Abstract

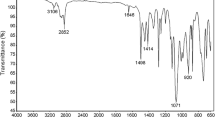

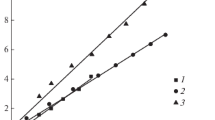

A series of well-defined acrylamide/methyl methacrylate random copolymers (PAM-ran-PMMA) were synthesized in this work. The polymerization reactions were carried out in N,N-dimethylformamide (DMF) at 25 °C using Cu(0)/hexamethylenetetramine (HMTA) and CCl4/hydrazine as the catalyst system and the initiator system, respectively. The number average molecular weights (Mn) and the distribution of molecular weight (Mw/Mn) of copolymers were analyzed by gel permeation chromatography (GPC). Experimental results revealed that the copolymerization reaction follows a pseudo first-order kinetic model. Mn of PAM-ran-PMMA increased linearly with the conversion of monomers while a narrow molecular weight distribution was obtained. By means of Fineman–Ross equation, the reactivity ratios of r1 (AM) and r2 (MMA) were calculated to be 0.81 and 3.21, respectively. The results implied that the amount of AM unites in PAM-ran-PMMA copolymers increased with the increase of the molar ratios of AM/MMA. The structure and the thermal stability of the resultant PAM-ran-PMMA copolymer were characterized by Fourier transform infrared spectroscopy (FTIR), nuclear magnetic resonance spectrometry (1H NMR) and thermogravimetric analysis (TGA). TGA revealed that copolymers with a greater content of AM unit exhibited a higher thermal stability. The obtained PAM-ran-PMMA copolymer was used as a macroinitiator to perform Cu(0)-catalyzed chain extension experiment, which led to the increase of Mn and demonstrated the living character of the polymerization. This current approach provided a controlled route for the synthesis of well-defined PAM-ran-PMMA.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

NothlingMD CaoH, McKenzie TG, Hocking DM, Strugnell RA, Qiao GG (2021) Bacterial redox potential powers controlled radical polymerization. J Am Chem Soc 143:286–293

Azuma Y, Terashima T, Sawamoto M (2017) Self-folding polymer iron catalysts for living radical polymerization. ACS Macro Lett 6:830–835

OliverS ZL, Gormley AJ, Chapman R, Boyer C (2019) Living in the fast lane-high throughput controlled/living radical polymerization. Macromolecules 52:3–23

Dervaux B, Camp WV, Du Prez FE (2008) Amphiphilic block and “block and like” copolymers based on poly(isobornyl acrylate) and poly(acrylic acid) via ATRP. Polym Prep 49:6–7

Lyra EP, Petzhold CL, Lona LMF (2019) Tin(II) 2-ethylhexanoate and ascorbic acid as reducing agents in solution ARGET ATRP: a kinetic study approach by mathematical modeling and simulation. Chem Eng J 364:186–200

Zhou Y, Wang K, Hu D (2021) An aqueous approach to functionalize waterlogged archaeological wood followed by improved surface-initiated ARGET ATRP for maintaining dimensional stability. Cellulose 28:2433–2443

Min K, Gao H, Matyjaszewski K (2007) Use of ascorbic acid as reducing agent for synthesis of well-defined polymers by ARGET ATRP. Macromolecules 40:1789–1791

Karkare P, Kumar S, Murthy CN (2019) ARGET-ATRP using β-CD as reducing agent for the synthesis of PMMA-b-PS-b-PMMA triblock copolymers. J Appl Polym Sci 136:47117

Paterson SM, Brown DH, Chirila TV, Keen I, Whittaker AK, Baker MV (2010) The synthesis of water-soluble PHEMA via ARGET ATRP in protic media. J Polym Sci 48:4084–4092

Kwak Y, Magenau AJD, Matyjaszewski K (2011) ARGET ATRP of methyl acrylate with inexpensive ligands and ppm concentrations of catalyst. Macromolecules 44:811–819

Leophairatana P, Samanta S, De Silva CC, Koberstein JT (2017) Preventing alkyne-alkyne (i.e., Glaser) coupling associated with the ATRP synthesis of alkyne-functional polymers/macromonomers and for alkynes under click (i.e., CuAAC) reaction conditions. J Am Chem Soc 139:3756–3766

Li Z, Shi S, Fei Y, Cao D, Zhang K, Wang B, Zhe Ma, Li P, Li Y (2020) Supertough and transparent poly(lactic acid) nanostructure blends with minimal stiffness loss. ACSOmega 5:13148–13157

Wu X, Chen X, Shi L, Fan Z (2016) Preparation, structure and properties of PLLA-TMC/PDLA-TMC stereocomplexes. Chem J Chin Univ 37:2101–2107

Zhong Z, Wang X, Zhao S, Peng F, Wang J, Ying L, Yang W, Peng J, Cao Y (2017) Effects of a random copolymer’s component distribution on its opto-electronic properties. J Mater Chem C 5:6163–6168

Tévenot Q, Kawahara S (2021) ATRP-ARGET of a styrene monomer onto modified natural rubber latex as an initiator. Langmuir 37:6151–6157

Cao J, Song T, Zhu Y, Wang S, Wang X, Lv F, Jiang L, Sun M (2018) Application of amino-functionalized nanosilica in improving the thermal stability of acrylamide-based polymer for enhanced oil recovery. Energy Fuel 32:246–254

Teh CY, Budiman PM, Shak KPY, Wu TY (2016) Recent advancement of coagulation-flocculation and its application in wastewater treatment. Ind Eng Chem Res 55:4363–4389

Alsubaie FM, Alothman OY, Alshammari BA, Fouad H (2021) Facile synthesis of hydrophilic homo-polyacrylamides via Cu(0)-mediated reversible deactivation radical polymerization. Polymers 13:1947–1958

Fan Y, Cao H, van Mastrigt F, Pei Y, Picchioni F (2018) Copper-mediated homogeneous living radical polymerization of acrylamide with waxy potato starch-based macroinitiator. Carbohyd polym 192:61–68

Abdurrahmanoglu S, Can V, Okay O (2009) Design of high-toughness polyacrylamide hydrogels by hydrophobic modification. Polymer 50:5449–5455

Wu S, Shanks RA (2004) Synthesis and characterization of hydrophobic modified polyacrylamide. Polym Int 53:1821–1830

Zhou Y, Zheng H, Huang Y, Zheng X, Liu Z, An Y, Liu Y (2019) Hydrophobic modification of cationic microblocked polyacrylamide and its enhanced flocculation performance for oily wastewater treatment. J Mater Sci 54:10024–10040

Zhuang L, Zhi X, Du B, Yuan S (2020) Preparation of elastic and antibacterial chitosan-citric membranes with high oxygen barrier ability by in situ cross-linking. ACS Omega 5:1086–1097

Hsiao S-H, Wang HM (2016) Facile fabrication of redox-active and electrochromic poly(amide-amine) films through electrochemical oxidative coupling of arylamino groups. Polym Chem 54:2476–2485

Zhang H, Carrillo-Navarrete F, López-Mesas M, Palet C (2020) Use of chemically treated human hair wastes for the removal of heavy metal ions. Water 12:1263–1273

Oualid HA, Abdellaoui Y, Laabd M, Ouardi ME, Brahmi Y, Iazza M, Oualid JA (2020) Eco-efficient green seaweed codium decorticatum biosorbent for textile dyes: characterization, mechanism, recyclability, and RSM optimization. ASC Omega 5:22192–22207

Song YY, Dong B, Wang SW, Wang ZR, Zhang M, Tian P, Wang GC, Zhao Z (2020) Selective oxidation of propylene on Cu2O(111) and Cu2O(110) surfaces: a systematically DFT study. ACS Omega 5:6260–6269

Andal V, Buvaneswari G (2017) Effect of reducing agents in the conversion of Cu2O nanocolloid to Cu nanocolloid. Eng Sci Technol 20:340–344

Fineman M, Ross SD (1950) Linear method for determining monomer reactivity ratios in copolymerization. J Polym Sci 5:259–262

Saini G, Leoni A, Franco S (1971) Solvent effects in radical copolymerization:1. Acrylamide Macromol Chem 144:235–244

Ryu JH, Han NK, Lee JS, Jeong YG (2019) Microstructure, thermal and mechanical properties of composite films based on carboxymethylated nanocellulose and polyacrylamide. Carbohyd Polym 211:84–90

Acknowledgements

We thank the National Natural Science Foundation of China (No. 51674117, 52173279), the Provincial Natural Science Foundation of China’s Hunan Province (No. 2020JJ4332), Scientific Research Fund of Hunan Provincial Education Department (No. 20A220, 20A215), the Key Laboratory of Hunan Province for Advanced Carbon-based Functional Materials, School of Chemistry and Chemical Engineering, Hunan Institute of Science and Technology, Yueyang, 414006, China, and Hunan Province (Xiangcai Construction Hunan Province, Xiangcai Construction).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhao, X., Liang, E., Zhou, F. et al. Acrylamide-ran-methyl methacrylate copolymers synthesized by copper(0)-catalyzed living radical polymerization. Iran Polym J 31, 983–990 (2022). https://doi.org/10.1007/s13726-022-01050-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-022-01050-y