Abstract

Purpose

Recent progress in material science allows researchers to use novel materials with enhanced capabilities like optimum biodegradability, higher strength, and flexibility in the design of coronary stents. Considering the wide range of mechanical properties of existing and newfangled materials, finding the influence of variations in mechanical properties of stent materials is critical for developing a practical design.

Methods

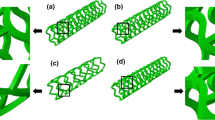

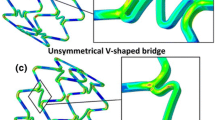

The sensitivity of stent functional characteristics to variations in its material plastic properties is obtained through FEM modeling. Balloon-expandable coronary stent designs: Absorb BVS, and Xience are examined for artificial and commercial polymeric, and metallic materials, respectively. Standard tests including (1) the crimping process followed by stent implantation in an atherosclerotic artery and (2) the three-point bending test, have been simulated according to ASTM standards.

Results

In Absorb BVS, materials with higher yield stress than PLLA have similar residual deflection and maximum bending force to PLLA, which is not the case for Xience stent and Co–Cr. Moreover, elevated yield stress significantly reduces stent flexibility only in Xience stent. For both stents, with different degree of influence, an increase in yield or ultimate stress improves stent radial strength and stiffness and reduces arterial stress and plastic strain of stent, which consequently enhances the stent mechanical performance. Contrarily, yield or ultimate stress elevation increases stent recoil which adversely affects stent performance.

Conclusion

Using high-strength materials has a double-edged sword effect on the stent performance and existing uncertainty in the precise estimate of stent mechanical properties adversely affects the reliability of numerical models’ predictions.

Similar content being viewed by others

References

Azaouzi, M., A. Makradi, and S. Belouettar. Numerical investigations of the structural behavior of a balloon expandable stent design using finite element method. Comput. Mater. Sci. 72:54–61, 2013.

Bobel, A. C., S. Petisco, J. R. Sarasua, W. Wang, and P. E. McHugh. Computational bench testing to evaluate the short-term mechanical performance of a polymeric stent. Cardiovasc. Eng. Technol. 6(4):519–532, 2015.

Borghi, T. C., J. R. Costa, A. Abizaid, D. Chamié, M. V. e Silva, D. Taiguara, R. Costa, R. Staico, F. Feres, Á. J. Chaves, and D. Siqueira. Comparison of acute stent recoil between the everolimus-eluting bioresorbable vascular scaffold and two different drug-eluting metallic stents. Revista Brasileira de Cardiologia Invasiva (English Edition) 21(4):326–331, 2013.

Bowen, P. K., E. R. Shearier, S. Zhao, R. J. Guillory, F. Zhao, J. Goldman, and J. W. Drelich. Biodegradable metals for cardiovascular stents: from clinical concerns to recent Zn-Alloys. Adv. Healthc. Mater. 5(10):1121–1140, 2016.

Chen, C., Y. Xiong, W. Jiang, Y. Wang, Z. Wang, and Y. Chen. Experimental and numerical simulation of biodegradable stents with different strut geometries. Cardiovasc. Eng. Technol. 2019. https://doi.org/10.1007/s13239-019-00433-2.

De Beule, M., P. Mortier, S. G. Carlier, B. Verhegghe, R. Van Impe, and P. Verdonck. Realistic finite element-based stent design: the impact of balloon folding. J. Biomech. 41(2):383–389, 2008.

Diez, M., M. H. Kang, S. M. Kim, H. E. Kim, and J. Song. Hydroxyapatite (HA)/poly-L-lactic acid (PLLA) dual coating on magnesium alloy under deformation for biomedical applications. J. Mater. Sci. 27(2):34, 2016.

Drumright, R. E., P. R. Gruber, and D. E. Henton. Polylactic acid technology. Adv. Mater. 12(23):1841–1846, 2000.

Everett, K. D. Mechanisms and implications of fracture in cardiovascular stents (Doctoral dissertation, Harvard University). 2014.

Gervaso, F., C. Capelli, L. Petrini, S. Lattanzio, L. Di Virgilio, and F. Migliavacca. On the effects of different strategies in modelling balloon-expandable stenting by means of finite element method. J. Biomech. 41(6):1206–1212, 2008.

Grogan, J. A., S. B. Leen, and P. E. McHugh. Comparing coronary stent material performance on a common geometric platform through simulated bench testing. J. Mech. Behav. Biomed. Mater. 12:129–138, 2012.

Holzapfel, G. A., G. Sommer, C. T. Gasser, and P. Regitnig. Determination of layer-specific mechanical properties of human coronary arteries with nonatherosclerotic intimal thickening and related constitutive modeling. Am. J. Physiol. Heart Circ. Physiol. 289(5):H2048–H2058, 2005.

Idziak-Jabłońska, A. Stress and strain distribution in expanded coronary stents depending on applied material. J. Appl. Math. Comput. Mech. 14(2):21–30, 2015.

Imani, M., A. M. Goudarzi, D. D. Ganji, and A. L. Aghili. The comprehensive finite element model for stenting: The influence of stent design on the outcome after coronary stent placement. J. Theor. Appl. Mech. 51(3):639–648, 2013.

Lally, C., F. Dolan, and P. J. Prendergast. Cardiovascular stent design and vessel stresses: a finite element analysis. J. Biomech. 38(8):1574–1581, 2005.

Lee, S. Continuum deformation model for drug-eluting stent (DES) medical devices using finite element analysis (FEA) (Doctoral dissertation, The University of Wisconsin-Milwaukee). 2013.

Loree, H. M., A. J. Grodzinsky, S. Y. Park, L. J. Gibson, and R. T. Lee. Static circumferential tangential modulus of human atherosclerotic tissue. J. Biomech. 27(2):195–204, 1994.

Martin, D., and F. J. Boyle. Computational structural modelling of coronary stent deployment: a review. Comput. Methods Biomech. Biomed. Eng. 14(04):331–348, 2011.

Moore, J. E., J. S. Soares, and K. R. Rajagopal. Biodegradable stents: biomechanical modeling challenges and opportunities. Cardiovasc. Eng. Technol. 1(1):52–65, 2010.

Morlacchi, S., G. Pennati, L. Petrini, G. Dubini, and F. Migliavacca. Influence of plaque calcifications on coronary stent fracture: a numerical fatigue life analysis including cardiac wall movement. J. Biomech. 47(4):899–907, 2014.

Obayi, C. S., R. Tolouei, A. Mostavan, C. Paternoster, S. Turgeon, B. A. Okorie, D. O. Obikwelu, and D. Mantovani. Effect of grain sizes on mechanical properties and biodegradation behavior of pure iron for cardiovascular stent application. Biomatter. 6(1):e959874, 2016.

Parker, T., V. Dave, and R. Falotico. Polymers for drug eluting stents. Curr. Pharm. Des. 16(36):3978–3988, 2010.

Pauck, R. G., and B. D. Reddy. Computational analysis of the radial mechanical performance of PLLA coronary artery stents. Med. Eng. Phys. 37(1):7–12, 2015.

Pericevic, I., C. Lally, D. Toner, and D. J. Kelly. The influence of plaque composition on underlying arterial wall stress during stent expansion: the case for lesion-specific stents. Med. Eng. Phys. 31(4):428–433, 2009.

Poncin, P., Millet, C., Chevy, J., Proft, J. L. Comparing and optimizing Co–Cr tubing for stent applications. Proceedings of the materials and processes for medical devices conference, 2004 (pp. 279–283).

Qiu, T. Y., M. Song, and L. G. Zhao. A computational study of crimping and expansion of bioresorbable polymeric stents. Mech. time-Depend. Mater. 22(2):273–290, 2018.

Qiu, T. Y., L. G. Zhao, and M. Song. A computational study of mechanical performance of bioresorbable polymeric stents with design variations. Cardiovasc. Eng. Technol. 10(1):46–60, 2019.

Sarasua, J. R., A. L. Arraiza, P. Balerdi, and I. Maiza. Crystallinity and mechanical properties of optically pure polylactides and their blends. Polym. Eng. Sci. 45(5):745–753, 2005.

Schiavone, A., C. Abunassar, S. Hossainy, and L. G. Zhao. Computational analysis of mechanical stress–strain interaction of a bioresorbable scaffold with blood vessel. J. Biomech. 49(13):2677–2683, 2016.

Schiavone, A., L. G. Zhao, and A. A. Abdel-Wahab. Effects of material, coating, design and plaque composition on stent deployment inside a stenotic artery—finite element simulation. Mater. Sci. Eng. C 42:479–488, 2014.

Schmidt, W., P. Behrens, and K. P. Schmitz. Biomechanical Aspects of Potential Stent Malapposition at Coronary Stent Implantation. In World Congress on Medical Physics and Biomedical Engineering, Munich, Germany. Berlin: Springer, pp. 136–139, 2009.

Standard A F2606-08. Standard guide for three-point bending of balloon expandable vascular stents and stent systems. ASTM International, West Conshohocken. 2014; https://doi.org/10.1520/f2606

Standard A F3067-14. Guide for radial loading of balloon expandable and self expanding vascular stents. ASTM International, West Conshohocken. 2014; https://doi.org/10.1520/F3067-14

Takashima, K., T. Kitou, K. Mori, and K. Ikeuchi. Simulation and experimental observation of contact conditions between stents and artery models. Med. Eng. Phys. 29(3):326–335, 2007.

U.S. Food and Drug Administration tcsdpac. Absorb Gt1™ Bioresorbable Vascular Scaffold System. 2016.

Uurto, I., A. Kotsar, T. Isotalo, J. Mikkonen, P. M. Martikainen, M. Kellomäki, P. Törmälä, T. L. Tammela, M. Talja, and J. P. Salenius. Tissue biocompatibility of new biodegradable drug-eluting stent materials. J. Mater. Sci. 18(8):1543–1547, 2007.

Vaizasatya, A. A methodology for coronary stent product development: design, simulation and optimization. Doctoral dissertation, North Carolina Agricultural and Technical State University. 2013.

Verheye, S., J. A. Ormiston, J. Stewart, M. Webster, E. Sanidas, R. Costa, J. R. Costa, D. Chamie, A. S. Abizaid, I. Pinto, and L. Morrison. A next-generation bioresorbable coronary scaffold system: from bench to first clinical evaluation: 6-and 12-month clinical and multimodality imaging results. JACC 7(1):89–99, 2014.

Wang, Q., G. Fang, Y. Zhao, G. Wang, and T. Cai. Computational and experimental investigation into mechanical performances of Poly-L-Lactide Acid (PLLA) coronary stents. J. Mech. Behav. Biomed. Mater. 65:415–427, 2017.

Wu, W., D. Gastaldi, K. Yang, L. Tan, L. Petrini, and F. Migliavacca. Finite element analyses for design evaluation of biodegradable magnesium alloy stents in arterial vessels. Mater. Sci. Eng. B 176(20):1733–1740, 2011.

Wu, W., W. Q. Wang, D. Z. Yang, and M. Qi. Stent expansion in curved vessel and their interactions: a finite element analysis. J. Biomech. 40(11):2580–2585, 2007.

Yang, H. Study of mechanical performance of stent implants using theoretical and numerical approach. Doctoral dissertation, University of North Texas. 2015.

Yu, C., and J. Kohn. Tyrosine–PEG-derived poly (ether carbonate) s as new biomaterials: part I: synthesis and evaluation. Biomaterials 20(3):253–264, 1999.

Yun, Y., Z. Dong, N. Lee, Y. Liu, D. Xue, X. Guo, J. Kuhlmann, A. Doepke, H. B. Halsall, W. Heineman, and S. Sundaramurthy. Revolutionizing biodegradable metals. Mater. Today 12(10):22–32, 2009.

Zhao S. Biomechanical response of artery following stent implantation: Implication for restenosis. Doctoral dissertation, University of Nebraska. 2013.

Acknowledgments

We convey our thanks to Dr. M. Dehghani and Dr. A. Alamdar for their great help.

Conflict of Interest

Ali Khalilimeybodi, Amir Alishzadeh Khoei and Babak Sharif-Kashani declare that they have no conflict of interest.

Ethical Approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Associate Editor Matthew J. Gounis oversaw the review of this article.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Khalilimeybodi, A., Alishzadeh Khoei, A. & Sharif-Kashani, B. Future Balloon-Expandable Stents: High or Low-Strength Materials?. Cardiovasc Eng Tech 11, 188–204 (2020). https://doi.org/10.1007/s13239-019-00450-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13239-019-00450-1