Abstract

The energy conservation plays an important role for low carbon development. In order to evaluate the energy conservation in the full life-cycle, a scheme to estimate the energy consumption, or alternatively the energy pay, in constructing an overhead transmission line is proposed in this paper. The analysis of a typical projection is given for demonstration. With new additional overhead transmission lines, the energy consumption, known as the power loss in power network, is expected to be decline, which is defined in this paper as the energy payback. In order to estimate this kind of contribution, the scheme that consisted of load forecast, production simulation for generating systems, load flow simulation and power loss calculation has been proposed. Case studies, based on the IEEE 24-bus test system, are given to demonstrate the efficacy of the schemes. Moreover, several presumptive scenarios are deployed and analysed with the presented schemes for comparison.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

For power system reliability and security, the power grid must be intensified as the increase in power demand and generation. Various important analysis works, known as power network planning [1], should be carried out in advance of establishing a new transmission project. Furthermore, power network planning is such an essential work which aims to consolidate the power network. Constructing new overhead transmission lines (OTLs) is considered as one basic part of power network planning.

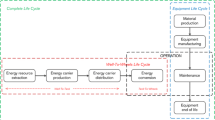

With the gradual exhaustion of fossil fuels, all kinds of efforts are made to promote the energy conservation [2] for the purpose of low carbon development [3, 4]. Therefore, the energy consumption, which is the major concern of this paper, is an important aspect for the performance of the power network. Allowing for life-cycle [5], an OTL project will go through several steps of manufacturing, installing, operating and dismantling. Each step has the demand of energy consumption. The quantity of the energy consumption at the stages of manufacturing and installing, which is largely determined by the design scheme, is defined here as the energy consumption of construction (ECC). The ECC will not fluctuate too much with an established design scheme, which specify where, when and how to execute the project. Section 2 gives a case study to demonstrate the analysis of ECC by a typical OTL project.

While an OTL integrates into the power network and participates in carrying the power, there is inevitably some electric power loss [6–10]. The total network power loss, which is defined here as the energy consumption of operation (ECO), is largely dependent on the system operation mode rendering the load demand and power source allocation. However, while new OTLs have been constructed and put into operation, the ECO is expected to be decline as the supplemented lines having positive effect on network connectivity. The potential decline in ECO by constructing new OTL is considered as a kind of energy payback. In order to estimate the OTL’s contribution to the energy payback in the future, load power should be obtained by load forecast [11–15] and generator outputs should be assigned by production simulation [16–19]. Then, the ECO can be produced by load flow [20] simulation. Section 3 details the steps comprising the above procedures.

This paper gives approximate approaches for estimating the ECC and the ECO of OTL projects. The comparison of those two kinds of energy consumptions is deployed in Section 4. Furthermore, case studies for different scenarios corresponding to optional OTL projects highlight the significant of the presented approaches. In Section 5, the main results are summarized and key conclusions are drawn.

Note that, the energy consumption is not the sole factor to evaluate the performance of a power network. Therefore, a transmission project may have more benefits to the system than just reducing losses. For example, a project could have reliability or stability benefits. A complex multi-objective decision should be made for network planning. However, the primary focus of this study is on the analysis with respect to energy consumption.

2 Energy consumption of construction

2.1 Descriptions of the typical project

Amount of equipment and industrial materials are used to construct an OTL projects. Plenty of energy should be consumed in producing those manufactures. To analyze the energy consumption at the stage of construction, a typical OTL project is elaborated in this section. As shown in Fig. 1, A denotes a high-voltage (230 kV) and double-circuit OTL. The new power plant (B) is going to be established. To transfer power from B to load center, an optimal scheme is to break up A and rebuild double π OTLs (C) to connect A and B. The total length of C is about 33.8 km.

2.2 Data of equipment

The equipment and industrial materials that forming the OTL project are various. In advance of carrying out a project, the task of top priority is estimating the plan. In accordance with related demands, such as system security and stability, the construction plan should detail the design concept and equipment selection of the project. The plan of a typical project is given in Table 1 with the type, the model, the quantity and the weight of those equipment and industrial materials elaborated.

2.3 Estimate for ECC

The typical values of energy consumptions (EC) are provided in Table 2. The unit of “kgce” denotes kilograms of standard coal. In accordance with the average coal consumption of thermal power units, the parity of 0.404 kgce is 1 kW h. In order to capture the consumed diesel oil in the process of excavation and transport, the diesel oil consumption is converted into equivalent EC according to the average efficacy of diesel generator.

Then, the ECC can be estimated in accordance with the information shown in Table 1 and related unit energy consumption given in Table 2. Figure 2 shows the proportion of the ECC. Apparently, the equipment with maximal energy consumption is the conductor, which is mainly composed of aluminum.

3 Energy consumption of operation

While new OTLs are going to be constructed and put into operation, the total power loss is expected to be decrease. To capture the contribution of establishing a new OTL, the power system simulation is needed. The process of ECO calculation consists of four steps is shown in Fig. 3.

3.1 Load forecasting

In this step, both the load active power and the load reactive power should be forecasted over a long period of time. Various optional methods, such as time series method and trend extrapolation method, can be qualified for this work.

3.2 Production simulation for generating system

While power demands at receiving buses vary continuously, power balance must be maintained by adjusting outputs of sending generators. Once the load power is determined, the optimal output of generators can be obtained by production simulation allowing for minimizing the operating costs. A security constrained UC model [21] as described by (1) to (12) is adapted.

where Σ represents the summation of all the corresponding elements; N represents the number of time periods in the daily dispatching model; f and c (subscripts) denote respectively generating units that can start and stop daily and that cannot start and stop daily; C f and C c represent the average cost of corresponding type of generation; C d represents the load shedding cost; V f is the start-stop cost of generating units that can start and stop daily; S t f is the start-stop cost of generating unit that can start and stop daily at t; θ is the amplification coefficient of load shedding penalty; γ is the amplification coefficient of start-stop cost; P t f and P t c represent the output of different types of generation at t; P f max, P f min, P c max, P c min, represent the maximum and minimum power of the different types of generation; \( \Delta P_{{f\,{\text{ down}}}} \), \( \Delta P_{{f\,{\text{ up}}}} \), \( \Delta P_{{c\,{\text{ down}}}} \), \( \Delta P_{{c\,{\text{ up}}}} \) represent the maximum and minimum ramping rates of units that can start and stop daily and units that cannot start and stop daily, respectively; \( I_{f}^{t} \) is the state at t of generating unit that can start and stop daily; I c is the state of unit that cannot start and stop over the dispatching day; D t is the nodal loads at t; D t d is the nodal load shedding at t; r t d and r t u are system up and down reserve requirements at t; A ngf and A ngc are units and nodes incidence coefficients of the different types of generation; A sl represents the incidence coefficient between transmission lines and transmission sections; W is generation distribution shift factors; F tmax represents the transmission line capacity at t; F t sr max and F t s max represents the forward and backward direction maximum capacity for transmission sections

The objective of the above optimization model is minimizing the total system operating cost, which consists of the costs of the fuel, start-stop and load shedding. The decision variables consist of P t f , P t c , D t d , S t f , I t f and I c . (2) represents the power balance between load and generation. (3) and (4) represents the output limits of each generator unit. (5) denotes the start-stop cost of generating units when their states change from stop to work. (6) and (7) respectively represent the system positive and negative reserve constraints. (8) and (9) represent the power constraints for transmission lines and sections capacity. (10) enforces the thermal generation ramp rate limits. (11) defines the states of the generators as discrete variables. (12) enforces the amount of load shedding to be zero or positive. By linearizing the cost functions of the thermal generating units, the mixed integer linear programming algorithm could be used to solve this optimal problem.

3.3 Load flow simulation

With the load power and generator output obtained using load forecast and production simulation (corresponding to step 1 and step 2, respectively), the load flow equations can be initialized and solved using the Newton iteration method. The shunt compensators are taken into account by operating in accordance with the bus voltage magnitude. As is shown in (13), When V i > V max (reactive power at bus i is redundant), the shunt reactors at bus i are switched off prior to switching on valid shunt capacitor, and vise versa.

Following steps simulate the operation of the compensators:

Step 1: Solving load flow equations using Newton iterations.

Step 2: Check voltage magnitude of each bus. If all the buses match (1), finish; else go to Step 3.

Step 3: Adjust the shunt compensator. If any status of compensator is changed, go back to Step 1; else, finish.

3.4 Load flow simulation

With the steps shown in Sections 3.1, 3.2 and 3.3, the power loss at various points in time can be obtained. In order to estimate the ECO for a period of time, following formulation can be applied.

where E CO represents the value of ECO corresponding to the hypothetical scenario in which the specified new OTL have been integrated into the network; n denotes the total of time points within a specific time window; P loss denotes the network power loss.

4 Energy payback ratio

With the method presented in Section 3, the ECO can be estimated over a period of time, which is defined here as the time window. It is assumed that all the OTLs and the transformers participate in operation without failure during the time window. Hence, the ECO of a target system for a specific time window is invariable unless the network is changed by establishing new OTLs. Since a new OTL is constructed and put into operation, the ECO is expected to be decline due to the improvement of the power transmission. To evaluate the contribution to this aspect of system operation, the decrease in ECO corresponding to a specific time window, or alternatively the energy payback, is defined by,

where \( E_{\text{CO}}^{ ( 0 )} \) represents the base value of ECO for the original case; E PB represents the value of EPB.

To estimate the EPB in life-cycle, the approach presented in Section 2 is available to obtain the ECC in establishing a new OTL. As a result, the energy payback ratio is defined by,

where E CC represents the value of ECC. This ratio is considered as a more comprehensive index to evaluate the contribution for energy conservation because of the consideration in life-cycle.

5 Case studies

5.1 Description of the test system

In this case, the IEEE 24-bus reliability test system [22] (see Fig. 4) is analyzed using the presented scheme. The S ref is set to 100 MW.

The values of load active power for 8,760 hours (one year) that derived from [22] are used as “the results of load forecast”. With the assumption that the power factor of each bus is fixed, the values of load reactive power for 8,760 hours are obtained.

The shunt compensators which are shown in Table 3 are supplemented to adjust the reactive power support. With the supplemented shunt compensators, the voltage magnitude at each bus could maintain in a range (0.9 p.u.~1.1 p.u.).

5.2 Calculation of ECO

Figure 5 gives the power loss of one OTL (from bus 14 to bus 16) for 24 hours. Obviously, the energy consumption that calculated by (14) is equivalent of the area of the shaded part in Fig. 5. Using (14), the power loss of each line for 8,760 hours could be obtained.

While the total load power for one year is approximately 15,297,075 MW h, the ECO accounts for about 3.5% of the total generation power. The ECO for each transmission line could be much different from each other. As can be seen from Fig. 6, the ECO (line power loss) mainly allocated at the specific transmission lines that performing poorly.

The details of the ECO for the test system are elaborated in Table 4 for comparison. The transmission line list ordered by ECO is beneficial for network planning due to the illustration of the weak links of the grid. In a way, the power loss is closely related to the power network connectivity. Thus, the power loss that shown in Table 4 deserves consideration for power network planning to consolidate the network.

5.3 Comparison for multiple scenarios

It is assumed that one double-circuit OTL is planning to be constructed. There exist four optional schemes which are marked as A 1, A 2, A 3, A 4 in Fig. 4. The type and model of the equipment are specified as those given in Table 1. In this case, the ECCs of those alternative projects are shown in Table 5.

In Section 3, the steps for obtain the ECO could be considered as an approach to foreseen the performance of the network in a specific imaginary scenario. Since one out of the four optional schemes (A 1, A 2, A 3, A 4) should be chosen, it is expected to learn how the network performs if any one of those optional lines has been constructed. Then, different scenarios are defined in Table 6. Scenario S i indicate the condition while line A i has been constructed. The index “i” refers to the ith optional line. Particularly, S0 indicates the original scenario. The results for the hypothetical scenarios are obtained and compared. Note that the time window for each scenario is specified as 8,760 hours.

As can be seen from Table 6, in each what-if scenario, the energy payback ratio is bigger than 100%, which implied that the ECC of the line is expected to be paid back in less than one year.

6 Discussion

As is known, the service life of an OTL is generally more than 30 years. One concern is that the energy payback for the entire life-cycle of OTL is more valuable. However, it is too difficult to take into account all the uncertainties in such a long period.

7 Conclusions

It is indicated that the energy consumption in constructing an OTL can be estimated by analyzing the components of the project. Then, the analysis of a typical OTL project is given for demonstration. To estimate the prospective energy consumption in system operation, or alternatively the power loss, a hybrid scheme is proposed for power system simulation. Then, the decrease in network power loss, which caused by integrating new transmission lines into network, is defined as the energy payback. With the case study, which uses the IEEE 24-bus test system, the energy payback is estimated and compared with consumption of construction energy. Results of the case study indicate that an OTL is expected to have a considerable energy payback ratio. Then, allowing for life-cycle, more attention should be paid to the energy payback while planning an OTL.

References

Shu J, Wu J, Shahidehpour M et al (2012) A new method for spatial power network planning in complicated environments. IEEE Trans Power Syst 27(1):381–389

Khan AZ (1996) Electrical energy conservation and its application to a sheet glass industry. IEEE Trans Energy Convers 11(3):666–671

Ji Z, Kang CQ, Chen QX et al (2013) Low-carbon power system dispatch incorporating carbon capture power plants. IEEE Trans Power Syst 28(4):4615–4623

Chen QX, Kang CQ, Xia Q et al (2010) Power generation expansion planning model towards low-carbon economy and its application in China. IEEE Trans Power Syst 25(2):1117–1125

Karlsson D, Wallin L, Olovsson HE et al (1997) Reliability and life cycle cost estimates of 400 kV substation layouts. IEEE Trans Power Delivery 12(4):1486–1492

Xu Y, Dong ZY, Wong KP et al (2013) Optimal capacitor placement to distribution transformers for power loss reduction in radial distribution systems. IEEE Trans Power Syst 28(4):4072–4079

Ochoa LF, Harrison GP (2011) Minimizing energy losses: optimal accommodation and smart operation of renewable distributed generation. IEEE Trans Power Syst 26(1):198–205

Al-Turki YA, Lo KL (2008) Power loss allocation in pool-based electricity markets. Australasian. In: Universities Power Engineering Conference (AUPEC2008), Sydney, 1–6 Dec 2008, 6pp

Quezeda VHM, Abbad JR, Gomez TGS (2006) Assessment of energy distribution losses for increasing penetration of distributed generation. IEEE Trans Power Syst 21(2):533–540

Federico J, Gonzalez V, Lyra C (2005) Learning classifiers shape reactive power to decrease losses in power distribution networks. In: Proceedings of the 2005 IEEE Power and Energy Society general meeting, San Francisco, 557–562 June 2005, 6 pp

Fidalgo JN, Lopes JAP (2003) Forecasting active and reactive power at substations’ transformers. In: IEEE Power Tech Conference Proceedings, Bologna, 23–26 June 2003, 4 pp

Mandal P, Senjyu T, Uezato K, Funabashi T (2004) Forecasting several-hours-ahead electricity demand using neural network. In: Electric utility deregulation, restructuring and power technologies, Proceedings of the 2004 IEEE International Conference, Hong Kong, 515–521 April 2004, 7 pp

Silva DD, Yu X, Alahakoon D et al. (2011) Incremental pattern characterization learning and forecasting for electricity consumption using smart meters. In: Industrial Electronics (ISIE), 2011 IEEE International symposium on, Gdansk, 807–812 June 2011, 6 pp

Wang Y, Niu D, Lee V (2011) Optimizing of BP neural network based on genetic algorithms in power load forecasting. In: IECON 2011—37th Annual Conference on IEEE Industrial Electronics Society, Melboume, 4322–4327 November 2011, 6 pp

Jin YX, Su J (2007) Similarity clustering and combination load forecasting techniques considering the meteorological factors. In: Proceedings of the 6th international conference on instrumentation, measurement, circuits & systems (WSEAS), Hangzhou, 115–119 April 2007, 5 pp

Yamayee ZA, Hakimmashhadi H (1985) Production simulation for power system studies. IEEE Trans Power Appar Syst PAS-104(12):3376–3381

Sondergren C, Ravn HF (1996) A method to perform probabilistic production simulation involving combined heat and power units. IEEE Trans Power Syst 11(2):1031–1036

Khan SU, Lee ST (1981) Estimation of power-pooling benefits from production simulations. IEEE Trans Power Appar Syst PAS-100(4):1759–1765

Li Y, Singh C (1999) A direct method for multi-area production simulation. IEEE Trans Power Syst 14(3):906–912

Stott B (1974) Review of load-flow calculation methods. Proc IEEE 62(7):916–929

Zhang N, Kang C, Kirschen DS et al (2013) Planning pumped storage capacity for wind power integration. IEEE Trans Sustain Energy 4(2):393–401

Subcommittee PM (1979) IEEE reliability test system. IEEE Trans Power Appar Syst PAS-98(6):2047–2054

Acknowledgments

This work was supported by the National Science Fund for Distinguished Young Scholars (No. 51325702) and the China Postdoctoral Science Foundation (No. 2014M560968). This study was also supported in part by scientific and technical project of State Grid Corporation of China. The authors gratefully acknowledge the contributions of Hongtao YIN, Ning LIU, Siyuan WANG and Qi HAN from the State Grid Corporation of China.

Author information

Authors and Affiliations

Corresponding author

Additional information

CrossCheck date: 14 November 2014

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

DONG, X., KANG, C., ZHANG, N. et al. Estimating life-cycle energy payback ratio of overhead transmission line toward low carbon development. J. Mod. Power Syst. Clean Energy 3, 123–130 (2015). https://doi.org/10.1007/s40565-014-0082-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40565-014-0082-y