Abstract

Robots are heralded as part of a new revolution in agriculture. The agricultural robot’s capacity to reduce working time or improve working conditions is often advanced as a major contribution to sustainable agriculture. But the transformations of work appear to be more complex. Here we review the transformations of work subsequent to adoption of agricultural robots on the farm. We carry out a systematic review of literature using a multidisciplinary analytical framework of transformations of work. We consider four dimensions of work: 1) farm structure and the labor market; 2) work organization; 3) meaning of work; and 4) technical-economic performances. Given that the deployment of robots in agriculture is still in its early stages, most of the studies concern the automated milking system (AMS). The transformations of agricultural work represent an emerging topic dominated by a technical and economic vision of work. The major points are as follows: Concerning farm structures, we find no evidence of a relationship between robotization and a certain farm size. Concerning the labor market, there is a risk of skill- and wage-related segmentation and exclusion. The AMS is an example of an in-depth re-organization of work with a decrease in the physical workload but which is concomitant with a new mental workload of monitoring alarms. Concerning the meaning of work with AMS, the changes in the animal-human relationship lead to the possibility of new identities and new self-perceptions by farmers and workers. There is no evidence to support a reduction in working time when an AMS is installed. Finally, a synthesis of the results allows us to propose a research agenda that can better orient future research to understand the diversity of transformations of work resulting from the adoption of robots in agriculture.

Similar content being viewed by others

-

1.1Agricultural robots: the issues of transformations of work

-

2.Methods

-

3.An emerging topic dominated by a technical and economic vision of work

-

7.1Reduction in human labor: level of evidence for the milking robot

-

8.1Robots and the transformation of work: between common logics and the singularity of each robot

-

10.Declarations

-

11.References

1 Introduction

1.1 Agricultural robots: the issues of transformations of work

The digitalization of agriculture is raising hopes that it may be able to transform agriculture and respond to societal and environmental challenges (Trendov et al. 2019). This socio-technical process encompasses a broad diversity of technologies and concepts: internet of things, sensors, artificial intelligence, machine learning, big data, blockchain, robots, etc. (Klerkx et al. 2019). These technologies are promoted as a solution to make agriculture more productive while preserving resources (Reddy et al. 2016). Among the various digital technologies, robotics stands out since it suggests a substitution of human work or at least a radical transformation of work. This is what the fictional origins of robots suggest (Capek 1921; Asimov 1950) and what many modern studies forecast (Marinoudi et al. 2021; Sparrow and Howard 2021). Since the 1960s, robots have been used in industry and more recently in the service sector (Wallén 2008). But agriculture has long remained untouched by this trend of robotization. Today, however, agricultural robotics is experiencing a significant development (Jin et al. 2021) and robots are being heralded in the media as the new revolution in agriculture: “The robot revolution down on the farm” (Abboud 2018), “The future of agriculture is in robotic farmers” (Engineers Australia 2021). Not only the media but public authorities (Auverlot et al. 2016; USDA 2020; European Commission 2021) and scientists (Ampatzidis et al. 2017; Arvanitis and Symeonaki 2020; Basso and Antle 2020; Fountas et al. 2020) are seeing promise in robots for a sustainable agriculture. The robotization of agricultural work is not a new idea. It has been the subject of studies dating back several decades on attempts to automate often arduous agricultural tasks (Kawamura and Namikawa 1989). In the late 1990s, many dairy farms in western and northern Europe started adopting automated milking systems (AMS) (Gallardo and Sauer 2018). But it is only over the past few years that agricultural robotics has experienced unprecedented development. Venture capitalists, start-ups, research entities and public policymakers are getting involved (Rotz et al. 2019a), and market analysts are predicting double-digit compounded annual growth rates for the sector (Brandessence Market Research and Consulting 2021; Francis 2021). This development of robotics is part of a context of profound transformations of work in agriculture. Agriculture is a labor-intensive sector. In 2019, this sector engaged 27% of the world’s active population (World Bank 2021). However, agricultural employment is decreasing (-50% between 1990 and 2017) due to productivity gains and other factors (ibid.). Working conditions are also less attractive than in other sectors (arduous tasks, job insecurity and low wages), and labor relations and organization are also changing (Hostiou et al. 2020). In developed countries, for instance, salaried employment and subcontracting are growing at the expense of family farming (Blanc et al. 2008). Agriculture is already experiencing profound changes in work. How do agricultural robots – which are heralded as work reducers – participate in these transformations or in driving new ones?

In social-science reviews, the singularity of the agricultural robot is rarely considered (Reddy et al. 2016; Lowenberg-DeBoer et al. 2020; Ryan et al. 2021). It is instead resituated within a diversity of digital innovations (Salemink et al. 2017; Klerkx et al. 2019; Wang and Siau 2019; Hackfort 2021). However, it is essential to study agricultural robots specifically in order to understand the nature and intensity of work transformations. For instance, the fruit picking robot and the smartphone do not have the same consequences on the transformation of work. Several authors highlight the opportunities and threats of the development of robotics in agriculture in various fields (e.g. social, cultural, health, safety, employment, politics, economics, etc.) (Rose et al. 2021; Ryan et al. 2021). The debate on robots in agriculture is essentially presented in terms of ethics and responsibility. There are no specific reviews concerning work and agricultural robotics. It is instead a dimension partially analyzed within more general questions. No literature review provides a broad view of the transformations of work arising from robotization in agriculture. That is why we still do not really know what are the diversity of work transformations that result from robotization in agriculture. In this review, we want to provide an answer to this question by focusing on work on farms. The scientific literature offers a wide variety of answers to this question. These answers depend in particular on the disciplines used and the conceptual and analytical choices made to study agricultural work (Malanski et al. 2019). This paper applies the standardized process of a systematic literature review to summarize the diversity of answers with rigor and transparency.

1.2 What is and what is not a robot?

The most commonly used definition of a robot comes from the Robotic Industries Association (RIA), which defines the robot as “a reprogrammable, multifunctional manipulator designed to move material, parts, tools, or specialized devices through various programmed functions for the performance of a variety of tasks.” The International Organization for Standardization (ISO) adapts this general definition of a robot according to the sectors of activity and defines industrial robots and service robots (International Organization for Standardization 2012). The agricultural robot requires a definition adapted to the particular context of work in agriculture (Fig. 1). Lowenberg-DeBoer et al. (2020) propose a definition of a field crop robot: “a mobile, autonomous, decision-making, mechatronic device that accomplishes crop production tasks (e.g. soil preparation, seeding, transplanting, weeding, pest control and harvesting) under human supervision, but without direct human labor.” The mobile characteristic does not apply to some livestock robots such as automated milking systems (AMS). Because this definition is limited to field crops, we proposed a definition of the agricultural robot that is suitable for all different farming sectors: An agricultural robot is a re-programmable mechatronic device that performs different farming tasks, interacting with the biological and physical environment without direct human intervention and adapted to its environment through data collection and analysis. It is composed of a physical artifact made up of one or more sensors (data collection), actuators (task execution) and software that allows data analysis and then modulation of tasks. The agricultural robot acquires data (sensors), carries out services (data analysis) and then executes tasks (actuators) (Martin et al. 2020).

1.3 What is agricultural work for us?

Agricultural work is a polysemous concept, studied by specialists from a variety of disciplines and traversed by a variety of visions (Malanski et al. 2019). And yet, there exists no framework for analyzing work in agriculture that can account for this diversity. To undertake this systematic review of literature (SRL), we constructed a framework for analyzing on-farm work that reflects the diversity of approaches found in the literature. To this end, we identified four main dimensions through which work is analyzed within a test corpus. This test corpus brings together a set of key articles on the transformations of work that accompany robotization on the farm and is compiled by the SRL authors (Martin et al. 2020). This framework is therefore inductive and the result of a multidisciplinary vision of work. In this paper, we are interested in human work on the farm, with this work being placed in a social and economic environment. Thus, we begin by studying work in its relationship to a market and as an economic factor of on-farm production (1st dimension: farm structure and labor market). Then, we study it in its spatial-temporal dimensions at the farm level: who does what, when and where? (2nd dimension: work organization). Then we analyze work through its technical and economic indicators (3rd dimension: work performances). Finally, we look at the meaning that workers assign to work, and the subjectivities and relationships implied in agricultural work (4th dimension: meaning of work).

2 Methods

2.1 Research strategy

In order to study the transformations of work when robots are used in agriculture, we carried out a systematic review of literature (SRL). A SRL is a “predetermined structured method to search, screen, select, appraise and summarize study findings to answer a narrowly focused research question” (Greenhalgh et al. 2018). This method, which originated with the biological, medical and ecological sciences, is also very well suited to the social sciences and indeed to questions about work (Petticrew and Roberts 2006). All details of the method we followed were included in a protocol that was published prior to the start of the SRL (Martin et al. 2020). The pre-publication protocol “ensures greater transparency in the research process and protects the wider community against a number of damaging research practices” (BMJ 2015). Our research strategy consisted of querying two reference databases: Web of Science Core Collection (WoS) and Scopus. We included articles, books, book chapters and reviews in this query’s scope. There were no limits on disciplines, methods and countries. We used a model called PICO (population, intervention, comparison, outcome) (Petticrew and Roberts 2006, p. 38; Frandsen et al. 2020) to design our research question and translate it into a research query (Table 1). The query we used consists of three key concepts as defined in the protocol: robot, agriculture, and work – and their lexicons (see the protocol for the complete equation, (Martin et al. 2020). Our query ranges from 1955 to December 2021 for WoS and from 1960 to December 2021 for Scopus.

2.2 Selection process

The first selection process – the screening – involved an abstract blind review by two co-authors of this paper using Rayyan, a web application for systematic reviews “that helps expedite the initial screening of abstracts and titles using a process of semi-automation while incorporating a high level of usability.” (Ouzzani et al. 2016). We excluded 2283 irrelevant records that were returned by our broad-spectrum search strategy. The conflict rate between the two co-authors was 3.8% (divergent decisions leading to discussions), which reflects the accuracy of both the selection criteria and the research question asked. The second stage of the selection started with 146 records and involved three eligibility criteria:

-

1.

At least one studied technology meets the criteria of our definition of a robot.

-

2.

At least one of our dimensions of work analysis is addressed: farm structure and labor market, work organization, work performances, and meaning of work.

-

3.

The work is studied at the farm level through at least one of the following analytical perspectives: the livestock/cropping system, the farming system (Therond et al. 2017), the activity system (Gasselin et al. 2012), and the farmers and/or farm workers in any agricultural sector (e.g. field crops cultivation, livestock husbandry, horticulture, viticulture).

These eligibility criteria reduced the selection down to 53 records. The last step of the selection process consisted of checking the references cited by the selected papers. Checking references is part of the SRL method and is recognized for its relevance (Horsley et al. 2011). Consequently, we checked the references of these 53 papers to identify 66 more records. In contrast to the initial query, we retained proceedings papers in this step, thus allowing more studies to be included. When these 66 records were submitted to our three eligibility criteria, only 37 remained, thus giving us a total of 90 records (=53 + 37) (to see the included and excluded records with the reasons for exclusion, please see Supplementary Table 2). We use the PRISMA flow diagram method (Moher et al. 2010) to show the complete selection process in Fig. 2. These 90 articles were then analyzed using bibliometric analysis (first part of this article) and qualitative analysis (second part).

PRISMA flow diagram (adapted from Moher et al. 2010)

3 An emerging topic dominated by a technical and economic vision of work

The topic of transformations of work due to robotization in agriculture is small and relatively recent (90 records). Even though the first publication dates back to 1992 (Seabrook 1992), the number of publications only increased significantly starting in the 2010s.

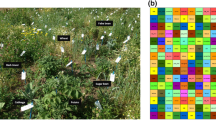

The automated milking system (AMS) or milking robot is the most studied robot for transformations of work: 60 of the 90 selected articles (i.e. 67%) focus exclusively on the AMS (Fig. 3). AMS was the robot that was most studied until the beginning of the 2010s. But in the last 5 years, studies on the transformation of work have focused on a wider variety of robots. This first result is consistent with the actual deployment of robots in agriculture. AMSs were the first robotic systems to be deployed in European agriculture, starting 30 years ago, with an acceleration which began in the 2010s in northern and western Europe, where the studies in our corpus are mainly situated. Other robots were less represented than the AMS in our literature review on transformations of work. We offer two main explanations for this low proportion of reference to other robots in our corpus: 1) the deployment of these robots is more recent and they are adopted in smaller numbers; 2) therefore the research on these robots focuses more on their design than on their effects. Indeed, the agricultural robotics sector is marked by a divide between the dynamism and communication of economic actors and the poor adoption of these technologies on farms (Caffaro and Cavallo 2019; Carolan 2019). Many challenges remain to be overcome in order to achieve a higher adoption rate (Wouter Bac et al. 2014).

Types of robot analyzed in our literature analysis by year of publication; An Automatic Herding System (AHS) is a system of slow-moving mobile fences controlled by an industrial controller. It herds all the cows to the milking robot (Drach et al. 2017);

Agricultural and livestock engineering and economics are more involved in the analysis of work transformations at the disciplinary level (Fig. 5a), with each accounting for 36% of total disciplinary composition of the corpus. Agricultural and livestock engineering analysis mainly concerns the “performance” dimension, which is therefore the first dimension of work analyzed in our corpus (57% of the records analyze the work in its “performance” dimension.). Moreover, the topic is not associated with a large and structured scientific community but instead with a fragmented one with a few recurrent authors (Fig. 4). An explanation may be that the transformations of work due to the robotization of agriculture are rarely an object of research in themselves. Work is essentially a secondary theme within technical and economic analyses of the transformations due to robots. While the first paper dates back to 1992, the social sciences only started to address this issue in the 2010s (Fig. 5b). In the social-sciences community, the main interest is on the analysis of human-animal and technology relations (Fig. 4) (Butler et al. 2012; Holloway et al. 2014a, b; Bear and Holloway 2015, 2018, 2019; Butler and Holloway 2016; Holloway and Bear 2017).

Co-author network (the graph was generated with the force-directed Fruchterman-Reingold algorithm). As the discipline is coded at the publication scale, the various authors of a particular article may be from many different disciplines; names of authors with a minimum of 4 publications are displayed

4 Farm structure and the labor market

4.1 Farm structures: robots for large or small farms?

According to Reddy et al. (2016), agricultural robotics has historically been framed by engineers. They have an industrial production vision of agricultural work in which “the machines could work entirely in predefined ways, much like a production line” – which partly explains the many repeated failures to automate agricultural tasks. Robots as part of digital agriculture are often associated with large farming systems (Dusty 2017). According to (Caffaro and Cavallo 2019), the lack of capital investment and insufficient knowledge explains why small farmers have a lower level of access to these tools. This situation creates a large digital divide between big and small farmers. Several studies have demonstrated that large farms are more inclined to adopt precision technologies, especially in the dairy sector (Moyes et al. 2014; Gargiulo et al. 2018).

In France, a study (Veysset et al. 2001) dating from the time of the increase in the adoption of AMS on farms reveals that farms with AMS are larger (in area and herd size) than the national average, and more diversified (non-fodder crops represent 42% of the total surface area and 55% include at least a second animal production unit). Heikkila et al. (2012) show that the ability to mobilize capital to install machinery is a significant factor behind the switch to automatic milking. This suggests that the most capitalized farms are more likely to robotize. However, a study from the early days of AMS development indicate no significant correlation between farm sizes and adoption of AMS (Hogeveen et al. 2004). What is more, Castro et al. (2015) show that farmers with herd sizes below the average (91% versus 58%) express a higher satisfaction with the adoption of AMS, thus suggesting that the technology is more adapted to small and medium farms. The dominance of the family farm structure in western and northern Europe thus partly explains why more than 90% of dairy farms using AMS are located in this area (Gallardo and Sauer 2018). The history of the adoption of AMS mainly by medium and family runs counter to the studies that suggest that it is large farms that tend to adopt the use of robots.

The link between farm structure and adoption of robotics should be considered from another point of view. An AMS transforms the farm’s technical and economic functioning and the structure evolves with it. Tse et al. (2017) report that herd size increases when a farm transitions to an AMS. At the scale of the dairy sector, this increase leads to a structural rise in milk production as an unintended consequence of the farmers’ aggregated investments in AMS (Vik et al. 2019). These authors explain that the increase in Norwegian milk production is the result of the sum of production increases on farms with AMS. At the farm level, this production increase is part of “changes to make investments in AMS structurally and economically viable” (ibid). Moreover, the farms that tend to adopt AMS are not the most labor-intensive ones but instead those oriented towards increasing milk production (Heikkila et al. 2012). Finally, big and small farms do not expect the robotization of the same type of work. According to Spykman et al. (2021), large farms consider field crop robots as a potential financial benefit and prefer large autonomous tractors. In contrast, small farms or organic farms are interested in robots for environmental benefits and prefer small robots. Thus, according to Daum (2021), the robot in agriculture can be part of a diversity of models. On the one hand, the robot can provide a solution to the labor problem that is an obstacle to the development of a more agroecological agriculture (Orsini et al. 2018; Daum 2021). On the other hand, the robot can contribute to a more productivist agriculture, supporting monoculture and large farms (ibid).

4.2 The robot and the labor market

The dominance of family dairy farms and the continued increase in average herd size are not the only factors that explain the development of AMS in Europe (Gallardo and Sauer 2018). The labor market is a significant driver for adoption of robotics in general (ibid) and AMS in particular (Schewe and Stuart 2015). In north-western Europe, agricultural investments are driven by high labor costs, and the labor shortage in many developed countries represents a potential for agricultural robotics (Marinoudi et al. 2019; Lowenberg-DeBoer et al. 2020). In Russia, Semin et al. (2020) identify three groups of workers differentiated by the evolution of employment in the face of robotization. The first group is the one whose number of jobs is decreasing due to the substitutability of the operations they perform. The second group of workers has a stable employment due to the difficulty of substituting their tasks with machines. Finally, the third group is the one whose employment increases because these workers are involved in the maintenance of the robots. The cost of robotization is today not so high, as compared to the price of labor, which raises questions about the availability of agricultural employment for migrants (in many countries, seasonal work is often performed by migrant workers) (Alarcón 2021). In some countries, the Covid pandemic and the associated lockdown have led to the emergence of robots as a solution to the labor shortage (Srivastava 2021). This is especially true when farms are dependent on seasonal work and this work is normally done by migrant workers (Christiaensen et al. 2020). Marinoudi et al. (2019) suggest that any analysis of how robots and automation affect the labor market should be conducted at the farm level instead of at the macroeconomic level that is generally used for labor market analyses.

Automation also transforms the labor market through the phenomenon of “job polarization” which “refers to the parallel growth of high-skill (and in principle, high-wage) jobs and low-skill (and in principle, low-wage) jobs at the expense of middle-skill jobs” (Marinoudi et al. 2019). This job polarization can lead to a “wage polarization”, thus calling for an examination of the sharing of added value. Rotz et al. (2019b) also underline the development of a high-skill/low-skill bifurcated labor market. This is why a disconnect between skills and labor availability has appeared in agri-food industry. AMS is an apt example of the evolution of skills due to automation at the farm level. A higher education level leads to a greater interest in AMS (Moyes et al. 2014). The inability to use and read data can be a barrier for many workers (Tse et al. 2018a) and may lead to the exclusion of some of them (Schewe and Stuart 2015). But the AMS can also help improve the farm’s attractiveness, and adoption of an AMS can be part of a strategy to attract higher-skilled employees (Lundström and Lindblom 2021).

4.3 Division of labor and power relations

Robotics, like other digital technologies, can be used to reinforce the surveillance of and control over workers. As investigated in other sectors (De Stefano 2018), the data collected and analyzed facilitate the evaluation of workers’ performances and thus make it easier to apply Taylor’s scientific management theory to agricultural work (Sparrow and Howard 2021; Prause 2021). However, this same data can provide access to other skills and knowledge for workers. But learning these new skills is sometimes less possible for the older generation and this may contribute to a “working-class fragmentation along age lines” (ibid.). With AMS, employees are no longer asked to milk the cows, instead they have to manage the herd, observe the animals, and finally transform themselves from “milkers to stockpersons” (Lundström and Lindblom 2021). Some of the results raise questions about how robots can reshape the division of labor and promote the outsourcing of some on-farm work. Spykman et al. (2021) surveys show that farmers in Germany prefer the option of not purchasing field crop robots and instead choose to hire them “as a service”. And when the purchase is considered, it is mostly at an individual level. On the farm, the management of AMS alarms requires a redistribution of work and of responsibilities within the collective. The employees now work during the daytime and the farmer must manage the alarms emitted by the robot day and night. As a farmer explains: “We have learnt how to go on holiday... we travel as far as possible so we end up in another time zone... so we can have the night alarms and the like in the evening... we fly to the USA... there we can walk on the beach and milk cow!"” (Lundström and Lindblom 2021).

5 Work organization

5.1 Flexibility and quality of life

Dairy farming involves arduous tasks and a rigid work organization given twice-daily milking duties. The majority of studies share the same main labor-oriented motivations for the adoption of an AMS: increased flexibility and reduced physical workload (Veysset et al. 2001; Jensen 2004; Mathijs 2004; Wade et al. 2004; Bergman and Rabinowicz 2013; Hansen 2015; Karttunen et al. 2016; Hostiou et al. 2017a; Stræte et al. 2017; Lundström and Lindblom 2021). The same motivations are revealed in studies on Automatic Feeding Systems (AFS) (Bisaglia et al. 2012; Grothmann et al. 2010; Da Borso et al. 2017). The examples of AMS and AFS demonstrate that it is not economic factors that motivate the choice to invest in a robot but rather an improvement of the working environment (de Koning 2011). Increasing the flexibility of work does not necessarily mean reducing working time, as we will see below. But this evolution of work contributes to a reduction in the number and difficulty of physical tasks and improves workers’ health (Pinzke 2016; Tse et al. 2018a). In farms equipped with AMS, the elimination of milking duties leads to a better lifestyle in which the time saved is often allocated to family and social life (Mathijs 2004; Molfino et al. 2014; Tse et al. 2018a) or other economic activities (Bergman and Rabinowicz 2013). However, the larger the herd, the lower the work flexibility and lower the job satisfaction (Hansen et al. 2020). Job satisfaction with AMS is also highly dependent on the number of years with AMS (ibid). This illustrates the importance of the transition period in reconfiguring work. Hence, robots help farmers live a “modern lifestyle” (Hansen 2015) and contribute to the attractiveness of dairy farming for the younger generation (Karttunen et al. 2016).

5.2 Displacement of tasks and creation of new ones

The robot displaces and transforms work in time and space. The AMS releases workers from one of the most time-consuming and arduous manual tasks: milking (Pinzke 2016). But in a conventional milking system (CMS), the worker milking the cow also uses the time for observing the cow for health and wellbeing, and for estrus monitoring (Dijkhuizen et al. 1997; Butler et al. 2012). The introduction of the milking robot displaces these tasks to a different time and space. Very often, some cows have to be helped to the milking robot, so human intervention for milking is not totally eliminated (Lundström and Lindblom 2021). Moreover, with AMS, an increase in working time is observed for feeding and cubicle cleaning (Gustafsson 2004). And in the case of AFS, the labor requirement increases for health inspections (Sinnott et al. 2021). In addition to the displacement and increase in duration of some tasks, new tasks appear. The robotic machine requires monitoring for mechanical flaws and proper functioning (Dijkhuizen et al. 1997). The advent of Management Information Systems (MIS) to monitor animal performance and even to manage the farm (e.g. costs, reproduction, feeding) leads to a new activity, shifting work out of the barn and into the office (Bear and Holloway 2018; Lunner-Kolstrup et al. 2018). The office thus becomes an unavoidable workspace and the computer an indispensable interface. Digital monitoring tethers the workers via their smartphone and can lead to on-call duties and information overload (Hansen 2015), blurring boundaries between personal and professional spaces and time. Not all farmers use this data in the same way. Stræte et al. (2017) identified two categories with respect to data use: “high and low levels of data options used. A low level suggests using only the most necessary data options.” But, in spite of new tasks and the increase in time taken for some tasks, the overall reduction of the working time is a major and positive aspect for many studies (see below “Reduction in human labor: level of evidence for the milking robot”).

6 Meaning of work

In general, the concept of meaning of work refers to the many forms of subjectivity and emotion (stress, satisfaction, recognition, autonomy, feeling of coherence, identity, etc.) and also relationships at work – with humans and with non-humans (Rosso et al. 2010; Dejours 2012). In our case, three main aspects are evoked by our corpus: mental workload and technostress, change in humans’ relationships with animals, robotization and the shaping of a new farmer. All three are the result of work on the AMS.

6.1 Mental workload and technostress

The AMS reduces stress due to the elimination of the repetitive task of milking as well as a reduction in physical workload, which benefits the worker’s lifestyle and family time (De Jong and Finnema 2003; Jensen 2004; Karttunen et al. 2016; Tse et al. 2018a). Thanks to information it provides, an AMS can be expected to reduce mental workload by anticipating events like insemination or mastitis (Hostiou et al. 2017a). But most of the studies report an increase in mental workload and stress. Our analysis identifies four reasons for this mental stress (Meskens et al. 2001; Hansen 2015; Karttunen et al. 2016; Hostiou et al. 2017b, a; Lunner-Kolstrup et al. 2018; Lundström and Lindblom 2021): (1) the demanding management of the AMS and complexity or overload of information; (2) the lack of adequate farmer or hired-worker skills; (3) the fact of being on 24/7 standby and having to deal with nocturnal alarms; and (4) the debt burden, which increases with the investment in an AMS. Mathijs (2004) shows that for farmers the improvement in mental health is less clear than in physical health, and varies widely from country to country. According to Hansen et al. (2020), this technostress – defined by Ragu-Nathan et al. (2008) as “stress experienced by end users of Information and Communication Technologies” – contributes to a reduction in farmer wellbeing in terms of mental health. Training in AMS and an adequate advisory can decrease this technostress and improve the success of the conversion to a milking robot (Bugge and Skibrek 2019; Hansen et al. 2020). For some farmers, relationships with AMS suppliers and maintenance services can cause stress (Lundström and Lindblom 2021). A possible interpretation is that while milking is no longer a physical task, the farmer is now dependent on the equipment supplier for the continued functioning of the robot.

6.2 Change in humans’ relationships with animals

With the implementation of the milking robot, farmers spend less time interacting with their animals (Hostiou et al. 2017b; Kling-Eveillard et al. 2020; Wildridge et al. 2020). This decrease in human-animal interaction changes the relationship between farmers and cows. Since “cows must voluntarily present themselves to be milked” (Driessen and Heutinck 2014), they develop a lack of fear of human presence and are less stressed by it (Bear and Holloway 2015). Once an AMS is deployed, this relationship between breeders and cows is also intermediated by a machine and the data it provides. For Cornou (2009), the farmers then perceives their animal as a product or a combination of parameters to monitor, with consequent impact on animal welfare. An AMS also changes the workers’ vision of the scale of management of the animal from the herd to the individual cow (Kling-Eveillard et al. 2020). The AMS leads to a redefinition of what are good and “lazy” cows according to their behavior towards the robot (Holloway et al. 2014a; Bear and Holloway 2018). But according to Porcher and Schmitt (2012), “the milking robot […] is not per se necessarily a tool that alienates animals and farmers.” Because cows work and have an active role in a working relationship with the human (ibid), they “co-produce changes in practices with farmers and robot” (Bear and Holloway 2018). This co-production leads to “new rural subjectivities” and “agricultural lives”, which implies “more-than-human negotiations” with humans, animals and machines (Bear and Holloway 2015, 2018, 2019). This “redefines the notion of care in dairy farming” and redistributes responsibility between human and non-human entities (Holloway et al. 2014a). Finstad et al. (2021) describe the process of domestication that leads to the transformation of a farmer into an “AMS farmer”. The farmer, the cows as also the machine learn and adapt to each other (the AMS adapts to cows via machine learning).

6.3 Robotization and the shaping of a new farmer?

In the corpus analyzed, changes in the farmers’ perception and identities are mainly studied through their relationship with cows. The definition of a “good” farmer changes once he adopts an AMS, both in terms of the relationship with animals (Driessen and Heutinck 2014) and the skills required to deal with data generated by the AMS (Seabrook 1992; Butler et al. 2012). New skills are acquired with the adoption of an AMS through the data produced. However, it can also lead to a loss of traditional skills, which can make some farmers lose interest in their profession (Kling-Eveillard et al. 2020). Two studies from the 1990s show a link between the self-perception of stockpersons and their attitude towards the milking robot (Seabrook 1992; Rossing et al. 1997). “Those stockpersons with a cognized self of being livestock-orientated appeared more demeaned by the prospects of automatic milking than those who had a cognized self of being machinery-orientated. Similarly, those who perceive themselves as progressive see greater opportunities than those who perceive themselves as traditional” (Seabrook 1992). The relationship with the animal is a determinant of the farmers’ satisfaction with their work following the adoption of the AMS. Different profiles have been identified and link the relationship of the farmer to the work, to the robot and to the animal (Hostiou et al. 2017b). Hansen and Stræte (2020) suggest that “AMS farmers experience a higher satisfaction with the working day, the occupational safety and the working environment compared to CMS farmers.” Some farmers become concerned about the loss of autonomy in their work because of the milking robot (Hostiou et al. 2017b). On the other hand, some say they have more control over the management of the herd (Kling-Eveillard et al. 2020). The question of autonomy in its different aspects is key in the evolution of work. However, it is very little studied by our corpus.

7 Work performances

7.1 Reduction in human labor: level of evidence for the milking robot

The per-hour physical productivity of the robot is still lower than that of human for many tasks such as milking cows or harvesting strawberries (Woo et al. 2020). But robots can often work all day and in all weather conditions. We present here the results of the studies on reduction in working time with the AMS and the AFS. These are the two main robotic systems for which the working time has been studied in real working situations and there is sufficient data for both to discuss this reduction in working time.

The AMS’s ability to reduce the demand for human labor is crucial in the context of increases in farm sizes and labor market constraints. Jiang et al. (2017) and Örs and Oğuz (2018) refer to several studies that show a significant reduction in work time. Örs and Oğuz (2018) calculate a reduction in working time of 28% by taking an average of the figures from the mobilized studies but do not take into account the diversity of the samples, the methods and the technical-economic contexts. In addition, these studies ignore research that shows no difference or an increase in work time. A critical assessment of the wide variety of results and methods is necessary to evaluate the evolution of working time due to robotization. In our corpus, 15 studies provide results on the change in working time following the adoption of the AMS (10 quantified results and 5 depending on the farmer’s perception). The majority of the studies (9 out of 15) are in agreement that there is a reduction in working time. Indeed, this reduction in labor is one of the major arguments put forward for the AMS’s adoption by many authors (Hogeveen et al. 2004; Castro et al. 2015) and AMS manufacturers alike (DeLaval 2021; Lely 2021), and forms the justification of many scientific studies. However, the extent of this reduction in working time varies greatly between studies: from -20% (Mathijs 2004) to -62% (Tse et al. 2018b). What is more, one robust quantitative study finds no significant difference in working time (Steeneveld et al. 2012). The five studies interested in the workers’ perceptions suggest no decrease in working time, two of them note an increase in working time (Lunner-Kolstrup et al. 2018; Vik et al. 2019) and the other three no difference in working time between before and after AMS adoption (De Jong and Finnema 2003; Butler et al. 2012; Hansen 2015). Three explanations are provided for this absence of reduction or even increase in perceived working time: (1) the working day is no longer structured around milking with “a clear and natural ‘start’ and ‘end’” (Lunner-Kolstrup et al. 2018); (2) a feeling of being permanently on call due to alarms: “They are never really done after a working day as there is always something more to be done in the dairy barn” (Butler et al. 2012; Lunner-Kolstrup et al. 2018); and (3) an increase in herd size often accompanies the adoption of AMS, and the time saved in milking is lost in other tasks whose working time increases with herd size (Jacobs and Siegford 2012; Vik et al. 2019).

The variations in the results and the existence of contradictory results make it difficult to state the significance of this change in working time. The diversity of results can be explained by a diversity of methods, and technical, social, economic and geographical contexts. Methodological choices are critical because various biases can influence the results. We have used five evaluation criteria to analyze these biases (Table 2) (for more details concerning bias analysis, see supplementary information).

None of the studies provides a sufficient level of evidence to rule on this issue of reduction in working time resulting from an AMS (Table 2). And the size of the sub-corpus is too small to enable correlations between the identified biases and the results. But the methods used could have influenced the strength of the evidence as well as the results (Supplementary Table 1). According to our assessment, the five studies that looked at the workers’ perceptions of the changes in their working times provide a higher level of evidence than the other studies (De Jong and Finnema 2003; Butler et al. 2012; Hansen 2015; Lunner-Kolstrup et al. 2018; Vik et al. 2019). The results of studies using a “questionnaire” approach showed a greater variation: a reduction in working time ranging from 20% (Mathijs 2004) to 62% (Tse et al. 2018b).

Feeding operations on European dairy farms could represent more than 25% of labor time (Pezzuolo et al. 2016). Automatic Feeding Systems (AFS) are also undergoing significant development. Although less studied than the AMS because they are more recent, AFS also allows a significant reduction in working time. Several studies show a significant reduction in working time with an AFS compared to conventional feeding systems (Gleeson et al. 2008; Grothmann et al. 2010; Pezzuolo et al. 2016; Da Borso et al. 2017; Sinnott et al. 2021). However, this reduction in labor time is only possible at a certain herd size. Grothmann et al. (2010) did not observe any difference in labor time with a herd size of 60 animals.

These variations of results illustrate the complexity in expressing the perceptions of farmers regarding changes in working time through objective numerical values. It seems essential for future researchers to consider all possible biases in order to better understand the real change in working time and to identify its determinants and variability. Above all, our results show that the adoption of robots leads more to a reorganization of work in time and space than to a real reduction in working time. Studies on work transformations should not be restricted to the measurement of time but rather to the way work is reorganized in time and space and between workers.

7.2 Economic performance

According to Caffaro and Cavallo (2019), capital costs are a limiting factor for the adoption of agricultural robots by small farms. In the case of AMS, the robotic machine, construction or modifications of the barn, and the purchases of cows increase the fixed costs (Heikkila et al. 2010; Steeneveld et al. 2012; Ferland et al. 2016). Most studies agree on a significant increase in the cost of capital with an investment in AMS, which consequently impacts the cost of producing milk (Jago et al. 2006; Bijl et al. 2007; Heikkila et al. 2010; Gargiulo et al. 2020). The high cost of AMS is the most important motivation for adoption of CMS instead of an AMS in the Netherlands according to Hogeveen et al. (2004). From the beginning of the development of the AMS, increased yields were announced as a positive effect of robotic milking (Rossing et al. 1997). Since then, most studies have confirmed this increase in milk yields (Speroni et al. 2006; de Koning 2011; Butler et al. 2012; Oudshoorn et al. 2012; Tse et al. 2018b; Örs and Oğuz 2018). Does this increase in yield compensate for the increase in fixed costs? The diversity of the results concerning margins, returns and profitability make it still difficult to quantify the changes in economic performance. Focusing only on profitability, while some authors conclude that AMS is more profitable than CMS (Bijl et al. 2007; Salfer et al. 2017; Tse et al. 2018a), mainly due to the extra production of milk and savings on labor, some argue the opposite (Heikkila et al. 2010; Shortall et al. 2016) and others find no significant difference (Gargiulo et al. 2020). According to Bergman and Rabinowicz (2013), profitability in AMS farming systems depends on a range of factors, with milking frequency being an important factor. For a given robotic milking capacity, the milking frequency decreases when the herd size increases, so the profitability decreases when the farm size increases (Pezzuolo et al. 2017). But according to Hansen et al. (2019), small farms (less than 50 cows) are also less profitable with AMS than with CMS. And the economic simulation of Salfer et al. (2017) showed that the 1500-cow parlor system was more profitable than AMS for very large farms. These results suggest that: (1) there is a size range in which investing in AMS is economically attractive: medium-sized farms; (2) the number of cows per robot determines the milking frequency and greatly influences profitability. While some authors note an increase in margins and returns with AMS (Bijl et al. 2007; Heikkila et al. 2010; Ferland et al. 2016), others show no significant difference (Rotz et al. 2003; de Koning 2011; Oudshoorn et al. 2012). However, the diversity of economic outcomes does seem to converge towards a higher cost of capital and a lower cost of labor. Finally, as we have seen above, economic factors are not the main reason for the adoption of AMS; it is instead the expectations of an improved quality of life that drives the decision. Nevertheless, the high cost of the AMS is one of the reasons for not installing it (Bergman and Rabinowicz 2013).

In the case of the feed pusher robot for dairy farms, Nabokov et al. (2020) has reported a significant economic gain – 87.8% return on investment – mainly explained by the reduction in feed losses and in labor costs. In the case of a robotic system performing light soil cultivation, the cost of the robotic system only becomes interesting if human labor is completely removed (Lampridi et al. 2019). Otherwise, whether for a small-case scenario (10 ha farm) or a large-scale scenario (100 ha farm), the cost is always higher with a robotic system (ibid). However, for the moment, removing all human work remains impossible and the robots continue to remain dependent on human work.

8 Towards a research agenda

8.1 Robots and the transformation of work: between common logics and the singularity of each robot

Studies on transformation of work due to the robotization of agriculture are relatively recent and essentially focused on AMS: 67% of our corpus is interested in AMS. Most of the knowledge on the transformations of work accompanying robotization comes from the adoption of AMS. Three main types of results can be extended to other robots and represent a continuity in the transformations of work occurring with robotization in agriculture: changes in the relationship with the living, changes related to the use of data and changes related to the temporal organization of work (work time and temporality). These three elements transform work in all its dimensions (farm structure and labor market, organization, meaning, performances). However, each robot has its own characteristics with regard to transformations of work. Three characteristics are to be considered to understand the singularity of the effects that each robot has on work: space (immobile or mobile robot), time (continuous or punctual task) and the type of worker (social status, degree of autonomy). While the AMS is an immobile robot, most of the robots developed for field crops or vegetables crops are mobile robots. Moreover, the AMS operates continuously whereas most of the technical operations in agriculture are punctual interventions (i.e. spraying, tilling, harvesting). Finally, the type of workers is also diverse in agriculture. Dairy farming in Western and Northern Europe is predominantly family-based. The transformations of work accompanying AMS therefore essentially concern family work, even if we have seen that AMS can support an emerging trend: the development of wage employment. On the contrary, vegetable crops, fruit production or viticulture are sectors marked by significant “work peaks” and the important recourse to salaried and often migrant labor. Consequently, the impact on the work is different because the workers are not the same in terms of social status, income, autonomy or degree of specialization. These specificities of each robot and each agricultural task impose caution in the generalization of the results. We must consider the materiality of the robot and the specifies of agricultural tasks but also consider the social characteristics of workers.

Once its specificities are considered, we propose a framework for analyzing the transformations of work accompanying robotization in agriculture. This framework (Table 3) combines three levels of analysis of work. The first includes the four analytical dimensions from which the corpus was selected. The second contains sub-dimensions that group the results of our corpus. These sub-dimensions represent the way in which the literature responds to the issue of transformation of work subsequent to adoption of agricultural robots on the farm. The third presents our interpretation of the lacunae in research with regard to the sub-dimensions studied. We present a research agenda by highlighting the sub-dimensions that are already well informed, those that are insufficiently informed, and the research frontiers that remain to be explored. This research agenda calls for an important role of the humanities and the social sciences since existing contributions are mainly from the post-2010 period and are skewed towards economics and the engineering sciences (Fig. 5).

8.2 Farm structure and the labor market

We can group the analysis of transformations of the labor market and farm structure into four main sub-dimensions: the farm’s size and farming model (large/small; organic/conventional); the segmentation of the labor market (substitution/complementarity, low-skill/high-skill); the supply of labor (immigrant labor, labor shortage, attractiveness); and the division of labor (control, outsourcing).

As concerns the labor market, two areas of research seem essential for understanding the dynamics of adoption of robots in agriculture. First, Marinoudi et al. (2019) remind us that the importance of unregistered workers and seasonal workers in agriculture makes macroeconomic approaches to the labor market inadequate for understanding the dynamics of automation. They propose “a bottom-up approach where the analysis should start from the farm level” in order to measure and predict the effect of automation in agricultural labor market. Second, the role of territorial labor markets in the adoption of robots are little considered in the literature. However, Hansen (2015) explains how territorial dynamics are shaping the adoption of AMS in Norway: “The dominating position of the oil sector in the area, which has driven up wages and led to a shortage of skilled farming labor, is also relevant to the adoption of AMS. Thus both the employment rate and the wage level are among the highest in Norway.” And many other spatial dynamics can have an influence on the labor market and thus on the adoption and deployment of AMS (areas of protected designation of origin, employment areas, topography and travel time, etc.).

As for the question of whether agricultural robots are suitable for large or for small farms, we have seen that the results are quite divergent. Because robotization is not just a new stage of productivity in the historical differentiation of farms (Mazoyer and Roudart 2012) but the result of new social aspirations of work, it is necessary to understand the diversity of work situations in order to understand which types of farms adopt the use of a robot. An approach based on the historical trajectories of both farming systems and labor groups seems more relevant to understand the diversity of robotized farms.

As for the division of labor, we propose to analyze it at three levels: (1) within the farm, (2) between the farm workers and their professional environment, and (3) within territorial collectives.

-

(1)

Robotization raises questions about another on-farm transformation: the increase in salaried employment (Dedieu 2019). Two results show a link between salaried employment and robot development: i) the robot can facilitate the control of work and thus facilitate the development of salaried employment (Sparrow and Howard 2021; Prause 2021) in a sector that is still essentially family-based (Hayami 2002). And ii), the robot can make the farm more attractive to prospective salaried workers (Lundström and Lindblom 2021). To explore this aspect, research needs to be conducted on the social relations of production between the different workers on the farm (hierarchy, roles, participation in decision-making, interpersonal relations, political experience, etc.).

-

(2)

The social relationships between farm workers and their off-farm professional environment (veterinarians, consultants, robot manufacturers, suppliers, etc.) are also an interesting area of research. For example, what is the nature of the relationship between the robot’s after-sales service technicians and the farmers, and does this relationship reconfigure the relationship between the farmer and his advisor? While the evolution of these relationships has been explored for several technologies (Eastwood et al. 2019), robotics has so far remained absent from this field of study.

-

(3)

Finally, the social relationships between farmers are manifested in collectives (machinery cooperatives, mutual help groups, designations of origin, etc.). Does the robot contribute to new working relationships within these groups? Doesn’t the emergence of self-help groups around the robot in France (Paysan Breton 2017) and the conflicts concerning the evolution of the specifications of some cheese designations of origin in France (European Commission 2018) and Switzerland (Galliker 2021) call for a study of the transformations by the milking robot of the collective dimensions of work?

8.3 Work organization

Changes in the organizational dimension of work are relatively well documented. But for this analytical dimension, most of the results pertain to the AMS. We can group them into six sub-dimensions: physical workload; work flexibility; relocation of tasks and time organization of the different farming tasks; adjustment period during the transition to the robot; change in herd management; data management and alarms monitoring.

The predominance of the “animal sciences” in the studies on transformations of work is reflected in the scales of analysis of organizational transformations. The livestock farming system is thus the preferred scale (31 of 90 papers) instead of the farm (farming system; Therond et al. 2017) or the activity system (Gasselin et al. 2012). However, even though milking robots are found mainly in western and northern Europe, areas where dairy farming is still largely linked to fodder production, it seems essential to characterize transformations of labor at the farming system level. In the same way, the importance of pluriactivity in agriculture (Blad 2010; Loughrey et al. 2013) calls for the analysis of transformations at the scale of the activity system.

Furthermore, our results show how robotization reshapes the boundaries of work. Since they are on permanent duty, workers feel that work is intruding into their private lives. Analyses of work organization must integrate these new boundaries of work.

8.4 Meaning of work

Three aspects of the meaning of work are studied by our corpus: mental workload and technostress, changes in humans’ relationships with the animal, and robotization and the shaping of a new farmer. Many other dimensions of the meaning of work remain to be studied (i.e. usefulness, quality, recognition, autonomy, coherence, learning, relationships, sensoriality) (Rosso et al. 2010; Dejours 2012). The results concerning the AMS show that the robot changes the working relationship of the human to the animal. The relationship with the living (animals, plants, soil) is a central element of the farmer’s work. The other robots must also be examined with regard to this singular aspect of agricultural work. The robot is profoundly changing the autonomy of farmers. The substitution of a part of the analysis of information by robots can lead to a loss of control and even of the sense of work. The loss of autonomy because of the dependence on the company supplying the robots must also be examined, especially since the development of robots in agriculture can favor outsourcing and delivery of services (Spykman et al. 2021). This loss of autonomy due to the use of robots and the need to maintain/repair them must also be investigated, as also the dependence in managing and using data.

8.5 Work performances

Work performance is the dimension most covered by our corpus (57% of the records analyze this dimension). These performance metrics are mainly technical and economic and essentially concern the livestock system: labor time, revenues, margins, profitability, break-even, costs, productivity, yields and milking frequency. The performance of the robot is also studied by the impact on the animal (animal health and wellbeing) and on the product (milk quality) but these aspects are not included in our framework for analyzing work.

Despite the wide range of economic studies on AMS, the impact of robotization on the sharing of added value remains little explored. In addition, a study of changes in worker remuneration could provide interesting insights into this “performance” dimension by differentiating between the types of workers (notably seasonal/permanent, family/partnership/employees).

Finally, the reduction in working time resulting from the adoption of agricultural robotics is often taken for granted and not debated. However, our bias analysis shows that there is currently no evidence of a reduction in working time following the adoption of an AMS. The diversity of results and, in particular, the significant role of biases in quantitative studies call for a more in-depth assessment of working time (see “Recommendations” in additional material). However, the attention devoted to this reduction in working time should not mask the diversity of the transformations of work, which require more than just a quantitative view.

9 Conclusion

The agricultural model inherited from the second half of the 20th century is facing a major crisis (McMichael 2009). Agricultural robotics is often advanced as a solution to the problems posed by this agricultural model. Its proponents claim that it contributes precision, leading to a more sustainable agriculture while freeing farmers from the constraints of their often arduous work. According to them, agricultural robotics should therefore make it possible to reconcile the interests of society with those of farmers. Faced with this promise, some voices are warning of the replacement of a large body of agricultural workers and the industrialization of agriculture. The current state of knowledge on the transformation of work allows us to affirm three things. First, our results show that the majority of knowledge on work transformations concerns the AMS (67%). Given the specificities of its development, it is difficult to generalize results and conclusions to all agricultural robots. Studies on other robots are required to better characterize these work transformations. Second, these transformations are challenging some of the conventional wisdom, which states that the robot results in a reduction in working time and is a technology best suited for large farms. Our results show that the adoption of robots leads more to a reorganization of work in time and space than to a real reduction in working time. Moreover, AMS is mainly being adopted in medium-sized farms, a development that differs in scale and scope from that of industrial robotics in large-scale factories. Agricultural work has its own specificities, which means that the usual patterns of robotics development from other sectors do not apply to agriculture. And this incites us to study the real transformations of agricultural work without preconceptions. Third, in the study of the transformations associated with the robotization of agriculture, work is not yet a field of study in itself. A major research focus on work seems essential to inform debates and public policies on the effects of these innovations. This research is all the more necessary since agricultural robotics is promoted as a development model for agriculture and is supported by public policies. Moreover, farm labor is becoming an increasingly important social and political issue. For example, the Common Agricultural Policy is likely to include certain labor law standards in the conditions for obtaining European subsidies (Foote 2021).

The main limitation of the review process used is the potential exclusion of studies exploring transformations of work without the mentioned work lexicons. Indeed, work is a complex, multidisciplinary object of study with many representations. Therefore, this SRL does not consider all the approaches to work. However, it does propose a broad and multidisciplinary analysis of work on the farm. More results could have been found by extending the query to other languages and other databases. We have chosen the method of systematic literature review. This method allows us to synthesize a diversity of answers to our issue: the transformations of work arising from robotization. A narrative review would be complementary to this SRL and could provide a critical interpretation of certain results (Greenhalgh et al. 2018). Finally, the dynamics of publication show a significant growth in the number of publications in the last two years (20 publications out of 90 date from the last two years). This is why a regular update of this SRL would be necessary in order to update the results as new robots appear on farms.

Data availability

Lists of publications included and excluded by the selection process are available in the supplementary material.

Code availability

The queries used for data collection on Web of Science and Scopus are available in the search protocol (Martin et al. 2020).

References

Abboud L (2018) The robot revolution down on the farm. In: Financial Times. https://www.ft.com/content/5854088a-ddda-11e8-b173-ebef6ab1374a. Accessed 31 Jan 2022

Alarcón C (2021) Agrarian questions, digitalisation of the countryside, immigrant labour in agriculture and the official discourses on rural development in the Uppsala region, Sweden. Italian Review of Agricultural Economics 76:19–32. https://doi.org/10.36253/rea-12824

Ampatzidis Y, De Bellis L, Luvisi A (2017) iPathology: Robotic applications and management of plants and plant diseases. Sustainability (Switzerland) 9:1–14. https://doi.org/10.3390/su9061010

Arvanitis KG, Symeonaki EG (2020) Agriculture 4.0: The Role of Innovative Smart Technologies Towards Sustainable Farm Management. The Open Agriculture Journal 14:130–135. https://doi.org/10.2174/1874331502014010130

Asimov I (2004) I, Robot. Bantam Books, New York

Auverlot G, Bel M, Clergerie A, et al (2016) La Révolution Numérique. Ministère de l’Agriculture, de l’Agroalimentaire et de la Forêt

Basso B, Antle J (2020) Digital agriculture to design sustainable agricultural systems. Nature Sustainability 3:254–256. https://doi.org/10.1038/s41893-020-0510-0

Bear C, Holloway L (2015) Country Life: Agricultural Technologies and the Emergence of New Rural Subjectivities. Geography Compass 9:303–315. https://doi.org/10.1111/gec3.12217

Bear C, Holloway L (2018) Redistributing labour in automated, milking systems and the more-than-human (Co)production of dairy farming. In: The SAGE handbook of nature: three volume set. SAGE Publications Ltd, London, pp 831–847

Bear C, Holloway L (2019) Beyond resistance: Geographies of divergent more-than-human conduct in robotic milking. Geoforum 104:212–221. https://doi.org/10.1016/j.geoforum.2019.04.030

Bergman K, Rabinowicz E (2013) Adoption of the Automatic Milking System by Swedish Milk Producers. AgriFood economics centre

Bijl R, Kooistra SR, Hogeveen H (2007) The profitability of automatic milking on Dutch dairy farms. Journal of Dairy Science 90:239–248. https://doi.org/10.3168/jds.S0022-0302(07)72625-5

Bisaglia C, Belle Z, Van Den Berg G, Pompe JCAM (2012) Automatic vs. conventional feeding systems in robotic milking dairy farms: a survey in The Netherlands. In: International Conference of Agricultural Engineering CIGR-AgEng 2012. Valencia, Spain, pp 5–10

Blad M (2010) Pluriactivity of farming families - old phenomenon in new times. European Rural Development Network Studies 155–165. https://doi.org/10.22004/AG.ECON.139799

Blanc M, Cahuzac E, Elyakime B, Tahar G (2008) Demand for on-farm permanent hired labour on family holdings. European Review of Agricultural Economics 35:493–518. https://doi.org/10.1093/erae/jbn032

BMJ (2015) Introducing ‘How to write and publish a Study Protocol’ using BMJ’s new eLearning pogramme: Research to Publication. https://blogs.bmj.com/bmjopen/2015/09/22/introducing-how-to-write-and-publish-a-study-protocol-using-bmjs-new-elearning-programme-research-to-publication/. Accessed 31 Jan 2022

Brandessence Market Research and Consulting (2021) At 28.7% CAGR , Agriculture Robots Market Size is Projected to Exceed USD 26679.4 Million by 2027, Says Brandessence Market Research. https://www.globenewswire.com/news-release/2021/07/15/2263678/0/en/At-28-7-CAGR-Agriculture-Robots-Market-Size-is-Projected-to-Exceed-USD-26679-4-Million-by-2027-Says-Brandessence-Market-Research.html. Accessed 31 Jan 2022

Breton P (2017) Entraide et achat groupé autour des robots de traite. https://www.paysan-breton.fr/2017/04/entraide-et-achat-groupe-autour-des-robots-de-traite/. Accessed 31 Jan 2022

Bugge CT, Skibrek PK (2019) Success with AMS: A quantitative study of what determines success of farmers using Automatic Milking Systems (AMS) in Norway. Master thesis in Financial Economics, Norwegian School of Economics

Butler D, Holloway L (2016) Technology and Restructuring the Social Field of Dairy Farming: Hybrid Capitals, ‘Stockmanship’ and Automatic Milking Systems. Sociologia Ruralis 56:513–530. https://doi.org/10.1111/soru.12103

Butler D, Holloway L, Bear C (2012) The impact of technological change in dairy farming: robotic milking systems and the changing role of the stockperson. Journal of the Royal Agricultural Society of England 173:1–6

Caffaro F, Cavallo E (2019) The effects of individual variables, farming system characteristics and perceived barriers on actual use of smart farming technologies: Evidence from the piedmont region, northwestern Italy. Agriculture (Switzerland) 9:. https://doi.org/10.3390/agriculture9050111

Capek K (2004) R.U.R. (Rossum’s Universal Robots). Penguin Classics

Carolan M (2019) Automated agrifood futures: robotics, labor and the distributive politics of digital agriculture. The Journal of Peasant Studies 1–24. https://doi.org/10.1080/03066150.2019.1584189

Castro A, Pereira JM, Amiama C, Bueno J (2015) Typologies of dairy farms with automatic milking system in northwest spain and farmers’ satisfaction. Italian Journal of Animal Science 14:207–219. https://doi.org/10.4081/ijas.2015.3559

Christiaensen L, Rutledge Z, Taylor JE (2020) The future of work in agriculture. World Bank Group

Cornou C (2009) Automation systems for farm animals: potential impacts on the human-animal relationship and on animal welfare. Anthrozoos 22:213–220. https://doi.org/10.2752/175303709X457568

Da Borso F, Chiumenti A, Sigura M, Pezzuolo A (2017) Influence of automatic feeding systems on design and management of dairy farms. Journal of Agricultural Engineering 48:48–52. https://doi.org/10.4081/jae.2017.642

Daum T (2021) Farm robots: ecological utopia or dystopia? Trends in Ecology & Evolution 36:774–777. https://doi.org/10.1016/j.tree.2021.06.002

De Jong W, Finnema A (2003) Survey of management practices of farms using automatic milking systems in North America. In: ASAE Annual International Meeting. Las Vegas

de Koning CJAM (2011) Robotic milking. In: Fuquay JW (ed) Encyclopedia of Dairy Sciences, second edition, pp 952–958

De Stefano V (2018) “Negotiating the algorithm”: Automation, artificial intelligence and labour protection. Internation Labour Office, Geneve

Dedieu B (2019) Transversal views on work in agriculture. Cahiers Agricultures 28:8. https://doi.org/10.1051/cagri/2019008

Dejours C (2012) From the psychopathology to the psychodynamics of work. In: Smith, Nicholas, and Jean-Philippe Dr Deranty, eds. New philosophies of labour: work and the social bond. Vol. 13:209–250

DeLaval (2021) DeLaval VMSTM V300. https://www.delaval.com/fr-fr/nos-solutions/traite/vms/v300/. Accessed 17 May 2021

Dijkhuizen AA, Huirne RBM, Harsh SB, Gardner RW (1997) Economics of robot application. Computers and Electronics in Agriculture 17:111–121. https://doi.org/10.1016/s0168-1699(96)01228-8

Drach U, Halachmi I, Pnini T, Izhaki I, Degani A (2017) Automatic herding reduces labour and increases milking frequency in robotic milking. Biosystems Engineering 155:134–141. https://doi.org/10.1016/j.biosystemseng.2016.12.010

Driessen C, Heutinck LFM (2014) Cows desiring to be milked? Milking robots and the co-evolution of ethics and technology on Dutch dairy farms. Agriculture and Human Values 32:3–20. https://doi.org/10.1007/s10460-014-9515-5

Dusty W (2017) How Smart Farms Are Making the Case for Rural Broadband. In: Association of Equipment Manufacturers. https://www.aem.org/news/how-smart-farms-are-making-the-case-for-rural-broadband. Accessed 29 Sep 2020

Eastwood C, Ayre M, Nettle R, Dela Rue B (2019) Making sense in the cloud: Farm advisory services in a smart farming future. NJAS - Wageningen Journal of Life Sciences 90–91:100298–100210. https://doi.org/10.1016/j.njas.2019.04.004

Engineers Australia (2021) The future of agriculture is in robotic farmers. https://www.engineersaustralia.org.au/News/future-agriculture-robotic-farmers. Accessed 31 Jan 2022

European Commission (2018) Official Journal of the European Union - Acte 2018/C187/07

European Commission (2021) Projects story: Autonomous robots to revolutionise agriculture. In: Shaping Europe’s digital future. https://digital-strategy.ec.europa.eu/en/news/autonomous-robots-revolutionise-agriculture. Accessed 31 Jan 2022

Ferland J, Vasseur E, Duplessis M, Pajor EA, Pellerin D (2016) Economic impact of introducing automatic milking system on Canadian dairy farms. Journal of Animal Science 94:600–601. https://doi.org/10.2527/jam2016-1246

Finstad T, Aune M, Egseth KA (2021) The domestication triangle: How humans, animals and technology shape each other – The case of automated milking systems. Journal of Rural Studies 84:211–220. https://doi.org/10.1016/j.jrurstud.2021.03.006

Foote N (2021) Fight over inclusion of labour rights in CAP heats up. In: Euractiv. https://www.euractiv.com/section/agriculture-food/news/fight-over-inclusion-of-labour-rights-in-cap-heats-up/. Accessed 1 Feb 2022

Fountas S, Espejo-Garcia B, Kasimati A, Mylonas N, Darra N (2020) The Future of Digital Agriculture: Technologies and Opportunities. IT Professional 22:24–28. https://doi.org/10.1109/MITP.2019.2963412

Francis S (2021) Global agriculture robot market expected to quadruple in size by 2026. In: Robotics and Automation News. https://roboticsandautomationnews.com/2021/06/14/global-agriculture-robot-market-expected-to-quadruple-in-size-by-2026/43841/. Accessed 31 Jan 2022

Frandsen TF, Bruun Nielsen MF, Lindhardt CL, Eriksen MB (2020) Using the full PICO model as a search tool for systematic reviews resulted in lower recall for some PICO elements. Journal of Clinical Epidemiology 127:69–75. https://doi.org/10.1016/j.jclinepi.2020.07.005

Gallardo RK, Sauer J (2018) Adoption of Labor-Saving Technologies in Agriculture. Annual Review of Resource Economics 10:185–206. https://doi.org/10.1146/annurev-resource-100517-023018

Galliker S (2021) Fronde vaudoise pour le retour du robot de traite. In: 24heures. https://www.24heures.ch/fronde-vaudoise-pour-le-retour-du-robot-de-traite-650522361041. Accessed 31 Jan 2022

Gargiulo JI, Eastwood CR, Garcia SC, Lyons NA (2018) Dairy farmers with larger herd sizes adopt more precision dairy technologies. Journal of Dairy Science 101:5466–5473. https://doi.org/10.3168/jds.2017-13324

Gargiulo JI, Lyons NA, Kempton K, Armstrong DA, Garcia SC (2020) Physical and economic comparison of pasture-based automatic and conventional milking systems. Journal of Dairy Science 103:8231–8240. https://doi.org/10.3168/jds.2020-18317

Gasselin P, Vaillant M, Bathfield B (2012) The activity system. A position paper. In: 10th European IFSA symposium ” producing and reproducing farming systems: New modes of organization for the sustainable food systems of tomorrow”. Aarhus, Denmark

Gleeson D, O’Brien B, O’Donovan K (2008) The labour input associated with calf care on Irish dairy farms. Livestock Science 116:82–89. https://doi.org/10.1016/j.livsci.2007.08.019

Greenhalgh T, Thorne S, Malterud K (2018) Time to challenge the spurious hierarchy of systematic over narrative reviews? 1–6. https://doi.org/10.1111/eci.12931

Grothmann A, Nydegger F, Häussermann A, Hartung E (2010) Automatic feeding systems (AFS) – potential for optimisation in dairy farming. Agricultural Engineering 65:129–131. https://doi.org/10.15150/lt.2010.610

Gustafsson M (2004) Working time studies in farms with conventional and automatic milking. In: Meijering A, Hogeveen H, de Koning CJAM (eds) Automatic milking. Wageningen Academic Publishers, For a better understanding, p 488

Hackfort S (2021) Patterns of Inequalities in Digital Agriculture : A Systematic Literature Review. Sustainability 13. https://doi.org/10.3390/su132212345

Hansen BG (2015) Robotic milking-farmer experiences and adoption rate in Jæren, Norway. Journal of Rural Studies 41:109–117. https://doi.org/10.1016/j.jrurstud.2015.08.004

Hansen BG, Bugge CT, Skibrek PK (2020) Automatic milking systems and farmer wellbeing–exploring the effects of automation and digitalization in dairy farming. Journal of Rural Studies 80:469–480. https://doi.org/10.1016/j.jrurstud.2020.10.028

Hansen BG, Herje HO, Höva J (2019) Profitability on dairy farms with automatic milking systems compared to farms with conventional milking systems. International Food and Agribusiness Management Review 22:215–228. https://doi.org/10.22434/IFAMR2018.0028

Hansen BG, Stræte EP (2020) Dairy farmers’ job satisfaction and the influence of automatic milking systems. NJAS - Wageningen Journal of Life Sciences 92:100328–100313. https://doi.org/10.1016/j.njas.2020.100328

Hayami Y (2002) Family farms and plantations in tropical development. Asian Development Review 19:67–89

Heikkila A-M, Myyra S, Pietola K (2012) Effects of economic factors on adoption of robotics and consequences of automation for productivity growth of dairy Farms. Centre for European Policy Studies (CEPS), Brussels

Heikkila A-M, Vanninen L, Manninen E (2010) Economics of Small-Scale Dairy Farms Having Robotic Milking. In: First North American Conference on precision dairy management. Toronto

Hogeveen H, Heemskerk K, Mathijs E (2004) Motivations of Dutch farmers to invest in an automatic milking system or a conventional milking parlour. In: Meijering A, Hogeveen H, de Koning CJAM (eds) Automatic milking. For a better understanding. Wageningen Academic Publishers, Wageningen, pp 56–61

Holloway L, Bear C (2017) Bovine and human becomings in histories of dairy technologies: robotic milking systems and remaking animal and human subjectivity. British Society for the History of Science 2:215–234. https://doi.org/10.1017/bjt.2017.2

Holloway L, Bear C, Wilkinson K (2014a) Robotic milking technologies and renegotiating situated ethical relationships on UK dairy farms. Agriculture and Human Values 31:185–199. https://doi.org/10.1007/s10460-013-9473-3

Holloway L, Bear C, Wilkinson K (2014b) Re-capturing bovine life: Robot-cow relationships, freedom and control in dairy farming. Journal of Rural Studies 33:131–140. https://doi.org/10.1016/j.jrurstud.2013.01.006

Horsley T, Dingwall O, Sampson M (2011) Checking reference lists to find additional studies for systematic reviews. Cochrane Database of Systematic Reviews 2011:. https://doi.org/10.1002/14651858.MR000026.pub2

Hostiou N, Fagon J, Chauvat S, Turlot A, Kling-Eveillard F, Boivin X, Allain C (2017a) Impact of precision livestock farming on work and human-animal interactions on dairy farms. A review. Biotechnology. Agronomy and Society and Environment 21:268–275. https://doi.org/10.25518/1780-4507.13706

Hostiou N, Kling-Eveillard F, Ganis E (2017b) The effects of PLF on human-animal relationships on farms. In: 8th European Conference on Precision Livestock Farming (ECPLF). Nantes, p 9

Hostiou N, Vollet D, Benoit M, Delfosse C (2020) Employment and farmers’ work in European ruminant livestock farms: A review. Journal of Rural Studies 74:223–234. https://doi.org/10.1016/j.jrurstud.2020.01.008

International Organization for Standardization (2012) ISO 8373:2012, Robots and robotic devices - Vocabulary. https://www.iso.org/obp/ui/#iso:std:iso:8373:ed-2:v1:en. Accessed 7 Feb 2022

Jacobs JA, Siegford JM (2012) Invited review: The impact of automatic milking systems on dairy cow management, behavior, health, and welfare. Journal of Dairy Science 95:2227–2247. https://doi.org/10.3168/jds.2011-4943

Jago JG, Davis KL, Newman M, Woolford MW (2006) An economic evaluation of automatic milking systems for New Zealand dairy farms. In: Proceedings of the New Zealand Society of Animal Production. Napier, New Zealand, pp 263–269