Abstract

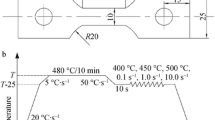

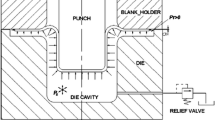

The present work demonstrates the effectiveness of combining the hydromechanical deep-drawing process with the Tailored Heat Treated Blank (THTB) technique. In the hydromechanical deep-drawing process, the fluid pressure is used for postponing the fracture occurrence in the blank, while the THTB technique allows to create a material property gradient through a suitable artificial aging treatment carried out prior to the forming process. Since the number of process variables is large, in the present work the authors propose an optimization loop for the determination of the parameters controlling the extension of the blank regions to be subjected to the aging treatment and the temperature levels to be set during the heat treatment. The proposed methodology couples a simple finite element model (Abaqus) with a multi-objective optimization platform (modeFRONTIER). A preliminary experimental campaign was carried out for determining the effect of the aging treatment on the mechanical (through tensile tests) and deformative (through formability tests) behavior of the AC170PX aluminum alloy. Optimization results prove the effectiveness of the adopted methodology and put in evidence that the adoption of properly aged blanks in the hydromechanical deep drawing allows to increase the limit drawing ratio and to simplify the process since it is conducted at room temperature.

Similar content being viewed by others

References

J. Hirsch, Trans. Nonferrous Met. Soc. China 24, 1995 (2014)

D. Li, A. Ghosh, Mater. Sci. Eng. A 352, 279 (2003)

L. Wang, Q. Qiao, Y. Liu, X. Song, J. Magn. Alloys 1, 312 (2013)

M.H. Parsa, P. Darbandi, J. Mater. Process. Technol. 198, 381 (2008)

G. Palumbo, A. Piccininni, Int. J. Adv. Manuf. Technol. 69, 731 (2013)

G. Palumbo, Mater. Des. 44, 365 (2013)

B. Meng, M. Wan, S. Yuan, X. Xu, J. Liu, Z. Huang, Int. J. Mech. Sci. 77, 217 (2013)

K.S. Swadesh, D. Ravi, Kumar. J. Mater. Process. Technol. 204, 169 (2008)

X. Liu, Y.C. Xu, S.J. Yuan, Trans. Nonferrous Met. Soc. China 21, 417 (2011)

Y.J. Luo, Y.Q. Zhang, D.N. He, Acta Metall. Sin. (Engl. Lett.) 16, 31 (2003)

L.H. Lang, D.C. Kang, S.H. Zhang, Z.R. Wang, S.J. Yuan, K.B. Nielsen, J. Dancket, Acta Metall. Sin. (Engl. Lett.) 13, 476 (2000)

W. Liu, Y. Xu, S. Yuan, Procedia Eng. 81, 914 (2014)

H.S. Halkaci, M. Turkoz, M. Dilmec, J. Mater. Process. Technol. 214, 1638 (2014)

G. Palumbo, L. Tricarico, J. Mater. Process. Technol. 184, 115 (2007)

G. Palumbo, D. Sorgente, L. Tricarico, S.H. Zhang, W.T. Zheng, J. Mater. Process. Technol. 191, 342 (2007)

D. Ghaffari Tari, M.J. Worswick, S. Winkler, J. Mater. Process. Technol. 213, 1337 (2013)

H. Nguyen, M. Merklein, Phys. Procedia 39, 318 (2012)

modeFRONTIER, v. 4.5.3. User’s Manual, Esteco

K. Deb, Evol. Comput. 7, 205 (1999)

M.D. Buhmann, D. Martin, Radial Basis Functions: Theory and Implementations (Cambridge University Press, UK, 2003), p. 99

L. Lang, J. Danckert, K.B.K.B. Nielsen, Int. J. Mach. Tool Manuf. 44, 495 (2004)

M. Ghosh, A. Miroux, R.J. Werkhoven, P.J. Bolt, L.A.I. Kestens, J. Mater. Process. Technol. 214, 756 (2014)

Acknowledgments

The authors wish to thank Region APULIA and the Ministry of Education, University and Research for financing equipment and facilities adopted for the present research activity (Projects Acronyms: TRASFORMA, code 028, and SMATI, Grant Number PON01_02584).

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Piccininni, A., Di Michele, G., Palumbo, G. et al. Improving the Hydromechanical Deep-Drawing Process Using Aluminum Tailored Heat Treated Blanks. Acta Metall. Sin. (Engl. Lett.) 28, 1482–1489 (2015). https://doi.org/10.1007/s40195-015-0347-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-015-0347-0