechanical properties of advanced composite materials. Int J Mol Sci 10(12):5115–5134

He D, Fan B, Zhao H, Lu X, Yang M, Liu Y et al (2017) Design of electrically conductive structural composites by modulating aligned CVD-grown carbon nanotube length on glass fibers. ACS Appl Mat Interfaces 9(3):2948–2958

Pasanovic-Zujo V, Gupta RK, Bhattacharya SN (2004) Effect of vinyl acetate content and silicate loading on EVA nanocomposites under shear and extensional flow. Rheol Acta 43(2):99–108

Adams JB, Wolfer WG, Foiles SM (1989) Elastic properties of grain boundaries in copper and their relationship to bulk elastic constants. Phys Rev B 40(14):9479–9484

Kamae T, Drzal LT (2022) Carbon fiber/epoxy composite property enhancement through incorporation of carbon nanotubes at the fiber-matrix interphase—part II: mechanical and electrical properties of carbon nanotube coated carbon fiber composites. Compos Part A Appl Sci Manuf 160:107023

Sinha Ray S, Okamoto M (2003) Polymer/layered silicate nanocomposites: a review from preparation to processing. Progr Polym Sci (Oxf) 28(11):1539–1641

Acknowledgements

The authors extend their appreciation to the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) for funding and supporting this work through Research Partnership Program No. RP-21-09-72.

Funding

The authors extend their appreciation to the Deanship of Scientific Research at Imam Mohammad Ibn Saud Islamic University (IMSIU) for funding and supporting this work through Research Partnership Program no RP-21-09-72.

Author information

Authors and Affiliations

Contributions

Conceptualization, WMD, AFA, MSS and FI; methodology, WMD, AFA, MSS and FI; validation, WMD, AFA, MSS and FI; formal analysis, WMD, AFA, MSS and FI; investigation, WMD, AFA, MSS and FI; resources, WMD; data curation, WMD, AFA, MSS and FI; writing—original draft preparation WMD; writing—review and editing, WMD, AFA, MSS and FI; visualization, WMD, AFA, MSS and FI supervision, WMD and FI; project administration, WMD All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Daoush, W.M., Al-Zuair, A.F., Saharudin, M.S. et al. Carbon fibers/nickel nanocomposite particles reinforced ethylene vinyl acetate stretchable conductive polymer: fabrication, microstructure, electrical and mechanical properties. Carbon Lett. 34, 1301–1316 (2024). https://doi.org/10.1007/s42823-023-00630-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42823-023-00630-z