Abstract

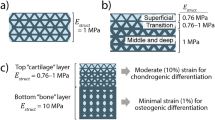

Additive manufacturing (AM) has revolutionized the design and manufacturing of patient-specific, three-dimensional (3D), complex porous structures known as scaffolds for tissue engineering applications. The use of advanced image acquisition techniques, image processing, and computer-aided design methods has enabled the precise design and additive manufacturing of anatomically correct and patient-specific implants and scaffolds. However, these sophisticated techniques can be time-consuming, labor-intensive, and expensive. Moreover, the necessary imaging and manufacturing equipment may not be readily available when urgent treatment is needed for trauma patients. In this study, a novel design and AM methods are proposed for the development of modular and customizable scaffold blocks that can be adapted to fit the bone defect area of a patient. These modular scaffold blocks can be combined to quickly form any patient-specific scaffold directly from two-dimensional (2D) medical images when the surgeon lacks access to a 3D printer or cannot wait for lengthy 3D imaging, modeling, and 3D printing during surgery. The proposed method begins with developing a bone surface-modeling algorithm that reconstructs a model of the patient’s bone from 2D medical image measurements without the need for expensive 3D medical imaging or segmentation. This algorithm can generate both patient-specific and average bone models. Additionally, a biomimetic continuous path planning method is developed for the additive manufacturing of scaffolds, allowing porous scaffold blocks with the desired biomechanical properties to be manufactured directly from 2D data or images. The algorithms are implemented, and the designed scaffold blocks are 3D printed using an extrusion-based AM process. Guidelines and instructions are also provided to assist surgeons in assembling scaffold blocks for the self-repair of patient-specific large bone defects.

Graphic abstract

Similar content being viewed by others

References

Schemitsch EH (2017) Size matters: defining critical in bone defect size! J Orthop Trauma 31:S20–S22. https://doi.org/10.1097/BOT.0000000000000978

Arrington ED, Smith WJ, Chambers HG et al (1996) Complications of iliac crest bone graft harvesting. Clin Orthop Relat Res 329:300–309. https://doi.org/10.1097/00003086-199608000-00037

Banwart JC, Asher MA, Hassanein RS (1995) Iliac crest bone graft harvest donor site morbidity: a statistical evaluation. Spine 20(9):1055–1066. https://doi.org/10.1097/00007632-199505000-00012

Flierl MA, Smith WR, Mauffrey C et al (2013) Outcomes and complication rates of different bone grafting modalities in long bone fracture nonunions: a retrospective cohort study in 182 patients. J Orthop Surg Res 8(1):33. https://doi.org/10.1186/1749-799X-8-33

Polo-Corrales L, Latorre-Esteves M, Ramirez-Vick JE et al (2014) Scaffold design for bone regeneration. J Nanosci Nanotechnol 14(1):15–56. https://doi.org/10.1166/jnn.2014.9127

Kim T, See CW, Li XC et al (2020) Orthopedic implants and devices for bone fractures and defects: past, present and perspective. Eng Regen 1:6–18. https://doi.org/10.1016/j.engreg.2020.05.003

Ji CD, Annabi N, Hosseinkhani M et al (2012) Fabrication of poly-DL-lactide/polyethylene glycol scaffolds using the gas foaming technique. Acta Biomater 8(2):570–578. https://doi.org/10.1016/j.actbio.2011.09.028

Wu X, Liu Y, Li X et al (2010) Preparation of aligned porous gelatin scaffolds by unidirectional freeze-drying method. Acta Biomater 6(3):1167–1177. https://doi.org/10.1016/j.actbio.2009.08.041

Pirhonen E, Moimas L, Haapanen J et al (2003) Porous bioactive 3-D glass fiber scaffolds for tissue engineering applications manufactured by sintering technique. Key Eng Mater 240–242:237–240. https://doi.org/10.4028/www.scientific.net/kem.240-242.237

Nandakumar A, Fernandes H, De Boer J et al (2010) Fabrication of bioactive composite scaffolds by electrospinning for bone regeneration. Macromol Biosci 10(11):1365–1373. https://doi.org/10.1002/mabi.201000145

Garg T, Singh O, Arora S et al (2012) Scaffold: a novel carrier for cell and drug delivery. Crit Rev Ther Drug Carrier Syst 29(1):1–63. https://doi.org/10.1615/CritRevTherDrugCarrierSyst.v29.i1.10

Christensen AM, Passalacqua NV, Bartelink EJ (2014) Forensic Anthropology: Current Methods and Practice. Academic Press, London. https://doi.org/10.1016/C2013-0-09760-5

Peacock M, Buckwalter KA, Persohn S et al (2009) Race and sex differences in bone mineral density and geometry at the femur. Bone 45(2):218–225. https://doi.org/10.1016/j.bone.2009.04.236

Rawal BR, Ribeiro R, Malhotra R et al (2012) Anthropometric measurements to design best-fit femoral stem for the Indian population. Indian J Orthop 46(1):46–53. https://doi.org/10.4103/0019-5413.91634

Mahaisavariya B, Sitthiseripratip K, Tongdee T et al (2002) Morphological study of the proximal femur: a new method of geometrical assessment using 3-dimensional reverse engineering. Med Eng Phys 24(9):617–622. https://doi.org/10.1016/S1350-4533(02)00113-3

Turnbull G, Clarke J, Picard F et al (2018) 3D bioactive composite scaffolds for bone tissue engineering. Bioact Mater 3(3):278–314. https://doi.org/10.1016/j.bioactmat.2017.10.001

Zhang L, Yang GJ, Johnson BN et al (2019) Three-dimensional (3D) printed scaffold and material selection for bone repair. Acta Biomater 84:16–33. https://doi.org/10.1016/j.actbio.2018.11.039

Zadpoor AA (2020) Meta-biomaterials. Biomater Sci 8(1):18–38. https://doi.org/10.1039/c9bm01247h

McCall TA, Brokaw DS, Jelen BA et al (2010) Treatment of large segmental bone defects with reamer-irrigator-aspirator bone graft: technique and case series. Orthop Clin North Am 41(1):63–73. https://doi.org/10.1016/j.ocl.2009.08.002

Acar AA (2020) Designing and additive manufacturing of customizable, modular scaffold blocks for large bone defects. MS Thesis, Sabanci University, Istanbul, Türkiye

Stojkovic M, Milovanovic J, Vitkovic N et al (2012) Analysis of femoral trochanters morphology based on geometrical model. J Sci Ind Res 71(3):210–216

Chen XZ, He KJ, Chen ZM et al (2015) Quick construction of femoral model using surface feature parameterization. MCB Mol Cell Biomech 12(2):123–146. https://doi.org/10.3970/mcb.2015.012.123

McNeel R (2020) Grasshopper-generative modelling with Rhino. McNeel North America, Seattle, USA. https://www.grasshopper3d.com. Accessed 24 Nov, 2023

McNeel R (2020) Rhinoceros-NURBS modeling for Windows (version 6.0). McNeel North America, Seattle, USA. https://www.rhino3d.com. Accessed 24 Nov, 2023

Wu G, Van Der Helm FCT, Veeger HEJ et al (2005) ISB recommendation on definitions of joint coordinate systems of various joints for the reporting of human joint motion-Part II: shoulder, elbow, wrist and hand. J Biomech 38(5):981–992. https://doi.org/10.1016/j.jbiomech.2004.05.042

Chantarapanich N, Rojanasthien S, Chernchujit B et al (2017) 3D CAD/reverse engineering technique for assessment of Thai morphology: proximal femur and acetabulum. J Orthop Sci 22(4):703–709. https://doi.org/10.1016/j.jos.2017.02.003

Koc B, Acar AA, Weightman A et al (2019) Biomanufacturing of customized modular scaffolds for critical bone defects. CIRP Ann 68(1):209–212. https://doi.org/10.1016/j.cirp.2019.04.106

Chen XZ, He KJ, Chen ZM et al (2016) A parametric approach to construct femur models and their fixation plates. Biotechnol Biotechnol Equip 30(3):529–537. https://doi.org/10.1080/13102818.2016.1145555

Noble PC, Alexander JW, Lindahl LJ et al (1988) The anatomic basis of femoral component design. Clin Orthop Relat Res 235:148–165. https://doi.org/10.1097/00003086-198810000-00015

Tamaddon M, Blunn G, Tan R et al (2022) In vivo evaluation of additively manufactured multi-layered scaffold for the repair of large osteochondral defects. Bio-des Manuf 5(3):481–496. https://doi.org/10.1007/s42242-021-00177-w

Acknowledgements

This research is supported by the Engineering and Physical Sciences Research Council (EPSRC) of the UK, the Global Challenges Research Fund (GCRF), Grant Number EP/R015139/1. This paper presents original research work that was conducted as part of a master's thesis at Sabanci University [20]. The authors would like to thank Sabanci University and Nanotechnology Research and Application Center.

Author information

Authors and Affiliations

Contributions

AAA: methodology, software, investigation, writing—original draft, and visualization; BK: supervision, writing—review and editing, conceptualization, and funding acquisition; ED: conceptualization; AW, GC, GB, and PB: conceptualization and funding acquisition.

Corresponding author

Ethics declarations

Conflict of interest

PB is an editorial board member for Bio-Design and Manufacturing and was not involved in the editorial review or the decision to publish this article. The authors declare that they have no conflict of interest.

Ethical approval

This article does not contain any studies with human or animal subjects performed by any of the authors.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Acar, A.A., Daskalakis, E., Bartolo, P. et al. Customized scaffolds for large bone defects using 3D-printed modular blocks from 2D-medical images. Bio-des. Manuf. 7, 74–87 (2024). https://doi.org/10.1007/s42242-023-00259-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42242-023-00259-x