Abstract

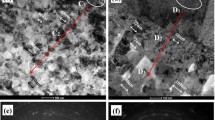

The effects of electropulsing-assisted ultrasonic surface rolling process on surface mechanical properties and microstructure evolution of commercial pure titanium were investigated. It was found that the surface mechanical properties were significantly enhanced compared to traditional ultrasonic surface rolling process (USRP), leading to smaller surface roughness and smoother morphology with fewer cracks and defects. Moreover, surface strengthened layer was remarkably enhanced with deeper severe plastic deformation layer and higher surface hardness. Remarkable enhancements of surface mechanical properties may be related to the gradient refined microstructure, the enhanced severe plastic deformation layer and the accelerated formation of sub-boundaries and twins induced by coupling effects of USRP and electropulsing. The primary intrinsic reasons for these improvements may be attributed to the thermal and athermal effects caused by electropulsing treatment, which would accelerate dislocation mobility and atom diffusion.

Similar content being viewed by others

References

H. Wang, G. Song, G. Tang, J. Alloys Compd. 681, 146 (2016)

C. Ye, A. Telang, A.S. Gill, S. Suslov, Y. Idell, Z. Kai, J.M.K. Wiezorek, Z. Zhou, D. Qian, S.R. Mannava, Mater. Sci. Eng. A 11–12, 613 (2014)

A. Amanov, I.S. Cho, D.E. Kim, Y.S. Pyun, Surf. Coat. Technol. 21, 207 (2012)

B. Wu, P. Wang, Y.S. Pyoun, J. Zhang, R.I. Murakami, Surf. Coat. Technol. 12, 213 (2012)

X.J. Cao, Y.S. Pyoun, R. Murakami, Appl. Surf. Sci. 21, 256 (2010)

G. Li, S.G. Qu, Y.X. Pan, X.Q. Li, Appl. Surf. Sci. 389, 324 (2016)

T. Liu, H. Wang, G. Tang, G. Song, Mater. Sci. Technol. 12, 33 (2017)

A. Amanov, J.H. Kim, Y.S. Pyun, T. Hirayama, M. Hino, Wear 332–333, 891 (2015)

A. Amanov, Y.S. Pyun, S. Sasaki, Tribol. Int. 4, 72 (2014)

A. Amanov, I.S. Cho, Y.S. Pyun, Appl. Surf. Sci. 388, 185 (2016)

H. Huang, Z. Wang, J. Lu, K. Lu, Acta Mater. 87, 150 (2015)

H. Wang, G. Song, G. Tang, Mater. Sci. Eng. A 662, 456 (2016)

X. Yang, J. Zhou, X. Ling, Mater. Des. 36, 477 (2012)

A.V. Panin, M.S. Kazachenok, A.I. Kozelskaya, R.R. Hairullin, E.A. Sinyakova, Mater. Sci. Eng. A 647, 43 (2015)

Y. Jiang, G. Tang, C. Shek, Y. Zhu, Z. Xu, Acta Mater. 16, 57 (2009)

J. Kuang, X. Du, X. Li, Y. Yang, A.A. Luo, G. Tang, Scr. Mater. 114, 151 (2016)

X. Li, G. Tang, J. Kuang, X. Li, J. Zhu, Mater. Sci. Eng. A 9, 612 (2014)

Y. Jiang, G. Tang, C. Shek, Y. Zhu, Appl. Phys. A 3, 97 (2009)

R. Zhu, G. Tang, S. Shi, M. Fu, J. Mater. Process. Technol. 1, 213 (2013)

R.S. Qin, A. Rahnama, W.J. Lu, X.F. Zhang, B. Elliottbowman, Mater. Sci. Technol. Lond. 9, 30 (2014)

Q. Xu, L. Guan, Y. Jiang, G. Tang, S. Wang, Mater. Lett. 9, 64 (2010)

V.E. Gromov, Y.F. Ivanov, V.V. Sizov, S.V. Vorob’Ev, S.V. Konovalov, J. Surf. Investig. X-Ray Synchrotron Neutron Tech. 1, 7 (2013)

R. Qin, S. Su, J. Mater. Res. 8, 17 (2002)

H. Wang, G. Song, G. Tang, Surf. Coat. Technol. 282, 149 (2015)

Y. Ye, H. Wang, G. Tang, G. Song, J. Mater. Eng. Perform., ed. by R. Asthana (2018 in press)

X. Liu, H. Zhang, K. Lu, Science 6156, 342 (2013)

R. Zhu, G. Tang, S. Shi, M. Fu, Mater. Des. 44, 606 (2013)

Y. Jiang, G. Tang, C. Shek, J. Xie, Z. Xu, Z. Zhang, J. Alloys Compd. 536, 94 (2012)

N.R. Tao, Z.B. Wang, W.P. Tong, M.L. Sui, J. Lu, K. Lu, Acta Mater. 18, 50 (2002)

M. Wen, G. Liu, J.F. Gu, W.M. Guan, J. Lu, Appl. Surf. Sci. 12, 255 (2009)

Q. Xu, G. Tang, Y. Jiang, Mater. Sci. Eng. A 13–14, 528 (2011)

Y.H. Zhu, S. To, W.B. Lee, X.M. Liu, Y.B. Jiang, G.Y. Tang, Mater. Sci. Eng. A 1, 501 (2009)

R.F. Zhu, G.Y. Tang, S.Q. Shi, M.W. Fu, V.E. Gromov, Appl. Phys. A 4, 111 (2013)

Z. Xu, G. Tang, S. Tian, F. Ding, H. Tian, J. Mater. Process. Technol. 1, 182 (2007)

G. Tang, J. Zhang, M. Zheng, J. Zhang, W. Fang, Q. Li, Mater. Sci. Eng. A 1–2, 281 (2000)

Y.G. Liu, M.Q. Li, Mater. Lett. 185, 488 (2016)

S. Nemat-Nasser, W.G. Guo, J.Y. Cheng, Acta Mater. 13, 47 (1999)

K.Y. Zhu, A. Vassel, F. Brisset, K. Lu, J. Lu, Acta Mater. 14, 52 (2004)

Acknowledgements

The authors acknowledge the financial support from the Shenzhen Development and Reform Commission Engineering Laboratory Project (Shenzhen development and Reform 2015-1033), the Shenzhen Science and Technology supporting Plan Project (GJHS20160331183313435) and the China Postdoctoral Science Foundation (No. 2017M620770).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Ye, YD., Li, XP., Sun, ZY. et al. Enhanced Surface Mechanical Properties and Microstructure Evolution of Commercial Pure Titanium Under Electropulsing-Assisted Ultrasonic Surface Rolling Process. Acta Metall. Sin. (Engl. Lett.) 31, 1272–1280 (2018). https://doi.org/10.1007/s40195-018-0738-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-018-0738-0