Abstract

The application of lightweight materials in automotive industry creates the demand to develop reliable and cost-effective solutions for joining hybrid material parts and assemblies. In this work, the microstructure and mechanical properties of the dissimilar joint between aluminum alloy 6061 (AA6061) and carbon fiber-reinforced polyphenylene sulfide (CF-PPS) processed by refill friction stir spot welding (RFSSW) were investigated. The results show that the joining between AA6061 and CF-PPS is attributed to the combined effect of mechanical interlocking and adhesive bonding. The rotation speed affects the porosity at the AA6061/CF-PPS interface which is the governing factor of the joints’ peak load during the lap-shear test. Varying rotation speed from 1000 to 1400 rpm, it illustrated that the lap-shear joints produced under 1200 rpm possess the highest peak load of 1460 N. Besides, it is observed that the joints produced with 1200 rpm have a thicker adhesive layer, which possess a strong mechanical interlocking effect. The failure mechanism for the joints includes cohesive and adhesive fracturing. Under the optimized rotation speed, the fracturing surface of the sample possess dimples with fiber pull-outed fibers, which infers a ductile failure.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

To meet the increasing requirements of environmentally friendly laws and the emphasis on safety, hybrid lightweight material structures are more and more widely designed in the automotive industry. The combination of aluminum alloy and carbon fiber-reinforced composites (CFRP) yields the merit of lightweight and high strength. For example, such structures are used in BRT (bus rapid transit) vehicles, which use carbon fiber composites to make articulated platform [1]. In the new generation of Audi A8L models, CFRP is used to make rear panels [2].

Due to the huge difference in physical and chemical properties, dissimilar joining between aluminum alloy and composite materials has become a challenge. Adhesive bonding, mechanical fastening, and ultrasonic spot welding are common methods used for the dissimilar joining between aluminum alloy and CFRP. However, large differences in the thermal expansion coefficient values of CFRP and aluminum alloy will induce thermal stress in the adhesive layer during the joining process, which deteriorates the mechanical properties of the joint. Zhang et al. [3] noticed that exerting high curing temperature will result in a significant increase of the residual stress in the adhesive layer, which lead to the joints’ failure under low external load. Mechanical fastening technology, such as self-piercing riveting, is largely limited by the mechanical properties. Lambiase et al. [4] pointed out that self-piercing riveting technology will lead to the mechanical damage to the fibers of CFRP; therefore, the joints are subject to significant performance degradation. Ultrasonic spot welding has been proved to be able to achieve high-strength bonding of aluminum alloy with CFRP. The research of Palardy et al. [5] showed that ultrasonic spot welding can be exerted to assemble both of the thermoplastic and thermosetting composites. An intelligent ultrasonic welding method is designed to monitor the changes of power and ultrasonic amplitude during the joining process. The optimum welding parameter is determined according to the feedback data of the interface reaction. Lionetto et al. [6] demonstrated the feasibility of ultrasonic joining of thermosetting composite with aluminum alloy by using PA6 thermoplastic composite as an interlayer. Although ultrasonic spot welding has advantages in joining aluminum alloy with CFRP, it still needs further development in automation to meet the needs of the modern automotive industry. Generally, novel joining technique is necessary to be developed for the high-quality joining between aluminum alloy and CFRP.

Refill friction stir spot welding (RFSSW) has shown its advantages in dissimilar joining between metal and composite materials. Scholars had carried out the research on the RFSSW of high-strength aluminum alloy and CFRP. Esteves et al. [7] had confirmed that RFSSW can obtain a high-strength joint of AA6181 and CF-PPS. Goushegir et al. [8] analyzed the effect of parameters on the peak load of aluminum alloy 2024/CF-PPS RFSSW joints. It was found that the weight of each parameter that affects the peak load follows this order: rotation speed (RS), plunge depth (PD), joining time (JT), and joining force (JF). Aiming to improve the mechanical properties of the joints and shorten the curing time, they added phenylene sulfide (PPS) interlayer between aluminum alloy 2024 and CFRP during RFSSW. The influence of thickness of interlayer on peak load of joints was analyzed. The results show that the peak load of joints that contains PPS interlayer is 20–55% higher than the ones that without interlayer [9, 10]. André et al. [11] studied the effect of surface pretreatment on the peak load of CFRP joints with interlayer film. The results show that increasing the surface roughness by sand blasting will strengthen the mechanical interlocking at the interface, which increase the peak load compared with untreated joints. Goushegir et al. [12] found that the peak load of the joints increased after electrochemical treatment of the aluminum alloy surface. They also analyzed the chemical bonding mechanism under conversion coating surface treatment by XPS test. XPS results showed evidence of Al-C and Zr-C chemical bonding form at the interface [13]. Ogawa et al. [14] found that the fatigue properties of aluminum alloy 5182/CFRP FSSW joints can also be improved by organic coating or anodic oxidation surface pretreatment. Tanaka et al. [15] comparatively analyzed the peak load of friction stir spot welding and hot-pressing joint of aluminum alloy 5052 with PA6, which showed that the peak load of RFSSW joint was relatively higher. A large number of studies have demonstrated the reliability of friction stir spot welding for the joining between aluminum alloys with CFRP. However, RFSSW has its unique advantages, and few relevant research has been carried out on process parameter optimization for welding of aluminum alloy 6XXX to CFRP, such as the effect of rotation speed on lap-shear peak load of the joint, as well as the formation mechanism of microdefects, like pores and microcracks.

In this paper, refill friction stir spot welded of aluminum alloy 6061 with carbon fiber-reinforced poly (phenylene sulfide, PPS) was performed. Effects of the rotation speed on the joining quality were investigated. The cross-section and the fracture surface of welded joint were analyzed, which is aimed at exploring the bonding mechanism, microstructure evolution, and the effect of rotation speed on the peak load.

2 Experimental procedure

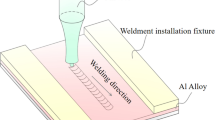

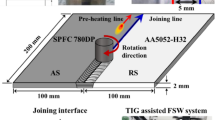

In this study, a 2-mm aluminum alloy sheet 6061-T4 (AA6061) and 2-mm polyphenylene sulfide (PPS) sheet reinforced with 40% chopped carbon fiber were used. The size of overlap joint is shown in Fig. 1. The chemical composition and mechanical properties of 6061-T4 are shown in Table 1. The mechanical and physical properties of CF-PPS are shown in Table 2. The AA6061 and PPS were brushed by sand paper before welding.

For the refill friction stir spot welding device, the main workpiece is the stirring tools, which consists of two independent moving units: the pin and sleeve in the middle of the clamping ring. In order to protect the composite materials, the plunge depth of the sleeve does not exceed 2 mm during the joining process. Single lap joints were produced using RFSSW equipment (see Fig. 2a, Aerospace engineering equipment (Suzhou) Co. Ltd) using specific fixtures (see Fig. 2b) with the parameters of united 0.8 mm (PD), 2 s (JT), and 8kN (JF) and different rotation speed which are 1000 rpm, 1200 rpm, and 1400 rpm respectively.

The whole joining process is divided into four steps as shown in Fig. 2c. In the first stage, clamping ring is fixed against the upper plate. The sleeve with pin begins to stir the AA6061 sheet. Secondly, the sleeve rotates and plunges into the AA6061 sheet when the pin retracts. In the third step, the pin rotates downward to backfills, while the sleeve rotates upward. Finally, the stirring tools leave off the workpiece.

The oxides and impurities on the surface of aluminum alloy and CF-PPS were removed before welding. Aluminum alloy is placed above the CF-PPS to set a lap joint during the joining process. The samples were clamped together with a special fixture (Fig. 2b) during the joining process. The processing temperature was monitored between the aluminum and CF-PPS by using a thermocouple temperature measurement system, as shown in Fig. 3. The thermocouple coil is placed in the center of the overlapping position between the aluminum alloy and CF-PPS. The time accuracy of the thermocouple coil which is used in this study is 0.5 s.

The mechanical properties of the joints were evaluated by the lap-shear test. The geometry of the specimens is illustrated in Fig. 1. MTS-810 tensile testing machine was used for the test. The tensile speed was 1.2 mm/min. To illustrate the stability of the results, five samples were examined for the welded joints at a certain rotation speed. The rotation speed of stir tool was set at the value of 1000 rpm, 1200 rpm, and 1400 rpm, respectively. The average value and the deviation of the shear strength were obtained.

In order to investigate the interface microstructure between the aluminum alloy and CF-PPS in the RFSSW process, the cross-section of joints was observed. The microstructural samples were treated by electrochemical etching (30 V, 120 s, room temperature) in Barker solution (20 ml water and fluoroboric acid) for polarization observation by a light optical microscopy (LOM, BX53M, OLYMPUS). The electron backscattered diffraction (EBSD) measurements were carried out using a JEM-7001FA field emission scanning electron microscope (SEM) with a TSL orientation imaging system after electropolishing in acid solution. The fracturing surface was analyzed with a scanning electron microscope (SEM) after gold sputtered.

3 Results and discussion

3.1 Temperature evolution at the interface

The results of interface temperature test are shown in Fig. 4a. The process temperature in all of the three conditions is higher than the melting point of PPS (276.9℃). The whole welding process is composed of rapid heating and cooling cycles. While the onset degradation temperature of PPS is 468℃, as shown in Fig. 4b, which was measured by thermogravimetric (TG) analysis. Therefore, within this temperature range, AA6061 transfer into a plastic state owing to the imposed heat input, while there is no degradation within PPS.

3.2 Microstructure of welded joint

The macro metallographic picture of the joint interface shows the protruding depth of aluminum alloy at the interface varied depending on rotation speed (Fig. 5). By measuring the width and depth of “metallic overlap,” the contact area of a AA6061/CF-PPS can be estimated by Eq. (1).

where \(S\) is the contact area, \(R\) is the length of half chord, and h is the depth from the bottom of the “metallic overlap” to the interface.

Results illustrated that the direct contact area is 21.83 mm2, 25.89 mm2, and 25.57 mm2, respectively, for samples in Fig. 5a–c. Therefore, the 1200 rpm sample has the largest contact area, which makes the joint present high peak load in the lap-shear test. Besides, the degree of the protruding region at the AA6061 side shows a positive relationship with the mechanical interlock between CF-PPS and aluminum, which contributes to the load-bearing capacity of the joint.

The cross-section of the joint is shown in Fig. 6a. Within the 6061 side, there is a “metallic overlap” that appears in the center of stirring zone (SZ) (shown in yellow rectangle) which plunging into the CF-PPS side. Besides, the mechanical interlocking is formed at the interface between 6061 and CF-PPS. This can be attributed to the expansion of the nugget in AA6061 side during the heating-up stage of RFSSW. Besides, a drastic rise in friction at the AA6061/CF-PPS causes PPS melting, which forms a cohesive layer (Fig. 6c). With the increase of joining force and stirring flow during the pin backfilling, deformation of soften aluminum alloy occurs along the vertical direction and penetrates into the softened surface of CF-PPS. Composite materials at the edge of pin are extruded into aluminum alloys (Fig. 6b), which forms a mechanical interlock.

A fluctuated macro-interface shape is of positive effects for the joint to bear transverse tensile shear load [16,17,18]. When the transverse shear stress extends to the zigzag region, offset and delay occur and subsequent distortion and deformation of the joint can be prevented. As mentioned by Mori et al. [19] and Çoban et al. [20], the larger the size of macro mechanical interlocking, the higher the peak load of the joint.

As shown in Fig. 7a and b, the thickness of the cohesive layer is 8 μm at the center, while this value is 3 μm at its periphery. The distribution pattern of cohesive layer thickness may be explained by the extrusion effect during the downward pushing stage of the stir tool.

In addition, cavities are observed to distribute on the edge of the cohesive layer (see Fig. 7a). The distribution of cavities is dense on the edge of the cohesive layer in the stir zone, while there are no cavities at the region far away from the stir zone. Based on the temperature test results (Fig. 4), the temperature at the AA6061/CF-PPS interface does not incur the decomposed PPS. Therefore, the cavities are not volatilized from the degradation of PPS. As shown in Fig. 7c and d, carbon fibers can be observed at one side of the cavities. Due to the different thermal expansion between carbon fiber and PPS polymer matrix, the debonding at the fiber and matrix interface occurs during the cooling process and results in peeling off of the fiber and the possible formation of these cavities [21].

Different sub-regions within the welded zone at AA6061 side are analyzed by EBSD (Fig. 8). The stir zone is mainly consisted of equiaxed crystals with uneven grain size distribution (Fig. 8a). The average grain size is 0.48 μm. The microstructure of TMAZ is highly affected by plastic deformation during RFSSW process (Fig. 8b). Comparing with other microzones, the grain size is extremely fine, averaging 0.44 μm. The grain orientation of HAZ (Fig. 8c) does not change significantly due to the low heat input from welding. The grains of heat-affected zone (Fig. 8c) are significantly coarsened compared with the base metal (Fig. 8d). The measured average grain size was 8.39 μm.

From the EBSD results of grain boundaries in right side of Fig. 8, it can be observed that the fraction of HAGB is in the following order: SZ ≈ TMAZ > HAZ > BM. The grain size distribution pattern implied that the heat source is mainly located into the stir zone in a RFSSW joint. This makes the nugget in AA6061 expanded during the RFSSW process, which lead to the protruding zone of AA6061 generated. Besides, this heat conduction pattern cause melting of PPS, subsequently the cohesive layer forms.

3.3 Effect of rotation speed on mechanical properties of joints

The mechanical properties of AA6061/CF-PPS joints under lap-shear test are shown in Fig. 9. It can be seen that the peak load of the joint at a rotation speed of 1200 rpm is higher (1460 N) than that at 1000 rpm (1080 N) and 1400 rpm (1270 N).

The interface profile of each samples processed under different rotation speed was shown in Fig. 10. It is obvious that the 1000 rpm sample’s interface presents the thinnest adhesive layer (~ 1 μm), which infers that the adhesive bonding is insufficient under this condition. Besides, there are large-scale cavities widely distributed at this interface. For the 1200 rpm sample, the joint has a uniform adhesive layer with the maximum thickness of 8 μm. The scale and distribution range of the cavities are smaller than that of the 1000 rpm sample (Fig. 10b). The 1400 rpm sample possess thinner adhesive layer than the 1200 rpm sample, while the cavities are more than that of its counterpart (Fig. 10c).

It is widely accepted that the rotation speed affects the heat generation during the RFSSW process [22]. At lower rotation speed, the heat generation is insufficient, which lead to a weak bonding between AA6061 and CF-PPS. This can be proofed by Fig. 10a which shows that there exists barely cohesive layer. At higher rotation speed, excess heat will be conducted from the AA6061 stir zone to the CF-PPS, which creates a thick layer of softened PPS. Meanwhile, this softened PPS layer would rotate with the sleeve in the AA6061 stir zone. Under this condition, the chopped carbon fibers are prone to separate from the softened PPS; therefore, the cavity forms. Besides, the cohesive layer is over-extruded by the stir tool under this condition. This explains the data observed in Fig. 8.

SEM images of the fractured samples were shown in Fig. 11. Fracture morphology shows that there are different sub-zones at the fracture of the composites. The fracture surface of the composites is mainly divided into plastic deformation zone (PDZ), adhesion zone (AZ), and transition zone (TZ) from the center to the outside [23], as shown in Fig. 11a and b.

The PDZ is considered to be the strongest bonding region of the joint [24], because the composite materials are in direct contact with the plastic deformed aluminum alloy. Both mechanical interlock and adhesive bonding are considered to be effective in this area. Fracture characteristics of this area show that joint failure and fiber breakage of PPS occur in PDZ area, which presents the feature of cohesive fracture, as shown in Fig. 11c and d. The formation of AZ is mainly due to the adhesive layer formed after cooling and solidification of the melted PPS flowing around the stirring center under the rotation of stir tools. The fracture surface in this area is relatively smooth (Fig. 11e), which indicates that the adhesive failure was the main fracture mode. Hence, bonding is weaker than that in PDZ area. Moreover, heat conduction also supports the bonding formation between TZ and the boundaries of the adhesive layer, as shown in Fig. 11f.

As shown in Fig. 12, further analysis of the fracture morphology of the joint under different RS reveals that there is almost no CF-PPS adhesive bonding at the fracturing surface of AA6061 for the 1000 rpm sample. For the 1200 rpm sample, there is a large amount of CF-PPS adhering at the fracturing surface. For the 1400 rpm sample, although the CF-PPS adhering is large, lots of cavities are observed at the fracturing surface. The results indicate that the more CF-PPS adheres, the stronger the bonding between the CF-PPS and AA6061 presents. Besides, it can be seen that the fracture surface on the CF-PPS side is very smooth for the 1000 rpm sample, while PDZ area is obvious at the 1200 rpm and 1400 rpm sample. And the area of PDZ at the 1200 rpm sample is more regular and bigger than the 1400 rpm sample. It can be concluded that the contribution of rotation on the heat generation is not negligible, according to the above analysis.

Figure 13 illustrates an overview of PDZ area under different RS. As can be observed from Fig. 13a, the PDZ of the 1000 rpm sample is very smooth. As a comparison, for the 1200 rpm sample, the PDZ region possesses appearance of dimples with pull-outed fibers (Fig. 13b), implying a ductile fracture characteristics. For the 1400 rpm sample PDZ region (Fig. 13c), there are more smoother regions in its center, which infers a mixed mode of brittle-ductile fracture.

4 Conclusions

In this paper, the microstructure, the mechanical properties, and fracture analysis of aluminum alloy 6061/CF-PPS joints obtained by the refilled friction stir spot welding were investigated. It has highlighted the effect of rotation speed on the mechanical property of single-lap RFSSW joints. The main conclusions are drawn as follows:

-

1)

During RFSSW process, heat generation at the AA6061/CF-PPS interface causes PPS to melt and form a cohesive layer. Besides, the expansion of the stir zone at AA6061 side forms a protruding region. The adhesive bonding and mechanical interlocking are considered the two main joining mechanisms.

-

2)

Cavities are observed within the CF-PPS side which is adjacent to the cohesive layer. SEM images proved that these cavities are caused by the separation of the fiber from the melted PPS.

-

3)

The joint welded at 1200 rpm presents an efficient mechanical interlock and thick cohesive layer with minimum cavities, which possess the highest peak load of 1460 N among all of the samples.

-

4)

The joint fracture morphology presents three kinds of features, which are plastically deformed zone, adhesion zone, and transition zone, respectively. Cohesive and adhesive failures are the two main modes of failure observed in the welded joints. The sample of the 1200 rpm joint failed mainly through ductile fracture, while the 1000 rpm joint shows brittle fracture, and the 1400 rpm joint shows a mixed brittle-ductile fracture.

References

Li HY, Dai Y, Lyu XF (2018) Application of carbon fiber reinforced composites on lightweight design of articulated platform[J]. Mater Sci Forum 921:85–90

Billur E, Teague R, Çetin B et al (2018) Economics of hot stamping[J]. Hot Stamping of Ultra High-Strength Steels 10:225–245

Zhang K, Yang Z, Li Y (2013) A method for predicting the curing residual stress for CFRP/Al adhesive single-lap joints[J]. Int J Adhes Adhes 46(5):7–13

Lambiase F, Ko DC et al (2016) Feasibility of mechanical clinching for joining aluminum AA6082-T6 and carbon fiber reinforced polymer sheets[J]. Mater Des 107(10):341–352

Palardy G, Villegas I (2015) Ultrasonic welding of thermoplastic composites with flat energy directors: influence of the thickness of the energy director on the welding process. Conference: International Conference on Composite Materials, Copenhagen, Denmark, 19-24th, July, 2015

Lionetto F, Morillas MN, Pappadà S (2018) Hybrid welding of carbon-fiber reinforced epoxy based composites. Compos A Appl Sci Manuf 104:32–40

Esteves JV, Goushegir SM, Santos JFD et al (2015) Friction spot joining of aluminum AA6181-T4 and carbon fiber-reinforced poly(phenylene sulfide): effects of process parameters on the microstructure and mechanical strength[J]. Mater Des 66(2):437–445

Goushegir SM, Dos Santos JF, Amancio-Filho ST (2015) Influence of process parameters on mechanical performance and bonding area of AA2024/carbon-fiber-reinforced poly(phenylene sulfide) friction spot single lap joints[J]. Mater Des 83:431–442

André NM, Goushegir SM, Dos Santos JF et al (2017) Influence of the interlayer film thickness on the mechanical performance of AA2024-T3/CF-PPS hybrid joints produced by friction spot joining[J]. Weld Int 32:1–10

Andre NM, Goushegir SM, Dos Santos JF et al (2016) Friction spot joining of aluminum alloy 2024–T3 and carbon-fiber-reinforced poly(phenylene sulfide) laminate with additional PPS film interlayer: microstructure, mechanical strength and failure mechanisms[J]. Composites 94:197–208

André NM, Goushegir SM, Scharnagl N et al (2017) Composite surface pre-treatments: improvement on adhesion mechanisms and mechanical performance of metal-composite friction spot joints with additional film interlayer[J]. J Adhes 94:723–742

Goushegir SM, Dos Santos JF, Amancio-Filho ST et al (2017) Influence of aluminum surface pre-treatments on the bonding mechanisms and mechanical performance of metal-composite single-lap joints[J]. Weld World 61:1099–1115

Goushegir SM, Scharnagl N, Santos JFD et al (2015) XPS analysis of the interface between AA2024-T3/CF-PPS friction spot joints[J]. Surf Interface Anal 48(8):706–711

Ogawa Y, Xiong Y, Akebono H et al (2018) Fatigue properties of friction stir welds of treated Al to carbon fibre-reinforced plastic[J]. Sci Technol Weld Joining 23:79–86

Tanaka K, Teramura T, Katayama T, Nishiguchi K (2016) Friction stir spot welding of CFRP and aluminum alloy with themoplastic adhesive. Proceedings of the 2nd International Conference on High Performance and Optimum Design of Structures and Material, Siena, Italy

Xu J, He X, Zeng K, et al. (2014) Effect of the technology characteristics of self-piercing riveting[J]. Trans China Weld Inst 35(7):91–95

Yang Y (2016) Simulation and experimental investigation on adhesive bonding process and mechanical behavior of steel/CFRP joint [D]. JiangSu University, ZhengJiang, pp 84

Schuberth A, Lindner T, Scharf I et al (2016) Effect of new adhesion promoter and mechanical interlocking on bonding strength in metal-polymer composites[J]. IOP Conf Ser: Mater Sci Eng 118:1–6

Mori KI, Abe Y et al (2018) A review on mechanical joining of aluminum and high strength steel sheets by plastic deformation[J]. Int J Lightweight Mater Manuf 1:1–11

Çoban O, Akman E, Bora MÖ et al (2019) Laser surface treatment of CFRP composites for a better adhesive bonding owing to the mechanical interlocking mechanism[J]. Polym Compos 40:3611–3622

Jung KW, Kawahito Y, Takahashi M et al (2013) Laser direct joining of carbon fiber reinforced plastic to zinc-coated steel[J]. Mater Des 47:179–188

Bagheri B, Abbasi M, Givi M et al (2019) Effects of vibration on microstructure and thermal properties of friction stir spot welded (FSSW) aluminum alloy (Al5083)[J]. Int J Precis Eng Manuf 20:1219–1227

Goushegir SM (2016) Friction spot joining (FSpJ) of aluminum-CFRP hybrid structures[J]. Weld World 60:1073–1093

Goushegir SM (2015) Friction spot joining of metal-composite hybrid structures[R]. HZG REPORT 2015-5, Helmholtz-Zentrum Geesthacht. Zentrum für Material- und Küstenforschung GmbH, Geesthacht, Germany, pp 180

Funding

This research work was financially supported by the Beijing Municipal Natural Science Foundation (Grant No. 3202002), China-CEEC Joint Education Project for Higher Education (Grant No. 2021113), 2021–2022 Sino-Poland Inter-governmental S&T Cooperation Projects (Grant No. 13), the National Natural Science Foundation of China (Grant Nos. 51905300 and 52074017), and the International Research Cooperation Seed Fund of Beijing University of Technology (Grant Nos. 2021A14 and 2021B27).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Li, H., Liu, Xs., Zhang, Y. et al. Influence of the rotation speed on the interface microstructure and joining quality of aluminum alloy 6061/CF-PPS joints produced by refill friction stir spot welding. Weld World 66, 923–933 (2022). https://doi.org/10.1007/s40194-022-01258-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-022-01258-9