Abstract

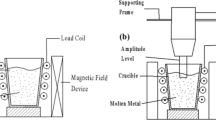

The Al–K2ZrF6–KBF4 system, (ZrB2 + Al3Zr)/AA6016 aluminum matrix composites were successfully synthesized in situ under different external fields, and ZrB2 + Al3Zr dual-phase reinforced particles were successfully synthesized in the composites by XRD. The morphology of the dual-phase particles was observed by SEM and EDS, and it was found that the primary function of the external ultrasonic field was to break the grain clusters and reduce the particle size; the position of the external magnetic field was to promote the in-situ reaction and improve the synthesis rate of the particles. The acoustic-magnetic coupling can play the role of two external areas at the same time. Through the hardness test, tensile test, friction and wear test, the experimental results show that the ultimate tensile strength and elongation of the composite material under the action of acoustic-magnetic coupling are 181.4 MPa and 24.5%, an increase of 51.3% and 102.5% over the same period of last year; the microhardness of the material under the action of acoustic-magnetic coupling increased to 71.9 HV, an increase of 43.8% compared with the matrix. The grains of the material through the acoustic-magnetic collar is more refined, with a size of 74.2 μm, and the dimensions of ZrB2 and Al3Zr are smaller. A single ultrasonic field reduces the particle size, increasing the friction coefficient and reducing the wear resistance; a single magnetic field promotes the synthesis of particles, increases the number of particles, and improves the wear resistance to a certain extent. The effects of magnetic field and ultrasonic coupling on the distribution and morphology of composites and their properties were investigated.

Similar content being viewed by others

Change history

01 November 2022

A Correction to this paper has been published: https://doi.org/10.1007/s40962-022-00909-3

References

O. Engler, C. Schafer, H.J. Brinkman, Crystal-plasticity simulation of the correlation of microtexture and roping in AA6xxx Al–Mg–Si sheet alloys for automotive applications. Acta Mater. 60, 5217–5232 (2012)

H. Zhong, P.A. Rometsch, L. Cao, Y. Estrin, The influence of Mg/Si ratio and Cu content on the stretch formability of 6xxx aluminium alloys. Mater. Sci. Eng. A 651, 688–697 (2016)

P. Lang, E. Povoden-Karadeniz, A. Falahati, E. Kozeschnik, Simulation of the effect of composition on the precipitation in 6xxx Al alloys during continuous heating DSC. J. Alloy. Comp. 612, 443–449 (2014)

A. Perovic et al., Precipitation in aluminum alloys AA6111 and AA6016. Scripta Materialia 41, 703–708 (1999)

A. Ghosh, A. Roy, A. Ghosh, M. Ghosh, Influence of temperature on microstructure, crystallographic texture and mechanical properties of EN AW 6016 alloy during plane strain compression. Mater. Today Commun. 26, 101808 (2021)

O. Engler, J. Hirsch, Texture control by thermomechanical processing of AA6xxx Al–Mg–Si sheet alloys for automotive applications-a review. Mater. Sci. Eng. A 336, 249–262 (2002)

X.P. Chen, L. Mei, D. Chen et al., The effect of initial aging treatment on the microstructure and mechanical properties of cryorolled 6016 Al alloy. Mater. Sci. Eng. A 667, 311–316 (2016)

C. Shi, K. Shen, D. Mao et al., Effects of ultrasonic treatment on microstructure and mechanical properties of 6016 aluminium alloy. Mater. Sci. Technol. 34, 1743–2847 (2018)

Z. Fan, X. Lei, L. Wang et al., Influence of quenching rate and aging on bendability of AA6016 sheet. Mater. Sci. Eng. A 730, 317 (2018)

J. David Raja Selvam, I. Dinaharan, In situ formation of ZrB2 particulates and their influence on microstructure and tensile behavior of AA7075 aluminum matrix composites. Int. J. Eng. Sci. Technol. 20(1), 187–196 (2017)

A. Mohan, G. Gautam, N. Kumar et al., Synthesis and tribological properties of AA5052-base insitu composites. Compos. Interfaces 23, 503–518 (2016)

M. Balakrishnan, I. Dinaharanc, R. Palanivel et al., Influence of friction stir processing on microstructure and tensile behavior of AA6061/Al3Zr cast aluminum matrix composites. J. Manuf. Process. 38, 148–157 (2019)

R. Vasanth Kumara, R. Keshavamurthyb, C.S. Peruguc et al., Influence of hot rolling on microstructure and mechanical behaviour of Al6061-ZrB2 in-situ metal matrix composites. Mater. Sci. Eng. A 738, 344–352 (2018)

R. Alia, F. Alia, A. Zahoora et al., Effect of sintering path on the microstructural and mechanical behavior of aluminum matrix composite reinforced with pre-synthesized Al/Cu core-shell particles. J. Alloys Comp. 889, 161531 (2021)

S.N. Khangholi, M. Javidani, A. Maltais et al., Effects of natural aging and pre-aging on the strength and electrical conductivity in Al–Mg–Si AA6201 conductor alloys. Mater. Sci. Eng. A 820, 141538 (2021)

G.S. Pradeep Kumar, R. Keshavamurthy, M.P. Akhil et al., Effect of salt spray parameters on TiC reinforced aluminium based in-situ metal matrix composites. Mater. Today Proc. 46, 4574–4578 (2021)

N. Kumar, R.K. Gautam, S. Mohan, In-situ development of ZrB2 particles and their effect on microstructure and mechanical properties of AA5052 metal-matrix composites. Mater. Des. 80, 129–136 (2015)

B. Kumar, P. Kumar, Preparation of hybrid reinforced aluminium metal matrix composite by using ZrB2: a systematic review. Mater. Today Proc. 61, 115 (2022)

Y.X. Liu, R.C. Wang, C.Q. Peng et al., Microstructures and mechanical properties of in-situ TiB2/Al−xSi−0.3Mg composites. Nonferrous Met. Soc. China 31, 331–344 (2021)

M. Mallik, P. Mitra, N. Srivastava et al., Abrasive wear performance of zirconium diboride based ceramic composite. Int. J. Refract. Met. Hard Mater. 79, 224–232 (2019)

I. Dinaharan, N. Murugan, Effect of friction stir welding on microstructure, mechanical and wear properties of AA6061/ZrB2 in situ cast composites. Mater. Sci. Eng. A 543, 257–266 (2012)

H. Li, L. Jiao, X. Huang et al., Effect of in situ reaction temperature on the microstructure and mechanical properties of 3 wt% ZrB2/A356. J. Mater. Eng. Perform. 30, 7295 (2021)

D. Gong, L. Jiang, J. Guan et al., Stable second phase: the key to high-temperature creep performance of particle reinforced aluminum matrix composite. Mater. Sci. Eng. A 770, 138551 (2020)

H. Li, S. Lu, P. Xu et al., Microstructure and tribological properties of in-situ formed Al3Zr/A356 composite. Mater. Res. Express 7, 056510 (2020)

T. Xu, G. Li, M. Xie et al., Microstructure and mechanical properties of in-situ nano γ-Al2O3/A356 aluminum matrix composite. J. Alloys Compd 787, 72–85 (2019)

Y. Ji, Y. Yuan, W. Zhang, Y. Xu, Y. Liu, Elevated temperature tensile creep behavior of aluminum borate whisker-reinforced aluminum alloy composites (ABOw/Al–12Si). Materials 14, 1217 (2021)

W. Qian, Y. Zhao, X. Kai et al., Characteristics of microstructural and mechanical evolution in 6111Al alloy containing Al3(Er, Zr) nanoprecipitates. Mater. Charact. 178, 111310 (2021)

W. Qian, Y. Zhao, X. Kai et al., Microstructure and properties of 6111Al matrix composites reinforced by the cooperation of in situ ZrB2 particles and Y. J. Alloys Compd 829, 154624 (2020)

F. Yongzhong, Y. Zhuang, X. Xiaojing et al., Mechanical properties and corrosion resistance of an Al–Zn–Mg–Cu aluminum matrix composite with in situ synthesis of Al3Zr and ZrB2 by mixed salt reaction. J. Mater. Eng. Perform. 29, 7908 (2020)

G. Gautam, N. Kumar, A. Mohan et al., ZrB2 nanoparticles transmuting tribological properties of Al3Zr/AA5052 composite. J. Braz. Soc. Mech. Sci. Eng. 41, 1 (2019)

G. Gautam, A. Mohan, Effect of ZrB2 particles on the microstructure and mechanical properties of hybrid (ZrB2+Al3Zr)/AA5052 insitu composites. J. Alloy. Compd. 649, 174–183 (2015)

Y.T. Zhao, S.L. Zhang, G. Chen, Aluminum matrix composites reinforced by in situ Al2O3 and Al3Zr particles fabricated via magnetochemistry reaction. Trans. Nonferrous Met. Soc. China 20, 2129–2133 (2010)

W. Qian, Y. Zhao, X. Kai et al., Synergistic reinforcement of in situ (ZrB2+TiB2) particles and Er on microstructure and properties of 6082Al matrix composites. J. Alloys Compd. 813, 152198 (2020)

H. Zhu, C. Jar, J. Song et al., High temperature dry sliding friction and wear behavior of aluminum matrix composites (Al3Zr+ɑ-Al2O3)/Al. Tribol. Int. 48, 78–86 (2012)

龙文元,陈勤,刘伟国.高能超声时间对原位自生TiB_2/Al复合材料组织和性能的影响. 材料热处理学报, 42(03), 15–21 (2021)

黄凯,蒋日鹏,李晓谦,李瑞卿,张立华.超声外场对原位TiB_2/2A14铝基复合材料的摩擦磨损性能的影响. 材料工程, 47(12), 78–84 (2019)

G. Chen, X. Song, N. Hu et al., Effect of initial Ti powders size on the microstructures and mechanical properties of Al3Ti/2024 Al composites prepared by ultrasonic assisted in-situ casting. J. Alloys Compd. 694, 539–548 (2017)

Z. Liu, T. Zhu, Y. Jia et al., Preparation of in-situ TiB2 reinforced aluminum matrix composites assisted by two steps of ultrasonic vibration. Mater. Res. Express 8, 046506 (2021)

S. Ramani, K. LeoDevWins, J. Nampoothiri et al., Effect of post-reaction ultrasonic treatment on synthesis, microstructural evolution and mechanical behaviour of Al 4043/TiB2 in situ nanocomposites. Arab. J. Sci. Eng. 46, 7521 (2021)

R. Gupta, G.P. Chaudhari, B.S.S. Daniel, Strengthening mechanisms in ultrasonically processed aluminium matrix composite with in-situ Al3Ti by salt addition. Compos. Part B 140, 27–34 (2018)

R. Gupta, B.S.S. Daniel, Strengthening mechanisms in Al3Zr-reinforced aluminum composite prepared by ultrasonic assisted casting. J. Mater. Eng. Perform. 30, 2504–2513 (2021)

X. Kai, K. Tian, C. Wang et al., Effects of ultrasonic vibration on the microstructure and tensile properties of the nano ZrB2/2024Al composites synthesized by directmelt reaction. J. Alloy. Compd. 668, 121–127 (2016)

S. Akram, A. Babutskyi, A. Chrysanthou et al., Improvement of the wear resistance of nickel-aluminium bronze and 2014–T6 aluminium alloy by application of alternating magnetic field treatment. Wear 480–481, 203940 (2021)

L. Jiao, L. Fan, Y. Zhao et al., Microstructure and tribological behavior of in situ ZrB2/A356 composites prepared under magnetic field. Metrol. Prop. 9, 015026 (2021)

S. Agrawal, A.K. Ghose, I. Chakrabarty, Effect of rotary electromagnetic stirring during solidification of In-situ Al–TiB2 composites. Mater. Des. 113, 195–206 (2017)

S. Zhang, Y. Zhao, G. Chen et al., (Al2O3+Al3Zr)/A356 nanocomposites fabricated by magnetochemistry in situ reaction. J. Alloy. Compd. 475, 261–267 (2009)

L. Jiao, Y. Zhao, Y. Wu et al., Microstructures of in-situ TiB2/7055Al composites by the ultrasonic and magnetic coupled field. Rare Met. Mater. Eng. 43(1), 6–10 (2014)

Y. Tsunekawa, H. Suzuki, Y. Genma, Application of ultrasonic vibration to in situ MMC process by electromagnetic melt stirring. Mater. Des. 22, 467–472 (2001)

X. Kai, S. Huang, Wu. Lin et al., High strength and high creep resistant ZrB2/Al nanocomposites fabricated by ultrasonic-chemical in-situ reaction. J. Mater. Sci. Technol. 35, 2107–2114 (2019)

R. Tao, Y. Zhao, X. Kai et al., Microstructures and properties of in situ ZrB2/AA6111 composites synthesized under a coupled magnetic and ultrasonic field. J. Alloy. Compd. 754, 114–123 (2018)

J. Li, L. Wang, J. Qin, Y. Chen, W. Lu, D. Zhang, Effect of microstructure on high temperature properties of in situ synthesized (TiB + La2O3)/Ti composite. Mater. Char. 66, 93–98 (2012)

J.G. Park, H.K. Dong, Y.H. Lee, Strengthening mechanisms in carbon nanotubereinforced aluminum composites. Carbon 95, 690–698 (2015)

C.J. Hsu, C.Y. Chang, P.W. Kao, Al-Al3Ti nanocomposites produced in situ by friction stir processing. Acta Mater. 54, 5241–5249 (2006)

Funding

This work is financially supported by the National Natural Science Foundation of China, No.52071158, U20A20274, U1664254.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: The authors’ names, some units of measure, funding information and Reference 47 were corrected.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiao, L., Wang, Z., Zhao, Y. et al. Influence of Electromagnetic Ultrasound Dual Field Coupling In Situ Synthesis of (ZrB2 + Al3Zr)/AA6016 Composites on the Structure and Properties. Inter Metalcast 17, 1736–1753 (2023). https://doi.org/10.1007/s40962-022-00893-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-022-00893-8