Abstract

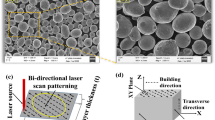

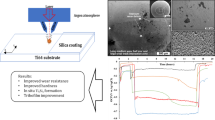

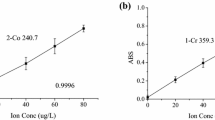

The frequency of surgeries involving the use of metal implants in orthopedic medicine to replace degenerative or fractured joints is increasing, and it is therefore important to optimize the lifespan and quality of these implants. Advances in additive manufacturing (AM), or 3D printing, are creating new opportunities to personalize implants in ways that reduce mechanical stress at the joint implant interface and improve bone ingrowth and implant stability; however, it is not well understood if and to what degree the AM process alters the corrosion behavior of the materials it produces. In this study, six Ti6Al4V prints manufactured via a selective laser melting (SLM) method were examined regarding their corrosion behavior in both saline and bovine calf serum (BCS) solutions. Ecorr and Icorr values were comparable between the CM-Ti6Al4V control and SLM-EDM surfaces; however, SLM surfaces were found to have more narrow passivation behavior evidenced by significant decreases in Epass values relative to CM-Ti6Al4V. We believe this is a consequence of microstructural differences between CM-Ti6Al4V and SLM-Ti6Al4V. Specifically, the SLM-Ti6Al4V demonstrated a dominant α′ martensitic microstructure and decreased vanadium-rich β-phase. BCS solution had a detrimental effect on potential parameters, Ecorr and OCP, decreasing these values relative to their saline counterparts. Increased surface roughness of the SLM-printed surface seemed to amplify the effects of the BCS solution. Furthermore, modest decreases in Epass and Ipass were observed in BCS solution, suggesting that the presence of protein may also interfere with passivation behavior. These findings have implications for how SLM-Ti6Al4V implants will perform in vivo and could possibly influence implant longevity and performance.

Similar content being viewed by others

Data Availability

Available upon request.

Material Availability

Available upon request.

Code Availability

Not applicable.

References

Kurtz SM, Ong KL, Lau E, Bozic KJ (2014) Impact of the economic downturn on total joint replacement demand in the United States: updated projections to 2021. J Bone Joint Surg Am 96:624–630

Ravi B et al (2012) The changing demographics of total joint arthroplasty recipients in the United States and Ontario from 2001 to 2007. Best Pract Res Clin Rheumatol 26:637–647

Bayliss LE et al (2017) The effect of patient age at intervention on risk of implant revision after total replacement of the hip or knee: a population-based cohort study. The Lancet 389:1424–1430

Huang H-H (2003) Effect of fluoride and albumin concentration on the corrosion behavior of Ti–6Al–4V alloy. Biomaterials 24:275–282

Guillemot F (2005) Recent advances in the design of titanium alloys for orthopedic applications. Expert Rev Med Devices 2:741–748

Rack HJ, Qazi JI (2006) Titanium alloys for biomedical applications. Mater Sci Eng C 26:1269–1277

Geetha M, Singh AK, Asokamani R, Gogia AK (2009) Ti based biomaterials, the ultimate choice for orthopaedic implants—a review. Prog Mater Sci 54:397–425

Srivastav A (2011) An overview of metallic biomaterials for bone support and replacement. Biomed Eng Trends Mater Sci. https://doi.org/10.5772/13488

Bagaria V, Bhansali R, Pawar P (2018) 3D printing-creating a blueprint for the future of orthopedics: current concept review and the road ahead! Journal of Clinical Orthopaedics and Trauma 9:207–212

Sidambe AT (2014) Biocompatibility of advanced manufactured titanium implants—a review. Materials 7:8168–8188

Wang X et al (2016) Topological design and additive manufacturing of porous metals for bone scaffolds and orthopaedic implants: a review. Biomaterials 83:127–141

Zhang L-C, Attar H (2016) Selective laser melting of titanium alloys and titanium matrix composites for biomedical applications: a review. Adv Eng Mater 18:463–475

Tan XP, Tan YJ, Chow CSL, Tor SB, Yeong WY (2017) Metallic powder-bed based 3D printing of cellular scaffolds for orthopaedic implants: a state-of-the-art review on manufacturing, topological design, mechanical properties and biocompatibility. Mater Sci Eng, C 76:1328–1343

Talib Mohammed M (2018) Mechanical properties of SLM-titanium materials for biomedical applications: a review. Materials Today: Proceedings 5:17906–17913

Zhao X et al (2016) Comparison of the microstructures and mechanical properties of Ti–6Al–4V fabricated by selective laser melting and electron beam melting. Mater Des 95:21–31

Kasperovich G, Haubrich J, Gussone J, Requena G (2016) Correlation between porosity and processing parameters in TiAl6V4 produced by selective laser melting. Mater Des 105:160–170

Thijs L, Verhaeghe F, Craeghs T, Humbeeck JV, Kruth J-P (2010) A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta Mater 58:3303–3312

Neto MQ et al (2021) The effect of additive manufacturing parameters on microstructure and mechanical properties of biomedical grade Ti-6Al-4V alloy. ASTM Selected Technical Papers. https://doi.org/10.1520/STP163720200121

Zhao B, Wang H, Qiao N, Wang C, Hu M (2017) Corrosion resistance characteristics of a Ti-6Al-4V alloy scaffold that is fabricated by electron beam melting and selective laser melting for implantation in vivo. Mater Sci Eng C 70:832–841

Dai N, Zhang L-C, Zhang J, Chen Q, Wu M (2016) Corrosion behavior of selective laser melted Ti-6Al-4V alloy in NaCl solution. Corros Sci 102:484–489

Toptan F et al (2019) Corrosion and tribocorrosion behaviour of Ti6Al4V produced by selective laser melting and hot pressing in comparison with the commercial alloy. J Mater Process Technol 266:239–245

de Damborenea JJ et al (2017) Corrosion of Ti6Al4V pins produced by direct metal laser sintering. Appl Surf Sci 393:340–347

Mathew MT, Jacobs JJ, Wimmer MA (2012) Wear-corrosion synergism in a CoCrMo hip bearing alloy is influenced by proteins. Clin Orthop Relat Res 470:3109–3117

Royhman D et al (2021) Fretting-corrosion in hip taper modular junctions: The influence of topography and pH levels —an in-vitro study. J Mech Behav Biomed Mater 118:104443

Panigrahi P et al (2014) Intergranular pitting corrosion of CoCrMo biomedical implant alloy. J Biomed Mater Res B Appl Biomater 102:850–859

Abey S et al (2014) Electrochemical behavior of titanium in artificial saliva: influence of pH. J Oral Implantol 40:3–10

G01 Committee. Test method for conducting cyclic potentiodynamic polarization measurements for localized corrosion susceptibility of iron-, nickel-, or cobalt-based alloys. http://www.astm.org/cgi-bin/resolver.cgi?G61-86R18. https://doi.org/10.1520/G0061-86R18.

Walter R, Kannan MB (2011) Influence of surface roughness on the corrosion behaviour of magnesium alloy. Mater Des 32:2350–2354

Yoo B, Shin KR, Hwang DY, Lee DH, Shin DH (2010) Effect of surface roughness on leakage current and corrosion resistance of oxide layer on AZ91 Mg alloy prepared by plasma electrolytic oxidation. Appl Surf Sci 256:6667–6672

Chen J-R, Tsai W-T (2011) In situ corrosion monitoring of Ti–6Al–4V alloy in H2SO4/HCl mixed solution using electrochemical AFM. Electrochim Acta 56:1746–1751

Eliaz N (2019) Corrosion of metallic biomaterials: a review. Materials (Basel) 12:407

Silva-Bermudez P, Rodil SE (2013) An overview of protein adsorption on metal oxide coatings for biomedical implants. Surf Coat Technol 233:147–158

Hedberg Y et al (2013) Surface-protein interactions on different stainless steel grades: effects of protein adsorption, surface changes and metal release. J Mater Sci: Mater Med 24:1015–1033

Hedberg Y, Karlsson M-E, Blomberg E, Odnevall Wallinder I, Hedberg J (2014) Correlation between surface physicochemical properties and the release of iron from stainless steel AISI 304 in biological media. Colloids Surf B: Biointerfaces 122:216–222

Khan MA, Williams RL, Williams DF (1999) The corrosion behaviour of Ti–6Al–4V, Ti–6Al–7Nb and Ti–13Nb–13Zr in protein solutions. Biomaterials 20:631–637

Funding

NIH R01 Grant AR070181 (PIs: Lundberg, Mathew, Pourzal), Blazer Foundation, University of Illinois College of Medicine James Scholar Program.

Author information

Authors and Affiliations

Contributions

Materials: AEO, RJA; surface characterization: DF, MQN, DH, RP; Experiments: DF, KC; Analysis: DF, KC; Manuscript drafting: DF, KC; Manuscript editing/review: DF, KC, DB, AEOs, RP, MM; mentorship: MM.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Ethical Approval

Not applicable.

Consent to Participate

Not applicable.

Consent for Publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fischer, D., Cheng, Ky., Neto, M.Q. et al. Corrosion Behavior of Selective Laser Melting (SLM) Manufactured Ti6Al4V Alloy in Saline and BCS Solution. J Bio Tribo Corros 8, 63 (2022). https://doi.org/10.1007/s40735-022-00657-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40735-022-00657-1