Abstract

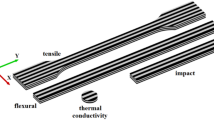

In order to study the hot melt extrusion process in fused deposition modeling (FDM), this study mainly explores the effects of printing temperature, heated block length, feeding speed on the exit morphology and mechanical properties of FDM printed Polylactic acid (PLA) samples. High-speed camera is used to capture the exit morphology of molten PLA just extruded to the nozzle. According to exit morphology, the outlet states of extruded molten material can be divided into four categories, namely, bubbled state, coherent state, expanding state, and unstable state. Tensile test results show that printing temperature, heated block length and printing speed have significant influence on tensile properties and fracture mode of FDM printed samples. When the heated block length is 15 mm and 30 mm, there is a ductile-brittle transition in fracture mode with the increase of printing speed. The printing process window under different heated block lengths and printing temperatures has been figured out and the distribution of printing process window under different printing speeds has been discussed. There is a maximum printing process window under the heated block length of 30 mm. This finding provides a frame work for performance prediction of FDM printed parts and theoretical guidance for expanding the scope of printing process window.

Similar content being viewed by others

References

Feng X, Ma L, Liang H et al (2020) Osteointegration of 3D-printed fully porous polyetheretherketone scaffolds with different pore sizes. ACS Omega 5(41):26655–26666

Rodríguez-Parada L, Mayuet PF, Gámez AJ (2019) Evaluation of reliefs’ properties on design of thermoformed packaging using fused deposition modelling moulds. Materials 12(3):478. https://doi.org/10.3390/ma12030478

Galatas A, Hassanin H, Zweiri Y et al (2018) Additive manufactured sandwich composite/ABS parts for unmanned aerial vehicle applications. Polymers 10(11):1262. https://doi.org/10.3390/polym10111262

Daneshmand S, Aghanajafi C (2012) Description and modeling of the additive manufacturing technology for aerodynamic coefficients measurement. Stroj Vestn J Mech E 58(2):125–133

Espalin D, Muse DW, Macdonald E et al (2014) 3D printing multifunctionality: structures with electronics. Int J Adv Manuf Tech 72(5/8):963–978

Yang C, Tian X, Li D et al (2017) Influence of thermal processing conditions in 3D printing on the crystallinity and mechanical properties of peek material. J Mater Process Tech 248:1–7

Sun Q, Rizvi GM, Bellehumeur CT et al (2008) Effect of processing conditions on the bonding quality of FDM polymer filaments. Rapid Prototyp J 14(2):72–80

Shelton TE, Willburn ZA, Hartsfield CR et al (2019) Effects of thermal process parameters on mechanical interlayer strength for additively manufactured Ultem 9085. Polym Test 81:106255. https://doi.org/10.1016/j.polymertesting.2019.106255

Heidari-Rarani M, Parisa S, Niloofar E (2020) Effect of processing parameters on tensile properties of FDM 3D printed of PLA specimens. J Sci Technol Compos 2(7):855–862

Rahmati A, Heidari-Rarani M, Lessard L (2021) A novel conservative failure model for the fused deposition modeling of polylactic acid specimens. Addit Manuf 48:102460. https://doi.org/10.1016/j.addma.2021.102460

Letcher T, Waytashek M (2014) Material property testing of 3D-printed specimen in PLA on an entry-level 3D printer. In: proceedings of the ASME 2014 international mechanical engineering congress and exposition. Volume 2A: Advanced Manufacturing. Montreal, Quebec, Canada. November 14–20, 2014. https://doi.org/10.1115/imece2014-39379

Peng A, Xiao X, Yue R (2014) Process parameter optimization for fused deposition modeling using response surface methodology combined with fuzzy inference system. Int J Adv Manuf Tech 73(1/4):87–100

Rajpurohit SR, Dave HK (2018) Analysis of tensile strength of a fused filament fabricated PLA part using an open-source 3D printer. Int J Adv Manuf Tech 101:1525–1536

Wang P, Zou B, Xiao H et al (2019) Effects of printing parameters of fused deposition modeling on mechanical properties, surface quality, and microstructure of peek. J Mater Process Tech 271:62–74

Chacón JM, Caminero MA, García PE et al (2017) Additive manufacturing of PLA structures using fused deposition modelling: effect of process parameters on mechanical properties and their optimal selection. Mater Des 124:143–157

Samykano M, Selvamani SK, Kadirgama K et al (2019) Mechanical property of FDM printed ABS: influence of printing parameters. Int J Adv Manuf Tech 102:2779–2796

Camargo JC, Machado LR, Almeida EC et al (2019) Mechanical properties of PLA-graphene filament for FDM 3D printing. Int J Adv Manuf Tech 103(5):2423–2443

Liu X, Zhang M, Li S et al (2017) Mechanical property parametric appraisal of fused deposition modeling parts based on the gray Taguchi method. Int J Adv Manuf Tech 89(5/8):2387–2397

Mst FA, Masood SH, Iovenitti P et al (2016) Effects of part build orientations on fatigue behaviour of FDM-processed PLA material. Prog Addit Manuf 1:21–28

Afrose MF, Masood SH, Nikzad M et al (2014) Effects of build orientations on tensile properties of PLA material processed by FDM. Adv Mat Res 1044/1045:31–34

Gonabadi H, Yadav A, Bull SJ (2020) The effect of processing parameters on the mechanical characteristics of PLA produced by a 3D FFF printer. Int J Adv Manuf Tech 111(3/4):695–709

Heidari-Rarani M, Ezati N, Parisa S et al (2020) Optimization of FDM process parameters for tensile properties of polylactic acid specimens using Taguchi design of experiment method. J Thermoplast Compos Mater 3:1–18

Zhou X, Hsieh SJ, Wang JC (2019) Accelerating extrusion-based additive manufacturing optimization processes with surrogate-based multi-fidelity models. Int J Adv Manuf Tech 103(1):4071–4083

Panda SK, Padhee S, Sood AK et al (2009) Optimization of fused deposition modelling (FDM) process parameters using bacterial foraging technique. Intell Inf Manag 1(2):89–97

Gurrala PK, Regalla SP (2014) Part strength evolution with bonding between filaments in fused deposition modelling. Virtual Phys Prototyp 9:141–149

Costa SF, Duarte FM, Covas JA (2015) Thermal conditions affecting heat transfer in FDM/FFE: a contribution towards the numerical modelling of the process. Virtual Phys Prototyp 10:35–46

Heidari-Rarani M, Rafiee-Afarani M, Zahedi AM (2019) Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites. Compos B Eng 175:107147. https://doi.org/10.1016/j.compositesb.2019.107147

Standards B (2012) Plastics-determination of tensile properties-Part 1: general principles (ISO 527-1:2012). CEN/TC 249-Plastics

Roger TF (1979) Principles of polymer processing. The Macmician Press Ltd., London. https://doi.org/10.1007/978-1-349-16234-5

Zehev T, Costas GG (1979) Principles of polymer processing. Wiley, New York. https://doi.org/10.1002/aic.690260135

Bower DI (1981) An Introduction to polymer physics. Cambridge University Press, Cambridge

Ward IM, Sweeney J (2013) Mechanical properties of solid polymers, 3rd edn. Wiley, New York

Shibata M, Inoue Y, Miyoshi M (2006) Mechanical properties, morphology, and crystallization behavior of blends of poly(l-lactide) with poly(butylene succinate-co-l-lactate) and poly(butylene succinate). Polymer 47(10):3557–3564

Pillin I, Montrelay N, Grohens Y (2006) Thermo-mechanical characterization of plasticized PLA: is the miscibility the only significant factor? Polymer 47(13):4676–4682

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11502269 and 11672304), and plan of Beijing Municipal Commission of Science and Technology (Grant No. Z181100003818015).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Bian, YH., Yu, G., Zhao, X. et al. Exit morphology and mechanical property of FDM printed PLA: influence of hot melt extrusion process. Adv. Manuf. 11, 56–74 (2023). https://doi.org/10.1007/s40436-022-00405-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40436-022-00405-1