Abstract

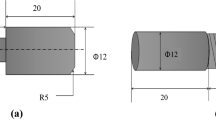

Friction stud welding of dissimilar metals has a variety of applications in the field of aerospace, automotive, nuclear engineering. Especially, in the field of automobile engineering, there is a requirement of joining a mild steel earthing pin to an aluminium car body. Hence, in this study, joining of aluminium (AA 6063) and mild steel (AISI 1030) was successfully carried out by friction welding technique. Experiments were conducted by varying friction time, and axial shortening distance and impact strength were measured. Macro and microstructural investigation was carried out using optical microscope, scanning electron microscope and energy dispersive X-ray analysis. Microhardness measurement shows increased plastic deformation of aluminium at the interfacial region. Optical micrograph reveals a dark region of about 240μm consisting of dynamic recrystallized grains on the aluminium side very near to the interfacial region. SEM micrograph and EDX analysis shows the presence of iron oxide on the aluminium side along with the formation of inter metallic compound FeAl at the joint interface. Hardness measured at the weld line is found to be higher than the hardness of the base metal due to increased plastic deformation.

Similar content being viewed by others

References

Tracie P.: Solid-state joining of metal matrix composites: a survey of challenges and potential solutions. Mater. Manuf. Processes 26(4), 636–648 (2011)

Mumin S., Erol A.H., Kaan O.: An experimental study on joining of severe plastic deformed aluminium materials with friction welding method. Mater. Des. 29(1), 1–10 (2006)

Ting-Fai K., Luen-Chow C., Tai-Chiu L.: Weld diffusion analysis of forming bimetallic components using statistical experimental methods. Mater. Manufac. Processes 24(4), 422–430 (2009)

Sahin M.: Joining of stainless-steel and luminium materials by friction welding. Int. J. Adv. Manuf. Technol. 41, 487–97 (2008)

Davari H., Parsa M.H., Hadian A.M., Nili M.: Ahmadabadi, experimental and numerical thermomechanical analysis of hybrid friction welding of commercially pure copper bars. Mater. Manuf. Processes 26(5), 694–702 (2011)

Ozdemir N.: Investigation of the mechanical properties of friction-welded joints between AISI 304L, AISI Steel as a function rotational speed. Mater. Lett. 59, 2504–2509 (2005)

Mohamad, Z.N.; Luay, B.H.; Zainal, A.A.: Alumina-mild steel friction welded at lower rotational speed. J. Mater. Processing Technol. 10, 1016–1021 (2007)

Chen Y.C., Nakata K.: Microstructural characterization and mechanical properties in friction stir welding of aluminium and titanium dissimilar alloys. Mater. Des. 30, 469–474 (2009)

Ahmad Fauzi M.N., Uday M.B., Zuhailawati H., Ismail A.B.: Microstructure and mechanical properties of alumina-6061 aluminum alloy joined by friction welding. Mater. Des. 31, 670–676 (2010)

Sare, C.; Ismail, E.: Investigation of the mechanical properties and microstructure of friction welded joints between AISI 4140 and AISI 050 steels. Mater. Des. 30, 970–976 (2009)

Sathiya P., Aravindan S., Noorul Haq A.: Effect of friction welding parameters on mechanical and metallurgical properties of ferritic stainless steel. Int. J. Adv. Manufac. Technol. 31, 1076–1082 (2007)

Hazman, S.; Ahmad, I.M.I.; Endri, R.; Zainal, A.A.: Mechanical evaluation and thermal modelling of friction welding of mild steel and aluminium. J. Mater. Processing Technol. 210, 1209–1216 (2010)

Mokhtar, A.; Victor, H.M.: Energy generation during friction stir spot welding of Al 6061-T6 plates. Mater. Manufact. Processes 25(1–3), 167–174 (2010)

Miller, S.F.; Wang, H.; Shih, A.J.; Li, R.: Experimental and numerical analysis of the friction drilling process. J. Manuf. Sci. Eng. 128(3), 802–810 (2006). doi:10.1115/1.2193554

Fu L., Duan L.: The coupled deformation and heat flow analysis by finite element method during friction welding. Weld. J. 77(5), 202–207 (1998)

Lee, W.B.; Kim, Y.J.; Jung, S.B.: Effects of copper insert layer on the properties of friction welded joints between TiAl and AISI 4140 structural steel. Intermetallics 12, 671–678 (2004)

Yilmaz, M.; Col, M.; Acet, M.: Interface properties of aluminium/steel friction welded components. Mater. Charact. 49, 421–429 (2003)

Taban E., Gould J.E., Lippold J.C.: Dissimilar friction welding of 6061-T6 aluminum and AISI 1018 steel: properties and microstructural characterization. Mater. Des. 31(5), 2305–2231 (2010)

Dey, H.C.; Ashfaq, M.; Bhaduri, A.K.; Prasad, R.K.: Joining of titanium to 304L stainless steel by friction welding. J. Mater. Processing Technol. 209, 5862–5870 (2009)

Fukumoto S., Tsubakino H., Okita K., Aritoshi M., Tomita T.: Amorphization by friction welding between 5052 aluminum alloy and 304 stainless steel. Scr. Materialia. 42(8), 807–881 (2000)

Mustafa Kemal, K.; Erdinc, K.; Aydin S.; Ozden B.: Experimental comparison of MIG and friction stir welding processes for EN AW-6061-T6 (Al Mg1 Si Cu) aluminium alloy. Arab. J. Sci. Eng. 35(1B), 321–330 (2009)

Akbari M.S.S.A., Rahbar K.A.: Experimental and numerical analysis of the friction welding process for the 4340 steel and mild steel combinations. Weld. Res. 87, 178–186 (2008)

Fuji A.: Friction welding of AlMgSi alloy to NiCrMo low alloy steel. Sci. Technol. Weld. Join. 9(1), 83–89 (2004)

Hazlett T.H., Gupta K.K.: Friction welding of high strength structural aluminium alloys. Weld. J. 43, 490–495 (1963)

RajeshJesudoss Hynes N., Nagaraj P., AngelaJennifa Sujana J.: Investigation on joining of aluminium and mild steel by friction stud welding. Mater. Manuf. Process. 27(12), 1409–1413 (2012)

Rajesh Jesudoss Hynes, N.; Nagaraj, P.; Palanichamy, R.; Arumugham, C.A.K.; Angela Jennifa Sujana, J.: Numerical simulation of heat flow in friction stud welding of dissimilar metals. Arab. J. Sci. Eng. (2014). doi:10.1007/s13369-013-0932-3

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajesh Jesudoss Hynes, N., Nagaraj, P. & Angela Jennifa Sujana, J. Mechanical Evaluation and Microstructure of Friction Stud Welded Aluminium–Mild steel Joints. Arab J Sci Eng 39, 5017–5023 (2014). https://doi.org/10.1007/s13369-014-1082-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-014-1082-y