Abstract

Organic electrode materials (OEMs) can deliver remarkable battery performance for metal-ion batteries (MIBs) due to their unique molecular versatility, high flexibility, versatile structures, sustainable organic resources, and low environmental costs. Therefore, OEMs are promising, green alternatives to the traditional inorganic electrode materials used in state-of-the-art lithium-ion batteries. Before OEMs can be widely applied, some inherent issues, such as their low intrinsic electronic conductivity, significant solubility in electrolytes, and large volume change, must be addressed. In this review, the potential roles, energy storage mechanisms, existing challenges, and possible solutions to address these challenges by using molecular and morphological engineering are thoroughly summarized and discussed. Molecular engineering, such as grafting electron-withdrawing or electron-donating functional groups, increasing various redox-active sites, extending conductive networks, and increasing the degree of polymerization, can enhance the electrochemical performance, including its specific capacity (such as the voltage output and the charge transfer number), rate capability, and cycling stability. Morphological engineering facilitates the preparation of different dimensional OEMs (including 0D, 1D, 2D, and 3D OEMs) via bottom-up and top-down methods to enhance their electron/ion diffusion kinetics and stabilize their electrode structure. In summary, molecular and morphological engineering can offer practical paths for developing advanced OEMs that can be applied in next-generation rechargeable MIBs.

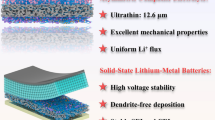

Graphical abstract

Similar content being viewed by others

1 Introduction of Organic Electrode Materials (OEMs)

1.1 Brief History of OEMs Development

The announcement of the first commercial lithium-ion batteries (LIBs) by Sony Corporation in 1991 began the epoch of portable smart electronic devices. In the first generation of LIBs, LiCoO2 (LCO) and graphite were used as the cathode and anode to deliver high specific capacities of approximately 274 mAh g−1 and 372 mAh g−1, respectively [1,2,3]. To further improve the energy density, rate capability and safety of LIBs, over 30 years of substantial efforts from the research and development world have been devoted to the exploration of high-performance electrode materials, particularly inorganic electrode materials (IEMs), such as LiMn2O4 [4], LiFePO4 [5], LiNiII1/3MnIV1/3CoIII1/3O2 (NMC) [6] cathodes, and silicon [7,8,9] and lithium titanate (LTO) [10] anodes. IEMs were first adopted for LIBs mainly due to their commercial availability and apparent advantages, as shown in Table 1. In particular, IEMs can generally maintain structural and property stability in organic electrolytes, partly ensuring a reasonable lifespan. To date, numerous kinds of general charge/discharge mechanisms for IEMs have been proposed and verified, including Li-ion intercalation/extraction, alloying/dealloying, and redox conversion reactions for both cathodes and anodes [1]. In addition, large-scale metal mines for raw materials are readily available to achieve the massive production of IEMs. Finally, morphological engineering over the past 20 years has resulted in the availability of a wide spectrum of nanostructured IEMs, including 0D, 1D, 2D, and 3D nanomaterials, which has also propelled the rapid development of IEMs. However, the present IEMs also face a series of drawbacks.

-

1.

The short lifetime and potential fire risk of IEMs can be attributed to the fact that they often have an inherently rigid structure that is not compatible with significant volume changes along with an irreversible phase transition during the charge/discharge processes.

-

2.

The large-scale production of IEMs demands high consumption of unsustainable natural sources and energy during mining (such as Li, Co, and Ni) and high-temperature treatments. Such high carbon footprint activities can lead to irreversible damage and severe pollution to the ecological environment.

-

3.

The limited amount of natural resources on Earth will not meet the nearly infinite demand of IEMs for large-scale LIB applications, such as electric vehicles and smart grids.

With the increasing awareness of the economic and environmental costs of natural resource consumption, the design, production, and application of advanced energy storage devices will promote the growth of the global green economy and meet the requirements of global carbon neutrality in the near future. For this reason, we not only need to further improve the energy density and safety of LIBs but also need to adopt sustainable electrode materials for designing a new generation of LIBs. Organic electrode materials (OEMs) can address the above challenges; therefore, OEMs may play an important role in the next generation of LIBs and even other metal-ion batteries (MIBs), including sodium-ion batteries (SIBs), potassium-ion batteries (PIBs), zinc-ion batteries (ZIBs), and aluminium-ion batteries (AIBs).

Generally, OEMs consist of low-cost and sustainable nonmetallic elements (e.g. C, H, O, S and N) that can have multiple tuneable redox potentials to suit current LIB charge/discharge processes. Accordingly, OEMs can be classified into six types of compounds (Fig. 1), i.e. carbonyl OEMs, sulphur-containing OEMs, nitrogen-containing OEMs, conducting polymer OEMs, radical-based OEMs, and overlithiated OEMs. The first OEM-based LIB was reported in 1960, approximately three decades before the commercialization of IEMs (Fig. 1). From the viewpoint of the electrochemical performance and properties of OEMs, it can be concluded that the development history of OEMs can be separated into two paths based on the enhancement of the energy density, i.e. raising the redox potential (the upper part of Fig. 1) and boosting the charge transfer number (the lower part of Fig. 1).

Historical development of OEMs. Twenty compounds have been selected to represent the development of six types of typical OEMs, including carbonyl OEMs, sulphur-containing OEMs, nitrogen-containing OEMs, conducting polymer OEMs, radical-based OEMs and overlithiated OEMs. The columns above the time axis represent the operating potential range, while the columns under the axis indicate the charge transfer number of the OEMs

In the first path, electrode materials with a high operating potential are used to advance the energy density of MIBs. The first inherent advantage of OEMs lies in the fact that the molecular structure of OEMs can be designed to tune their redox potentials of OEMs and, therefore, the potential output of the relevant MIBs (see the upper part of Fig. 1). Carbonyl OEMs were the first type of OEM to confirm the mechanistic viability of this approach. In fact, via the introduction of functional groups, the redox potential of the carbonyl OEMs can be tuned between 1.7 and 3.2 V (vs. Li/Li+), such as dichloroisocyanuric acid (DCA, No. 1) [11], quinone (No. 6) [12], polyimide (No. 10) [13], pyrene 4,5,9,10-tetraone (PYT, No. 12), and cyclohexanehexone (No. 14) [14]. As an example, the redox potential of DCA [11] can be increased to 3.2 V (vs. Li/Li+) due to the introduction of three chlorine atoms. Conjugated dicarboxylate (No. 15) [15] has a low-voltage redox potential of 0.8 V because of the aromaticity of its core and resonance of the carboxylates. Overlithiated OEMs, such as 1,4,5,8-naphthalenetetracarboxylic dianhydride (NTCDA, No. 16) [16], polyazaacene analogue (PQL, No. 17) [17], imine-based COFs (No. 18) [18], multicarbonyl polyimides (PMTA, No. 19) [19], and polyimide Schiff base (NBI-PI, No. 20) [20], can achieve an obvious anodic working plateau between 0 and 1.6 V (vs. Li/Li+). In addition, the representative sulphur-containing OEM tetraethylthiuram disulphide (TETD, No. 7) [21] delivers a high voltage of approximately 3.0 V (vs. Li/Li+). Nitrogen-containing OEMs also have a wide working potential between 1.55 and 3.00 V, such as 7,7,8,8-tetracyanoquinodimethane (TCNQ, No. 4) [22], 5,6,11,12,17,18-hexaazatri-naphthylene (HATNA, No. 11) [23], and azo compounds (No. 13) [24]. It is interesting that p-type OEMs, including conducting polymer OEMs and radical-based OEMs, work at a high potential above 3.5 V (vs. Li/Li+). In 1981, through iodine doping, the conductivity of the conducting polymer polyacetylene (PA, No. 2) was enhanced by approximately 10 orders of magnitude, showing that PA was an excellent OEM with a redox potential of 3.95 V (vs. Li/Li+) [25, 26]. Later, conducting polymers continued to be used as OEMs at high voltages, e.g. from 2.50 to 3.95 V (vs. Li/Li+) for polyacetylene (No. 3), from 3.0 to 4.3 V (vs. Li/Li+) for polythiophene (No. 3) [27], from 2.50 to 4.01 V (vs. Li/Li+) for polyaniline (No. 5) [28], and from 2.0 to 3.5 V (vs. Li/Li+) for polypyrrole (No. 8) [29]. However, conducting polymers encounter severe barriers in delivering ample capacity in charge/discharge processes because of the limited doping level, which is typically below 50% [26, 30]. In 2002, poly(2,2,6,6-tetramethylpiperidinyloxy methacrylate (PTMA, No. 9), a radical OEM associated with a 2,6,6-tetramethyl-1-piperidinyloxy (TEMPO) redox unit, delivered a high potential plateau at approximately 3.6 V (vs. Li/Li+) and a high voltage range from 2.5 to 4.3 V (vs. Li/Li+). Additionally, PTMA exhibited a low theoretical capacity of approximately111 mAh g−1 based on a one-electron transfer reaction with anion insertion [31]. After that, in 2012, the above OEM exhibited another voltage range of from 2.5 to 3.2 V (vs. Li/Li+) based on the second-stage electron transfer of PTMA with a reversible cation (e.g. Li+) insertion through the construction of an improved electronic conductive network [32]. The strategies for tuning the redox activity of OEMs by molecular engineering, such as tailing the redox potential by grafting functional groups, are reviewed systematically in Sect. 2.

In the second path, the charge transfer number (including the electron, cation, or anion transfer number during the energy storage reaction) of electrode materials is another parameter that determines the specific capacity. Through molecular and morphological engineering of OEMs, an increased number of active sites can be realized, thereby increasing the charge transfer number (see the lower part of Fig. 1), which leads to an increased theoretical capacity [33, 34]. This roadmap of OEMs implies that their development with more redox electrons can be a promising research direction. Conducting polymers and radical OEMs usually undergo 0–2 electron reactions with relatively low theoretical capacity, while carbonyl, sulphur-containing, nitrogen-containing, and overlithiated OEMs can exhibit a larger number of active sites or redox electrons (from 2 to 22). In 1969, DCA, the first reported carbonyl OEM, could perform a 4-electron transfer in a redox reaction [11]. Carbonyl functional groups became popular in OEMs because of their high reactivity and theoretical capacity of approximately 957 mAh g−1 per C=O unit. Later, significant attention was devoted to increasing the number of redox-active carbonyl groups. Carbonyl compounds, including monomeric carbonyl compounds No. 6 [12], No. 12 [35] and No. 14 [14], equipped with two, four, and six carbonyl groups delivered increasing theoretical capacities of 257 mAh g−1, 409 mAh g−1, and 957 mAh g−1, respectively. In 1988, Visco et al. bestowed a sulphur-containing OEM (No. 7) with high redox activity at the sulphur–sulphur bond (S–S) [21] by using the cleavage and regeneration of covalent disulphide (S–S) bonds to enable a 2-electron reaction when forming sulphide salts. Later, various molecular designs were developed to covalently bind poly(sulphide)s (–Sx–) into π-cyclic backbones and achieve a higher number of S–S bond reactions and a corresponding increase in the number of electron transfers [36]. Nitrogen-containing groups, including highly redox-active C≡N, C=N, and N=N bonds, provide another approach to improve the diversity and high charge storage capacity of OEMs. No. 4, a representative nitrogen-based electron-poor molecule incorporated with an unsaturated carbon–nitrogen bond, can transfer up to 4 electrons [22], while No. 11, a Schiff base with a carbon–nitrogen double bond (C=N) and π-conjugated aromatic compounds, can realize the transfer of 6 electrons in a redox energy storage reaction [23]. The hexaazatriphenylene (HAT) shown in the No. 11 molecule is an electron-deficient aromatic system with a planar and rigid structure, playing a critical role as a scaffold for fabricating HAT-based π-conjugated microporous polymers (CMPs) [37,38,39]. These π-conjugated CMPs create a new platform for higher energy storage because of their porous structure and multiple built-in redox-active sites. In 2018, a new family of OEMs containing active azo groups (No. 13) was adopted in LIBs [24]. These azo functional groups pave another way to reversibly use the nitrogen–nitrogen double bond (N=N) to store two lithium ions with a high initial Coulombic efficiency (ICE). Furthermore, overlithiated OEMs are a promising strategy for a large number of redox sites to store metal ions. The polymerization of No. 10 [13] and No. 16 [16] produces inherent conjugated structures that allow overlithiation at the conjugated aromatic rings at low working voltages. Sun et al. [16] was the first to employ a naphthalene-based multiring, aromatic compound (No. 16), illustrating the possibility of electrochemically adding 6 lithium ions to the fused C6 ring. A large π-conjugated ladder polymer (No. 17) realizes a storage mechanism for 12 lithium ions [17]. Larger amounts of Li+-accessible OEMs have also been realized with similar conjugated aromatic compounds, such as No. 18 (14 electrons) [18], No. 19 (22 electrons) [19], and No. 20 (12 electrons) [20].

1.2 Advantages of OEMs

It is widely recognized that OEMs have a series of merits in comparison with IEMs (Table 1) [40].

-

1.

Most OEMs can be produced from naturally sustainable resources (such as plants, microorganisms, and animal products) in low energy consuming fabrication processes, thereby achieving a smaller carbon footprint.

-

2.

The entrenched relationships between the electrochemical properties (such as the redox potentials) and functional groups (such as electron donating and attraction of functional groups) allow us to tune the energy storage performance of OEM-based LIBs, including the output voltage, specific theoretical energy density and power capability, by grafting the functional groups onto the stable polymer backbones. Taking TCNQ (No. 4) as an example, in 2013, Morita et al. studied the voltage changes after the substitution of methyl groups and fluorine atoms with TCNQ molecules [41]. The methyl group, an electron donor group, enabled the donation of the electron cloud to the C≡N redox centre, leading to an easier way to extract the electron from the C≡N bond and lowering the output voltage by approximately 0.1 V. In contrast, the organic electron acceptor (fluorine atom) had the opposite effect towards the redox centre, increasing the voltage by approximately 0.2 V.

-

3.

OEMs often have a soft molecular skeleton, which is suitable for flexible electrodes and devices. For example, belt-shaped flexible batteries incorporated with OEMs have been fabricated and illustrated to have good electrochemical performance [42, 43].

-

4.

OEMs can universally accommodate monovalent metal ions, such as Li+, Na+, and K+, and multivalent metal ions, such as Zn2+, Mg2+, Ca2+ and Al3+ [44].

1.3 Challenges of OEMs

According to the molecular weight (MW), OEMs can be classified into two main types: small-MW OEMs with short molecular chains and large-MW OEMs with long molecular chains, or more typically, polymers. The latter is often designated as OEM polymers since it has repeated functional units in the long main chain and side chain. OEMs have many critical challenges (Table 1) that must be addressed in the course of their commercialization. OEMs, especially small-MW OEMs, commonly show poor thermal stability and significant solubility at room temperature. The chemical and electrochemical stability in existing Li-based organic electrolytes is another indispensable parameter that affects the suitability of MIB applications. The high solubility in aprotic electrolytes can dramatically reduce the cycling life of the resultant LIBs, while the poor electronic conductivity of OEMs (except for those with conducting polymers) is another barrier that must be addressed during electrode fabrication to fully utilize the redox sites in the charge/discharge processes. High-degree self-polymerization of polymeric carbonyl materials based on quinone and PYT was performed to address the solubility issue in aprotic electrolytes, leading to improved stability and high capacity [45,46,47,48,49,50]. Moreover, due to the characteristics of polymerization (such as homogeneous chain reactions), the morphology of OEMs is controlled in a much more complicated way compared to the scenarios for synthesizing IEMs. As a result, compared to those of IEMs, the reported morphologies of OEMs are limited, and most of the obtained OEMs are either in powder or bulk form. Finally, the charge/discharge mechanisms, i.e. the general redox schemes of OEMs that will specifically be introduced in this review, are still unclear, vague, and even controversial.

1.4 General Strategies of OEMs Development

This work reviews the history, strategies, progress, and achievements and provides prospective views and solutions in addressing the challenges of OEMs and promoting their merits, as concluded in Table 1. Following the historical OEM development trend in the roadmap (Fig. 1), we systematically summarize the strategies of molecular and morphological engineering to boost the electrochemical performance of OEMs in MIBs. The particular aims and operation of the design strategies are summarized as follows.

-

1.

To design a new controllable polymerization reaction to increase the molecular weight of OEMs, thereby addressing their dissolution and stability.

-

2.

To improve redox potential via the adoption of suitable functional groups in a conjugated organic structure.

-

3.

To increase the number of active functional group sites to store more ions and allow a higher electron transfer number.

-

4.

To increase the surface area for storage and accelerate the mass transport of ions and to establish nanostructures that enhance the conduction of electrons in OEMs by morphologically engineering them.

With such coherent efforts, it can be envisaged that the next generation of OEMs for MIBs will eventually achieve a large energy capacity, high power capability, and long cycling life.

2 Electrochemistry of OEMs

2.1 Fundamental Redox Mechanism of OEMs

As mentioned above, electroactive OEMs are promising for next-generation sustainable energy storage systems via various electrochemical redox reaction mechanisms [51,52,53,54,55,56,57]. Based on the abilities of OEMs in a neutral state to accept or release electrons during electrochemical processes, OEMs can be categorized into three types: the n-type, the p-type, and the bipolar-type [54, 58, 59]. As shown in Fig. 2, OEMs have one or more specific redox centres in their organic molecule structure that primarily play the dominant role in their redox mechanism.

Electrochemical redox reaction mechanisms of OEMs and their electrochemical cell configurations. a The n-type reactions are based on the reversible intercalation/deintercalation of lithium ions (Li+) into an organic skeleton, where lithium terephthalate is the example. These OEMs are amenable as an anode (charge first) or cathode (discharge first) in a battery. b The p-type reactions reversibly occur with bulk anions (B−), such as the example with diamine radicals, and these OEMs are applied as a cathode (charge first). c Bipolar-type reactions have two oxidative states with the insertion of cations (A+) or anions (B−), such as the example with TEMO-based radicals, and these OEMs are employed as a cathode

2.1.1 n-Type OEMs

The n-Type OEMs in neutral states tend to attract electrons and are reduced to negatively charged states, which readily bond with active cations (e.g. Li+, Na+, K+, Mg2+, Zn2+, Ca2+, and Al3+) [60,61,62,63,64,65,66,67,68,69,70]. When charging, the OEMs in negative states release electrons and are oxidized into neutral states, followed by their reversible decoupling from cations. Such highly reversible redox chemistry of the organic functional groups endows the OEMs with good potential use in MIBs. These n-type OEMs generally deliver redox potentials below 3 V (vs. Li+/Li) [60, 71,72,73,74]. Therefore, they can work as either cathodes or anodes in MIBs (Fig. 2a) based on the redox potential of the specific counter electrodes [72, 75, 76].

Generally, n-type OEMs include carbonyl compounds (–C=O), imine compounds (–C=N–), azo compounds (–N=N–), cyano derivatives (–C≡N), organosulphur compounds (–S–S–), conducting polymers (–C=C–), etc. They usually undergo different bond reactions and intramolecular electron transfer in the redox process. During the reduction process, electroactive carbonyl groups convert into enolate monoanions (–C–O–) and then react with active cations. In the oxidation process, a reverse enol-ketone transformation occurs at the carbonyl active sites. For imine compounds [18, 77,78,79], their electroactive imine groups can reversibly accept/donate electrons during the redox process. Simultaneously, the cations combined or left from the functional groups ensure the charge balance between imine groups and active cations. Similar redox chemistries of intramolecular electron transfer can also be authenticated for different electroactive groups in other n-type OEMs, such as the cyano groups in cyano derivatives and carbon bonds in conducting polymers [71, 80]. Unlike the above mechanism, the disulphide groups in some organosulphur compounds [81,82,83,84] are subject to breakage and form thiolates during the reduction reactions and reversibly regenerate disulphide bonds in the subsequent oxidation process. In addition, the azo groups in azo compounds [85, 86] undergo distinct redox chemistry, namely a direct reaction between the azo groups and cations without intramolecular electron transfer.

2.1.2 p-Type OEMs

The p-type OEMs tend to reversibly release electrons and be oxidized into positively charged states, accompanying their combination with active anions (PF6−, ClO4−, FSI−, CF3SO3−, etc.), when charging batteries [87,88,89,90,91]. Generally, p-type OEMs have higher redox potentials because of the relatively low molecular energy levels formed via their transformation from a neutral state to a positively charged state. In contrast, n-type OEMs have higher molecular energy levels when in their negatively charged state. Thus, p-type OEMs have higher operating voltages than n-type OEMs when they work as cathodes in batteries. Because the redox chemistry of p-type OEMs is associated with the combination of active anions instead of conventional cations, the corresponding batteries based on p-type OEMs are also well known as dual-ion batteries (Fig. 2b) involving anion-cation dual-carrier chemistry [92,93,94].

According to previous works, p-type OEMs typically include amine derivatives (–NH–), thioethers (–S–), organic radicals (e.g. –N–O–), and conjugated N-heterocycles (e.g. = N–). Especially for amine-based derivatives [93, 95, 96], during oxidation reactions, neutral amine groups release electrons to form positively charged N cations while also bonding with active anions. Conversely, the corresponding reduction reactions undergo reversible electron acceptance and anion disassociation. Thioethers are organosulphur compounds but present different redox schemes than disulphides and polysulphides [52, 84, 97]. Generally, thioethers endow thioradicals (–S–) with redox chemistry, releasing and accepting electrons during the charge/discharge processes, respectively. In addition, radical organic compounds [89, 98], mainly nitroxyl radicals, can be oxidized to positively charged oxoammonium radicals and combined with anions during charging. Reverse reduction chemistry occurs in the corresponding discharge process. Finally, the conjugated N-heterocycles [64, 96, 99] can store and convert energy relating to intramolecular electron transfer at high charge/discharge potentials. The N atoms are capable of losing one electron, thus generating sp2-hybridized ions that bond with anions. The other remaining electron can be shared with an adjacent carbon. However, the p-type reactions of conjugated N-heterocycles generally result in relatively low specific capacities.

2.1.3 Bipolar-Type OEMs

Bipolar-type OEMs in their neutral state combine the merits of n-type and p-type OEMs because they can form negatively and positively charged states depending on the operating potential.

In the reverse redox process, these negatively (or positively) charged OEMs can be reduced/oxidized to their initial neutral state and even to positively (or negatively) charged states by attracting and releasing electrons. This redox process is achieved via successive two-step reduction/oxidation reactions accompanying cation (anion) dissociation and subsequent anion (cation) combination. Accordingly, bipolar-type OEMs can be used as anodes and cathodes in conventional rechargeable batteries and dual-ion batteries (Fig. 2c). [89,90,91] Furthermore, when paired with appropriate anodes, they can be assembled into hybrid batteries (Fig. 2c) in conjunction with the “rocking-chair” cation shuttle characteristic (stage I) and anion-cation dual-ion mechanism (stage II) [100, 101].

Due to the features of the bipolar charging process, bipolar-type OEMs usually have two compositions: free radicals with good electron-withdrawing and electron-donating capabilities [89] and implants with different functional groups that individually undergo n-type and p-type reactions [91]. Typically, these OEMs include radical polymers (e.g. nitronyl nitroxide) and conducting polymers (e.g. polyaniline and polypyrrole). Taking conducting polymers as an example, they participate in redox chemical reactions based on delocalization along their main chain and then incorporate anions and cations during oxidation and reduction. In addition, for radical compounds, when neutral radical polymers undergo p-type and n-type reactions, their free radicals, such as nitroxyl radicals, can be oxidized to positively charged oxoammonium cations and reversibly reduced to negatively charged aminoxy anions [32, 89]. Interestingly, these electrochemical redox processes are carried out without intramolecular electron transfer.

2.2 Classification of OEMs

Since the first demonstration of OEMs in 1969, a number of organic materials containing diverse electroactive organic functions have been successfully exploited for electrochemical energy storage. Based on electroactive redox centres, OEMs can be classified into six categories (Table 2), including carbonyl compounds, sulphur-containing OEMs, nitrogen-containing compounds, conducting polymers, radical-based polymers, and overlithiated compounds [51, 52, 56, 96, 99, 102]. They show variable electrochemical properties at the material level, including their operating potential, specific capacity, conductivity, and cycling stability, which will be introduced in the following section.

2.2.1 Carbonyl OEMs

In 1969, the first carbonyl OEM, dichloroisocyanuric acid, was found to exhibit high electrochemical activity for LIBs but suffered from fast capacity fading [11]. After that, carbonyl compounds were extensively studied for electrochemical energy storage because of their high theoretical capacity (up to 957 mAh g−1), high reversibility, and structural diversity [14, 15, 50, 103,104,105,106,107,108]. These carbonyl compounds can be sorted into quinones, carboxylates, imides, anhydrides, etc. For example, quinones are typical carbonyl compounds with two carbonyl groups in hexagonal cyclic diketone structures, and their specific capacity is strongly dependent on the number of carbonyl groups in their molecular structure (Fig. 3a1) [70, 109,110,111,112,113]. One 1,4-benzoquinone (BQ) molecule with two carbonyl groups can transfer two electrons when reduced, which yields a theoretical specific capacity of 496 mAh g−1 [110, 114]. Dilithium rhodizonate (Li2C6O6), with its four electroactive carbonyl groups, has a capacity of up to 589 mAh g−1 [109, 115, 116]. Particularly, among all carbonyl compounds, hexagonal cyclic ketone (C6O6), with its six carbonyl groups in one molecule, can deliver the highest capacity of 957 mAh g−1 (Fig. 3a2) [14]. Carboxylates are composed of aromatic ring(s) bonding with carboxylate groups (e.g. –COOLi, –COONa, –COOK) (Fig. 3b) [72, 75, 108, 117]. Compared with carbonyl groups, carboxylate groups are akin to the addition of electron-donating groups to carbonyl groups, which leads to a lower operating potential. Thus, carboxylates are more appropriate for anode materials. Imides have a structural formula of –(C=O)–(N–R)–(C=O)–, where N atoms bond with two carbonyl groups connected to the aromatic ring structure [13, 118,119,120,121]. Their electrochemical redox mechanism is associated with the enolization reactions of carbonyl groups, the association/dissociation of active cations with/from O atoms (Fig. 3c) [120,121,122], and generally also involves the p-type redox reaction between N atoms and active anions for carboxylate-based polymers [91, 123]. Anhydrides are comprised of at least one aromatic ring and two anhydride groups, resulting in anhydrides with large, conjugated structures (Fig. 3d) [124,125,126]. As a result, anhydrides generally present good cycling reversibility.

Reproduced with permission from Ref. [109]. Copyright 2016, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim.) and a2 redox mechanism of C6O6 in lithium batteries confirmed by DFT calculations (Reproduced with permission from Ref. [14]. Copyright 2019, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim.). b Carboxylates: DFT simulations of K4PM for potassium-ion storage and the typical charge/discharge curves of different current densities. Reproduced with permission from Ref. [72]. Copyright 2021, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim. c Imides: redox mechanisms of (N,N′-bis(2-anthraquinone))-perylene-3,4,9,10-tetracarboxydiimide (PTCDI-DAQ). Reproduced with permission form Ref. [122]. Copyright 2020, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim. d Anhydrides: the simulated PTCDA unit cell incorporating two H3O+ ions and a comparison of the charge/discharge profiles for the storage of Na+ ions at 1 A g−1, K+ ions at 0.5 A g−1, and hydronium ions (the 10th cycle) at 1 A g−1 in PTCDA. Reproduced with permission from Ref. [125]. Copyright 2017, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim

Electrochemical performance and mechanisms of different types of carbonyl OEMs. a Quinone derivatives: a1 preparation, structures, theoretical reactions and initial discharge capacity of oxocarbon salts (

Nevertheless, carbonyl compounds, particularly those with low molecular mass, present severe dissolution issues in aprotic electrolytes because of their facile interaction with electrolyte solvents [50, 127, 128]. In addition, their discharge products can dissolve in aqueous electrolytes even though carbonyl compounds have low solubility in water solvents. Accordingly, these electrodes based on carbonyl compounds deliver high electrochemical irreversibility and fast capacity fading during charge/discharge processes [70]. For example, although BQ features a high theoretical capacity via a two-electron reaction, it generally undergoes a severe dissolution problem, which correlates with its relative polarity, donor number, and intermolecular interaction energy [110, 111]. 9,10-Anthraquinone (AQ) is another typical carbonyl compound with good electrochemical redox reversibility and high theoretical capacity; however, its one main challenge is its inferior cycling performance due to its serious solubility in electrolytes [129, 130]. Yang et al. [129] observed the poor cycling performance of AQ with less than 50% capacity retention after 80 cycles.

The low electronic conductivity of carbonyl OEMs is another hurdle that leads to low energy densities and rate capabilities [20, 99]. In the preparation of OEM electrodes, the extra addition of a conductive agent, e.g. up to 50 wt% carbon black (wt% means the weight percentage), is needed, which inevitably lowers the specific capacity of the electrode and resultant energy density [131]. Thus, the current studies on carbonyl-based OEMs mainly focus on enhancing the cycling stability and electronic conductivity.

2.2.2 Sulphur-Containing OEMs

The low specific capacity of early conductive polymer cathodes called for the exploration of alternative OEMs with high capacity. Sulphur-containing OEMs are defined as compounds including redox-active sulphur atoms, such as disulphides, polysulphides and thioethers; furthermore, these promising OEMs are inexpensive, environmentally friendly, and biodegradable. The bond length of the S–S bond is longer than that of the C–S bond, indicating that the bond energy of the S–S bond is smaller than that of the C–S bond. Thus, disulphides and polysulphides are based on the reversible breakage and regeneration of S−S bonds that undergo n-type two/multielectron redox, making them capable of delivering higher capacity [82, 84, 132]. In contrast, thioethers are subject to the reversible p-type reaction between C−S−C and C−S+−C because the large atomic radius of the sulphur atoms has less binding force for electrons outside the nucleus. Hence, thioether cathodes are prone to bind with active anions from electrolytes when charging and deliver relatively high discharge potentials [133, 134]. In addition, there is no breakage or regeneration of S−S bonds during the electrochemical redox reaction of thioethers; thus, it is expected to present better cycling stability than disulphides and polysulphides. In addition, owing to the existence of the π-electron delocalization effect between the aromatic rings and S atoms with a lone pair of electrons, the thioether bond can contribute to faster electron transfer. Since Visco et al. reported the first n-type sulphur-containing OEMs in 1988 [21], increasing efforts have been devoted to developing organosulphur compounds as cathode materials. For example, Fu et al. [135] developed an organotrisulphide cathode material (DMTS, CH3−S−S−S−CH3) with a four-electron redox reaction mechanism, which delivered an initial capacity of up to 720 mAh g−1 (Fig. 4a). Ren et al. synthesized two thianthrene-containing poly(phenylacetylene)s, in which thianthrene groups with C−S−C bonds served as redox-active centres. Both polymer cathodes could deliver high discharge potentials of 4.1 V versus Li/Li+, unfortunately, their specific capacities were below 100 mAh g−1 (Fig. 4b) [134]. Some thioethers, involving a four-electron reaction mechanism of “thioether–sulfoxide–sulfone”, are capable of obtaining high specific capacities ranging from 500 to 800 mAh g−1 [136].

Reproduced with permission from Ref. [135]. Copyright 2016, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim. b Thioethers: charge–discharge curves of poly(phenylacetylene)s bearing thianthrene groups and their corresponding cycling performance. Reproduced with permission from Ref. [134]. Copyright 2019, Elsevier B.V. c Challenges and improvement of sulphur-containing OEMs: c1 chemical structures of DPDS, 2,2′-DpyDS, 4,4′-DpyDS and DpyDSDO; c2 their electron density of the lowest unoccupied molecular orbital (LUMO) and the highest occupied molecular orbital (HOMO); c3 their voltage–capacity profiles for Li+ storage in the 100th cycle; and c4 their cycling performance at a C/2 rate. Reproduced with permission from Ref. [81]. Copyright 2019, The Royal Society of Chemistry

Electrochemical performance of sulphur-containing OEMs. a Disulphides/polysulphides: specific capacity and cycling performance of high-loading DMTS.

Disulphides and polysulphides usually demonstrate poor cycling performance due to the dislocation of broken S–S bonds and the severe dissolution of these organosulphides and their products in aprotic electrolytes. When discharging, the products resulting from the breakage of the –S–S– bonds in sulphides commonly have lower molecular weights and are more soluble in electrolytes [84, 135]. For example, poly(2,5-dimercapto-1,3,4-thiadiazole) (PDMcT), a typical polymeric organodisulphide, has a high theoretical capacity of 362 mAh g−1 [137]. Due to the breakage of S–S bonds in the main chains, the polymer in the cathode is converted into a small organic molecule of DMcT2− when discharging, which undergoes severe dissolution in the electrolyte and causes poor cycling stability. Additionally, Wang et al. [81] improved the cycling performance of organodisulphides via the substitution of N-containing heterocycles for aromatic rings in diphenyl disulphide (DPDS) (Fig. 4c). Compared with DPDS, the designed 2,2′-dipyridyl disulphide (2,2′-DpyDS) showed superior cycling performance due to the coordination of the N/Li/S bridge lowering the solubility of the discharge product of 2,2′-DPyDS. In the case of thioethers, the unusual redox reaction mechanism involving the formation of sulphoxide and sulphone groups generally results in poor cycling performance after dozens of cycles.

In addition, organosulphur compounds suffer from low electronic conductivity and thus sluggish kinetics for energy storage applications. For example, only when the temperature is above 100 °C can DMcT be utilized for the reversible storage of Li+ [138]. Considering the poor conductivity of organosulphur electrode materials and the high solubility of small-molecule products, researchers have developed a type of organodisulphide (poly(2,2′-dithiodianiline), PDTDA) consisting of polymeric main chains and side chains that contain S–S bonds [138]. The polymeric main chains are generally insoluble and electronically conductive, which boosts cycling performance. Nevertheless, the dislocation of different chains in the discharged state gives rise to a low rebonding efficiency of the broken S–S bonds on the side chains. To surmount this problem, S–S bonds are designed to decorate the sides of the same chains and enhance the rebonding capability. Deng et al. [139] developed such an organosulphur compound, namely poly(5,8-dihydro-1H,4H-2,3,6,7-tetrathia-anthracene) (PDTTA), which markedly presented a high specific capacity of 422 mAh g−1 and enhanced cycling performance. However, owing to the intrinsically slow kinetics of organosulphur compounds, their electrochemical properties need to be further improved.

2.2.3 Nitrogen-Containing OEMs

It is well known that reversible electrochemical redox reactions are prone to occur on organic moieties with conjugated structures or at redox-active heteroatom centres (e.g. N, S, and O) with a lone pair of electrons. These conjugated structures can facilitate electron transfer during electrochemical redox reactions and the charge delocalization of redox products. Regarding redox-active heteroatom centres, their intrinsic lone-pair electrons bestow them with higher redox activity and enhanced electronic conductivity [78, 136, 140]. Compared with S and O heteroatoms, N heteroatoms exhibit several unique characteristics and different electrochemical behaviour. On the one hand, N atoms have strong bonds with adjacent C/O/N atoms so that the breakage of N–C/N–O/N–N bonds rarely takes place during redox reactions, thereby ensuring good electrochemical reversibility. On the other hand, compared with C atoms, the N atoms of saturated amines uniquely feature sp3 hybridization and have one lone pair of electrons, which can be shared with a cation to produce quaternary ammonium ions. Interestingly, the N atoms allow the loss of one electron and interact with one anion [102]. Such behaviour indicates bipolar electrochemical character. N-containing compounds are defined as OEMs in which their electrochemical redox-active centres contain N [96]. N-containing compounds can be divided into various types according to their different redox-active centres: imine compounds, containing N=C bonds; cyano derivatives, containing N≡C bonds; azo compounds, containing N=N bonds; and arylamine compounds, containing arylamine groups.

Imine compounds, which contain redox-active N=C bonds, have served as OEMs for electrochemical energy storage since 2014 [141, 142]. The redox reaction mechanism is associated with single/multielectron redox chemistry, namely the conversion of C=N bonds into C–N bonds, intramolecular electron transfer in the conjugated structure, and insertion of active ions (e.g. Li+, Na+); notably, this mechanism corresponds to the acceptance of 1 or 1.4 electrons per C=N group [141, 142]. Generally, redox-active C=N centres in common aromatic groups, except for strong electron-deficient groups such as pyrazine rings, show relatively low redox potentials, implying that they are promising anode materials. Imine compounds, typically including pyrazinyl compounds [140], triazinyl compounds [100, 143], Schiff bases [142], and pteridine derivatives [144], are characterized by tunable electrochemical redox activity, which is strongly dependent on their conjugated structure and geometric plane structure [79, 145]. For example, a phenazine molecule consisting of pyrazine bonding with two aromatic rings is usually subject to an n-type reaction of active cation insertion, in which the N atoms are redox-active centres. During the n-type reaction process of phenazine at moderate potentials (generally below 2.0 V vs. Li/Li+), there is the transformation of C=N bonds into C–N bonds and the simultaneous formation of N–M bonds (M denotes active metal cations) [146]. Such an electrochemical process can yield N-substituted phenazine with p-type character, which can undergo a p-type reaction to produce positively charged N atoms accompanied by the re-formation of N=C without the breakage of N–M (nitrogen-metal cation) bonds at relatively high potentials (above 3.0 V vs. Li/Li+) [145]. The positively charged state of the N atoms is stable due to the increased conjugation and balanced anions stemming from the electrolyte. However, some high-capacity pyrazinyl compounds usually exhibit high solubility in electrolytes, resulting in poor cycling performance [140]. For example, small-molecule hexaazatrinaphthalene (HATN) with six C=N groups per unit has a high specific capacity but exhibits fast capacity fading (Fig. 5a) [78, 140] and that generally restricts its practical application. Polymer HATN (PHATN) has been proposed to limit the solubility and simultaneously boost electronic conductivity [147]. As a result, PHATN not only presents enhanced cycling performance but also achieves fast reaction kinetics and a high rate capability [79, 140, 148]. Triazinyl compounds generally consist of polymerized triazine rings with different linkers (e.g. benzene) [100] and share a similar redox mechanism with pyrazinyl compounds. Interestingly, in comparison with pyrazinyl groups, triazinyl groups theoretically have a higher reversible capacity. Additionally, the porous structure of polymeric triazinyl compounds results in fast ionic transfer, and thus, a high rate capability.

Reproduced with permission from Ref. [78]. Copyright 2017, Macmillan Publishers Limited, part of Springer Nature. b Cyano derivatives: the charge/discharge profile of DCA. Reproduced with permission from Ref. [151]. Copyright 2016, Elsevier B.V. c Azo compounds: c1 charge/discharge curves, c2 rate capability, and c3 cycling performance of ADALS. Reproduced with permission from Ref. [85]. Copyright 2018, Proceedings of the National Academy of Sciences. d Arylamine compounds: d1 long-term cycling stability of a potassium-ion battery with a PTPAn cathode (Reproduced with permission from Ref. [155]. Copyright 2017, American Chemical Society.) and d2 charge/discharge characteristics of potassium-ion batteries with a p-DPPZ cathode. Reproduced with permission from Ref. [156]. Copyright 2019, American Chemical Society

Electrochemical performance of some typical nitrogen-containing OEMs. a Imine compounds: structural evolution of 3Q during lithiation.

Nevertheless, it is noteworthy that a wide voltage window is necessary for triazinyl compounds to fully deliver their specific capacities because of their sloping potentials during the charge/discharge processes. In addition, regarding pyrazinyl and triazinyl compounds, their working potentials for n-type redox reactions are located in the range of 1–2 V vs. Li/Li+; however, their capacities for p-type redox reactions are still insufficient even though they can achieve relatively high redox potentials. Schiff bases with a configuration of R1–N=CH–R2 (R1 and R2 typically denote aromatic groups) can undergo a two-electron redox reaction at 1 V versus Li/Li+, implying that they are a potential anode material for batteries. Compared with monomeric Schiff bases, polymeric Schiff bases feature low solubility, high thermal stability, and mechanical strength. Commonly, polymeric Schiff bases, consisting of the Hückel-stabilized repeating unit of –N=CH–Ar–HC=N– (Ar denotes an aromatic group) with ten-π-electron electrochemical activity, can accommodate more than one Na+ per redox-active –C=N– bond. The repeating unit complies with the Hückel rule of aromaticity, i.e. cyclic coplanar units with (4n + 2) π electrons (n is a positive integer) have extra stability [141, 149]. Accordingly, the existence of inactive Ar aromatic groups is highly conducive to boosting the stability of the Schiff-base structure; otherwise, the Schiff bases present poor cycling performance. It should be emphasized that the isoelectronic inverse unit of –CH=N–Ar–N=HC– is electrochemically inactive because the strong interaction between N atoms and the neighbouring aromatic ring results in the loss of its planarity. Pteridine derivatives are also a typical classification of imine compounds. Distinct from other imine compounds, pteridine derivatives have biologically occurring redox centres of conjugated diazabutadiene moieties, which are capable of facilitating proton-coupled electron transfer reactions even when the N atoms have been reduced [144]. Flavin, a typical pteridine derivative, can reversibly store two electrons and two balancing active cations per molecule, in which the n-type redox reaction reversibly occurs at the conjugated diazabutadiene moiety of the isoalloxazine ring, accompanied by the reversible conversion of the isoalloxazinic structure to an alloxazinic structure, via the two successive proton-coupled single-electron transfer processes of N5 and N1 [144, 150]. Note that, the carbonyl groups in flavin do not work as redox-active sites.

Cyano derivatives were reported as cathode materials for lithium-ion batteries in 1984 [22]. 7,7,8,8-Tetracyanoquinodimethane (TCNQ) is a typical cyano derivative. Its redox reaction mechanism involves two-step n-type reactions in which TCNQ is converted into TCNQ– and then into TCNQ2– followed by the insertion of Li+. The corresponding potential is approximately 3.0 V versus Li/Li+, which is among the highest values for n-type OEMs. Further reducing the operating potential to below 1 V versus Li/Li+ will possibly cause an irreversible electrochemical redox reaction relating to the formation of LiCN. In addition, some cyano derivatives are composed of aromatic rings decorated with cyanide groups, which usually deliver relatively low redox potentials of 1.0–2.0 V (Fig. 5b) [151]. However, these cyano derivatives also suffer from high solubility in electrolytes, which results in poor electrochemical reversibility.

Azo compounds are an emerging type of OEM, where azo (N=N) groups act as redox-active centres for reversible electrochemical redox reactions; these compounds were first reported by Luo et al. [24, 85]. Azo compounds undergo n-type reactions, where N=N bonds are added into N–N bonds followed by the insertion of two active cations (e.g. Li+ and Na+). Compared with every imine group that can accept 1 or 1.4 electrons, every azo group can achieve a higher theoretical capacity with 2 electrons [24, 85, 152]. However, the azo groups connected with two phenyl rings generally result in a redox potential of ~ 1.5 V versus Li/Li+ (Fig. 5c) [24, 85, 152]. Nevertheless, azo compounds also have undergo dissolution in organic electrolytes, which results in possible electrochemical redox irreversibility at low operating potentials.

Unlike other redox-active centres in N-based redox compounds, the N atoms in arylamine compounds [93, 153] can serve as p-type redox-active centres, simultaneously donating electrons and being stabilized by anions. Triphenylamine polymers, such as poly(triphenylamine) (PTPAn), are a typical type of arylamine compound in which the N atoms situated at the centre link with three phenyl rings [154]. This triphenylamine group results in a nonplanar structure, and positive charges in the oxidized state are prone to localize at these N atoms [95, 155]. For example, the redox reaction mechanism of the PTPAn cathode involves the N atom donating one electron and being converted to positively charged N+, which is stabilized by the insertion of one PF6− anion from the electrolyte [154, 155]. An organic potassium-ion battery with PTPAn as the cathode has delivered an encouragingly high rate capability and demonstrated stable cycling performance (capacity retention of 85% after 500 cycles) (Fig. 5d1) [155]. Interestingly, although the N atoms in poly(N-phenyl-5,10-dihydrophenazine) (p-DPPZ) have a similar location structure as PTPAn, its redox mechanism is remarkably different from the latter. The redox reaction of p-DPPZ during oxidation, which involves the redox chemistries of intramolecular electron transfer, can be divided into two steps [156]. The first step is associated with the transformation of every second 1,4-phenylenediamine moiety in the main polymer chain to quinoneimine. The second step corresponds to the further conversion of all 1,4-phenylenediamine fragments into quinoneimines. In addition, carbazole polymers are typical arylamine compounds in which conjugated arylamine groups are appended on nonconjugated polymer backbones. Not only are these separated redox-active centres beneficial for stabilizing the working voltage but also the intramolecular π–π stacking interaction between arylamine groups favours charge transfer, which is conducive to boosting the reaction kinetics and cycling performance (Fig. 5d2) [51]. For example, poly(N-vinylcarbazole) (PVK) was exploited by Li et al. as a cathode material for a potassium-ion battery [157]. The PVK cathode underwent a similar p-type reaction relating to the electron-donating/accepting process of the N atom in PTPAn. The battery delivered a high rate performance and a high medium discharge voltage of 4.05 V versus K/K+. Nevertheless, the obvious disadvantage of these arylamine compounds is their low specific capacity.

2.2.4 Conducting Polymer OEMs

Conjugated conducting polymers are a class of attractive OEMs because of their inherently high electronic conductivity and chemical stability. Since the first investigation of polyacetylene conductive polymers for cathodes in lithium-based dual-ion batteries in 1981 [158], tremendous efforts have been devoted to developing electroactive conducting polymers for OEMs. In view of the different electroactive redox groups, conjugated conducting polymers can be classified into four major groups: conjugated hydrocarbons with an electronic conductivity of approximately 10−5 S cm−1 (e.g. polyacetylene), conjugated benzene (approximately 10−3–10−4 S cm−1, e.g. polyparaphenylene), conjugated amines (approximately 10−2–10−4 S cm−1, e.g. polyaniline and polypyrrole), and conjugated thioethers with a high electronic conductivity of 100 S cm−1 (e.g. polythiophene) (Fig. 6a) [52, 56, 99, 136]. Generally, electron delocalization in the conjugated structure enables either the acceptance or donation of electrons (bipolar-type reactions) and stabilizes the resultant products. Some conjugated conducting polymers (such as polyaniline, polypyrrole, and polythiophene) are mainly used as p-type redox cathodes. On the one hand, most conducting polymers have an electron-rich character, meaning they have more stable oxidized states than reduced states. On the other hand, their p-type reactions have relatively high electrochemical redox potentials (2.5–4.5 V vs. Li/Li+) [159,160,161,162]. In addition, if the working voltage windows are sufficiently wide, conjugated conducting polymers with electrochemical bipolar characteristics (such as polyacetylene and polyparaphenylene) can successively be subject to n-type and p-type reactions, thus making them appropriate for use as cathodes in hybrid batteries (generally on the basis of alkali(ne) metal anodes) [100, 101]; additionally, this property is beneficial for improving the energy density of MIBs. Compared with small-molecule carbonyl compounds suffering from low electronic conductivity and high solubility in aprotic electrolytes, conducting polymers as electrodes present superior characteristics of a relatively high electronic conductivity and limited solubility in electrolytes; these properties are beneficial for enhancing their rate capability and cycling stability [159, 162]. For example, Wan et al. [101] reported an aqueous rechargeable zinc-organic battery using conducting polyaniline (PANI) with a hybrid mechanism as the cathode, which exhibited excellent rate capability and cycling performance (Fig. 6b). Nitrogen was doped (=NH+–) and undoped (=N–) in PANI because it was mostly in the half-oxidation state. During the 1st discharge, the doped nitrogen (=NH+–) was reduced, and the Cl− ions dropped off from the PANI. Simultaneously, the –NH– moiety was reduced to –N− and interacted with Zn2+. In the rate test, the capacity at the high current density of 5 A g−1 was as high as 95 mAh g−1, which was approximately 47.5% of that at 0.05 A g−1. After 35 cycles at different rates, a high capacity of 191 mAh g−1 could be recovered when the current density was returned to 0.05 A g−1.

Reproduced with permission from Ref. [161]. Copyright 2019, American Chemical Society. b Typical bipolar characteristics and electrochemical properties: the redox mechanism, rate capability, and cycling performance of the conducting polymer polyaniline. Reproduced with permission from Ref. [101]. Copyright 2018, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim. c Doping level and sloped potential profiles of conducting polymer OEMs: c1 typical electrochemical redox process of a p-type conducting polymer, (Reproduced with permission from Ref. [136]. Copyright 2013, The Royal Society of Chemistry.) and c2 experimental charge/discharge profiles of the polyaniline cathode (Reproduced with permission from Ref. [164]. Copyright 2018, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim.)

Electrochemical characteristics of conducting polymer OEMs. a The p-type reaction mechanism of typical conducting polymer OEMs.

However, some drawbacks for conjugated conducting polymers remain to be further studied, including their low discharge capacity, sloped operating voltage profile, and self-discharge issue. Unlike small-molecule OEMs, conducting polymers have a high molecular mass, and their energy storage mechanism is based on ion doping. As a result, their specific capacity is theoretically determined by the doping ability of the repeating structural units and the type of active anions. The doping degree can be estimated by (Px+·xA–)n (0 \(\leqslant\) x \(\leqslant\) 1), where P and A– denote the repeating structural unit (e.g. aniline groups and acetylene groups) and the active anion (e.g. PF6– and ClO4–) [136]. Generally, conducting polymers with higher degrees of doping are capable of higher specific capacities. However, the process for achieving a high degree of doping at the neighbouring repeating structural units causes severe charge repulsion interactions, leading to inactive structural units and low reversibility [84, 136]. For example, a polyacetylene cathode delivers a relatively high Coulombic efficiency of 65.6% at a doping degree of 0.097. The value sharply decreases to 35.5% when the doping degree is increased to 0.194 [163]. Thus, the low doping level (approximately 0.3–0.5) is the main reason for the low specific capacities of conducting polymers [84].

In addition, the electrochemical working potentials of conjugated conducting polymers present sloped profiles because the continuously increasing/decreasing doping degrees persistently change the equilibrium potentials during electrochemical reactions. Figure 6c1 schematically illustrates a typical evolution of the electrochemical working potential against the doping degree for a p-type conductive polymer cathode [136]. As observed, there is an approximately linear correlation between the electrochemical working potential and doping degree. Pristine conducting polymers are in an intermediate state, which can be discharged to a full-reduction state along with a decreasing working potential and charged to a semioxidation state followed by an increasing working potential. Unfortunately, a full-oxidation state during the charge process is generally inaccessible for conducting polymers because fully oxidized conducting polymers at high potentials are usually unstable and tend to induce severe parasitic reactions with electrolytes as soon as the electrochemical oxidation process passes through the C point; this restricts the practical capacity of conductive polymer cathodes. Figure 6c2 shows a sloped working potential profile ranging from 2.0 to 4.0 V as a function of its specific capacity in a potassium-based dual-ion battery, in which polyaniline serves as the cathode having a p-type reaction with PF6− doping during the charging process [164]. Similar sloped potential profiles have been reported in other studies [165]. In addition, although the polyaniline cathode has a theoretical capacity of 295 mAh g−1 (full-oxidation state), its experimental capacity is below 140 mAh g−1 even at an ultralow current density of 10 mA g−1. Furthermore, although the capacitive-controlled response boosts the reaction kinetics, anion dopants are inclined to disassociate from conducting polymers during long-term storage periods, potentially causing self-discharge issues when used in energy storage systems.

2.2.5 Radical-Based OEMs

Radical polymers with pendant free radicals per repeating unit as the redox-active centres take advantage of a high rate capability and good cycling stability. These radical polymers have densely popularized unpaired electrons, and their electrochemical redox during the charge/discharge processes is generally associated with slight structural variations and electron rearrangements. A considerable number of studies have focused on radical polymers for electrode materials since Nakahara et al. [31] reported the first radical polymer of poly(2,2,6,6-tetramethyl-piperidinyl-1-oxy-4-yl methacrylate) (PTMA) as a cathode material to the battery community (Fig. 7a). During the anodic process, the nitroxyl radical was oxidized into a cation and interacted with the electrolyte anion to generate oxoammonium salt. During the cathodic process, a reverse reaction occurred. Regarding the cells using the PTMA cathode and Li anode, a cut-off charge voltage of 4.0 V was observed along with obvious charge/discharge profiles at current densities of 0.1 and 1.0 mA cm−2. The plateau voltage of approximately 3.5 V corresponds to the redox potential of PTMA, indicating the presence of oxoammonium salt in the charged state and pristine state in the subsequent discharge process. Wang et al. [89] demonstrated that the electrochemical redox reaction mechanism of PTMA was dominated by dual-doping modes, which probably consisted of lithium expulsion and anion uptake I and II, as shown in Fig. 7b. In the first mode, the PTMA in the electrolyte was doped by the anion, resulting in lithium cation expulsion into the bulk electrolyte. In the second mode, the anion was exchanged from the external electrolyte. In the third mode, the doped anion came from the internal electrolyte and was balanced by the anion taken from the external electrolyte. Anion uptake I and II coexisted in the doping reactions. The doping in PTMA was controlled by the anion type, electrolyte concentration, and timescale. In addition, among the redox-active radicals in these radical polymers, nitroxyl groups have attracted the most attention, such as nitronyl nitroxide radicals, 2,2,6,6-tetramethylpiperidinyl-N-oxyl (TEMPO), and 2,2,5,5-tetramethylpyrrolidin-N-oxyl. In addition, there are some other radicals, including dialkoxyaryl, O-centred phenoxyls and galvinoxyls. Although nitroxyl radicals in the neutral state are bipolar-type functional groups and can be either oxidized to form oxoammonium cations (> 3.0 V vs. Li/Li+) or reduced to yield aminoxy anions (~ 2.0 V vs. Li/Li+) based on one-electron transfer (Fig. 7c) [166], they mainly work as p-type cathode materials along with redox reactions that utilize active anions in the electrolyte due to the competitive electrochemical redox potentials.

Reproduced with permission from Ref. [31]. Copyright 2002, Elsevier Science B.V. b Different modes of anion doping into radical-based OEMs: three modes of anionic doping in a swollen PTMA electrode. Reproduced with permission from Ref. [89]. Copyright 2018, Springer Nature Limited. c Working potential and specific capacity of some typical radical-based OEMs: the energy diagram of p-type (red) and n-type (blue) radical polymers as a map of the redox potentials versus the formula weight-based capacities. Reproduced with permission from Ref. [166]. Copyright 2009, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim. d Rate capability and cycling performance: d1 positive charge propagation during the oxidation of p-type radical polymers, showing the direction of charge transport in the slab of the polymer (Reproduced with permission from Ref. [166]. Copyright 2009, WILEY–VCH VERLAG GMBH & CO. KGAA, WEINHEIM.), d2 rate performance of the PGVS||PTN battery (Reproduced with permission from Ref. [168]. Copyright 2009, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim.) and d3 charge/discharge curves and cycling performance of a redox-active nitroxide polyether (Reproduced with permission from Ref. [169]. Copyright 2010, American Chemical Society.)

Electrochemical redox mechanism and performance of radical-based OEMs. a Typical p-type reaction of radical-based OEMs and their corresponding charge/discharge profiles.

Despite the insulating feature of their main chains, radical polymer electrode materials result in superior rate capability and small voltage polarization, which is probably ascribed to the outer-sphere electron self-exchange reaction mechanism between adjacent radical redox sites induced by redox gradient-driven electron transport (Fig. 7d1) [166]. For example, PTMA can maintain a capacity retention that is above 90% at 12C relative to that at 1.2C and deliver a stable discharge potential plateau of ~ 3.5 V versus Li/Li+. Nishide et al. [167] reported a hydrophilic radical polymer of poly(2,2,6,6-tetramethylpiperidinyloxy-4-yl vinyl ether) (PTVE) bearing pendant TEMPO radicals to serve as a cathode material in an aqueous zinc-ion battery; this polymer simultaneously exhibited a low overpotential of less than 0.1 V (even at an ultrahigh rate of 60C) and relatively stable working voltage plateaus. Moreover, radical polymers have also been reported as n-type electrode materials such as poly(galvinoxylstyrene) (PGVS). Pairing the PGVS anode with a poly(TEMPO-substituted norbornene) (PTN) cathode yields an all-radical polymer battery, which can be operated at an extremely high rate of 360C (Fig. 7d2) [168]. Similar to nitroxyl radical polymers, other radical-based polymers also present the advantage of fast reaction kinetics. In addition, with an appropriate electrolyte, radical polymers exhibit excellent cycling stability due to their stable polymer structure. PTMA can maintain a stable specific capacity without apparent fading for 500 cycles. Another radical polymer of poly(2,2,5,5-tetramethyl-3-oxiranyl-3-pyrrolin-1-oxyl ethylene oxide) (PTEO) presents extremely small electrochemical polarization, a superior rate capability, and excellent long-term cycling performance with no substantial capacity decay after 1 000 cycles (Fig. 7d3) [169].

Nevertheless, the practical application of radical polymer electrode materials is still restricted by their low specific capacity of less than 150 mAh g−1 due to the intrinsic single-electron redox reaction mechanism and the high large molecular mass of these radical polymers. For example, PTMA, PTVE, PTEO, PGVS, and PTN have theoretical capacities of 112, 135, 147, 51, and 109 mAh g−1, respectively [136]. It is noteworthy that further improvement in the specific capacities of these radical polymers is highly challenging via structural optimization. In addition, the intrinsically low conductivity of radical polymers generally requires a high ratio of conductive additives to guarantee smooth electron transfer inside the electrodes, which inevitably imposes a further restriction on their full specific capacities [170].

2.2.6 Overlithiated OEMs

Despite the structural diversity and tunability of OEMs with different electrochemical redox-active centres, the large majority cannot deliver a practical capacity of over 400 mAh g−1, which renders them insufficient to compete with their inorganic counterparts [171]. Rational molecular engineering, such as the introduction of redox-active moieties and conjugated structures, can increase the specific capacity [71]; however, the extra weight scarcely ensures a remarkable improvement in the specific capacity of OEMs. Interestingly, there is another classification of OEMs, namely multifunctional overlithiated OEMs; these demonstrate overlithiated energy storage processes due to the reversible reduction in their unsaturated C=C or C≡C bonds and other redox groups [16, 17, 20, 90, 96, 172,173,174,175]. The overlithiation reactions can greatly boost electron transfer and realize an exciting 1:1 Li/C ratio, and theoretically, the corresponding maximum specific capacity is approximately 2 232 mAh g−1. Han et al. [16] reported the overlithiated behaviour of 1,4,5,8-naphthalenetetracarboxylic dianhydride (NTCDA) containing a naphthalene ring structure (Fig. 8a). The electrochemical Li+-storage process of NTCDA included two successive steps. The first step was the enolization of four carbonyl groups, and the second step was the reversible reduction in the unsaturated C=C bonds in NTCDA. The enolization reaction step corresponded to a four-electron lithiation process, while the second reduction step referred to a 14-electron overlithiation process. Thus, the whole lithiation process was accompanied by electrochemical reduction with the transfer of 18 electrons, resulting in NTCDA having a high specific capacity of up to ~ 1 800 mAh g−1. He et al. [19] constructed a multicarbonyl polyimide material (PMTA) containing six carbonyl groups per repeated unit. On the basis of the similar two-step reaction of the enolization of carbonyl groups and the overlithiation of unsaturated carbon bonds, each unit of PMTA was subject to a reversible 22-electron reduction reaction, which corresponded to a theoretical capacity of 1 704 mAh g−1. Consequently, PMTA could deliver a high experimental capacity of 1 638 mAh g−1. Through a condensation reaction between 1,4-diaminobenzene and 1,3,5-benzenetricarboxaldehyde, Lei et al. [18] designed a covalent organic framework (COF) material anchored with carbon nanotubes (CNTs) to form a composite, namely COF@CNT. It was demonstrated that the electrochemical redox reaction involved a transfer of 14 electrons per repeated unit. The method also underwent two steps, individually relating to the lithiation of two C=N groups and the overlithiation of unsaturated C6 rings. The overlithiation reaction included four stages due to the variable free energy (ΔG) at various stages of the lithiated COF monomer (Fig. 8b1). Accordingly, the COF in COF@CNT could deliver a high reversible capacity of 1 536 mAh g−1 (Fig. 8b2).

Reproduced with permission from Ref. [16]. Copyright 2012, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim. b Specific capacity and structural evolution: b1 structural evolution of the COF monomer during the lithiation process and b2 its capacity contribution (Reproduced with permission from Ref. [18]. Copyright 2018, Springer Nature.). c Oversodiated and overpotassiated OEMs: the electrochemical c1 oversodiation process (Reproduced with permission from Ref. [177]. Copyright 2014, Wiley–VCH Verlag GmbH & Co. KGaA, Weinheim.) and c2 overpotassiation process of PTCDA (Reproduced with permission from Ref. [176]. Copyright 2015, Elsevier Science B.V.)

Electrochemical redox process, performance and structural evolution of overlithiated OEMs. a Electrochemical redox process: a1 the electrochemical insertion of Li ions onto NTCDA during the discharge process, a2 potential profile of NTCDA during the discharge process, exhibiting five distinct discharge plateaus corresponding to the insertion of 1, 2, 4, 8, and 18 Li ions, respectively, and a3 reaction free energy (ΔG) for the addition of lithium onto the aromatic rings of NTCDA (red), pyrene (black), and naphthalene (green).

High specific capacities can also be achieved for the storage of Na+ and K+ via similar oversodiation and overpotassiation of specific OEMs (Fig. 8c) [176, 177]. Chen et al. [176] demonstrated that 3,4,9,10-perylene–tetracarboxylicacid–dianhydride (PTCDA) underwent the four-electron potassium enolization reaction between carbonyl groups and K+ and further underwent another transfer of 7 electrons during the overpotassiation reaction between K+ and unsaturated C6/anhydride rings. The whole reduction process of K+ storage corresponded to the transfer of 11 electrons per PTCDA molecule, which experimentally bestowed PTCDA with a high specific capacity of 753 mAh g−1. Similarly, the sodium enolization reaction and successive oversodiation reaction of PTCDA could generate Na15PTCDA, which involved a transfer of 15 electrons and delivered a high capacity of 1 157 mAh g−1 [177]. Compared with Li24PTCDA [16], the smaller numbers of inserted Na+ and K+ in the same molecular structure were probably attributed to the larger ionic radius of the latter two [171].

It should be highlighted that functional groups play significant roles in the electrochemical processes of the overlithiation reaction. For example, aromatic compounds with anhydride groups (e.g. PTCDA and NTCDA) can demonstrate a performance efficiency (the ratio of experimental capacity to theoretical capacity) of 100%; in contrast, for the counterparts with carbonyl groups (e.g. 1,4-naphthoquinone (NQ) and anthraquinone), the performance efficiencies are in the range of 30%–40% [16]. Furthermore, aromatic compounds without anhydride and carbonyl groups (e.g. perylene and pyrene) present extremely low performance efficiencies of below 25% [16]. Anhydride groups have a significantly lower free energy for the Li+ insertion reaction than unsubstituted aromatics. In addition, once the sp3-hybridized oxygen atoms are substituted by the carbonyl reduction process, there is no overlithiation reduction in unsaturated C=C bonds in the diimide derivatives of NTCDA [171].

Furthermore, despite their high specific capacities, multifunctional overlithiated OEMs still suffer from some practical challenges. The overlithiation/sodiation/potassiation process may destroy the crystal structure, thus leading to inferior cycling performance and a low initial Coulombic efficiency. For example, although the oversodiation of PTCDA can form Na15PTCDA corresponding to a total specific capacity up to 1 017 mAh g–1, only a charge capacity of 227 mAh g–1 can be achieved after five cycles, and the initial Coulombic efficiency is approximately 43% [177]. In addition, the overlithiation process inevitably damages the π-conjugated structure and lowers the conductivity, giving rise to high electrochemical polarization. Renault et al. [171] reported a multifunctional overlithiated OEM of dilithium benzenedipropiolate (Li2BDP), which delivered an initial specific capacity of 1 363 mAh g−1; this corresponded to an 11.5-electron reduction process. However, fast capacity fading could be observed in the initial stage, stemming from its intrinsic instability that resulted in structural damage. In addition, there was a large polarization (above 1.0 V) between the charge/discharge processes. Therefore, surmounting these challenges is of great significance for the practical application of multifunctional overlithiated OEMs.

3 Molecular Engineering of OEMs

As mentioned above, although OEMs have structural diversity, showing different electrochemical properties for energy storage applications, they also individually have a series of challenges, such as their low output voltage, insufficient capacity, poor conductivity, or high solubility. These challenges stem from the inherent features of OEMs, including a relatively low redox potential, a limited number of transferred electrons per redox-active centre, high solubility, or an insufficient electronic conductivity, all of which are remarkably dominated by the molecule-level structure and material-level morphology. Nevertheless, the molecular tunability of OEMs makes it feasible to controllably design their molecular structure, allowing these challenges to be targeted for improvement. This section aims to review the sophisticated molecular design strategies that have been regarded as fundamental approaches to tuning the electrochemical performance of OEMs. As shown in the overall scheme (Fig. 9) for molecular engineering, these strategies cover the introduction of functional groups, the rearrangement of molecular skeletons, and the polymerization of small molecules, depending on the requirements of the OEMs.

3.1 Specific Energy Density

The specific energy density is one of the most critical indexes in evaluating the electrochemical performance of energy storage devices. The specific energy density (E) is directly proportional to the working voltage (V) and specific capacity (C), i.e. E = V × C. The theoretical specific capacity (C) of electrode materials can be determined by the following formula: C = nF/(3.6Mw), where n, F and Mw denote the electron transfer number per molecule or repeated unit, the Faraday constant, and the molecular weight of the molecule or repeated unit, respectively. Therefore, E = nFV/(3.6Mw). Theoretically, it is clear that rationally tuning the electrochemical redox potential of electrode materials and designing a molecular structure with a high n and low Mw are effective approaches to promoting the specific energy densities of OEMs.

3.1.1 Voltage Output

The working voltage plays a decisive role in the energy density of batteries, which is determined by the difference in redox potentials between the anode and cathode during charge/discharge processes. Thus, rationally tuning the redox potentials of OEMs, i.e. increasing/decreasing the electrochemical potential of redox-active centres in organic cathodes/anodes can result in batteries with an increased energy density. For example, p-type OEMs are generally used as cathode materials due to their high redox potentials (typically greater than 3.5 V vs. Li/Li+) during the p-type reactions, e.g. conducting polymers, radical polymers and arylamine compounds. Unfortunately, despite their higher theoretical capacities, n-type OEMs are usually subject to relatively low redox potentials of less than 3.0 V versus Li/Li+ when they are used as cathodes. Moreover, the redox potentials of these n-type OEMs are too high to be applied as anodes. Therefore, the rational tuning of n-type OEMs is of great significance according to their practical application scenarios in batteries, which can be realized by different molecular design strategies, such as the introduction of electron-withdrawing/donating groups and modulating the degree of conjugation.