Abstract

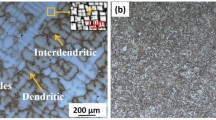

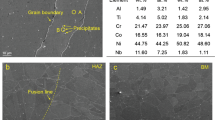

Simulation defects in IN 939 superalloy were repaired by gas tungsten arc welding (GTAW) using Nimonic C263 as filler metal. The microstructures and chemical compositions of fusion zone under the condition of as-welded and post-weld heat treatment (PWHT) were investigated by optical microscopy (OM), scanning electron microscopy (SEM), transmission electron microscopy (TEM), and electron probe X-ray microanalysis (EPMA). Moreover, the liquation cracking and strain age cracking in heat-affected zone (HAZ) were characterized as well. Post-weld hot isostatic pressing (HIP) was also applied to heal the HAZ cracks. The results show that elements segregation at as-welded joints could be significantly reduced by PWHT. HAZ cracks consisted of liquation cracking and strain age cracking. The liquation cracking was shorter than the strain age cracking. HIP is an effective way to heal the cracks in the repaired joints especially for liquation cracking. Though the strain age cracking can be healed by HIP, the healed trace concentrated with Al, Ti, B, and Zr elements can still be detected. Post-weld HIP is a necessary process to obtain crack-free joints.

Similar content being viewed by others

References

Gibbons TBS, Stickler R (1982) IN939: Metallurgy, properties and performance, in: R.B.E. al. (Ed.) high temperature alloys for gas turbines 1982, Brussels and Luxembourg, pp. 369–393

Wang DK, Wu HC, Shiue RK, Chen C (2008) Vacuum repair brazing of the Inconel 939 superalloy. Adv Mater Res 51:71–78

Göran Sjöberg DI, Gabel J, Caballero O, Brooks JW, Ferté J-P, Lugan A (2004) Evaluation of the IN 939 alloy for large aircraft engine structures. Superalloys 2004:441–450

Kim Dae -Young HJ-H, -Soo KK, Joong-Geun Y (2000) A study on fusion repair process for a precipitation hardened IN738 Ni-based superalloy. J Eng Gas Turbines Power 122:5

González MA, Martínez DI, Pérez A, Guajardo H, Garza A (2011) Microstructural response to heat affected zone cracking of prewelding heat-treated Inconel 939 superalloy. Mater Charact 62(12):1116–1123

DuPont JN, Lippold JC, Kiser SD (2009) Welding metallurgy and weldability of nickel base alloys. John Wiley & Sons, Inc., Hoboken, New Jersey

Sidhu RK, Ojo OA, Chaturvedi MC (2007) Microstructural analysis of laser-beam-welded directionally solidified INCONEL 738. Metall Mater Trans A 38(4):858–870

Henderson MB, Arrell D, Larsson R, Heobel M, Marchant G (2004) Nickel based superalloy welding practices for industrial gas turbine applications. Sci Technol Weld Join 9(1):13–21

Thamburaj R, Wallace w, Goldak JA (1983) Post-weld heat-treatment cracking in superalloys. Int Metals Rev 28(1):1–22

Kayacan R, Varol R, Kimilli O (2004) The effects of pre- and post-weld heat treatment variables on the strain-age cracking in welded Rene 41 components. Mater Res Bull 39(14–15):2171–2186

Ola OT, Ojo OA, Chaturvedi MC (2014) Role of filler alloy composition on laser arc hybrid weldability of nickel-base IN738 superalloy. Mater Sci Technol 30(12):1461–1469

Chang SH, Huang KT, Liu CM (2013) Effect of HIP temperature on microstructure and tensile properties of 713LC cast superalloy. Int J Cast Met Res 24(2):113–118

Yang J, Li F, Wang Z, Zeng X (2015) Cracking behavior and control of Rene 104 superalloy produced by direct laser fabrication. J Mater Process Technol 225:229–239

Ruttert B, Ramsperger M, Mujica Roncery L, Lopez-Galilea I, Körner C, Theisen W (2016) Impact of hot isostatic pressing on microstructures of CMSX-4 Ni-base superalloy fabricated by selective electron beam melting. Mater Des 110:720–727

Kim JK, Park HJ, Shim DN (2016) Effects of PWHT on microstructure and mechanical properties of weld metals of Ni-based Superalloy 617 and 263 for hyper-supercritical power plants. Acta Metall Sin (English Letters) 29(12):1107–1118

Zhao JC, Ravikumar V, Beltran AM (2001) Phase precipitation and phase stability in nimonic 263. Metall Mater Trans A 32(6):1271–1282

Ojo OA, Richards NL, Chaturvedi MC (2006) Study of the fusion zone and heat-affected zone microstructures in tungsten inert gas-welded INCONEL 738LC superalloy. Metall Mater Trans A 37(2):421–433

Reed RC, The superalloys fundamentals and applications, Cambridge University Press 2006

Sidhu RK, Richards NL, Chaturvedi MC (2005) Effect of aluminium concentration in filler alloys on HAZ cracking in TIG welded cast Inconel 738LC superalloy. Mater Sci Technol 21(10):1119–1131

Guédou JY, Crozet C, Devaux A, Béchet D, Choné J (2014) Microstructure stability: optimisation of 263 Ni-based superalloy, MATEC Web of Conferences, EDP Sciences, p. 17006

Ojo OA, Richards NL (2012) Heat-affected zone cracking in welded nickel superalloys, Welding and joining of aerospace materials, Woodhead Publishing Limited, pp. 142–177

Lim LC, Yi JZ, Liu N (2013) Mechanism of post-weld heat treatment cracking in Rene 80 nickel based superalloy. Mater Sci Technol 18(4):407–412

Sidhu RK, Richards NL, Chaturvedi MC (2007) Post-weld heat treatment cracking in autogenous GTA welded cast Inconel 738LC superalloy. Mater Sci Technol 23(2):203–213

Carter LN, Martin C, Withers PJ, Attallah MM (2014) The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy. J Alloys Compd 615:338–347

Ojo OA, Richards NL, Chaturvedi MC (2004) Liquation of various phases in HAZ during welding of cast Inconel* 738LC. Mater Sci Technol 20(8):1027–1034

Ojo OA, Richards NL, Chaturvedi MC (2004) Contribution of constitutional liquation of gamma prime precipitate to weld HAZ cracking of cast Inconel 738 superalloy. Scr Mater 50(5):641–646

Ojo OA, Chaturvedi MC (2005) On the role of liquated γ′ precipitates in weld heat affected zone microfissuring of a nickel-based superalloy. Mater Sci Eng A 403(1–2):77–86

Zhao X, Lin X, Chen J, Xue L, Huang W (2009) The effect of hot isostatic pressing on crack healing, microstructure, mechanical properties of Rene88DT superalloy prepared by laser solid forming. Mater Sci Eng A 504(1–2):129–134

Stevens RA, Flewitt PEJ (1980) Removal of casting porosity in superalloy IN738 using hydrostatic pressure sintering. Metal Sci 14(3):81–88

Acknowledgments

The authors thank Zhanhui Du for the X-ray non-destructive testing and hot isostatic pressing. The authors are also grateful to Professor Shunnan Zhang and Xianchao Hao for the valuable discussions.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission II - Arc Welding and Filler Metals

Rights and permissions

About this article

Cite this article

Xie, J., Ma, Y., Xing, W. et al. Heat-affected zone crack healing in IN939 repaired joints using hot isostatic pressing. Weld World 62, 471–479 (2018). https://doi.org/10.1007/s40194-018-0579-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-0579-5