Abstract

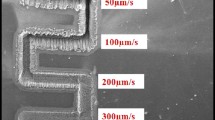

Hierarchical structures significantly influence the development of metal surface wettability. In this study, three kinds of hierarchical structures formed by the superimposition of different nanoscale (quasi-) periodic structures on micro-column arrays were fabricated on 304 stainless steel surfaces via picosecond laser irradiation. Scanning Electron Microscope (SEM) and Confocal Laser Scanning Microscope (CLSM) were used to characterize the created hierarchical structures. An optical contact angle meter was used to analyse the wetting performances. The results show that the surfaces of these fabricated samples have superhydrophobic properties and strong adhesion performances, which can be attributed to the formation of hierarchical structure that causes a reduction in the liquid-solid contact area and the change in the direction of surface tension. By controlling the dimensionof the nanotextures on the micro-column arrays, the hydrophobic property of 304 stainless steel surfaces can be greatly improved.

Similar content being viewed by others

References

Patankar N A. Mimicking the lotus effect: Influence of double roughness structures and slender pillars. Langmuir, 2004, 20, 8209–8213.

Bharat B, Eun Kyu H. Fabrication of superhydrophobic surfaces with high and low adhesion inspired from rose petal. Langmuir, 2010, 26, 8207–8217.

Long J Y, Fan P X, Gong D W, Jiang D F, Zhang H J, Li L, Zhong M L. Superhydrophobic surfaces fabricated by femtosecond laser with tunable water adhesion: From lotus leaf to rose petal. ACS Applied Materials & Interfaces, 2015, 7, 9858–9865.

Bhushan B, Nosonovsky M. The rose petal effect and the modes of superhydrophobicity. Philosophical Transactions Mathematical Physical and Engineering Sciences, 2010, 368, 4713–4728.

Bhushan B, Jung Y C, Koch K. Micro-, nano- and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion. Philosophical Transactions Mathematical Physical and Engineering Sciences, 2009, 367, 1631–1672.

Jaggessar A, Shahali H, Mathew A, Yarlagadda P. Bio-mimicking nano and micro-structured surface fabrication for antibacterial properties in medical implants. Journal of Nanobiotechnology, 2017, 15, 64.

Suryaprabha T, Sethuraman M G. Fabrication of copper-based superhydrophobic self-cleaning antibacterial coating over cotton fabric. Cellulose, 2017, 24, 395–407.

Han Z W, Mu Z Z, Yin W, Li W, Niu S C, Zhang J Q, Ren L Q. Biomimetic multifunctional surfaces inspired from animals. Advances in Colloid and Interface Science, 2016, 234, 27–50.

Li H J, Fan W Z, Pan H H, Wang C W, Qian J, Zhao Q Z. Fabrication of “petal effect” surfaces by femtosecond laser-induced forward transfer. Chemical Physics Letters, 2017, 667, 20–24.

Barthlott W, Mail M, Bhushan B, Koch K. Plant surfaces: Structures and functions for biomimetic innovations. Nano-Micro Letters, 2017, 9, 23.

Wang Q, Dong Z, Yan X X, Chang Y J, Ren L L, Zhou J. Biomimetic hydrophobic surfaces with low or high adhesion based on poly(vinyl alcohol) and SiO2 nanoparticles. Journal of Bionic Engineering, 2017, 14, 476–485.

Gou X L, Guo Z G. Superhydrophobic plant leaves with micro-line structures: An optimal biomimetic objective in bionic engineering. Journal of Bionic Engineering, 2018, 15, 851–858.

Lai Y K, Gao X F, Zhuang H F, Huang J Y, Lin C J, Lei J. Designing superhydrophobic porous nanostructures with tunable water adhesion. Advanced Materials, 2010, 21, 3799–3803.

Song X Y, Jin Z, Wang Y L, J Lei. Fabrication of superhydrophobic surfaces by self-assembly and their water-adhesion properties. Journal of Physical Chemistry B, 2005, 109, 4048–4052.

Bai W B, Lai N S, Guan M Q, Yao R J, Xu Y L, Lin J H. Petal-effect superhydrophobic surface self-assembled from poly(p-phenylene)s. European Polymer Journal, 2018, 101, 12–17.

Yong J L, Yang Q, Chen F, Zhang D S, Farooq U, Du G Q, Hou X. A simple way to achieve superhydrophobicity, controllable water adhesion, anisotropic sliding, and anisotropic wetting based on femtosecond-laser-induced line-patterned surfaces. Journal of Materials Chemistry A, 2014, 2, 5499–5507.

Jopp J, Grull H, Yerushalmi-Rozen R. Wetting behavior of water droplets on hydrophobic microtextures of comparable size. Langmuir, 2004, 20, 10015–10019.

Szczepanski C R, Guittard F, Darmanin T. Recent advances in the study and design of parahydrophobic surfaces: From natural examples to synthetic approaches. Advances in Colloid and Interface Science, 2017, 241, 37–61.

Bao Z J, Wang C W, Zhang Y, Zhao Q Z. Modification of wettability of stainless steel by picosecond laser surface microstructuring. Photonics Research, 2015, 3, 180–183.

Shum P W, Zhou Z F, Li K Y. To increase the hydrophobicity, non-stickiness and wear resistance of DLC surface by surface texturing using laser ablation process. Tribology International, 2014, 78, 1–6.

Martínez-Calderon M, Rodríguez A, Dias-Ponte A, Morant-Miñana M C, Gómez-Aranzadi M, Olaizola S M. Femtosecond laser fabrication of highly hydrophobic stain less steel surface with hierarchical structures fabricated by combining ordered microstructures and LIPSS. Applied Surface Science, 2016, 374, 81–89.

Wang X S, Li C Y, Hong W, Ma C B, Xing Y Q, Feng J. Fabrication of ordered hierarchical structures on stainless steel by picosecond laser for modified wettability applications. Optics Express, 2018, 26, 18998–19008.

Rukosuyev M V, Lee J, Cho S J, Lim G, Jun M B G. One-step fabrication of superhydrophobic hierarchical structures by femtosecond laser ablation. Applied Surface Science, 2014, 313, 411–417.

Wang X S, Li C Y, Ma C B, Feng J, Hong W, Zhang Z. Formation of laser induced periodic structures on stainless steel using multi-burst picosecond pulses. Optics Express, 2018, 26, 6325–6330.

Noh J, Lee J, Na S, Lim H, Jung D H. Fabrication of hierarchically micro- and nano-structured mold surfaces using laser ablation for mass production of superhydrophobic surfaces. Japanese Journal of Applied Physics, 2010, 49, 106502.

Varlamova O, Hoefner K, Ratzke M, Reif J, Sarker D. Modification of surface properties of solids by femtosecond LIPSS writing: Comparative studies on silicon and stainless steel. Applied Physics A, 2017, 123, 725.

Nathala C S, Ajami A, Ionin A A, Kudryashov S I, Makarov S V, Ganz T, Assion A, Husinsky W. Experimental study of fs-laser induced sub-100-nm periodic surface structures on titanium. Optics Express, 2015, 23, 5915–5929.

Luo B H, Shum P W, Zhou Z F, Li K Y. Surface geometrical model modification and contact angle prediction for the laser patterned steel surface. Surface & Coatings Technology, 2010, 205, 2597–2604.

Extrand C W. Model for contact angles and hysteresis on rough and ultraphobic surfaces. Langmuir, 2002, 18, 7991–7999.

Yong C J, Bhushan B. Contact angle, adhesion and friction properties of micro-and nanopatterned polymers for superhydrophobicity. Nanotechnology, 2006, 17, 4970–4980.

Acknowledgement

This work was financially supported by the Natural Science Foundation of Jiangsu Province (BK20150685), the National Natural Science Foundation of China (51705258), and the Foundation for Distinguished Young Talents, College of Engineering, Nanjing Agricultural University (YQ201604).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ma, C., Kang, M., Wang, X. et al. Fabrication of Regular Hierarchical Structures with Superhydrophobic and High Adhesion Performances on a 304 Stainless Steel Surface via Picosecond Laser. J Bionic Eng 16, 806–813 (2019). https://doi.org/10.1007/s42235-019-0098-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42235-019-0098-0