Abstract

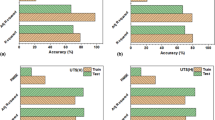

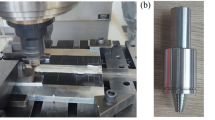

Nickel-based superalloys are widely used in fabrication of components in aero space and nuclear sectors due to excellent strength, corrosion resistance, good ductility and high-temperature resistance. Inconel 825 superalloy is predominantly used for making aircraft engine components. This work investigates single pass welding of Inconel 825 strips employing gas tungsten arc welding. Four weld parameters, viz. welding speed (V), welding current (I), arc length (N) and gas flow rate (GFR), were used to investigate ultimate tensile strength (UTS) of weld employing Box–Behnken design having 27 experiments. The welding current is found the most dominating factor followed by welding speed (V). Higher heat input with low welding speed increases deposition rate that ensures more strength in weldment. Microstructural analysis shows two different grain boundaries, i.e., solidification sub-grain boundaries and solidification grain boundaries, in fusion zone. Artificial neural network (ANN) modelling for UTS is developed, and its predictive capability is compared with multiple regression analysis. A new integrated ANN–TLBO-based soft computing modelling and optimization approach is proposed for obtaining optimum weld parameters to maximize weld strength. The proposed optimization methodology obtained maximum UTS of 701.73 MPa at optimal weld parameters I = 120 A, V = 180 mm/min, GFR= 12 l/min and N = 2.24 mm. Validation result was found highly encouraging with 0.60% error with confirmation experiment. The proposed method has better convergent capability with minimum number of iterations.

Similar content being viewed by others

References

Dupont JN, Lippold JC, Kiser SD (2009) Welding metallurgy and weldability of nickel based alloys. Wiley, Hoboken

Caron JL, Sowards JW (2014) Weldability of nickel based alloys, vol 6. Elsevier, Amsterdam

Choudhury B, Chandrasekaran M (2017) Investigation on welding characteristics of aerospace materials—a review. Mater Today Proc 4:7519–7526. https://doi.org/10.1016/j.matpr.2017.07.083

Agilan M, Vankatswaran T, Sivkumar D (2014) Effect of heat input on microstructure and mechanical properties of Inconel 718 EB welds. Procedia Mater Sci 5:656–662. https://doi.org/10.1016/j.mspro.2014.07.312

Ren W, Lu F, Yang R, Liu X, Zhuguo L (2015) Liquation cracking in fiber laser welded joints of Inconel 617. J Mater Process Technol 226:214–220. https://doi.org/10.1016/j.jmatprotec.2015.07.004

Xin Y, Hua X, Wang M, Lou S (2015) Controlling hot cracking in Ni-based Inconel-718 superalloy cast sheets during tungsten inert gas welding. J Mater Process Technol 222:381–390. https://doi.org/10.1016/j.jmatprotec.2015.03.031

BenyounisKY Olabi AG, Hashmi MSJ (2005) Optimizing the laser-welded butt joints of medium carbon steel using RSM. J Mater Process Technol 164–165:986–989. https://doi.org/10.1016/j.jmatprotec.2005.02.067

Benyounis KY, Olabi AG, Hashmi MSJ (2005) Effect of laser welding parameters on the heat input and weld-bead profile. J Mater Process Technol 164–165:978–985. https://doi.org/10.1016/j.jmatprotec.2005.02.060

Huang W, Kovacevic R (2011) A neural network and multiple regression method for the characterization of the depth of weld penetration in laser welding based on acoustic signatures. J Intell Manuf 22:131–143. https://doi.org/10.1007/s10845-009-0267-9

Dutta P, Pratihar DK (2007) Modeling of TIG welding process using conventional regression analysis and neural network-based approaches. J Mater Process Technol 184:56–68. https://doi.org/10.1016/j.jmatprotec.2006.11.004

He H, Yang C, Chen Z, Lin S, Fan C (2014) Strength prediction of aluminum–stainless steel-pulsed TIG welding–brazing joints with RSM and ANN. Acta Metall Sin (Engl Lett) 27(6):1012–1017. https://doi.org/10.1007/s40195-014-0115-6

Anand K, Shrivastava R, Tamilmannan K, Sathiya P (2015) A comparative study of artificial neural network and response surface methodology for optimization of friction welding of Incoloy 800 H. Acta Metall Sin (Engl Lett) 28(7):892–902. https://doi.org/10.1007/s40195-015-0273-1

Olabi AG, Casalino G, Benyounis KY, Hashmi MSJ (2006) An ANN and Taguchi algorithms integrated approach to the optimization of CO2 laser welding. Adv Eng Softw 37:643–648. https://doi.org/10.1016/j.advengsoft.2006.02.002

Sathiya P, Panneerselvam K, Jaleel MYA (2012) Optimization of laser welding process parameters for super austenitic stainless steel using artificial neural networks and genetic algorithm. Mater Des 36:490–498. https://doi.org/10.1016/j.matdes.2011.11.028

Teimouri R, Baseri H (2015) Forward and backward predictions of the friction stir welding parameters using fuzzy-artificial bee colony-imperialist competitive algorithm systems. J Intell Manuf 26:307–319. https://doi.org/10.1007/s10845-013-0784-4

Rong Y, Zhang G, Chang Y, Huang Y (2016) Integrated optimization model of laser brazing by extreme learning machine and genetic algorithm. Int J Adv Manuf Technol 87:2943–2950. https://doi.org/10.1007/s00170-016-8649-6

Gupta SK, Pandey KN, Kumar R (2018) Artificial intelligence-based modelling and multi-objective optimization of friction stir welding of dissimilar AA5083-O and AA6063-T6 aluminium alloys. Proc IMechE Part L J Mater Des Appl 232:333–342. https://doi.org/10.1177/1464420715627293

Babu KK, Panneerselvam K, Sathiya P, Haq AN, Sundarrajan S, Mastanaiah P, Murthy CVS (2018) Parameter optimization of friction stir welding of cryorolled AA2219 alloy using artificial neural network modeling with genetic algorithm. Int J Adv Manuf Technol 94:3117. https://doi.org/10.1007/s00170-017-0897-6

Maji K, Pratihar DK (2010) Forward and reverse mappings of electrical discharge machining process using adaptive network-based fuzzy inference system. Expert Syst Appl 37:8566–8574. https://doi.org/10.1016/j.eswa.2010.05.019

Tamang SK, Chandrasekaran M (2017) Integrated optimization methodology for intelligent machining of Inconel 825 and its shop-floor application. J Braz Soc Mech Sci Eng 39:865. https://doi.org/10.1007/s40430-016-0570-2

Devarajaiah D, Muthumari C (2019) Fuzzy logic-integrated PSO methodology for parameters optimization in end milling of Al/SiCp MMC. J Braz Soc Mech Sci Eng 41:222. https://doi.org/10.1007/s40430-019-1725-8

Rao RV, Savsani VJ, Vakharia DP (2011) Teaching–learning-based optimization: a novel method for constrained mechanical design optimization problems. Comput Aided Des 43:303–315. https://doi.org/10.1016/j.cad.2010.12.015

Uzlu E, Kankal M, Akpınar A, Dede T (2014) Estimates of energy consumption in Turkey using neural network with the teaching learning-based optimization algorithm. Energy 75:295–303. https://doi.org/10.1016/j.energy.2014.07.078

Naik B, Nayak J, Behera HS (2016) A TLBO based gradient descent learning-functional link higher order ANN: an efficient model for learning from non-linear data. J King Saud Univ Comput Inf Sci 30(1):120–139. https://doi.org/10.1016/j.jksuci.2016.01.001

Baghban A, Kardani MN, Mohammadi AH (2018) Improved estimation of Cetane number of fatty acid methyl esters (FAMEs) based biodiesels using TLBO-NN and PSO-NN models. Fuel 232:620–631. https://doi.org/10.1016/j.fuel.2018.05.166

Kangazian J, Sayyar N, Shamanian M (2017) Influence of microstructural features on the mechanical behavior of Incoloy 825 welds. Metall Microstruct Anal 6:190–199. https://doi.org/10.1007/s13632-017-0353-x

Chandrasekaran M, Muralidhar M, Krishna CM, Dixit US (2010) Application of soft computing techniques in machining performance prediction and optimization: a literature review. Int J Adv Manuf Technol 46:445. https://doi.org/10.1007/s00170-009-2104-x

Kecman V (2001) Learning and soft computing: support vector machines, neural networks, and fuzzy logic models. The MIT Press, Cambridge

Dixit US, Chandra S (2003) A neural network based methodology for the prediction of roll force and roll torque in fuzzy form for cold flat rolling process. Int J Adv Manuf Technol 22:883–889. https://doi.org/10.1007/s00170-003-1628-8

Kohli A, Dixit US (2005) A neural-network-based methodology for the prediction of surface roughness in a turning process. Int J Adv Manuf Technol 25:118–129. https://doi.org/10.1007/s00170-003-1810-z

Karaoglu S, Secgin A (2008) Sensitivity analysis of submerged arc welding process parameters. J Mater Process Technol 202:500–507. https://doi.org/10.1016/j.jmatprotec.2007.10.035

Chandrasekaran M, Devarasiddappa D (2014) Artificial neural network modeling for surface roughness prediction in cylindrical grinding of Al–SiCp metal matrix composites and ANOVA analysis. Adv Prod Eng Manag 9(2):59–70. https://doi.org/10.14743/apem2014.2.176

Acknowledgements

The authors acknowledge the financial support received from NERIST, Arunachal Pradesh, under TEQIP-II scheme and would like to thank the authorities of IIT, Guwahati, and MSME Tool Room, Guwahati, for providing the facilities to carry out this work. Also the authors are thankful to the anonymous reviewers for their comments that help to improve the quality of the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Izabel Fernanda Machado, Dr.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choudhury, B., Chandrasekaran, M. & Devarasiddappa, D. Development of ANN modelling for estimation of weld strength and integrated optimization for GTAW of Inconel 825 sheets used in aero engine components. J Braz. Soc. Mech. Sci. Eng. 42, 308 (2020). https://doi.org/10.1007/s40430-020-02390-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-020-02390-7