Abstract

Resistive switching memory devices with tantalum oxide (\(\hbox {TaO}_{\textrm{x}}\)) and hafnium oxide (\(\hbox {HfO}_{\textrm{x}}\)) mono- and bilayers were fabricated using atomic layer deposition. The bilayer devices with Ti and TiN electrodes show non-linear switching characteristics, and can operate without requiring an initial electroforming step. The insertion of the \(\hbox {HfO}_{\textrm{x}}\) layer induces the switching behaviour on single layer \(\hbox {TaO}_{\textrm{x}}\) that shows Zener diode-like characteristics, with conductivity depending on the top electrode metal. The electronic conductivity mechanism study shows Schottky emission at low voltage regime followed by tunneling at higher applied bias, both indicating interface-dominated conduction. The switching mechanism study is supported by X-ray photoelectron spectroscopy characterization of the films that show a formation of \(\hbox {TaO}_{\textrm{x}}\hbox {N}_{\textrm{y}}\) and \(\hbox {TaN}_{\textrm{x}}\) species at the oxide-electrode interface. This interfacial layer serves as a high resistivity barrier layer enabling the homogeneous resistive switching behavior.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Resistive random access memory (RRAM) is considered to be the most promising candidate to replace the NAND flash memory when its scaling ends [1]. The advantages of the RRAM include its simple structure, feasibility for high-density 3D applications, and low-power consumption [2]. However, the remaining challenges, such as the need for a high-voltage electroforming and current sneak-path issues in the array have hindered the commercialization of the RRAM technology [2, 3]. Electroforming-free RRAM are particularly necessary when considering the low-voltage supplies supported by more advanced CMOS technology nodes [4]. Meanwhile, in order to avoid the sneak-path issues in the array configuration, the RRAM cell is usually stacked with a selector (either diode or transistor) to produce non-linear \(I-V\) behavior [5].

Employing a bilayer stack in the resistive switching memory cell can overcome some of the RRAM issues by reducing the forming voltages, and improving the switching stability and uniformity [6]. Bilayer systems can also stabilize the multi-bit operation in the analog resistive switching performance, which is a critical factor for the high-capacity memory applications [7], as well as in the adaptation of these devices in neuromorphic computing [8].

\(\hbox {TaO}_{\textrm{x}}\) and \(\hbox {HfO}_{\textrm{x}}\) bilayers for resistive switching have demonstrated to have forming-free and self-rectifying characteristics when combined with noble metal electrodes such as Pt [9,10,11,12,13,14,15]. However, there seems to be discrepancies in the reported device operation, i.e. whether the resistive switching takes place in the \(\hbox {TaO}_{\textrm{x}}\) [12, 13], or \(\hbox {HfO}_{\textrm{x}}\) layer [9, 11], and it is clear that the oxide deposition methods, layer thicknesses, electrode materials, and oxide-metal and oxide-oxide interfaces all play significant roles in the device operation and performance. For instance, in the reports on \(\hbox {TaO}_{\textrm{x}}\) & \(\hbox {HfO}_{\textrm{x}}\) bilayer memory devices either one, typically \(\hbox {TaO}_{\textrm{x}}\) [13,14,15], or both [10] oxide layers are fabricated using physical vapor deposition (PVD) methods, namely magnetron/RF sputtering. PVD provides better tuneability on the stoichiometry and vacancy concentration via the control of the oxygen partial pressure during the deposition, and in these devices the resistive switching can be attributed to the formation of the conductive filament in the thicker (> 10 nm) \(\hbox {TaO}_{\textrm{x}}\) layer [13]. In devices where both of the layers are fabricated by chemical approaches such as atomic layer deposition (ALD), e.g. Refs [9, 11], with the \(\hbox {HfO}_{\textrm{x}}\) grown first on the bottom electrode in Pt/\(\hbox {TaO}_{\textrm{x}}\)/\(\hbox {HfO}_{\textrm{x}}\)/TiN stacks, the interfaces between the subsequently deposited layers appear critical: e.g. by chemical modification leading to increased number of deep trap states within the film that enable the resistive switching, or by forming Schottky barriers to constitute the rectifying behaviour [9, 11].

In this paper we propose that the electroforming-free and the non-linear behavior can be achieved by a (\(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\)) bilayer RRAM design without the necessity of a selector stack. Tuneable non-linearity capability of a single RRAM cell is a highly desirable feature as it can ideally be utilized in fabrication of small footprint crossbar arrays as the non-linearity could eliminate the need for external selector devices [16, 17]. Atomic layer deposited (ALD) Ta and Hf oxides were chosen as they have already shown compatibility with existing technologies and back-end-of-line (BEOL) processes for monolithic 3D integration [18, 19]. The use of ALD also enables the fabrication of uniform and pinhole-free films, allowing the use of ultra-thin films in the resistive switching devices also in vertical geometries, and thus the miniaturization of memory components to match the advanced technology nodes.

2 Methods

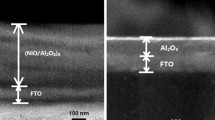

The patterning of device structures were done on 150 mm Si wafers with 200 nm thermal oxide. A photolithography process with negative photoresist (AZ2070, MicroChemicals GmbH) was used for the lift-off patterning of bottom electrodes: room-temperature sputtered (Angstrom Engineering) 50 nm TiN with 10 nm Ti adhesion layer between the TiN and \(\hbox {SiO}_2\). A Ti target was used in the TiN reactive sputtering with nitrogen plasma (20 sccm, 10 mTorr, 600 W). The \(\hbox {TaO}_{\textrm{x}}\) layer (5 nm) was deposited by plasma-enhanced atomic layer deposition (ALD) (Oxford Instruments FlexAL, with 13.56 MHz remote inductively-coupled plasma source) using pentakis(dimethylamino)tantalum (PDMAT, Ta(N(\(\hbox {CH}_3\))\(_2\))\(_5\) from Pegasus Chemicals) precursor with \(\hbox {O}_2\)-plasma as the oxygen source. The PDMAT source was kept at \({65}\,^{\circ }\hbox {C}\) and the \(\hbox {TaO}_{\textrm{x}}\) deposition temperature was \({200}\,^{\circ }\hbox {C}\). One ALD cycle consisted of 1.25 s PDMAT pulse/8 s purge/4 s \(\hbox {O}_2\)-plasma pulse (250 W, 50 sccm \(\hbox {O}_2\) flow)/3 s purge. This process yielded a growth per cycle (GPC) of 0.93 Å on \(\hbox {SiO}_2\)/Si substrate, measured by a spectroscopic ellipsometer (J A Woollam M-2000). Subsequently, the wafer was transferred to another ALD reactor (Veeco Savannah S200) where the \(\hbox {HfO}_{\textrm{x}}\) (3 nm), was grown by thermal ALD process at \({175}\,^{\circ }\hbox {C}\) using tetrakis(dimethylamino)hafnium (TDMAH, \(\hbox {Hf}(\hbox {N}(\hbox {CH}_3)_2)_4\) from Sigma-Aldrich), sublimed at \({75}\,^{\circ }\hbox {C}\), and \(\hbox {H}_2\)O. Each \(\hbox {HfO}_{\textrm{x}}\) ALD cycle consisted of 0.2 s TDMAH pulse/10 s purge/0.03 s \(\hbox {H}_2\)O pulse/10 s purge. Prior to the TDMAH pulse Ar was released in the precursor container for 0.05 s via a boost valve to enable enhanced precursor delivery to the deposition chamber. The \(\hbox {HfO}_2\) GPC on \(\hbox {SiO}_2\)/Si substrate was 1.05 Å. A positive photoresist (Microposit S1813) was used as an etching mask for oxide patterning by ion beam etching (Oxford Instruments Ionfab 300, 800 W Ar beam) prior to deposition of top electrodes (TE). 60 nm TiN or 10 nm Ti + 15 nm Pt top electrodes were fabricated similarly to the bottom electrodes, using negative photoresist lift-off process and magnetron sputtering at room temperature. In the Pt/Ti top electrode stacks the Pt served as an oxidation barrier to prevent the formation of insulating \(\hbox {TiO}_2\) layer on the electrode surface. The electrode materials were selected because they are typical semiconductor processing materials, Ti is commonly used for metal interconnects and TiN in diffusion barriers. The device structure and layout are presented in Fig. 1a. For materials characterization, single \(\hbox {TaO}_{\textrm{x}}\) and \(\hbox {HfO}_{\textrm{x}}\) films on on \(\hbox {SiO}_2\)/Si, and unpatterned TE/\(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\)/TiN samples were prepared. For XPS depth profiling the TiN top electrode thickness was reduced from 60 to 20 nm.

Atomic force microscopy (AFM, Bruker Icon) in peak force mode was used to investigate the topographic properties of the thin film stacks. X-ray photoelectron spectroscopy (XPS, ThermoFisher ThetaProbe with Al \(\hbox {K}_{\upalpha }\) 1.487 eV X-ray source, beam spot diameter 400 \(\upmu \hbox {m}\)) was used to characterize the oxide films and to depth profile the device stacks. For depth profiling \(\hbox {Ar}^+\) ion etching was applied (1 kV, \(1~\upmu \hbox {A}\), raster area 2 mm \(\times \) 2 mm) and core level spectra of relevant elements were collected after each 30 s etch step. \(\hbox {Ar}^+\) beam etch with lower energy (0.5 keV) was used for surface cleaning before measuring the oxide film samples. The XPS data was analysed using CasaXPS analysis software, shirley background was used in the peak deconvolution together with Gaussian-Lorentzian GL(30) lineshape, except for metallic and nitride peaks, where an asymmetric lineshape was used. The devices were measured using a Cascade probe station and ArC One measurement platform. During the measurement the positive and negative bias voltages were applied to the top electrode while the bottom electrode was kept grounded.

3 Results and Discussion

3.1 Preliminary Materials Characterization

Prior to the device fabrication, the growth and physical properties of the ALD oxide films were investigated. The XPS analysis of 10 nm oxide films grown on \(\hbox {SiO}_2\)/Si substrates confirmed that the used ALD processes yielded nearly stoichiometric \(\hbox {HfO}_2\) and \(\hbox {Ta}_2\hbox {O}_5\) films, with very minor sub-oxide concentration detected in the tantalum oxide film, presented in Fig. 1b, c respectively. The excess oxygen can be associated with the hydrogen-containing species, namely -OH and physisorbed water, as shown in the Supporting Information Figs. S1 and S2. In the \(\hbox {Ta}_2\hbox {O}_5\) film a minor carbon content (\(\le \) 1%) was also measured, but no other impurities were detected. The sub-oxides and impurities were also shown as a slight increase in the gap states ca. 1.4 eV below the Fermi level in the valence band edge spectrum of the \(\hbox {TaO}_{\textrm{x}}\) sample, seen in Fig. S2d. Atomic force microscopy scans confirmed that each of the subsequently deposited layer (bottom TiN, \(\hbox {TaO}_{\textrm{x}}\), and \(\hbox {HfO}_{\textrm{x}}\)) is uniform and smooth, with RMS roughness of the \(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\)/TiN film stack being \(r_{\textrm{RMS}}\,\approx \, 0.2\) nm (Fig. 1d). The AFM images of the TiN bottom electrode and \(\hbox {TaO}_{\textrm{x}}\)/TiN layers are presented in Fig. S3.

a Top: an example of the cross-point device layout, the dark features on the top and left of the image are the attached probes of the probecard measurement setup; bottom: a schematic of the device structure. b XPS Hf 4f spectrum of \(\hbox {HfO}_{\textrm{x}}\) film and c XPS Ta4f spectrum of \(\hbox {TaO}_{\textrm{x}}\) film, both deposited on \(\hbox {SiO}_{2}\hbox {/Si}\). d Atomic force micrograph of 3 nm \(\hbox {HfO}_{\textrm{x}}\)/5 nm \(\hbox {TaO}_{\textrm{x}}\)/50 nm TiN thin film stack

3.2 Device Characterization

Monolayers: No resistive switching was observed in monolayer \(\hbox {HfO}_{\textrm{x}}\) and \(\hbox {TaO}_{\textrm{x}}\) devices, as depicted in Figs. 2a(i–iv). Both the TE/\(\hbox {HfO}_{\textrm{x}}\)/TiN devices [Fig. 1a(i, ii)] exhibit pure ohmic conduction, as confirmed by the linear I-V behaviour (Fig. S4). The low resistance (R \(\approx \) 10 \(\hbox {k}\Omega \)) of the \(\hbox {HfO}_{\textrm{x}}\), even at higher film thickness up to 7 nm, is likely a result of the relatively low deposition temperature (175 \(^{\circ }\)C), which leads to a lower film density and increases contents of light element impurities, such as hydrogen and carbon, that can have a detrimental impact on the electrical characteristics [20, 21]. As discussed earlier, in our \(\hbox {HfO}_{\textrm{x}}\) films the carbon content was below the detection level of our XPS system (< 1 at%), but it was observed that the films contained ca. 10 % of excess, non Hf-bound oxygen in the form of hydrogen containing species i.e. hydroxyl OH– and physisorbed \(\hbox {H}_2\)O residues from the TDMAH + \(\hbox {H}_2\)O deposition process which can cause the observed high leakage current as high-mobility interstitials [22]. Hydrogen and hydrogen containing species can also hamper the formation and migration of the oxygen vacancies required for the resistive switching [23, 24], as well as accumulate into electron traps at the oxide-electrode interface [25].

a \(I-V\) characteristics of a monolayer \(\hbox {HfO}_{\textrm{x}}\) (7 nm) devices with (i) TiN and (ii) Pt/Ti top electrode; and a monolayer \(\hbox {TaO}_{\textrm{x}}\) (5 nm) devices with (iii) TiN and (iv) Pt/Ti top electrode. All the devices have TiN bottom electrodes. b \(I-V\) curves of the \(\hbox {TaO}_{\textrm{x}}\) monolayer devices with i TiN and ii Pt/Ti top electrodes, respectively, showing the regions where the Schottky emission (red) and Fowler–Nordheim tunneling (FNT, blue) dominate the electronic conduction. c Non-linearity ratio \(I(V_{\textrm{read}})/I(\frac{1}{2}V_{\textrm{read}})\) of the \(\hbox {TaO}_{\textrm{x}}\) monolayer devices with TiN (blue circles) and Pt/Ti (orange triangles) top electrodes, respectively. All the data in a–c are measured from pristine devices with 5 \(\times \) 5 \(\upmu \hbox {m}\) device area. (Color figure online)

Like the \(\hbox {HfO}_{\textrm{x}}\), the \(\hbox {TaO}_{\textrm{x}}\) monolayer devices exhibit no resistive switching behaviour, as shown in Fig. 2a(iii–iv). Instead, the \(\hbox {TaO}_{\textrm{x}}\) devices show Zener diode (varistor) characteristics, where the current below threshold voltage, approximately 1.5 V for TiN TE, and 0.5 V for Pt/Ti TE devices, respectively, is very low (0.1 nA regime), and increases rapidly above the threshold. The conduction mechanism analysis shows that the electron conduction is dominated by Schottky emission at the low-voltage range above the threshold voltage, and at higher voltages the Fowler–Nordheim tunneling becomes the dominant mechanism, as shown in Fig. 2b. The (\(\log (I) \propto \sqrt{V}\)) and (\(\log (I/V^2) \propto I/V\)) fits for defining the Schottky emission and the Fowler–Nordheim tunneling (FNT) regimes, respectively, are shown in Fig. S5. These results indicate that significant barrier height exists at the \(\hbox {TaO}_{\textrm{x}}\)/TiN junctions. In addition, the non-linearity ratio \(I(V_{\textrm{read}})/I(\frac{1}{2}V_{\textrm{read}})\) of the TiN/\(\hbox {TaO}_{\textrm{x}}\)device can achieve up to \(2.7\times 10^4\) when 2.8 V is applied. The Pt/Ti/\(\hbox {TaO}_{\textrm{x}}\) device also exhibit a non-linear behaviour, but with a more modest non-linearity ratio of \(\sim 200\) at 1.5 V \(V_{\text {read}}\) (Fig. 2c).

The Schottky emission and Fowler–Nordheim tunneling are well known electron transfer mechanisms in oxide thin film systems [26], including the \(\hbox {TaO}_{\textrm{x}}\) thin film diodes, where the dominant mechanisms are largely determined by the work function of the biased electrode [27]. Moreover TiN has a high metallic stability, and the oxidation of this film for TiON interfacial layer formation is a diffusion-limited process which doesn’t readily occur at room temperature [28]. Ti has more negative Gibbs free energy of \(\hbox {TiO}_{\textrm{x}}\) formation (\(\Delta \hbox {G}^{0}=-889.5\) kJ/mol) [29] than that of TiN forming TiON (\(\Delta \hbox {G}^{0}=-580.3\) kJ/mol) [28] which leads to more efficient oxygen scavenging from the oxide layer. When we replace the TiN top electrode with Ti, we can assume that a \(\hbox {TiO}_{\textrm{x}}\) layer forms at the interface. This \(\hbox {TiO}_{\textrm{x}}\) interfacial layer decreases the barrier height at the electrode/oxide interface via several different mechanisms e.g. change in the electron affinity of the formed oxide and formation of metal-induced gap states and positively charged defects [30], and hence, decreases the non-linearity of the Pt/Ti/\(\hbox {TaO}_{\textrm{x}}\) device.

Bilayers: the insertion of the thin (3 nm) \(\hbox {HfO}_{\textrm{x}}\) into the TE/\(\hbox {TaO}_{\textrm{x}}\)/TiN diode stack induces resistive switching behavior, as shown in Fig. 3a, b. The bilayer devices do not require a forming process to activate the switching characteristics, and they exhibit bipolar switching mode, where positive and negative bias turn On (set) and Off (reset) the device, respectively. The pristine TiN/\(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\)/TiN (TiN/bi-) devices have a high resistance both at high and low resistance states (HRS, LRS), ca. \(1~\hbox {G}\Omega \) at HRS and \(65~\hbox {M}\Omega \) at LRS, measured at \(\hbox {V}_{\textrm{read}}=1.5~\hbox {V}\). However, the HRS resistance decreases upon the initial \(I-V\) sweeping before stabilising to ca. \(200~\hbox {M}\Omega \), resulting in a switching ratio of 3 (Fig. 3c). The TiN/bi- devices can be swept up to 5 V with both polarities without breakdown. However, a voltage > 3 V is required to induce the switching, as devices swept with lower voltage range retain diode characteristics similar to the \(\hbox {TaO}_{\textrm{x}}\) monolayers (Fig. 3a). The conduction mechanisms in different bias regions are shown in Fig. 3b, with detailed analysis in Fig. S6a–c. The conduction mechanisms at the HRS and LRS are found to be similar to the TiN/\(\hbox {TaO}_{\textrm{x}}\)/TiN diodes with both the Schottky emission and Fowler–Nordheim tunneling present. Although the interfacial barriers are changing during the \(I-V\) sweeping due to processes that enable the resistive switching characteristics (redox, trapping/de-trapping, and ionic motions), these results indicate that the interface-limited electronic conduction mechanisms dominate also in the bilayer devices. However, if the bias voltage is further increased, the conduction mechanism switches to Frenkel–Poole emission, (\(\log (I/V) \propto \sqrt{V}\)), as depicted in Fig. 3b. Unlike Schottky emission and Fowler–Nordheim tunneling that are of interfacial type, the Frenkel–Poole emission at high voltage regime indicates a “soft breakdown” by filament formation, and an electron hopping mechanism which could possibly occur via donor defects in the films. Similar behaviour has been reported also with different material systems exhibiting analog resistive switching operation [31].

a \(I-V\) characteristics of bilayer \(\hbox {HfO}_{\textrm{x}}\) (3 nm)/\(\hbox {TaO}_{\textrm{x}}\) (5 nm) devices with (i) TiN and (ii) Pt/Ti top electrodes (TE), respectively. b Same \(I-V\) curves of the bilayer devices with (i) TiN and (ii) Pt/Ti TE highlighting the regions where the Schottky emission (red), Fowler–Nordheim tunneling (FNT, blue) and Frenkel-Poole emission (FP, green) dominate the electronic conduction. d Read margin (\(\Delta V/V\)) on the crossbar wordline number based on Eq. (1). e Endurance plots showing the stabilization of the high and low resistance states (HRS, LRS) of the TiN/bi- (top) and Pt/Ti/bi- (bottom) devices, measured from \(I-V\) sweeps at \(V_{\textrm{read}} = 1.5\) V. d Potentiation(P)/Depression(D) plots of a Pt/Ti/bi- device with pulse scheme amplitudes of 3.5 V (P) & \(-\)3.5 V (D) (black) and 3.5 V (P) and \(-4.0\) V (D) (blue), respectively; note that the pulse width is 0.1 ms and \(V_{\textrm{read}} = 1.5\) V. (Color figure online)

As in the case of the \(\hbox {TaO}_{\textrm{x}}\) monolayer device characteristics, the choice of the TE metal has a significant impact on the device performance. Figure 3a(ii), b(ii) show \(I-V\) curve of a Pt/Ti/\(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\)/TiN (Pt/Ti/bi-) device. It is found that the device can operate at a lower set and reset voltages (±3 V) compared to the TiN/bi- devices. The endurance sweep resistances measured at \(\hbox {V}_{\textrm{read}}=1.5~\hbox {V}\) are \(15~\hbox {M}\Omega \) and \(1.5~\hbox {M}\Omega \) for HRS and LRS, respectively, and stabilise into \(7~\hbox {M}\Omega \) (HRS) and \(2.5~\hbox {M}\Omega \) (LRS) after some applied \(I-V\) sweeps resulting a switching ratio of 2.8 (Fig. 3c). The LRS and HRS of the bilayer devices are found to be depended on the size of the cell, where the current increases as the device area increases, demonstrated in Fig. S7a with measurements of devices with different cell size. We also found that the retention performance of the HRS and LRS of the bilayer devices tend to decay after 500 s, depicted in Fig. S7b. The size dependency and weak retention are the unique feature of interfacial type homogeneous switching mechanism [32]. However, owing to the high non-linearity, these devices can be beneficial to various short-term memory applications [33, 34]. The non-linearity (\(\hbox {I}_{\textrm{Vset}}/\hbox {I}_{\mathrm{0.5Vset}}\)) of the Pt/Ti/bi- and TiN/bi- devices is found to be 420 and 318, respectively, indicating an excellent selectivity [35,36,37]. Moreover, the estimation using the Kirchoff equation suggested in Ref. [38]:

where here \(R_{\text {pu}}=R_{\text {LRS}}\) and \(V_{\text {read}} = 1.5\) V with different number of wordlines (N), gives us an estimation of the potential maximum array size. At 10% read margin \(41 \times 41\) and \(138 \times 138\) crossbar configurations result in 1.64 Kb and 18.59 Kb for TiN/bi- and Pt/Ti/bi- devices, respectively, as depicted in Fig. 3d.

The switching characteristics of the bilayer devices implicated a potential to analog/synaptic operation. Synaptic characteristic of Pt/Ti/bi- device is presented in Fig. 3e. One epoch training consists of 5000 pulses [each potentiation (P) and depression (D) scheme consisting of 2500 pulses], measured as sequences of programming (P/D) pulses and read pulses (\(\hbox {V}_{\textrm{read}} = 1.5~\hbox {V}\)). The result indicates that the potentiation scheme is able to produce good analog behavior with thousands of conduction levels ranging from approx. \(0.06~\upmu \hbox {S}\) (base) to \(0.14~\upmu \hbox {S}\) (peak), without significant noise. On the other hand, an abrupt fall of conductance occurs during the first pulse of the depression scheme. We tried to minimize this abrupt fall by decreasing the amplitude of the depression (\(\hbox {V}_{\textrm{D}}\)); however, \(\hbox {V}_{\textrm{D}}\) lower than \(-4\) V is not sufficient for the base to reach the original conductance level (from the previous epoch) which results in dynamic instability.

3.3 Interface Characterization

In order to better understand the observed device characteristics, we conducted XPS analysis to investigate the stack embedded films and the nature of interfacial layers. Figure 4a–d show the 3D-profiles of the Ti 2p, Hf 4f, Ta 4f, and O 1 s core electron spectra, respectively, measured from the Pt/Ti/bi- (Pt/Ti/\(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\)/TiN) stack (see corresponding data of the TiN/bi- stack in the Fig. S8 in the Supporting Information). The 2D evolution of the Hf 4f and Ta 4f spectra as the function of the etching time are shown in the Figs. S9 and S10.

XPS 3D profiles of the a Ti 2p, b Hf 4f, c Ta 4f, and d O 1 s core electrons from a 7 nm Pt/10 nm Ti/3 nm \(\hbox {HfO}_{\textrm{x}}\)/5 nm \(\hbox {TaO}_{\textrm{x}}\)/TiN thin film stack, measured with 30 s \(\hbox {Ar}^+\) ion beam etch steps. e Ti 2p spectrum measured at the Ti/\(\hbox {HfO}_{\textrm{x}}\) top electrode interface, f Hf 4f spectrum of \(\hbox {HfO}_{\textrm{x}}\) layer, g Ta 4f spectrum of the \(\hbox {TaO}_{\textrm{x}}\) layer, and h normalised Ti 2p spectrum at the \(\hbox {TaO}_{\textrm{x}}\)/TiN bottom electrode interface compared to the Ti 2p spectrum measured deeper in the TiN film bulk

The Ti oxidation at the Ti/\(\hbox {HfO}_{\textrm{x}}\) electrode/oxide interface is clearly seen in the Ti 2p spectrum in Fig. 4e, where the deconvolution reveals the presence of different \(\hbox {TiO}_{\textrm{x}}\) phases. This also contributes to the corresponding \(\hbox {HfO}_{\textrm{x}}\) spectra depicted in Figs. 4f and S8f, which show increased amount of sub-oxide contribution appearing to lower binding energies (Hf 4f 7/2 at ca. 15.9 eV). The Gibbs free energy of formation of \(\hbox {HfO}_2\) (\(\Delta \hbox {G}^{0}=-1054\) kJ/mol at 300 K) is more negative than that of \(\hbox {TiO}_2\) or TiON (\(\Delta \hbox {G}^0_{\text {TiO}_{2}}=-889.5\) kJ/mol, \(\Delta \hbox {G}^0_{\text {TiON}}=-580.3\) kJ/mol) [28, 29], however it has been shown that a band offset at metal/\(\hbox {HfO}_2\) interface can lead to a formation of doubly-charged negative oxygen interstitials diffusing into the Ti or TiN interface enabling the oxygen scavenging from the \(\hbox {HfO}_2\) film and formation of the \(\hbox {TiO}_{\textrm{x}}\) or \(\hbox {TiN}_{\textrm{x}}\hbox {O}_{\textrm{y}}\) interface layer [39].

Even more evident signs of changes in the oxide layer composition at the oxide/metal interface can be seen in the \(\hbox {TaO}_{\textrm{x}}\) spectra in Fig. 4c, g, as well as in the Figs. S8c, g that present the corresponding film in the TiN/bi-stack. the Ta 4f spectra show significant increase in the peak intensities towards lower binding energies when the etching time is increased i.e. the spectrum is measured closer to the \(\hbox {TaO}_{\textrm{x}}\)/TiN interface (see Figs. S9b, S10b). High sub-oxide content is commonly observed in the \(\hbox {TaO}_{\textrm{x}}\) films grown by physical vapor deposition methods for RRAM applications. However, in our film stacks we can assume that the high intensity peaks at 22.8 eV (4f 7/2) and 24.7 eV (4f 5/2) are rather originating from \(\hbox {TaN}_{\textrm{x}}\) and \(\hbox {TaO}_{\textrm{x}}\hbox {N}_{\textrm{y}}\) species instead of the sub-oxides or metallic Ta. The Ta 4f spectra indicate that at the TiN BE interface majority of the Ta are bound to nitrogen, and the film exhibit the characteristics of a \(\hbox {TaO}_{\textrm{x}}\) only at the \(\hbox {HfO}_{\textrm{x}}\) interface. This is a surprising result considering that a high energy oxygen source (\(\hbox {O}_2\) plasma) was used in the \(\hbox {TaO}_{\textrm{x}}\) deposition by plasma-enhanced ALD. We propose, that during the early stages of the deposition the PDMAT precursor dosing reduces the TiN, and later \(\hbox {TaO}_{\textrm{x}}\) surface [39]. Furthermore, the interface modification of from discrete TaOx/TiN interface to more blended complex with \(\hbox {TaN}_{\textrm{x}}\), \(\hbox {TaO}_{\textrm{x}}\hbox {N}_{\textrm{y}}\) and \(\hbox {TiO}_{\textrm{x}}\hbox {N}_{\textrm{y}}\) species is advanced by the diffusion of oxygen to the TiN layer and the subsequent replacement of oxygen in the growing \(\hbox {TaO}_{\textrm{x}}\) by nitrogen from the TiN electrode surface [40, 41]. Despite using an aminoalkyl precursor in the PEALD, it is unlikely that the nitrogen in the \(\hbox {TaO}_{\textrm{x}}\) layer originates from the PDMAT precursor ligands as no N 1 s signal nor corresponding Ta 4f peaks were detected in the \(\hbox {TaO}_{\textrm{x}}\) films grown in the \(\hbox {SiO}_2\)/Si substrates under same conditions.

The XPS results support the \(I-V\) characteristics that showed the \(\hbox {TaO}_{\textrm{x}}\) monolayer has higher resistivity compared to the \(\hbox {HfO}_{\textrm{x}}\) (Fig. 2a). This is due to the formation of \(\hbox {TaO}_{\textrm{x}}\hbox {N}_{\textrm{y}}\) layer at the \(\hbox {TaO}_{\textrm{x}}\)/TiN interface that tend to inhibit the oxygen vacancies formation and movement due to the strong N–O bonds [42]. This interfacial layer provides an internal resistance in the bilayer stack and serves as an electron tunnelling barrier layer [43]. Consequently, the Zener diode characteristic of the \(\hbox {TaO}_{\textrm{x}}/\hbox {TaO}_{\textrm{x}}\hbox {N}_{\textrm{y}}\) persists after the insertion of the \(\hbox {HfO}_{\textrm{x}}\) (Fig. 3a). The Ta oxynitride barrier layer dissipates the electrons across the bulk providing a low injection of electrons into the \(\hbox {HfO}_{\textrm{x}}\) layer that facilitates a movement of defects to form low and high resistive regions in the \(\hbox {HfO}_{\textrm{x}}\) layer during set and reset processes, respectively, which leads to the interfacial type homogeneous switching mechanism. Homogeneous switching mechanism relies on a valence change process at the interface region rather than a rupture process of a conducting filament, which tends to exhibit analog performance but with small on/off ratio [32]. This interfacial effect is further enhanced by the formation of \(\hbox {TiO}_{\textrm{x}}\) layer at the interface between the Pt/Ti top electrode and the \(\hbox {HfO}_{\textrm{x}}\) layer; the \(\hbox {TiO}_{\textrm{x}}\) serves as an oxygen reservoir that helps the occurrence of switching at low voltage operation and more stable endurance, which was not observed in devices with TiN top electrodes (Fig. 3b). Note that Pt/Ti/\(\hbox {TaO}_{\textrm{x}}\)/TiN monolayer device is unable to show resistive switching behavior [Fig. 2a(iv)], this could be due to the \(\hbox {TiO}_{\textrm{x}}\) interface being too thin due to the insufficient oxygen scavenging from the \(\hbox {TaO}_{\textrm{x}}\) layer to allow the effective homogeneous mechanism to happen.

According to the \(I-V\) measurements, the current injection from Pt/Ti layer to \(\hbox {HfO}_{\textrm{x}}\) layer (Pt/Ti/bi- device) is easier than that of from \(\hbox {TaO}_{\textrm{x}}\)/TiN layer to \(\hbox {HfO}_{\textrm{x}}\) layer, and because of this the switching current of the reverse bias in Pt/Ti TE devices tends to be higher than the forward bias. Similarly, abrupt fall in conductance occurs during the depression process. The abrupt fall indicates that abundant oxygen at the \(\hbox {TiO}_{\textrm{x}}\) top interface layer can be easily ionized and fill large number of oxygen vacancies in the \(\hbox {HfO}_{\textrm{x}}\) layer during the initial depression pulse; however, the initial pulse alone is not sufficient to fill oxygen vacancies near the \(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\) bottom interface region and continuous injection of electrons is required to make the base reach the original conductance (Fig. 3d). Nevertheless, thousands conductance levels with low noise can be produced by potentiation scheme and this performance could be useful for multibit data storage [7] and neuromorphic applications [2].

4 Conclusion

Varistor-like resistive memory devices can be fabricated by stacking a low resistivity film (\(\hbox {HfO}_{\textrm{x}}\)) with a high resistivity film (\(\hbox {TaO}_{\textrm{x}}\)). \(\hbox {HfO}_{\textrm{x}}\) will act as the switching film while \(\hbox {TaO}_{\textrm{x}}\), and its interface with a TiN electrode serve as an internal resistance in the cell. Neither monolayer devices with an ultra-thin \(\hbox {HfO}_{\textrm{x}}\) nor \(\hbox {TaO}_{\textrm{x}}\) layer alone can perform resistive switching behavior. The low-temperature ALD \(\hbox {HfO}_{\textrm{x}}\) monolayer has high leakage current due to the presence of abundance of OH- species in the film. On the other hand, the \(\hbox {TaO}_{\textrm{x}}\) monolayer on TiN electrode has high resistivity and it exhibits Zener diode characteristics; the formation of TaON at the interface limits the redox reaction in the cell due to the strong N-O bonds, thus, reducing the electron flow into the oxide. The low electron injection into the cell, nevertheless, facilitates redox process at the \(\hbox {HfO}_{\textrm{x}}\) region, inducing a homogeneous non-linear switching in the \(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\) bilayer device. This study provides insight into the fabrication of selector-less resistive memory for realizing high-density arrays.

Availability of data and materials

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Salahuddin, S., Ni, K., Datta, S.: The era of hyper-scaling in electronics. Nat. Electron. 1(8), 442–450 (2018). https://doi.org/10.1038/s41928-018-0117-x

Zidan, M.A., Strachan, J.P., Lu, W.D.: The future of electronics based on memristive systems. Nat. Electron. 1(1), 22–29 (2018). https://doi.org/10.1038/s41928-017-0006-8

Fang, Z., Yu, H.Y., Li, X., Singh, N., Lo, G.Q., Kwong, D.L.: HfO\(_x\)/TiO\(_x\)/HfO\(_x\)/ TiO\(_x\) multilayer-based forming-free RRAM devices with excellent uniformity. IEEE Electron Device Lett. 32(4), 566–568 (2011). https://doi.org/10.1109/LED.2011.2109033

Shuai, Y., Ou, X., Luo, W., Mücklich, A., Bürger, D., Zhou, S., Wu, C., Chen, Y., Zhang, W., Helm, M., Mikolajick, T., Schmidt, O.G., Schmidt, H.: Key concepts behind forming-free resistive switching incorporated with rectifying transport properties. Sci. Rep. 3(1), 2208 (2013). https://doi.org/10.1038/srep02208

Zhang, K., Long, S., Liu, Q., Lü, H., Li, Y., Wang, Y., Lian, W., Wang, M., Zhang, S., Liu, M.: Progress in rectifying-based RRAM passive crossbar array. Sci. China Technol. Sci. 54(4), 811–818 (2011). https://doi.org/10.1007/s11431-010-4240-9

Wang, T., Brivio, S., Cianci, E., Wiemer, C., Perego, M., Spiga, S., Lanza, M.: Improving HfO\(_2\)-based resistive switching devices by inserting a TaO\(_x\) thin film via engineered in situ oxidation. ACS Appl. Mater. Interfaces 14(21), 24565–24574 (2022). https://doi.org/10.1021/acsami.2c03364

Stathopoulos, S., Khiat, A., Trapatseli, M., Cortese, S., Serb, A., Valov, I., Prodromakis, T.: Multibit memory operation of metal-oxide bi-layer memristors. Sci. Rep. 7(1), 17532 (2017). https://doi.org/10.1038/s41598-017-17785-1

Yao, P., Wu, H., Gao, B., Eryilmaz, S.B., Huang, X., Zhang, W., Zhang, Q., Deng, N., Shi, L., Wong, H.-S.P., Qian, H.: Face classification using electronic synapses. Nat. Commun. 8(1), 15199 (2017). https://doi.org/10.1038/ncomms15199

Yoon, J.H., Song, S.J., Yoo, I.-H., Seok, J.Y., Yoon, K.J., Kwon, D.E., Park, T.H., Hwang, C.S.: Highly uniform, electroforming-free, and self-rectifying resistive memory in the Pt/\(\text{ Ta}_2\text{ O}_5\)/\(\text{ HfO}_{2-x}\)/TiN structure. Adv. Funct. Mater. 24, 5086–5095 (2014). https://doi.org/10.1002/adfm.201400064

Park, M.R., Abbas, Y., Abbas, H., Hu, Q., Lee, T.S., Choi, Y.J., Yoon, T.-S., Lee, H.-H., Kang, C.J.: Resistive switching characteristics in hafnium oxide, tantalum oxide and bilayer devices. Microelectron. Eng. 159, 190–197 (2016). https://doi.org/10.1016/j.mee.2016.03.043

Yoon, J.H., Yoo, S., Song, S.J., Yoon, K.J., Kwon, D.E., Kwon, Y.J., Park, T.H., Kim, H.J., Shao, X.L., Kim, Y., Hwang, C.S.: Uniform self-rectifying resistive switching behavior via preformed conducting paths in a vertical-type Ta\(_2\)O\(_5\)/HfO\(_2\)-x structure with a sub-\(\upmu \text{ m }\)2 cell area. ACS Appl. Mater. Interfaces. 8(28), 18215–18221 (2016). https://doi.org/10.1021/acsami.6b05657

Ma, H., Zhang, X., Wu, F., Luo, Q., Gong, T., Yuan, P., Xu, X., Liu, Y., Zhao, S., Zhang, K., Lu, C., Zhang, P., Feng, J., Lv, H., Liu, M.: A self-rectifying resistive switching device based on \(\text{ HfO}_2\)/TaO \(_{x}\) bilayer structure. IEEE Trans. Electron. Dev. 66(2), 924–928 (2019). https://doi.org/10.1109/TED.2018.2883192

Ryu, J.-H., Mahata, C., Kim, S.: Long-term and short-term plasticity of ta2o5/hfo2 memristor for hardware neuromorphic application. J. Alloy. Compd. 850, 156675 (2021). https://doi.org/10.1016/j.jallcom.2020.156675

Ryu, H., Kim, S.: Implementation of a reservoir computing system using the short-term effects of Pt/HfO\(_2\)/TaO\(_x\)/TiN memristors with self-rectification. Chaos, Solitons Fractals 150, 111223 (2021). https://doi.org/10.1016/j.chaos.2021.111223

Park, M., Jeon, B., Park, J., Kim, S.: Memristors with nociceptor characteristics using threshold switching of Pt/HfO\(_2\)/TaO\(_x\)/TaN devices. Nanomaterials 12(23) (2022). https://doi.org/10.3390/nano12234206

Luo, Q., Xu, X., Liu, H., Lv, H., Gong, T., Long, S., Liu, Q., Sun, H., Banerjee, W., Li, L., Gao, J., Lu, N., Liu, M.: Super non-linear RRAM with ultra-low power for 3D vertical nano-crossbar arrays. Nanoscale 8, 15629–15636 (2016). https://doi.org/10.1039/C6NR02029A

Kim, W., Rösgen, B., Breuer, T., Menzel, S., Wouters, D., Waser, R., Rana, V.: Nonlinearity analysis of TaOx redox-based RRAM. Microelectron. Eng. 154, 38–41 (2016). https://doi.org/10.1016/j.mee.2016.01.025

Applied Materials Inc.: Apparatuses for atomic layer deposition. US Patent US8343279B2 (2004)

Micron Technology Inc.: Atomic layer deposited hafnium tantalum oxide dielectrics. U.S. Patent US7560395B2 (2005)

Niu, G., Kim, H.-D., Roelofs, R., Perez, E., Schubert, M.A., Zaumseil, P., Costina, I., Wenger, C.: Material insights of \(\text{ HfO}_2\)-based integrated 1-transistor-1-resistor resistive random access memory devices processed by batch atomic layer deposition. Sci. Rep. 6(1), 28155 (2016). https://doi.org/10.1038/srep28155

Grossi, A., Perez, E., Zambelli, C., Olivo, P., Miranda, E., Roelofs, R., Woodruff, J., Raisanen, P., Li, W., Givens, M., Costina, I., Schubert, M.A., Wenger, C.: Impact of the precursor chemistry and process conditions on the cell-to-cell variability in 1T–1R based \(\text{ HfO}_2\) RRAM devices. Sci. Rep. 8(1), 11160 (2018). https://doi.org/10.1038/s41598-018-29548-7

Blaschke, D., Munnik, F., Grenzer, J., Rebohle, L., Schmidt, H., Zahn, P., Gemming, S.: A correlation study of layer growth rate, thickness uniformity, stoichiometry, and hydrogen impurity level in HfO2 thin films grown by ALD between \(100^{\circ }{{\rm c}}\) and \(350^{\circ }{{\rm c}}\). Appl. Surf. Sci. 506, 144188 (2020). https://doi.org/10.1016/j.apsusc.2019.144188

McIntyre, P.: Bulk and interfacial oxygen defects in HfO2 gate dielectric stacks: a critical assessment. ECS Trans. 11(4), 235–249 (2007). https://doi.org/10.1149/1.2779564

Traoré, B., Blaise, P., Vianello, E., Perniola, L., De Salvo, B., Nishi, Y.: HfO2-based RRAM: electrode effects, Ti/HfO2 interface, charge injection, and oxygen (o) defects diffusion through experiment and ab initio calculations. IEEE Trans. Electron Dev. 63(1), 360–368 (2016). https://doi.org/10.1109/TED.2015.2503145

Kunwar, S., Somodi, C.B., Lalk, R.A., Rutherford, B.X., Corey, Z., Roy, P., Zhang, D., Hellenbrand, M., Xiao, M., MacManus-Driscoll, J.L., Jia, Q., Wang, H., Joshua Yang, J., Nie, W., Chen, A.: Protons: critical species for resistive switching in interface-type memristors. Adv. Electron. Mater. 9(1), 2200816. https://doi.org/10.1002/aelm.202200816

Chiu, F.-C.: A review on conduction mechanisms in dielectric films. Adv. Mater. Sci. Eng. 2014, 578168 (2014). https://doi.org/10.1155/2014/578168

Flannery, W.E., Pollack, S.R.: Electron transfer processes through tantalum–tantalum-oxide diodes. J. Appl. Phys. 37(12), 4417–4422 (1966). https://doi.org/10.1063/1.1708052

Wittmer, M., Noser, J., Melchior, H.: Oxidation kinetics of tin thin films. J. Appl. Phys. 52(11), 6659–6664 (1981). https://doi.org/10.1063/1.328659

Dean, J.A.: Lange’s Handbook of Chemistry, 15th edn. McGraw-Hill, New York (1999)

Pantisano, L., Afanas’ev, V.V., Cimino, S., Adelmann, C., Goux, L., Chen, Y.Y., Kittl, J.A., Wouters, D., Jurczak, M.: Towards barrier height modulation in HfO2/TiN by oxygen scavenging—dielectric defects or metal induced gap states? Microelectron. Eng. 88(7), 1251–1254 (2011). https://doi.org/10.1016/j.mee.2011.03.057. Proceedings of the 17th Biennial International Insulating Films on Semiconductor Conference

Michalas, L., Stathopoulos, S., Khiat, A., Prodromakis, T.: Conduction mechanisms at distinct resistive levels of Pt/TiO2-x/Pt memristors. Appl. Phys. Lett. 113(14), 143503 (2018). https://doi.org/10.1063/1.5040936

Huang, C.-H., Huang, J.-S., Lai, C.-C., Huang, H.-W., Lin, S.-J., Chueh, Y.-L.: Manipulated transformation of filamentary and homogeneous resistive switching on ZnO thin film memristor with controllable multistate. ACS Appl. Mater. Interfaces. 5(13), 6017–6023 (2013). https://doi.org/10.1021/am4007287

Park, J., Kim, T.-H., Kwon, O., Ismail, M., Mahata, C., Kim, Y., Kim, S., Kim, S.: Implementation of convolutional neural network and 8-bit reservoir computing in CMOS compatible VRRAM. Nano Energy 104, 107886 (2022). https://doi.org/10.1016/j.nanoen.2022.107886

John, R.A., Demirağ, Y., Shynkarenko, Y., Berezovska, Y., Ohannessian, N., Payvand, M., Zeng, P., Bodnarchuk, M.I., Krumeich, F., Kara, G., Shorubalko, I., Nair, M.V., Cooke, G.A., Lippert, T., Indiveri, G., Kovalenko, M.V.: Reconfigurable halide perovskite nanocrystal memristors for neuromorphic computing. Nat. Commun. 13(1), 2074 (2022). https://doi.org/10.1038/s41467-022-29727-1

Tamanna, N., Misha, S.H., Prakash, A., Lee, D., Woo, J., Cha, E., Attarimashalkoubeh, B., Song, J., Lee, S., Moon, K., Hwang, H.: Non-linear I–V characteristics of TIOY film by optimizing thickness and trap density for selector-less RERAM. ECS Solid State Lett. 3(10), 117 (2014). https://doi.org/10.1149/2.0021410ssl

Chen, Y.-C., Huang, H.-C., Lin, C.-Y., Hu, S.-T., Lin, C.-C., Lee, J.C.: Selectorless resistive switching memory: non-uniform dielectric architecture and seasoning effect for low power array applications. AIP Adv. 9(7), 075119 (2019). https://doi.org/10.1063/1.5097233

Park, S.-G., Yang, M.K., Ju, H., Seong, D.-J., Lee, J.M., Kim, E., Jung, S., Zhang, L., Shin, Y.C., Baek, I.-G., Choi, J., Kang, H.-K., Chung, C.: A non-linear ReRAM cell with sub-1\(\mu \); a ultralow operating current for high density vertical resistive memory (VRRAM). In: 2012 International Electron Devices Meeting, pp. 20–812084. IEEE (2012). https://doi.org/10.1109/IEDM.2012.6479084. http://ieeexplore.ieee.org/document/6479084/

Aluguri, R., Kumar, D., Simanjuntak, F.M., Tseng, T.-Y.: One bipolar transistor selector—one resistive random access memory device for cross bar memory array. AIP Adv. 7(9), 095118 (2017). https://doi.org/10.1063/1.4994948

Yong, Z., Persson, K.-M., Saketh Ram, M., D’Acunto, G., Liu, Y., Benter, S., Pan, J., Li, Z., Borg, M., Mikkelsen, A., Wernersson, L.-E., Timm, R.: Tuning oxygen vacancies and resistive switching properties in ultra-thin \(\text{ HfO}_2\) RRAM via TiN bottom electrode and interface engineering. Appl. Surf. Sci. 551, 149386 (2021). https://doi.org/10.1016/j.apsusc.2021.149386

Egorov, K.V., Lebedinskii, Y.Y., Markeev, A.M., Orlov, O.M.: Full ALD Ta2O5-based stacks for resistive random access memory grown with in vacuo XPS monitoring. Appl. Surf. Sci. 356, 454–459 (2015). https://doi.org/10.1016/j.apsusc.2015.07.217

Ma, Y., Cullen, D.A., Goodwill, J.M., Xu, Q., More, K.L., Skowronski, M.: Exchange of ions across the TiN/TaOx interface during electroformation of TaOx-based resistive switching devices. ACS Appl. Mater. Interfaces. 12(24), 27378–27385 (2020). https://doi.org/10.1021/acsami.0c06960

Jeon, H., Park, J., Jang, W., Kim, H., Kang, C., Song, H., Seo, H., Jeon, H.: Resistive switching of a TaOx/TaON double layer via ionic control of carrier tunneling. Appl. Phys. Lett. 104(15), 151603 (2014). https://doi.org/10.1063/1.4871692

Sugawara, T., Oshima, Y., Sreenivasan, R., McIntyre, P.C.: Electrical properties of germanium/metal-oxide gate stacks with atomic layer deposition grown hafnium-dioxide and plasma-synthesized interface layers. Appl. Phys. Lett. 90(11), 112912 (2007). https://doi.org/10.1063/1.2472197

Acknowledgements

The authors wish to thank the Southampton Nanofabrication Centre cleanroom staff for their help and support and Dr Irwan Purnama from Indonesian National Agency for Research and Innovation for the fruitful discussion on the array level.

Funding

This work was financially supported by the European Commission H2020 Grant Agreement No. 824162“A SYnaptically connected Neural Closed-loop Hybrid system (SYNCH)”, the United Kingdom Engineering and Physical Sciences Research Council (EPSRC) Programme Grant EP/R024642/1 “Functional Oxide Reconfigurable Technologies (FORTE)”, the RAEng Chair in Emerging Technologies (CiET1819/2/93), and European Commission Marie Sklowodska-Curie Action Individual Fellowship Grant Agreement No. 224 (101029535-MENESIS)

Author information

Authors and Affiliations

Contributions

MN: Methodology; Writing—original draft; Writing—review and editing. SS: Writing—original draft; Writing—review and editing TP: Funding acquisition; Writing—review and editing. FM: Methodology; Writing—original draft; Writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflicts to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Napari, M., Stathopoulos, S., Prodromakis, T. et al. Forming-Free and Non-linear Resistive Switching in Bilayer \(\hbox {HfO}_{\textrm{x}}\)/\(\hbox {TaO}_{\textrm{x}}\) Memory Devices by Interface-Induced Internal Resistance. Electron. Mater. Lett. (2024). https://doi.org/10.1007/s13391-023-00481-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13391-023-00481-w