Abstract

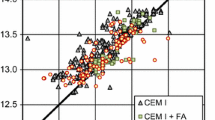

The effect of SiO2 and B2O3 on viscosity and surface tension of CaF2–CaO–Al2O3–MgO–SiO2–B2O3 slag designed for electroslag remelting of rotor steel was investigated. The viscosity of the slag melts increases with increasing the SiO2 content from 0.37 to 8.03 mass%, and the viscous activation energy increases from 54.21 to 58.49 kJ/mol. Increasing B2O3 content of the slag from 0 to 3.62 mass% exhibits a similar effect on the viscosity, and the activation energy increases from 47.30 to 55.71 kJ/mol. The increase in the viscosity and activation energy for viscous flow of slag is attributed to the enhanced polymerization degree of slag melts network with increasing either SiO2 or B2O3 content. The surface tension of slag melts decreases with increasing temperature. The surface tension of slag melts decreases with increasing either SiO2 or B2O3 content, which is originated from the increase in the polymerization degree and the decrease in the CaO content of the slag.

Similar content being viewed by others

References

C.B. Shi, J. Li, J.W. Cho, F. Jiang, I.H. Jung, Metall. Mater. Trans. B 46 (2015) 2110–2120.

L.Z. Peng, Z.H. Jiang, X. Geng, Calphad 70 (2020) 101782.

S.C. Duan, M.J. Lee, D.S. Kim, J.H. Park, J. Mater. Res. Technol. 17 (2022) 574–585.

P.J. Wen, D.L. Xiang, Heavy Casting and Forging (2016) No. 6, 48–50+52.

P.J. Wen, D.L. Xiang, Heavy Casting and Forging (2017) No. 3, 53–55+57.

J. Fedko, M. Krucinski, Ironmak. Steelmak. 16 (1989) 116–122.

C.B. Shi, Y. Huang, J.X. Zhang, J. Li, X. Zheng, Int. J. Miner. Metall. Mater. 28 (2021) 18–29.

J.T. Ba, J.J. Gao, S.B. Wang, Q.H. Yang, Heavy Casting and Forging (2018) No. 3, 1–4+7.

B.H. Yoon, K.H. Heo, J.S. Kim, H.S. Sohn, Ironmak. Steelmak. 29 (2002) 214–217.

M. Nakamoto, M. Hanao, T. Tanaka, M. Kawamoto, L. Holappa, M. Hämäläinen, ISIJ Int. 47 (2007) 1075–1081.

K. Narita, T. Onoye, T. Ishii, T. Kusamichi, Tetsu-to-Hagané 64 (1978) 1568–1577.

M.E. Fraser, A. Mitchell, Ironmak. Steelmak. 3 (1976) 279–287.

S.J. Wang, C.B. Shi, Y.J. Liang, X.X. Wang, X. Zhu, Metall. Mater. Trans. B 53 (2022) 3095–3114.

C.B. Shi, J.W. Cho, D.L. Zheng, J. Li, Int. J. Miner. Metall. Mater. 23 (2016) 627–636.

F. Shahbazian, D. Sichen, S. Seetharaman, ISIJ Int. 39 (1999) 687–696.

Y.B. Peng, C.S. Liu, L. Yang, S.W. Hou, R.J. Cheng, H. Zhang, H.W. Ni, J. Iron Steel Res. Int. 29 (2022) 1434–1445.

Z.Y. Hu, H.J. Duan, L.F. Zhang, Metall. Mater. Trans. B 53 (2022) 1339–1343.

J.O’M. Bockris, J.D. Mackenzie, J.A. Kitchener, Trans. Faraday Soc. 51 (1955) 1734–1748.

L.J. Zhou, W.L. Wang, B.X. Lu, G.H. Wen, J. Yang, Met. Mater. Int. 21 (2015) 126–133.

R. Zhang, Y.F. Meng, Z. Wang, S.Y. Jiao, J.X. Jia, Y. Min, C.J. Liu, Metall. Mater. Trans. B 53 (2022) 571–583.

Q. Gao, Y. Min, M.F. Jiang, Metall. Mater. Trans. B 49 (2018) 1302–1310.

S. Sukenaga, T. Higo, H. Shibata, N. Saito, K. Nakashima, ISIJ Int. 55 (2015) 1299–1304.

S. Sukenaga, S. Haruki, Y. Nomoto, N. Saito, K. Nakashima, ISIJ Int. 51 (2011) 1285–1289.

J.Y. Choi, H.G. Lee, ISIJ Int. 42 (2002) 221–228.

C.M. Cui, G.F. Zhang, X.G. Xu, W.R. Han, Nonferrous Metals 48 (1996) No. 1, 49–53.

J.C. Li, S.C. Qi, J.F. Xu, J.Y. Zhang, Z. Li, Shanghai Metals 38 (2016) No. 2, 69–73+78.

Y. Huang, C.B. Shi, X.X. Wan, J.L. Li, D.L. Zheng, J. Li, J. Iron Steel Res. Int. 28 (2021) 1530–1540.

C.B. Shi, S.H. Shin, D.L. Zheng, J.W. Cho, J. Li, Metall. Mater. Trans. B 47 (2016) 3343–3349.

C.B. Shi, D.L. Zheng, S.H. Shin, J. Li, J.W. Cho, Int. J. Miner. Metall. Mater. 24 (2017) 18–24.

J.B. Kim, I. Sohn, ISIJ Int. 54 (2014) 2050–2058.

T.A. Litovitz, J. Chem. Phys. 20 (1952) 1088–1089.

G.H. Kim, I. Sohn, J. Non-Cryst. Solids 358 (2012) 1530–1537.

W.L. Li, X.X. Xue, ISIJ Int. 58 (2018) 1751–1760.

G. Urbain, Y. Bottinga, P. Richet, Geochim. Cosmochim. Acta 46 (1982) 1061–1072.

H. Kim, H. Matsuura, F. Tsukihashi, W.L. Wang, D.J. Min, I. Sohn, Metall. Mater. Trans. B 44 (2013) 5–12.

Y.Q. Sun, J.L. Liao, K. Zheng, X.D. Wang, Z.T. Zhang, JOM 66 (2014) 2168–2175.

L.G. Liu, L.G. Zhu, X.J. Wang, X.D. Xu, Y. Sun, Journal of North China University of Science and Technology 40 (2018) No. 3, 31–38.

Y.W. Dong, Z.H. Jiang, Y.L. Cao, H.K. Zhang, H.J. Shen, J. Cent. South Univ. 21 (2014) 4104–4108.

J.F. Xu, J.C. Li, W.P. Weng, M.Q. Sheng, D. Chen, J.Y. Zhang, Y. Chen, Chin. J. Nonferrous Met. 27 (2017) 206–214.

Acknowledgements

The financial support by the National Natural Science Foundation of China (Grant Nos. 52074027 and 51874026) is greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there are no conflicts of interest and ethical rule that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Huang, Y., Shi, Cb., Wan, Xx. et al. Viscosity and surface tension of CaF2–CaO–Al2O3-based slag with varying SiO2 and B2O3 contents for ESR of rotor steel. J. Iron Steel Res. Int. 30, 74–81 (2023). https://doi.org/10.1007/s42243-022-00861-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00861-w