Abstract

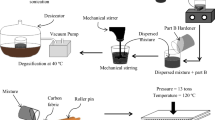

A composite is a material having two or more components with diverse chemical or physical properties. Due to the special feature of the composites, the use of various materials and research in their field is developing. By considering the above points, in this work a series of the nanocomposites from α-Al2O3 nanoparticles (α-Al2O3 NPs, at 2, 5, and 10% by wt), carbon fibers (CF), and epoxy resin were fabricated and their thermal and mechanical performance were evaluated. The dispersion mode of α-Al2O3 NPs in the composite structure was evaluated through a field emission scanning electron microscope (FE-SEM). The FE-SEM analysis revealed that the α-Al2O3 NPs and CF were homogeneously dispersed in the epoxy matrix and the morphology of α-Al2O3 NPs–CF/epoxy composites is uniform. The results of the mechanical tests exhibited that the flexural strength and module of E-40 (epoxy resin: carbon fiber: α-Al2O3, 65:25:10) were at their highest levels; 295 MPa and 11,917 MPa, respectively. For flexural strength and module, improvements were made by 95.5% and 91.8% in comparison with the samples in the absence of NPs. The highest tensile strength was obtained for E-30 (epoxy resin: carbon fiber: α-Al2O3, 70:25:5); 341 MPa. There is a 24% enhancement in tensile strength as compression by a sample without NPs. Accordingly, we can conclude that the addition of α-Al2O3 NPs in composite structures has significantly affected the mechanical response. However, the thermal analysis was illustrated as an inverse trend by the addition of NPs. Therefore, the performance of experimental tests revealed that the composite with the required feature could be prepared based on the obtained results.

Similar content being viewed by others

References

Chowdhury P, Sehitoglu H, Rateick R (2018) Damage tolerance of carbon-carbon composites in aerospace application. Carbon 126:382–393

Tekin E, Kapan Ö (2016) Composite manufacturing data management in aerospace industry. Procedia CIRP 41:1039–1042

Hou P, Li R, Li Q, Lu N, Wang K, Liu M, Cheng X, Shah S (2018) Novel superhydrophobic cement-based materials achieved by construction of hierarchical surface structure with FAS/SiO2 hybrid nanocomposites. ES Mater Manuf 1:57–66

Naskar AK, Keum JK, Boeman RG (2016) Polymer matrix nanocomposites for automotive structural components. Nat Nanotechnol 11:1026–1030

Balakrishnan VS, Seidlitz H (2018) Potential repair techniques for automotive composites: a review. Compos Part B: Eng 145:28–38

Deshmukh K, Ahamed MB, Sadasivuni KK, Ponnamma D, Deshmukh RR, Trimukhe AM, Pasha SKK, Polu AR, AlMaadeed MA-A, Chidambaram K (2017) Solution-processed white graphene-reinforced ferroelectric polymer nanocomposites with improved thermal conductivity and dielectric properties for electronic encapsulation. J Polym Res 24

Alsaadi M, Bulut M, Erkliğ A, Jabbar A (2018) Nano-silica inclusion effects on mechanical and dynamic behavior of fiber reinforced carbon/Kevlar with epoxy resin hybrid composites. Compos Part B Eng 152:169–179

An Q, Chen J, Ming W, Chen M (2020) Machining of SiC ceramic matrix composites: a review. In press, Chin J Aeronautics

Yıldız H, Tokalıoğlu Ş, Soykan C (2021) Preparation of polyacrylonitrile/polyindole conducting polymer composite and its use for solid phase extraction of copper in a certified reference material. Spectrochim Acta Part A Mol Biomol Spectr 244:118826

Manivannan I, Ranganathan S, Gopalakannan S (2019) Tribological behavior of aluminum nanocomposites studied by application of response surface methodology. Adv Compos Hybrid Mater 2:777–789

Ma Y, Zhuang Z, Ma M, Yang Y, Li W, lin J, Dong M, Wu S, Ding T, Guo Z, (2019) Solid polyaniline dendrites consisting of high aspect ratio branches self-assembled using sodium lauryl sulfonate as soft templates: synthesis and electrochemical performance. Polymer 182:121808

Ma Y, Ma M, Yin X, Shao Q, Lu N, Feng Y, Lu Y, Wujcik EK, Mai X, Wang C, Guo Z (2018) Tuning polyaniline nanostructures via end group substitutions and their morphology dependent electrochemical performances. Polymer 156:128–135

Tabrizi AG, Arsalani N, Namazi H, Ahadzadeh I (2017) Vanadium oxide assisted synthesis of polyaniline nanoarrays on graphene oxide sheets and its application in supercapacitors. J Electroanal Chem 798:34–41

Tabrizi AG, Arsalani N, Mohammadi A, Namazi H, Ghadimi LS, Ahadzadeh I (2017) Facile synthesis of a MnFe2O4/rGO nanocomposite for an ultra-stable symmetric supercapacitor. New J Chem 41:4974–4984

Namazi H, Belali S (2016) Starch-g-lactic acid/montmorillonite nanocomposite: synthesis, characterization and controlled drug release study. Starch-Stärke 68:177–187

Nia SB, Pooresmaeil M, Namazi H (2020) Carboxymethylcellulose/layered double hydroxides bio-nanocomposite hydrogel: a controlled amoxicillin nanocarrier for colonic bacterial infections treatment. Int J Biolog Macromol 155:1401–1409

Pooresmaeil M, Namazi H (2018) Surface modification of graphene oxide with stimuli-responsive polymer brush containing β-cyclodextrin as a pendant group: preparation, characterization, and evaluation as controlled drug delivery agent. Colloid Surf B: Biointerf 172:17–25

Namazi H, Fard AMP, Pooresmaeil M (2019) Peripherally functionalized based dendrimers as the template for synthesis of silver nanoparticles and investigation the affecting factors on their properties. Polym Bull 76:4659–4675

Kretsis G (1987) A review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastics. Composites 18:13–23

Li S, Lin Q, Zhu H, Cui C, Hou H, Lv T, Li Y (2016) Investigations on mechanical characteristics of glass fiber reinforced epoxy composite modified with amino-terminated hyperbranched polymer. Fiber Polym 17:282–288

Mechtcherine V, Michel A, Liebscher M, Schneider K, Großmann C (2020) Mineral-impregnated carbon fiber composites as novel reinforcement for concrete construction: material and automation perspectives. Auto Constr 110:103002

Neto DBF, Xavier FFS, Matsubara EY, Parmar R, Gunnella R, Rosolen JM (2020) The role of nanoparticle concentration and CNT coating in high-performance polymer-free micro/nanostructured carbon nanotube-nanoparticle composite electrode for Li intercalation. J Electroanal Chem 858:113826

Makeev A, Ghaffari S, Seon G (2019) Improving compressive strength of high modulus carbon-fiber reinforced polymeric composites through fiber hybridization. Int J Eng Sci 142:145–157

Zhao X, Chen H, Wang S, Wu Q, Xia N, Kong F (2018) Electroless decoration of cellulose paper with nickel nanoparticles: a hybrid carbon fiber for supercapacitors. Mater Chem Phys 215:157–162

Bustero I, Gaztelumendi I, Obieta I, Mendizabal MA, Zurutuza A, Ortega A, Alonso B (2020) Free-standing graphene films embedded in epoxy resin with enhanced thermal properties. Adv Compos Hybrid Mater 3:31–40

Zhang X, Chen Z, Li K, Yang Z, Li Z, Xie D, Zhou W, Wang T, Ma S, Burns R, Ruso JM, Tang Z, Liu Z (2019) Immobilization of penicillin G acylase on a novel paramagnetic composite carrier with epoxy groups. Adv Compos Hybrid Mater 2:720–734

Namazi H, Ahmadi H (2011) Improving the proton conductivity and water uptake of polybenzimidazole-based proton exchange nanocomposite membranes with TiO2 and SiO2 nanoparticles chemically modified surfaces. J Power Sourc 196:2573–2583

Zhang D, Sun J, Lee LJ, Castro JM (2020) Overview of ultrasonic assisted manufacturing multifunctional carbon nanotube nanopaper based polymer nanocomposites. Eng Sci 10:35–50

Yan X, Liu J, Khan MA, Sheriff S, Vupputuri S, Das R, Sun L, Young DP, Guo Z (2020) Efficient solvent-free microwave irradiation synthesis of highly conductive polypropylene nanocomposites with lowly loaded carbon nanotubes. ES Mater Manuf 9:21–33

Pooresmaeil M, Namazi H (2019) Preparation and characterization of polyvinyl alcohol/β-cyclodextrin/GO-Ag nanocomposite with improved antibacterial and strength properties. Polym Adv Technol 30:447–456

Mahato KK, Dutta K, Ray BC (2019) Assessment of mechanical, thermal and morphological behavior of nano-Al2O3 embedded glass fiber/epoxy composites at in-situ elevated temperatures. Compos Part B: Eng 166:688–700

Wang C, Zhao M, Li J, Yu J, Sun S, Ge S, Guo X, Xie F, Jiang B, Wujcik EK (2017) Silver nanoparticles/graphene oxide decorated carbon fiber synergistic reinforcement in epoxy-based composites. Polymer 131:263–271

Sonmez M, Ficai D, Ardelean IL, Trusca R, Alexandrescu L, Constantinescu D, Ghizdavet Z, Oprea O, Ficai A, Andronescu E (2019) Flax fibres fabric surface decoration with nanoparticles-a promising tool for developing hybrid reinforcing agent of thermoplastic polymers. Fiber Polym 20:2407–2415

Taketa I, Ustarroz J, Gorbatikh L, Lomov SV, Verpoest I (2010) Interply hybrid composites with carbon fiber reinforced polypropylene and self-reinforced polypropylene. Compos Part A Appl Sci Manuf 41:927–932

Atiqah A, Maleque M, Jawaid M, Iqbal M (2014) Development of kenaf-glass reinforced unsaturated polyester hybrid composite for structural applications. Compos Part B Eng 56:68–73

Sun L, Liang L, Shi Z, Wang H, Xie P, Dastan D, Sun K, Fan R (2020) Optimizing strategy for the dielectric performance of topological-structured polymer nanocomposites by rationally tailoring the spatial distribution of nanofillers. Eng Sci 12:95–105

Dong C, Davies IJ (2014) Flexural and tensile strengths of unidirectional hybrid epoxy composites reinforced by S-2 glass and T700S carbon fibres. Mater Des 1980–2015(54):955–966

Dong C, Davies IJ (2014) Flexural and tensile moduli of unidirectional hybrid epoxy composites reinforced by S-2 glass and T700S carbon fibres. Mater Des 1980–2015(54):893–899

Li J, Xia YC (2009) The reinforcement effect of carbon fiber on the friction and wear properties of carbon fiber reinforced PA6 composites. Fiber Polym 10:519–525

Xie P, Zhu S, Shao Y, Peng W, Zhan L, Li S (2019) Simulation and experimental analysis of autoclave co-curing CFRP hat-stiffened panels with silicone airbag mandrels. Iran Polym J 28:505–514

Ipakchi H, Shegeft A, Rezadoust AM, Zohuriaan-Mehr MJ, Kabiri K, Sajjadi S (2020) Bio-resourced furan resin as a sustainable alternative to petroleum-based phenolic resin for making GFR polymer composites. Iran Polym J 29:287–299

Sørensen BF, Goutianos S (2018) Increase of fracture resistance by the interaction of two cracks-cohesive law scale effects. In: 7th Eur Conf Comput Fluid Dynamics (ECFD 7)

Piao H, Kiryu Y, Chen L, Yamashita S, Ohsawa I, Takahashi J (2019) Influence of water absorption on the mechanical properties of discontinuous carbon fiber reinforced polyamide 6. J Polym Res 26:1–8

Xiong C, Li Q, Lan T, Li H, Long W, Xing F (2021) Sustainable use of recycled carbon fiber reinforced polymer and crumb rubber in concrete: mechanical properties and ecological evaluation. J Clean Prod 279:123624

Shi L, Song G, Li P, Li X, Pan D, Huang Y, Ma L, Guo Z (2021) Enhancing interfacial performance of epoxy resin composites via in-situ nucleophilic addition polymerization modification of carbon fibers with hyperbranched polyimidazole. Compos Sci Technol 201:108522

Shi K, Shen Y, Zhang Y, Wang T (2018) A modified imidazole as a novel latent curing agent with toughening effect for epoxy. Eng Sci 5:66–72

ASTMCASTM Standards 1958 In: American Society for Testing Materials Philadelphia

Eskizeybek V, Ulus H, Kaybal HB, Şahin ÖS, Avcı A (2018) Static and dynamic mechanical responses of CaCO3 nanoparticle modified epoxy/carbon fiber nanocomposites. Compos Part B Eng 140:223–231

Alsaadi M, Erkliğ A (2018) Effect of perlite particle contents on delamination toughness of S-glass fiber reinforced epoxy matrix composites. Compos Part B Eng 141:182–190

Zare Y (2016) Study of nanoparticles aggregation/agglomeration in polymer particulate nanocomposites by mechanical properties. Compos Part A Appl Sci Manuf 84:158–164

Kagitci YC, Tarakcioglu N (2016) The effect of weld line on tensile strength in a polymer composite part. Int J Adv Manuf Technol 85:1125–1135

Cheng X, Du X, Zhang J, Zhang J, Guo X, Bao J (2018) Effects of stacking sequence and rotation angle of patch on low velocity impact performance of scarf repaired laminates. Compos Part B Eng 133:78–85

Jing X, Wei J, Liu Y, Song B, Liu Y (2020) Deployment analysis of aramid fiber reinforced shape-memory epoxy resin composites. Eng Sci 11:44–53

Wei W, Qi X, Li J, Zhong Y, Zuo G, Pan X, Su T, Zhang J, Dong W (2017) Synthesis and characterization of a novel cationic hydrogel base on salecan-g-PMAPTAC. Int J Biolog Macromol 101:474–480

Qi X, Wei W, Li J, Zuo G, Hu X, Zhang J, Dong W (2016) Development of novel hydrogels based on Salecan and poly(N-isopropylacrylamide-co-methacrylic acid) for controlled doxorubicin release. RSC Adv 6:69869–69881

Acknowledgments

The authors appreciate the University of Tabriz (Grant number: 959644703) for the financial support of this research work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is not any conflict of interest.

Rights and permissions

About this article

Cite this article

Chamkouri, H., Pooresmaeil, M. & Namazi, H. Carbon fiber/epoxy resin/α-aluminum oxide nanocomposites; fabrication, mechanical and thermal analysis. Iran Polym J 30, 523–533 (2021). https://doi.org/10.1007/s13726-021-00909-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00909-w