Abstract

Zirconium oxide thin films were grown successfully by thermal annealing of zirconium thin films deposited on quartz and silicon substrates by direct current magnetron sputtering technique. The structural and optical properties in relation to thermal annealing times were investigated. The X-ray diffraction patterns revealed that structure of films changes from amorphous to crystalline by increase of annealing times in range 60–240 min. The composition of films was determined by Rutherford back scattering spectroscopy. Atomic force microscopy results exhibited that surface morphology and roughness of films depend on the annealing time. The refractive index of the films was calculated using Swanepoel’s method. The optical band gap energy of annealed films decreased from 5.50 to 5.34 eV with increasing thermal annealing time.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Zirconia thin films (ZrO2) are one of the transition-metal oxides with outstanding physical, optical and chemical properties [1–14] including high hardness, low electrical conductivity, high melting point, good thermodynamic stability in contact with silicon, transparency in the visible and near-infrared region, high refractive index, high dielectric constant and large optical band gap [2, 10, 11]. Through having such properties ZrO2 thin films have attracted a lot of attention and applied in diverse field such as, optical filters [5], memory device [6], it is also used as a material to store capacitors [7] in dynamic random access memories. Such wide range of important applications has motivated researchers into growing ZrO2 thin films on different substrates by a variety of techniques. Balakrishnan et al. [8] fabricated ZrO2 thin films on silicon substrate at different oxygen partial pressure by pulsed laser deposition. Shen et al. [10] were employed electron beam evaporation technique to prepare ZrO2 thin films. Rebib et al. [11] have studied the structural and optical properties of zirconia thin films deposited by sputtering a ZrO2 target under an argon–oxygen gas mixture and different total gas pressures. The sol–gel dip coating method was used for the preparation of highly transparent nanocrystalline zirconia thin films by Joy et al. [12]. RF sputtering deposition was employed by Yildiz et al. [13] for preparation of nano-crystalline zirconia thin films with high transparency. In this investigation nanocrystalline zirconia thin films were prepared by thermal annealing of zirconium (Zr) thin films grown on silicon and quartz substrates by DC magnetron sputtering. As the structural and optical properties of thin films can be affected by some factors such as the growth method, the deposition conditions and thermal annealing, this investigation focuses on the influence of annealing time on structural and optical characteristics of ZrO2 thin films.

Experimental details

In the present experiment, firstly, the zirconium (Zr) thin films were grown on silicon and quartz substrates by DC magnetron sputtering from a zirconium target (purity 99.999 %). The deposition chamber was initially evacuated to achieve a base pressure of 5.3 × 10−5 torr by means of a rotary and diffusion pumps. After introducing argon gas as working gas, the total pressure was kept constant at 5.3 × 10−2 torr. Silicon and quartz substrates were first cleaned, using ultrasonic bath for 15 min in acetone and ethanol. Then deposition process was performed for 2 min for all films. After that, the prepared films were annealed in an electrical furnace at 450 °C for 60–240 min under the oxygen atmosphere. The effect of annealing time on the structural, morphological and optical properties of ZrO2 thin films were studied by different analyzing method. The crystal structure of the films were characterized by X-ray diffraction (XRD, Philips, pw 1800) using Cu Kα radiation (λ = 0.1506 nm) at 40 kV and 30 mA in the 2θ scan range from 10 to 60. The morphology of prepared thin films was studied by atomic force microscopic (AFM, park Scientific Instrument, Auto probe cp USA) and the transmittance spectra of the annealed films were recorded using a spectrophotometer (CARY 500 Scan). The composition of films were determined by Rutherford back scattering spectroscopy (RBS) [15] using a 2 MeV proton beam of a 3 MV single-ended Van de Graaff machine. The scattered particles were measured by a surface barrier detector at 165°. Numerical analysis of the collected data was performed via the SIMNRA simulation package.

Results and discussion

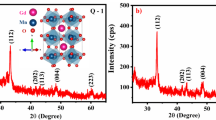

The XRD patterns of the as-deposited Zr thin film and the annealed films on silicon substrate at different annealing times are shown in Fig. 1.

We can observe that the as-deposited films show a peak due to the Zr in (100) crystallography direction. After annealing the Zr films for 60 min the film is amorphous. The tetragonal ZrO2 phases can be observed in annealing times in range120-240 min due to the oxidation of zirconium films after thermal annealing in oxygen atmosphere. Also, nanocrystalline tetragonal ZrO2 thin films at different annealing temperatures was obtained by Joy et al. [12] Up to annealing time of 180 min the peak along with (111) plane of tetragonal ZrO2 phase can be observed and the crystallography direction, changes to (002) direction at annealing time of 240 min. The surface morphology of thin films is one of the important factors that can influence the thin films applications. Therefore the surface morphology and the microstructural properties of deposited thin films were studied by AFM analyses. The 2 × 2 μm2 AFM images of as-deposited Zr thin films and the ZrO2 films annealed at various annealing times are shown in Fig. 2. The 3D micrographs show the presence of hills on the top of the surface. The sharpness and number of the hills increased after annealing time of 60 min. Also we can observe the growth of columnar structure on the surface of the films due to the grain nucleation and growth during the crystallization process [16]. The root mean square roughness (R rms) and average roughness (R a) of prepared films are shown in Fig. 3. As can be seen from Fig. 3, the R rms and R a follow the similar evolution as previous microscopic observation. The R rms value of 1.42 nm for as-deposited Zr thin films increased to 2.28 nm by increasing of annealing times up to 120 min due to phase change and grains growth then for higher annealing times the R rms decreased. The AFM results exhibited that the surface morphology and roughness of ZrO2 thin films depend on the annealing time.

The composition of films was determined by RBS analysis. The typical experimental RBS spectrum of zirconium oxide film on silicon substrate at annealing time of 240 min along with simulated curve calculated by SIMNRA cod is shown in Fig. 4. The signals of the elements of the film such as Zr, O as well as Si substrate are clearly observe in the spectrum. The ion scattering from Zr atoms occurs at higher backscattering energy. This is because the backscattered energy of the incident ions is depending on the atomic mass of the elements from which the ions backscatters. The atomic masses of the elements are 15.99, 28.09 and 91.22 for O, Si and Zr, respectively, and the Zr is the heaviest among the elements either in the film or in the substrate.

The RBS spectra of the zirconium oxide films at various annealing times are displayed in Fig. 5. As can be seen from the Fig. 5 the back edge of the Zr peak in RBS spectra shifted to lower energies and the width of peak which is a measure of thickness of oxide layer is increased with annealing time. Similar behavior was obtained for ZrO2 thin films prepared at different annealing temperatures. [17].

The optical behavior of thin films is generally characterized by their optical constants, such as refractive index (n) and extinction coefficient (k). In order to determine the optical constant of annealed zirconium oxide films, we used the transmittance spectra and Swanepoel’s method [18]. The optical transmittance spectra of the ZrO2 thin films on quartz substrates as a function of wavelength in range 200–900 nm are shown in Fig. 6.

As can be seen in the visible wavelength region the films are transparent and the transparency of the ZrO2 films enhances and reaches to 90 % by increasing the annealing time from 60 to 240 min. The interference fringes in the transmittance spectra of the films indicated that the films have a uniform thickness and the ZrO2 thin films are homogeneous. The derived values of the films refractive indices are shown in Fig. 7. We can observe that the refractive index decreases with increasing wavelength of incident photon and at higher wavelength the refractive index tends to be constant. Similar behavior was obtained for CuO thin films prepared at different annealing temperatures. [19].

Also, the refractive index of the annealed ZrO2 thin films decreases by enhancing of annealing time. In this study the values of the refractive index at wavelength of 600 nm decreased from 2.18 to 2.04 with increase of annealing time from 60 to 240 min. A similar behavior with annealing time is also reported for TeO2 thin films by Siciliano et al. [20]. A decrease of refractive indices with oxygen partial pressure is also obtained and reported by Shen et al. [10] for ZrO2 thin films prepared at different oxygen partial pressures. The refractive index values of the zirconium oxide thin films calculated in the present study are in good agreement with the value reported by [10–12].

Determination of band gap energy (E g) is often necessary to develop the electronic band structure of thin film materials. The band gap energy (E g) of the films is calculated from the dependence of absorption coefficient on the incident photon energy (hν) by the relation [21] as:

where B is a constant that depends on the transition probability and p is an exponent that depends on the type of optical transition between the valence and conduction band direct or indirect. For the crystalline semiconductors, p is theoretically equal to 1/2, 3/2, 2 or 3 for the direct allowed, direct forbidden, indirect allowed and indirect forbidden transitions, respectively. Figure 8 presents the variation of (αhν)2 versus the photon energy (hν) for ZrO2 thin films prepared at different annealing times. The plots indicate a direct optical band gap for annealed ZrO2 films. The optical band gap energy is evaluated by extrapolating the linear part of the curve (αhν)2 where (α = 0). It is found that from the figure, the deduced band gap energy of ZrO2 films are in range 5.34–5.50 eV and decreases with increasing the annealing time. The decrease in energy band gap is in consistent with a change in the structure of ZrO2 thin films from amorphous to crystalline phase. Also, the crystallinity and the grain size of the films increases with the annealing time resulting in a decrease of energy band gap. The results of the band gap energy are in agreement with the XRD results. The band gap value of the ZrO2 obtained in the present work closely matches with earlier reports [11, 22, 23].

Conclusion

ZrO2 thin films were prepared by thermal annealing of as-deposited Zr films on silicon and quartz substrate using dc magnetron sputtering technique. The thermal annealing times were varied between 60 and 240 min. It was found that the annealed ZrO2 films on silicon substrate were crystallized in a tetragonal structure at annealing time in range 120–240 min. XRD and RBS studies show that the ZrO2 films has been formed in all annealed films. The AFM studies show that the grain size of the films is very small and the films surface is very smooth. Optical transmittance spectra of ZrO2 films on quartz substrates confirmed the films are transparent and homogeneous. The refractive index at wavelength of 600 nm varied between 2.04 and 2.18. A reduction in optical band gap energy is observed from 5.50 to 5.34 eV with an increase of the annealing time from 60 to 240 min may be due to a change in the structure of ZrO2 thin films from amorphous to crystalline phase that observed in XRD results.

References

Li, W., Liu, X., Huang, A., Chu, P.K.: Structure and properties of zirconia (ZrO2) films fabricated by plasma-assisted cathodic arc deposition. J. Phys. D. Appl. Phys. 40, 2293 (2007)

Ma, C.Y., Laspostolle, F., Briois, P., Zhang, Q.Y.: Effect of O2 gas partial pressure on structures and dielectric characteristics of rf sputtered ZrO2 thin films. Appl. Surf. Sci. 253, 8718 (2007)

Wong, Y.H., Cheong, K.Y.: Band alignment and enhanced breakdown field of simultaneously oxidized and nitrided Zr film on Si. Nanoscal. Res. Lett. 6, 489 (2011)

Khojier, K., Savaloni, H., Jafari, F.: Structural, electrical, and decorative properties of sputtered zirconium thin films during post-annealing process. J. Theor. Appl. Phys. 7, 55 (2013)

Andrieux, M., Ribot, P., Gasqueres, C., Servet, B., Garry, G.: Effect of the oxygen partial pressure on the toughness of tetragonal zirconia thin films for optical applications. Appl. Surf. Sci. 263, 284 (2012)

Lin, C.Y., Wu, C.Yi., Wu, C.Yu., Lin, C.C., Tseng. T.Y.: Memory effect of RF sputtered ZrO2 thin films. Thin Solid Films. 516 444 (2007)

Brunet, M., Mafhoz Kotb, H., Bouscayrol, L., Scheid, E., Andrieux, M., Legros, C., Schamm-Chardon. S.: Nanocrystallized tetragonal metastable ZrO2 thin films deposited by metal-organic chemical vapor deposition for 3D capacitors. Thin Solid Films. 519, 5638 (2011)

Basahel, S.N., Ali, T.T., Mokhtar, M., Narasimharao, K.: Influence of crystal structure of nanosized ZrO2 on photocatalytic degradation of methyl orange. Nanoscal. Res. Lett. 10, 73 (2015)

Balakrishnan, G., Sairam, T.N., Kuppusami, P., Thiumurugesan, R., Mohandas, E., Ganesan, V., Sastikumar, D.: Influence of oxygen partial pressure on the properties of pulsed laser deposited nanocrystalline zirconia thin films. Appl. Surf. Sci. 257, 8506 (2011)

Shen, Y., Shao, S., Yu, H., Fan, Z., He, H., Shao, J.: Influences of oxygen partial pressure on structure and related properties of ZrO2 thin films prepared by electron beam evaporation deposition. Appl. Surf. Sci. 254, 552 (2007)

Rebib, F., Laidani, N., Gottardi, G., Micheli, V., Bartali, R., Jestin, Y., Tomasella, E., Ferrari, M., Thomas, L.: Investigation of structural and optical properties of sputtered zirconia thin films. Eur. Phys. J. Appl. Phys. 43, 363 (2008)

Joy, K., Berlin, I.J., Nair, P.B., Lakshmi, J.S., Daniel, G.P., Thomas, P.V.: Effects of annealing temperature on the structural and photoluminescence properties of nanocrystalline ZrO2 thin films prepared by sol–gel route. J. Phys. Chem. Solids 72, 673 (2011)

Yildiz, K., Akgul, U., Coskun, B., Atici, Y.: Rf-sputtering deposition of nano-crystalline zirconia thin films with high transparency. Mater. Lett. 94, 161 (2013)

Panda, D., Tseng, T.-Y.: Growth, dielectric properties, and memory device applications of ZrO2 thin films. Thin Solid Films 531, 1 (2013)

Chu, W.K., Mayer, J.W., Nicolet, M.A.: Backscattering spectrometry. Academic Press, New York (1978)

Hojabri, A., Hajakbari, F., Emami, A.: Structural and optical properties of nanocrystalline α-MoO3 thin films prepared at different annealing temperatures. Meibodi. J. Theor. Appl. Phys. 9, 67 (2015)

Larijani, M.M., Hasani, E., Fathollahhi, V., Safa, S.: Thermally oxidized zirconium nanostructured films grown on Si substrates. Crys. Res. Technol. 47, 443 (2012)

Dorranian, D., Dejam, L., Mosayebian, G.: Optical characterization of Cu3N thin film with Swanepoel method. J. Theor. Appl. Phys. 6, 13 (2012)

Hojabri, A., Hajakbari, F., Soltanpoor, N., Hedayati, M.S.: Annealing temperature effect on the properties of untreated and treated copper films with oxygen plasma. J. Theor. Appl. Phys. 8, 132 (2014)

Siciliano, T., Di Giulio, M., Teprore, M., Filippo, E., Micocci, G., Tepore, A.: Effect of thermal annealing time on optical and structural properties of TeO2 thin films. Vaccum 84, 935 (2010)

Hajakbari, F., Larijani, M.M., Ghoranneviss, M., Aslaninejad, M., Hojabri, A.: Optical properties of amorphous AlN thin films on glass and silicon substrates grown by single ion beam sputtering. Jpn. J. Appl. Phys. 49, 095802 (2010)

Zhu, L.Q., Fang, Q., He, G., Liu, M., Zhang, L.D.: Microstructure and optical properties of ultra-thin zirconia films prepared by nitrogen-assisted reactive magnetron sputtering. Nanotechnology 16, 2865 (2005)

Yusoh, R., Horprathum, M., Eiamchai, P., Chindaudom, P., Aiempanakit, K.: Determination of optical and physical properties of ZrO2 films by spectroscopic ellipsometry. Procedia Eng. 32, 745 (2012)

Acknowledgments

This work was supported by Islamic Azad University, Karaj Branch, Karaj, Iran.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Hojabri, A. Structural and optical characterization of ZrO2 thin films grown on silicon and quartz substrates. J Theor Appl Phys 10, 219–224 (2016). https://doi.org/10.1007/s40094-016-0218-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40094-016-0218-8