Abstract

Purpose

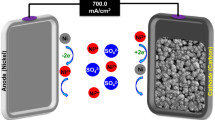

A bioelectricity producing system was configured by connecting to a microbial electrolysis cell producing hydrogen, in which both systems were without mediator, to treatment the landfill leachate of the and generate bioelectricity and hydrogen.

Methods

The anode electrode was made with MWCNTs polyscale coating on graphite felt and the cathode electrode with activated carbon coating on carbon cloth. In the MFC-MEC coupled system, the electrodes were connected in series using copper wire. The system was set up in a fed-batch mode and the landfill synthetic leachate was injected into the anode MFC-MEC chamber as fuel.

Results

In MFC, the highest voltage, current density and power density were 1114 mV, 44.2A/m3 and 49.24 W/m3, respectively. The maximum of the coulombic efficiency system was 94.10%. The highest removed COD, NH4-N and P was 97.38%, 79.56% and 74.61%, respectively. In the MEC, the maximum of voltage input, current density and power density was 1106 mV, 43.88 A/m3and 48.54 W/m3, respectively. The maximum coulombic efficiency system was 125.54%. Also the highest removed COD, NH4-N and P was 97.46%, 78.81% and 76.25%, respectively. The highest biogas production rate and its yield were 39 mL/L.d, and 0.0118 L/g CODrem, respectively.

Conclusion

This study found that the MFC-MEC coupled system had promising potential for strong wastewaters treatment, such as the leachate of landfill; and the in-site use of generated electricity and the production of useful fuels such as biogas.

Similar content being viewed by others

References

Das S, Lee SH, Kumar P, Kim K-H, Lee SS, Bhattacharya SS. Solid waste management: scope and the challenge of sustainability. J Clean Prod. 2019;228:658–78. https://doi.org/10.1016/j.jclepro.2019.04.323.

Roodbari A, Nabizadeh R, Mahvi A, Nasseri S. Dehghani mh, Alimohammadi M. use of a sonocatalytic process to improve the biodegradability of landfill leachate. Braz J Chem Eng. 2012;29:221–30. https://doi.org/10.1590/S0104-66322012000200003.

Gálvez A, Greenman J, Ieropoulos I. Landfill leachate treatment with microbial fuel cells; scale-up through plurality. Bioresour Technol. 2009;100(21):5085–91. https://doi.org/10.1016/j.biortech.2009.05.061.

Ziyang L, Yu S, Xiaoliang C, Youcai Z, Nanwen Z. Application of hydration reaction on the removal of recalcitrant contaminants in leachate after biological treatment. Waste management (New York, NY). 2014;34(4):791–7. doi:https://doi.org/10.1016/j.wasman.2014.01.009.

Iyamu HO, Anda M, Ho G. A review of municipal solid waste management in the BRIC and high-income countries: a thematic framework for low-income countries. Habitat Int. 2020;95:102097. https://doi.org/10.1016/j.habitatint.2019.102097.

Li J, He C, Tian T, Liu Z, Gu Z, Zhang G, et al. UASB-modified Bardenpho process for enhancing bio-treatment efficiency of leachate from a municipal solid waste incineration plant. Waste Manag. 2020;102:97–105. https://doi.org/10.1016/j.wasman.2019.10.028.

Chaturvedi H, Kaushal P. Comparative study of different biological processes for non-segregated municipal solid waste (MSW) leachate treatment. Environ Technol Innov. 2018;9:134–9. https://doi.org/10.1016/j.eti.2017.11.008.

Mahvi A, Roodbari A, Nabizadeh R, Nasseri S, Dehghani MH, Alimohammadi M. Improvement of Landfill Leachate Biodegradability with Ultrasonic Process. PLoS One. 2012;7:e27571. https://doi.org/10.1371/journal.pone.0027571.

Liu Y, Wang J. Treatment of fresh leachate from a municipal solid waste incineration plant by combined radiation with coagulation process. Radiat Phys Chem. 2020;166:108501. https://doi.org/10.1016/j.radphyschem.2019.108501.

Lozinski D, Bolyard SC, Reinhart DR, Motlagh AM. Treatment of leachate organic matter through sunlight driven processes. Waste Manag. 2019;94:18–26. https://doi.org/10.1016/j.wasman.2019.05.015.

Jamali HA, Mahvi AH, Nabizadeh R, Vaezi F, Ali GAM, Omrani, editors. Combination of Coagulation-Flocculation and Ozonation Processes for Treatment of Partially Stabilized Landfill Leachate of Tehran2009.

Javahershenas M, Nabizadeh R, Alimohammadi M, Mahvi A. The effects of Lahijan landfill leachate on the quality of surface and groundwater resources. Int J Environ Anal Chem. 2020:1–17. https://doi.org/10.1080/03067319.2020.1724984.

Abourached C, Catal T, Liu H. Efficacy of single-chamber microbial fuel cells for removal of cadmium and zinc with simultaneous electricity production. Water Res. 2014;51:228–33. https://doi.org/10.1016/j.watres.2013.10.062.

Cai T, Meng L, Chen G, Xi Y, Jiang N, Song J, et al. Application of advanced anodes in microbial fuel cells for power generation: a review. Chemosphere. 2020;248:125985. https://doi.org/10.1016/j.chemosphere.2020.125985.

Doherty L, Zhao Y, Zhao X, Hu Y, Hao X, Xu L, et al. A review of a recently emerged technology: constructed wetland--microbial fuel cells. Water Res. 2015;85:38–45. https://doi.org/10.1016/j.watres.2015.08.016.

Gajaraj S, Hu Z. Integration of microbial fuel cell techniques into activated sludge wastewater treatment processes to improve nitrogen removal and reduce sludge production. Chemosphere. 2014;117:151–7. https://doi.org/10.1016/j.chemosphere.2014.06.013.

Yegane Badi M, Azari A, Esrafili A, Ahmadi E, Gholami M. Performance evaluation of magnetized multiwall carbon nanotubes by Iron oxide nanoparticles in removing fluoride from aqueous solution. J Mazandaran Univ Med Sci. 2015;25(124):128–42.

Ahmadi E, Kakavandi B, Azari A, Izanloo H, Gharibi H, Mahvi AH, et al. The performance of mesoporous magnetite zeolite nanocomposite in removing dimethyl phthalate from aquatic environments. Desalin Water Treat. 2016;57(57):27768–82. https://doi.org/10.1080/19443994.2016.1178174.

Wu S, He W, Yang W, Ye Y, Huang X, Logan BE. Combined carbon mesh and small graphite fiber brush anodes to enhance and stabilize power generation in microbial fuel cells treating domestic wastewater. J Power Sources. 2017;356:348–55. https://doi.org/10.1016/j.jpowsour.2017.01.041.

Cho S-K, Lee M-E, Lee W, Ahn Y. Improved hydrogen recovery in microbial electrolysis cells using intermittent energy input. Int J Hydrog Energy. 2019;44(4):2253–7. https://doi.org/10.1016/j.ijhydene.2018.07.025.

Colantonio N, Kim Y. Cadmium (II) removal mechanisms in microbial electrolysis cells. J Hazard Mater. 2016;311:134–41. https://doi.org/10.1016/j.jhazmat.2016.02.062.

Li B, Zhou J, Zhou X, Wang X, Li B, Santoro C, et al. Surface modification of microbial fuel cells anodes: approaches to practical design. Electrochim Acta. 2014;134:116–26. https://doi.org/10.1016/j.electacta.2014.04.136.

Mehdinia A, Ziaei E, Jabbari A. Multi-walled carbon nanotube/SnO2 nanocomposite: a novel anode material for microbial fuel cells. Electrochim Acta. 2014;130:512–8. https://doi.org/10.1016/j.electacta.2014.03.011.

Janicek A, Gao N, Fan Y, Liu H. High performance activated carbon/carbon cloth cathodes for microbial fuel cells. Fuel Cells. 2015;15(6):855–61. https://doi.org/10.1002/fuce.201500120.

Li X, Zhu N, Wang Y, Li P, Wu P, Wu J. Animal carcass wastewater treatment and bioelectricity generation in up-flow tubular microbial fuel cells: effects of HRT and non-precious metallic catalyst. Bioresour Technol. 2013;128:454–60. https://doi.org/10.1016/j.biortech.2012.10.053.

More TT, Ghangrekar MM. Improving performance of microbial fuel cell with ultrasonication pre-treatment of mixed anaerobic inoculum sludge. Bioresour Technol. 2010;101(2):562–7. https://doi.org/10.1016/j.biortech.2009.08.045.

Vicari F, Albamonte M, Galia A, Scialdone O. Effect of mode of operation, substrate and final electron acceptor on single-chamber membraneless microbial fuel cell operating with a mixed community. J Electroanal Chem. 2018;814:104–10. https://doi.org/10.1016/j.jelechem.2018.02.044.

Yousefzadeh S, Ahmadi E, Gholami M, Ghaffari HR, Azari A, Ansari M, et al. A comparative study of anaerobic fixed film baffled reactor and up-flow anaerobic fixed film fixed bed reactor for biological removal of diethyl phthalate from wastewater: a performance, kinetic, biogas, and metabolic pathway study. Biotechnol Bioeng. 2017;10(1):139. https://doi.org/10.1186/s13068-017-0826-9.

Mohanakrishna G, Abu-Reesh IM, Kondaveeti S, Al-Raoush RI, He Z. Enhanced treatment of petroleum refinery wastewater by short-term applied voltage in single chamber microbial fuel cell. Bioresour Technol. 2018;253:16–21. https://doi.org/10.1016/j.biortech.2018.01.005.

Scholten JCM, Conrad R, Stams AJM. Effect of 2-bromo-ethane sulfonate, molybdate and chloroform on acetate consumption by methanogenic and sulfate-reducing populations in freshwater sediment. FEMS Microbiol Ecol. 2000;32(1):35–42. https://doi.org/10.1111/j.1574-6941.2000.tb00696.x.

Croese E, Jeremiasse AW, Marshall IPG, Spormann AM, Euverink G-JW, Geelhoed JS, et al. Influence of setup and carbon source on the bacterial community of biocathodes in microbial electrolysis cells. Enzym Microb Technol. 2014;61–62:67–75. https://doi.org/10.1016/j.enzmictec.2014.04.019.

Cha J, Choi S, Yu H, Kim H, Kim C. Directly applicable microbial fuel cells in aeration tank for wastewater treatment. Bioelectrochemistry. 2010;78(1):72–9. https://doi.org/10.1016/j.bioelechem.2009.07.009.

Wen Q, Wu Y, Cao D, Zhao L, Sun Q. Electricity generation and modeling of microbial fuel cell from continuous beer brewery wastewater. Bioresour Technol. 2009;100(18):4171–5. https://doi.org/10.1016/j.biortech.2009.02.058.

Wei FS. Water and wastewater monitoring analysis method. Publishing house of environmental science of China, Beijing.

Tenca A, Cusick RD, Schievano A, Oberti R, Logan BE. Evaluation of low cost cathode materials for treatment of industrial and food processing wastewater using microbial electrolysis cells. Int J Hydrog Energy. 2013;38(4):1859–65. https://doi.org/10.1016/j.ijhydene.2012.11.103.

Wang H, Wang Q, Li X, Wang Y, Jin P, Zheng Y, et al. Bioelectricity generation from the decolorization of reactive blue 19 by using microbial fuel cell. J Environ Manag. 2019;248:109310. https://doi.org/10.1016/j.jenvman.2019.109310.

Call D, Logan BE. Hydrogen production in a single chamber microbial electrolysis cell lacking a membrane. Environ Sci Technol. 2008;42(9):3401–6. https://doi.org/10.1021/es8001822.

Gil-Carrera L, Escapa A, Mehta P, Santoyo G, Guiot SR, Morán A, et al. Microbial electrolysis cell scale-up for combined wastewater treatment and hydrogen production. Bioresour Technol. 2013a;130:584–91. https://doi.org/10.1016/j.biortech.2012.12.062.

Gajda I, Greenman J, Ieropoulos I. Microbial fuel cell stack performance enhancement through carbon veil anode modification with activated carbon powder. Appl Energy. 2020;262:114475. https://doi.org/10.1016/j.apenergy.2019.114475.

Goud RK, Babu PS, Mohan SV. Canteen based composite food waste as potential anodic fuel for bioelectricity generation in single chambered microbial fuel cell (MFC): bio-electrochemical evaluation under increasing substrate loading condition. Int J Hydrog Energy. 2011;36(10):6210–8. https://doi.org/10.1016/j.ijhydene.2011.02.056.

Puig S, Serra M, Coma M, Cabré M, Dolors Balaguer M, Colprim J. Microbial fuel cell application in landfill leachate treatment. J Hazard Mater. 2011;185(2–3):763–7. https://doi.org/10.1016/j.jhazmat.2010.09.086.

Hassan M, Wei H, Qiu H, Su Y, Jaafry SWH, Zhan L, et al. Power generation and pollutants removal from landfill leachate in microbial fuel cell: variation and influence of anodic microbiomes. Bioresour Technol. 2018;247:434–42. https://doi.org/10.1016/j.biortech.2017.09.124.

Wang J, Song X, Wang Y, Zhao Z, Wang B, Yan D. Effects of electrode material and substrate concentration on the bioenergy output and wastewater treatment in air-cathode microbial fuel cell integrating with constructed wetland. Ecol Eng. 2017a;99:191–8. https://doi.org/10.1016/j.ecoleng.2016.11.015.

Wang H, Jiang SC, Wang Y, Xiao B. Substrate removal and electricity generation in a membrane-less microbial fuel cell for biological treatment of wastewater. Bioresour Technol. 2013;138:109–16. https://doi.org/10.1016/j.biortech.2013.03.172.

Hou Y, Zhang R, Luo H, Liu G, Kim Y, Yu S, et al. Microbial electrolysis cell with spiral wound electrode for wastewater treatment and methane production. Process Biochem. 2015;50(7):1103–9. https://doi.org/10.1016/j.procbio.2015.04.001.

Hernández-Flores G, Poggi-Varaldo HM, Romero-Castañón T, Solorza-Feria O, Rinderknecht-Seijas N. Harvesting energy from leachates in microbial fuel cells using an anion exchange membrane. Int J Hydrog Energy. 2017;42(51):30374–82. https://doi.org/10.1016/j.ijhydene.2017.08.201.

Greenman J, Gálvez A, Giusti L, Ieropoulos I. Electricity from landfill leachate using microbial fuel cells: comparison with a biological aerated filter. Enzym Microb Technol. 2009;44(2):112–9. https://doi.org/10.1016/j.enzmictec.2008.09.012.

Hassan M, Pous N, Xie B, Colprim J, Balaguer MD, Puig S. Influence of iron species on integrated microbial fuel cell and electro-Fenton process treating landfill leachate. Chem Eng J. 2017;328:57–65. https://doi.org/10.1016/j.cej.2017.07.025.

Zhang G, Zhao Q, Jiao Y, Wang K, Lee D-J, Ren N. Biocathode microbial fuel cell for efficient electricity recovery from dairy manure. Biosens Bioelectron. 2012;31(1):537–43. https://doi.org/10.1016/j.bios.2011.11.036.

Mansoorian HJ, Mahvi AH, Jafari AJ, Khanjani N. Evaluation of dairy industry wastewater treatment and simultaneous bioelectricity generation in a catalyst-less and mediator-less membrane microbial fuel cell. J Saudi Chem Soc. 2016;20(1):88–100. https://doi.org/10.1016/j.jscs.2014.08.002.

Li Y, Styczynski J, Huang Y, Xu Z, McCutcheon J, Li B. Energy-positive wastewater treatment and desalination in an integrated microbial desalination cell (MDC)-microbial electrolysis cell (MEC). J Power Sources. 2017;356:529–38. https://doi.org/10.1016/j.jpowsour.2017.01.069.

Juang DF, Yang PC, Chou HY, Chiu LJ. Effects of microbial species, organic loading and substrate degradation rate on the power generation capability of microbial fuel cells. Biotechnol Lett. 2011;33(11):2147–60. https://doi.org/10.1007/s10529-011-0690-9.

Escapa A, San-Martín MI, Mateos R, Morán A. Scaling-up of membraneless microbial electrolysis cells (MECs) for domestic wastewater treatment: bottlenecks and limitations. Bioresour Technol. 2015;180:72–8. https://doi.org/10.1016/j.biortech.2014.12.096.

Kargi F, Catalkaya EC, Uzuncar S. Hydrogen gas production from waste anaerobic sludge by electrohydrolysis: effects of applied DC voltage. Int J Hydrog Energy. 2011;36(3):2049–56. https://doi.org/10.1016/j.ijhydene.2010.11.087.

Li Y, Yang H-Y, Shen J-Y, Mu Y, Yu H-Q. Enhancement of azo dye decolourization in a MFC–MEC coupled system. Bioresour Technol. 2016;202:93–100. https://doi.org/10.1016/j.biortech.2015.11.079.

Sun M, Sheng G-P, Mu Z-X, Liu X-W, Chen Y-Z, Wang H-L, et al. Manipulating the hydrogen production from acetate in a microbial electrolysis cell–microbial fuel cell-coupled system. J Power Sources. 2009;191(2):338–43. https://doi.org/10.1016/j.jpowsour.2009.01.087.

Zhang P, Liu J, Qu Y, Zhang J, Zhong Y, Feng Y. Enhanced performance of microbial fuel cell with a bacteria/multi-walled carbon nanotube hybrid biofilm. J Power Sources. 2017;361:318–25. https://doi.org/10.1016/j.jpowsour.2017.06.069.

Liu W, Niu X, Chen W, An S, Sheng H. Effects of applied potential on phosphine formation in synthetic wastewater treatment by microbial electrolysis cell (MEC). Chemosphere. 2017;173:172–9. https://doi.org/10.1016/j.chemosphere.2017.01.006.

Gil-Carrera L, Escapa A, Moreno R, Morán A. Reduced energy consumption during low strength domestic wastewater treatment in a semi-pilot tubular microbial electrolysis cell. J Environ Manag. 2013b;122:1–7. https://doi.org/10.1016/j.jenvman.2013.03.001.

Wang K, Sheng Y, Cao H, Yan K, Zhang Y. Impact of applied current on sulfate-rich wastewater treatment and microbial biodiversity in the cathode chamber of microbial electrolysis cell (MEC) reactor. Chem Eng J. 2017b;307:150–8. https://doi.org/10.1016/j.cej.2016.07.106.

Rader GK, Logan BE. Multi-electrode continuous flow microbial electrolysis cell for biogas production from acetate. Int J Hydrog Energy. 2010;35(17):8848–54. https://doi.org/10.1016/j.ijhydene.2010.06.033.

Ullah Z, Zeshan S. Effect of substrate type and concentration on the performance of a double chamber microbial fuel cell. Water Sci Technol. 2019;81:1336–44. https://doi.org/10.2166/wst.2019.387.

Callegari A, Cecconet D, Molognoni D, Capodaglio AG. Sustainable processing of dairy wastewater: long-term pilot application of a bio-electrochemical system. J Clean Prod. 2018;189:563–9. https://doi.org/10.1016/j.jclepro.2018.04.129.

Elakkiya E, Matheswaran M. Comparison of anodic metabolisms in bioelectricity production during treatment of dairy wastewater in microbial fuel cell. Bioresour Technol. 2013;136:407–12. https://doi.org/10.1016/j.biortech.2013.02.113.

Ichihashi O, Hirooka K. Removal and recovery of phosphorus as struvite from swine wastewater using microbial fuel cell. Bioresour Technol. 2012;114:303–7. https://doi.org/10.1016/j.biortech.2012.02.124.

Molognoni D, Puig S, Balaguer MD, Capodaglio AG, Callegari A, Colprim J. Multiparametric control for enhanced biofilm selection in microbial fuel cells. J Chem Technol Biotechnol. 2016;91(6):1720–7. https://doi.org/10.1002/jctb.4760.

Tamilarasan K, Banu JR, Jayashree C, Yogalakshmi KN, Gokulakrishnan K. Effect of organic loading rate on electricity generating potential of upflow anaerobic microbial fuel cell treating surgical cotton industry wastewater. J Environ Chem Eng. 2017;5(1):1021–6. https://doi.org/10.1016/j.jece.2017.01.025.

Pannell TC, Goud RK, Schell DJ, Borole AP. Effect of fed-batch vs. continuous mode of operation on microbial fuel cell performance treating biorefinery wastewater. Biochem Eng J. 2016;116:85–94. https://doi.org/10.1016/j.bej.2016.04.029.

Zhang X, Zhu F, Chen L, Zhao Q, Tao G. Removal of ammonia nitrogen from wastewater using an aerobic cathode microbial fuel cell. Bioresour Technol. 2013;146:161–8. https://doi.org/10.1016/j.biortech.2013.07.024.

Yu C-P, Liang Z, Das A, Hu Z. Nitrogen removal from wastewater using membrane aerated microbial fuel cell techniques. Water Res. 2011;45(3):1157–64. https://doi.org/10.1016/j.watres.2010.11.002.

Kim T, An J, Jang JK, Chang IS. Coupling of anaerobic digester and microbial fuel cell for COD removal and ammonia recovery. Bioresour Technol. 2015;195:217–22. https://doi.org/10.1016/j.biortech.2015.06.009.

Lu N, Zhou S-G, Zhuang L, Zhang J-T, Ni J-R. Electricity generation from starch processing wastewater using microbial fuel cell technology. Biochem Eng J. 2009;43(3):246–51. https://doi.org/10.1016/j.bej.2008.10.005.

Mansoorian HJ, Mahvi AH, Jafari AJ, Amin MM, Rajabizadeh A, Khanjani N. Bioelectricity generation using two chamber microbial fuel cell treating wastewater from food processing. Enzym Microb Technol. 2013;52(6):352–7. https://doi.org/10.1016/j.enzmictec.2013.03.004.

Ye Y, Ngo HH, Guo W, Liu Y, Chang SW, Nguyen DD, et al. Feasibility study on a double chamber microbial fuel cell for nutrient recovery from municipal wastewater. Chem Eng J. 2019;358:236–42. https://doi.org/10.1016/j.cej.2018.09.215.

Tao Q, Luo J, Zhou J, Zhou S, Liu G, Zhang R. Effect of dissolved oxygen on nitrogen and phosphorus removal and electricity production in microbial fuel cell. Bioresour Technol. 2014;164:402–7. https://doi.org/10.1016/j.biortech.2014.05.002.

Santoro C, Babanova S, Artyushkova K, Atanassov P, Greenman J, Cristiani P, et al. The effects of wastewater types on power generation and phosphorus removal of microbial fuel cells (MFCs) with activated carbon (AC) cathodes. Int J Hydrog Energy. 2014;39(36):21796–802. https://doi.org/10.1016/j.ijhydene.2014.09.167.

Acknowledgements

The present study originated as a Ph.D. thesis at the Tehran University of Medical Sciences. The authors gratefully acknowledge the financial support given by the Center for Solid Waste Research (CSWR), Institute for Environmental Research (IER), Tehran University of Medical Sciences (Grant No. 97-03-46-40151).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interests regarding the publication of this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mansoorian, H.J., Mahvi, A., Nabizadeh, R. et al. Evaluating the performance of coupled MFC-MEC with graphite felt/MWCNTs polyscale electrode in landfill leachate treatment, and bioelectricity and biogas production. J Environ Health Sci Engineer 18, 1067–1082 (2020). https://doi.org/10.1007/s40201-020-00528-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40201-020-00528-2