Abstract

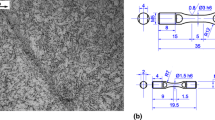

This paper presents the results obtained from the investigation of the mechanical behaviour of two different batches of pure tungsten specimens. The interest in pure tungsten is due to its special properties, which has led to it finding applications in several fields, including nuclear physics. At this moment, it is used as a core material for fixed particle producing targets in several accelerator facilities around the world and it is a candidate for future ones. In these facilities, tungsten directly interacts with high energy proton beams and, consequently, is subjected to considerable deformation at high strain-rates and temperatures. From these considerations, there comes the need to properly investigate the material response under these extreme conditions. For this purpose, an ad-hoc testing campaign was performed on small dog-bone specimens in tension. The results will be applicable to the ongoing design of CERN’s AD-target as well as to other future tungsten targets operating at high power and dynamically loaded in multiple accelerator facilities. Due to tungsten’s high Ductile-to-Brittle Transition temperature, it was not possible to test it at temperatures less than 250 °C. Tests were performed at two different strain-rates (nominal value of 1 s−1 and 103 s−1) reaching a maximum temperature of 1000 °C. The dynamic tests were performed by using a Hopkinson Bar setup in the direct impact configuration. Both at low and high strain-rates, heating of the specimen was achieved using an induction coil system. A numerical inverse procedure was applied to analyse the experimental data with the aim to obtain the equivalent stress versus effective plastic strain at the different loading conditions to be used for calibration of the strength model and for the evaluation of strain-rate and thermal softening sensitivities of the material.

Similar content being viewed by others

References

Lassner E, Schubert W-D (1999) Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds. Kluwer Academic/Plenum Publishers, New York

Rieth M et al (2011) Review on the EFDA programme on tungsten materials technology and science. J Nucl Mater 417:463–467

Thomason JWG (2008) Upgrades to ISIS for the new second target station. In Proceedings of EPAC08, 2008.

Calviani M et al (2016) Preliminary conceptual design of the n_TOF Spallation Target #3. CERN Technical Note: TOF-TAR-EN-0001, EDMS no: 1580996, Geneva, 2016.

Skoro GP, Bennet JR, Brooks SJ, Edgecock TR et al (2009) Solid target for a Neutrino Factory, in PAC09, Vancouver, Canada, 2009.

Peggs S, Kreier R (2012) ESS Technical Design Report, ESS, 2012.

De Lellis G (2015), SHiP: a new facility with a dedicated detector for neutrino physics. PoS, Vols. EPS-HEP2015, p. 37, 2015.

Torregrosa C, Perillo-Marcone A, Calviani M (2015) Designs characteristics and main inherent concerns of the antiproton decelerator target, CERN-ACC-NOTE-2015–0004, Geneva, 2015.

Torregrosa C, Perillo-Marcone A, Calviani M, Muñoz-Cobo JL (2016) CERN antiproton target: Hydrocode analysis of its core material dynamic response under proton beam impact. Phys Rev Accel Beams 19(7):073402

Torregrosa C, Perillo-Marcone A, Calviani M, Butcher M, Horvath D, Fornasiere E, Gentini L, Humbert J (2016) The HRMT27 (Rodtarg) Experiment: design, operation and first results, CERN internal note ACC-Note-2016–004, Geneva, 2016.

Scapin M, Peroni L, Dallocchio A (2012) Effects induced by LHC high energy beam in copper structures. J Nucl Mater 420:463–472. https://doi.org/10.1016/j.jnucmat.2011.10.036

Skoro GP, Bennet JRJ, Edgecock TR, Booth CN (2012) Yield strength of molybdenum, tantalum and tungsten at high strain rates and very high temperatures. J Nucl Mater 426:45–51

Batelle Memorial Institute (1963) The engineering properties of tungsten and tungsten alloys. Defense Metals Information Center, DMIC Report 191. Colombus, Ohio, p 1963

Zurek AK, Gray GT III (1991) Dynamic strength and strain rate effects on fracture behavior of tungsten and tungsten alloys. J de Phys IV 1(C3):631–637

Lennon AM, Ramesh KT (1998) The thermoviscoplastic response of polycrystalline tungsten in compression. Mater Sci Eng A276:9–21

Chen SR, Gray III GT (1995) Constitutive behavior of tungsten and tantalum: experiments and modelling. In 2nd International Conference on Tungsten and Refractory metals. Metals Powder Industries Federation, p. 489–498, Princeton, 1995.

Yin C et al (2018) Tensile properties of baseline and advanced tungsten grades for fusion applications. Int J Refract Metals Hard Mater 75:153–162

Shen T, Dai Y, Lee Y (2016) Microstructure and tensile properties of tungsten at elevated temperatures. J Nucl Mater 468:348–354

Scapin M, Peroni L, Fichera C, Cambriani A (2014) Tensile behaviour of T91 steel over a wide range of temperatures and strain-rate up to 104 s−1. J Mech Eng Perform 23:3007–3017

Børvik T, Hopperstad OS, Dey S, Pizzinato EV, Langseth M, Albertini C (2005) Strength and ductility of Weldox 460 E steel at high strain rates, elevated temperatures and various stress triaxialities. Eng Fract Mech 72(7):1071–1087

Scapin M, Peroni L, Carra F (2016) Investigation and mechanical modelling of pure molybdenum at high strain-rate and temperature. J Dyn Behav Mater 2(4):460–475

Scapin M et al (2017) Experimental results and strength model identification of pure iridium. Int J Impact Eng 106:191–201

Chen W, Song B (2011) Split Hopkinson (Kolsky) Bar—design, testing and applications. Mechanical engineering series. Springer, New York

Hull D, Bacon DJ (2001) Introduction to dislocations. Elsevier, New York

Nemat-Nasser S, Guo W, Liu M (1999) Experimentally-based micromechanical modeling of dynamic response of molybdenum. Scr Mater 40(7):859–872

Johnson GR, Cook WA (1983) A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. Proceeding of 7th International Symposium on Ballistics 1983; 541–547

Armstrong RW, Zerilli FJ (1998) Dislocation mechanics based analysis of material dynamic behavior. J Phys IV 49:529–534

Peroni L, Scapin M (2018) Experimental analysis and modelling of the strain-rate sensitivity of sheet niobium. EPJ Web of Conferences, vol. 183, 12th International Conference on the Mechanical and Physical Behaviour of Materials under Dynamic Loading, DYMAT 2018; Arcachon (France) 9–14 September 2018.

Scapin M (2015) Mechanical characterization and modeling of the heavy tungsten alloy IT180. Int J Refract Metals Hard Mater 50:258–268. https://doi.org/10.1016/j.ijrmhm.2015.01.018

Acknowledgements

The authors thank Ana Teresa Perez Fontenla (EN-MME-MM, CERN) for the help in the microstructure analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Scapin, M., Peroni, L., Torregrosa, C. et al. Effect of Strain-Rate and Temperature on Mechanical Response of Pure Tungsten. J. dynamic behavior mater. 5, 296–308 (2019). https://doi.org/10.1007/s40870-019-00221-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-019-00221-y