Abstract

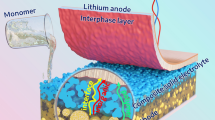

Porous metal architectures are widely adopted as three-dimensional conducting scaffolds for constructing Li metal composite anodes, whereas their macropores hinder their practical application due to limited surface area and large pore size of few hundred micrometers. In this work, a network of LixCu solid solution alloy nanowires is in situ formed via infiltrating molten Li-Cu alloy into Ni foam and subsequent cooling treatment, whereby a three-component composite anode consisting of Li metal, LixCu alloy, and Ni foam is fabricated. The LixCu nanowires nested as secondary frame split the macropores into micropores, enlarging the active surface area and inducing uniform Li deposition significantly. The lithiophilicity of the alloy wires and the shrunken void size built by the hierarchical architecture can further tune the nucleation and growth behavior of Li. The multiscale synergetic effect between the primary and secondary scaffold guarantees the composite anode sheet with extraordinarily long-term cycling stability even under high current rates.

摘要

多孔金属骨架已经被广泛应用于制备Li金属复合负极的三维集流体, 但其孔径通常达到几百微米, 表面积有限, 阻碍了其实际应用. 在本工作中, 我们通过将熔融的锂铜合金热灌入到泡沫镍中再进行冷却,原位形成了LixCu合金网络, 整个体系由Li金属、LixCu合金和泡沫镍组成. LixCu纳米线嵌套在泡沫镍内部, 组成了次级网络, 将泡沫镍的大孔结构分割成了微孔, 增大了表面积, 并显著诱导Li均匀沉积. LixCu合金纳米线良好的亲锂性和次级网络减小的孔尺寸, 可以进一步调控Li的成核和生长行为. 泡沫镍和次级合金网络之间的多尺度协同效应使得复合负极即使在高电流密度下仍表现出超长循环稳定性.

Similar content being viewed by others

References

Manthiram A. An outlook on lithium ion battery technology. ACS Cent Sci, 2017, 3: 1063–1069

Lin D, Liu Y, Cui Y. Reviving the lithium metal anode for high-energy batteries. Nat Nanotech, 2017, 12: 194–206

Guo Y, Li H, Zhai T. Reviving lithium-metal anodes for next-generation high-energy batteries. Adv Mater, 2017, 29: 1700007

Ghazi ZA, Sun Z, Sun C, et al. Key aspects of lithium metal anodes for lithium metal batteries. Small, 2019, 15: 1900687

Choudhury S, Archer LA. Lithium fluoride additives for stable cycling of lithium batteries at high current densities. Adv Electron Mater, 2016, 2: 1500246

Ding F, Xu W, Graff GL, et al. Dendrite-free lithium deposition via self-healing electrostatic shield mechanism. J Am Chem Soc, 2013, 135: 4450–4456

Jia W, Fan C, Wang L, et al. Extremely accessible potassium nitrate (KNO3) as the highly efficient electrolyte additive in lithium battery. ACS Appl Mater Interfaces, 2016, 8: 15399–15405

Shuai Y, Zhang Z, Chen K, et al. Highly stable lithium plating by a multifunctional electrolyte additive in a lithium-sulfurized poly-acrylonitrile battery. Chem Commun, 2019, 55: 2376–2379

Jia W, Wang Q, Yang J, et al. Pretreatment of lithium surface by using iodic acid (HIO3) to improve its anode performance in lithium batteries. ACS Appl Mater Interfaces, 2017, 9: 7068–7074

Qu S, Jia W, Wang Y, et al. Air-stable lithium metal anode with sputtered aluminum coating layer for improved performance. Electrochim Acta, 2019, 317: 120–127

Li K, Wang Y, Jia W, et al. Polymer electrolyte film as robust and deformable artificial protective layer for high-performance lithium metal anode. ACS Appl Mater Interfaces, 2020, 12: 2285–2292

Li NW, Yin YX, Yang CP, et al. An artificial solid electrolyte interphase layer for stable lithium metal anodes. Adv Mater, 2016, 28: 1853–1858

Liang J, Li X, Zhao Y, et al. In situ Li3PS4 solid-state electrolyte protection layers for superior long-life and high-rate lithium-metal anodes. Adv Mater, 2018, 30: 1804684

Yu Y, Huang G, Wang JZ, et al. In situ designing a gradient Li+ capture and quasi-spontaneous diffusion anode protection layer toward long-life Li-O2 batteries. Adv Mater, 2020, 32: 2004157

Wang D, Zhang W, Zheng W, et al. Towards high-safe lithium metal anodes: Suppressing lithium dendrites via tuning surface energy. Adv Sci, 2017, 4: 1600168

Cheng XB, Hou TZ, Zhang R, et al. Dendrite-free lithium deposition induced by uniformly distributed lithium ions for efficient lithium metal batteries. Adv Mater, 2016, 28: 2888–2895

Lin D, Liu Y, Liang Z, et al. Layered reduced graphene oxide with nanoscale interlayer gaps as a stable host for lithium metal anodes. Nat Nanotech, 2016, 11: 626–632

Lin D, Liu Y, Pei A, et al. Nanoscale perspective: Materials designs and understandings in lithium metal anodes. Nano Res, 2017, 10: 4003–4026

Zhao Y, Yang X, Sun Q, et al. Dendrite-free and minimum volume change Li metal anode achieved by three-dimensional artificial inter-layers. Energy Storage Mater, 2018, 15: 415–421

Yang CP, Yin YX, Zhang SF, et al. Accommodating lithium into 3D current collectors with a submicron skeleton towards long-life lithium metal anodes. Nat Commun, 2015, 6: 8058

Yun Q, He YB, Lv W, et al. Chemical dealloying derived 3D porous current collector for Li metal anodes. Adv Mater, 2016, 28: 6932–6939

Zhao H, Lei D, He YB, et al. Compact 3D copper with uniform porous structure derived by electrochemical dealloying as dendrite-free lithium metal anode current collector. Adv Energy Mater, 2018, 8: 1800266

Qiu H, Tang T, Asif M, et al. 3D porous Cu current collectors derived by hydrogen bubble dynamic template for enhanced Li metal anode performance. Adv Funct Mater, 2019, 29: 1808468

An Y, Fei H, Zeng G, et al. Vacuum distillation derived 3D porous current collector for stable lithium-metal batteries. Nano Energy, 2018, 47: 503–511

Chi SS, Liu Y, Song WL, et al. Prestoring lithium into stable 3D nickel foam host as dendrite-free lithium metal anode. Adv Funct Mater, 2017, 27: 1700348

Shen X, Cheng X, Shi P, et al. Lithium-matrix composite anode protected by a solid electrolyte layer for stable lithium metal batteries. J Energy Chem, 2019, 37: 29–34

Yan K, Lu Z, Lee HW, et al. Selective deposition and stable encapsulation of lithium through heterogeneous seeded growth. Nat Energy, 2016, 1: 16010

Zhang R, Chen XR, Chen X, et al. Lithiophilic sites in doped graphene guide uniform lithium nucleation for dendrite-free lithium metal anodes. Angew Chem Int Ed, 2017, 56: 7764–7768

Chen KH, Sanchez AJ, Kazyak E, et al. Synergistic effect of 3D current collectors and ALD surface modification for high coulombic efficiency lithium metal anodes. Adv Energy Mater, 2019, 9: 1802534

Lu LL, Zhang Y, Pan Z, et al. Lithiophilic Cu-Ni core-shell nanowire network as a stable host for improving lithium anode performance. Energy Storage Mater, 2017, 9: 31–38

Qin L, Xu H, Wang D, et al. Fabrication of lithiophilic copper foam with interfacial modulation toward high-rate lithium metal anodes. ACS Appl Mater Interfaces, 2018, 10: 27764–27770

Wu K, Zhao B, Yang C, et al. ZnCo2O4/ZnO induced lithium deposition in multi-scaled carbon/nickel frameworks for dendrite-free lithium metal anode. J Energy Chem, 2020, 43: 16–23

Xia Y, Jiang Y, Qi Y, et al. 3D stable hosts with controllable lithiophilic architectures for high-rate and high-capacity lithium metal anodes. J Power Sources, 2019, 442: 227214

Ye H, Xin S, Yin YX, et al. Stable Li plating/stripping electrochemistry realized by a hybrid Li reservoir in spherical carbon granules with 3D conducting skeletons. J Am Chem Soc, 2017, 139: 5916–5922

Cheng Y, Ke X, Chen Y, et al. Lithiophobic-lithiophilic composite architecture through co-deposition technology toward high-performance lithium metal batteries. Nano Energy, 2019, 63: 103854

He D, Liao Y, Cheng Z, et al. Facile one-step vulcanization of copper foil towards stable Li metal anode. Sci China Mater, 2020, 63: 1663–1671

Adair KR, Iqbal M, Wang C, et al. Towards high performance Li metal batteries: Nanoscale surface modification of 3D metal hosts for prestored Li metal anodes. Nano Energy, 2018, 54: 375–382

Huang X, Feng X, Zhang B, et al. Lithiated NiCo2O4 nanorods anchored on 3D nickel foam enable homogeneous Li plating/stripping for highpower dendrite-free lithium metal anode. ACS Appl Mater Interfaces, 2019, 11: 31824–31831

Sun C, Li Y, Jin J, et al. ZnO nanoarray-modified nickel foam as a lithiophilic skeleton to regulate lithium deposition for lithium-metal batteries. J Mater Chem A, 2019, 7: 7752–7759

Yue XY, Wang WW, Wang QC, et al. CoO nanofiber decorated nickel foams as lithium dendrite suppressing host skeletons for high energy lithium metal batteries. Energy Storage Mater, 2018, 14: 335–344

Ren F, Lu Z, Zhang H, et al. Pseudocapacitance induced uniform plating/stripping of Li metal anode in vertical graphene nanowalls. Adv Funct Mater, 2018, 28: 1805638

Huang G, Guo P, Wang J, et al. Lithiophilic V2O5 nanobelt arrays decorated 3D framework hosts for highly stable composite lithium metal anodes. Chem Eng J, 2020, 384: 123313

Wang R, Shi F, He X, et al. Three-dimensional lithiophilic Cu@Sn nanocones for dendrite-free lithium metal anodes. Sci China Mater, 2020, 64: 1087–1094

Huang G, Lou P, Xu GH, et al. Co3O4 nanosheet decorated nickel foams as advanced lithium host skeletons for dendrite-free lithium metal anode. J Alloys Compd, 2020, 817: 152753

Lu S, Wang Z, Yan H, et al. High rate and cycling stable Li metal anodes enabled with aluminum-zinc oxides modified copper foam. J Energy Chem, 2020, 41: 87–92

Zhao F, Zhou X, Deng W, et al. Entrapping lithium deposition in lithiophilic reservoir constructed by vertically aligned ZnO nanosheets for dendrite-free Li metal anodes. Nano Energy, 2019, 62: 55–63

Deng W, Zhou X, Fang Q, et al. Graphene/sulfur composites with a foam-like porous architecture and controllable pore size for high performance lithium-sulfur batteries. ChemNanoMat, 2016, 2: 952–958

Hu G, Xu C, Sun Z, et al. 3D graphene-foam-reduced-graphene-oxide hybrid nested hierarchical networks for high-performance Li-S batteries. Adv Mater, 2016, 28: 1603–1609

Zhu W, Deng W, Zhao F, et al. Graphene network nested Cu foam for reducing size of lithium metal towards stable metallic lithium anode. Energy Storage Mater, 2019, 21: 107–114

Jia W, Wang Z, Li J, et al. A dual-phase Li-Ca alloy with a patternable and lithiophilic 3D framework for improving lithium anode performance. J Mater Chem A, 2019, 7: 22377–22384

Yao Z, Jia W, Wang Z, et al. Fast ion/electron conducting scaffold of Li-Zn dual-phase alloy enable uniform deposition of Li metal at high current densities. J Energy Chem, 2020, 51: 285–292

Jia W, Liu Y, Wang Z, et al. Low-temperature fusion fabrication of Li-Cu alloy anode with in situ formed 3D framework of inert LiCu nanowires for excellent Li storage performance. Sci Bull, 2020, 65: 1907–1915

Fu L, Wan M, Zhang B, et al. A lithium metal anode surviving battery cycling above 200 °C. Adv Mater, 2020, 32: 2000952

Zhang T, Hong M, Yang J, et al. A high performance lithium-ion-sulfur battery with a free-standing carbon matrix supported Li-rich alloy anode. Chem Sci, 2018, 9: 8829–8835

Wu X, Zhang W, Wu N, et al. Structural evolution upon delithiation/lithiation in prelithiated foil anodes: A case study of AgLi alloys with high Li utilization and marginal volume variation. Adv Energy Mater, 2021, 11: 2003082

Choi SH, Lee SJ, Yoo D, et al. Marginal magnesium doping for highperformance lithium metal batteries. Adv Energy Mater, 2019, 9: 1902278

Wan M, Kang S, Wang L, et al. Mechanical rolling formation of interpenetrated lithium metal/lithium tin alloy foil for ultrahigh-rate battery anode. Nat Commun, 2020, 11: 829

Acknowledgements

This work was partly supported by the National Natural Science Foundation of China (21673033), Sichuan Science and Technology Program (2020071) and the Fundamental Research Founds for the Central Universities (ZYGX2019J024).

Author information

Authors and Affiliations

Contributions

Wang Z conducted the experiments and characterizations. Xing J, Liu Y, Xue J, Zhou A, Zhou F and Zou W gave some valuable suggestion. Wang Z wrote the paper with support from Li J and Li H. All authors contributed to the general discussion.

Corresponding authors

Additional information

Zihao Wang received his bachelor’s degree in materials science and engineering from the Southwest Petroleum University in 2018. Now he is pursuing his master’s degree under the supervision of Prof. Jingze Li at the University of Electronic Science and Technology of China (UESTC). His research interests are lithium metal anodes.

Jingze Li is a full-time professor at UESTC. He obtained his PhD degree of science from the Institute of Physics, Chinese Academy of Sciences in 2000. His research focuses on the field of energy storage including lithium-ion batteries and solid-state batteries.

Hong Li is currently a professor at the Institute of Physics, Chinese Academy of Sciences. His research interests are focused on the fundamental scientific problems in energy storage devices and their key materials. He has published more than 100 papers with over 2000 citations.

Conflict of interest

The authors declare no conflict of interest.

Electronic Supplementary Material

Rights and permissions

About this article

Cite this article

Wang, Z., Xue, J., Liu, Y. et al. LixCu alloy nanowires nested in Ni foam for highly stable Li metal composite anode. Sci. China Mater. 65, 69–77 (2022). https://doi.org/10.1007/s40843-021-1728-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40843-021-1728-2