Abstract

This study aimed to analyze the effect of nutritional supplements on improving conidia production of Metarhizium rileyi Nm017 at laboratory scale (yields of conidia/substrate and biomass/substrate, and substrate consumption). Also, the influence on quality parameters were evaluated (germination at 36 and 48 h, enzymatic activity, and insecticidal activity on Helicoverpa zea). Six treatments (T1–T6) were assessed and all of them reached maximum conidia concentration after 7 days fermentation, a feasible production timetable. Yields from treatment T6 (yeast extract + V8 juice) were 1.5–threefold higher than the other treatments. Conidia from T6 reached germinations of 56% and 12% at 36 and 48 h, respectively, higher than T1 (without supplements), which had the lowest values found. M. rileyi conidia obtained from treatment T6 had the highest enzymatic activity (0.45 U chitinase g−1, 0.28 U lipase g−1, and 1.29 U protease g−1). However, treatments with the highest conidia yields and enzymatic activity were not positively correlated to the efficacy against H. zea. When M. rileyi was produced on T5 (yeast hydrolysate + V8 juice), conidia were 35% more virulent than treatment T6. The findings evidenced the noticeable impact of nutritional substrate amended for conidia production and quality. This work showed the relevance of insecticidal activity assessment as a selection criterion in the mass production development of a biocontrol agent.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metarhizium rileyi Farlow (previously known as Nomuraea rileyi) is a widespread dimorphic entomopathogenic fungus, used to control lepidopterans pests including more than 60 species such as Anticarsia gemmatalis, Spodoptera frugiperda, Heliothis virescens, and Helicoverpa zea (Boucias et al. 2016; Fronza et al. 2017; Liu et al. 2019). Its virulence is due in part to its high genetic variability, enzyme production, and stress tolerance that drive epizootics (Bertholdo et al. 2003; Boucias et al. 2016; Butt et al. 2016; Edelstein et al. 2005). M. rileyi is a very desirable microorganism as a biocontrol agent due to its narrow host specificity (Sinha et al. 2016).

The adoption of a microorganism as a biological control agent as part of integrated pest management will require more predictable performance and higher efficiency in propagule production (Lacey et al. 2001). Mass production of entomopathogenic fungi should show high versatility, require relatively low nutritional requirements for growth, and can be carried out using two main techniques: submerged fermentation and solid-state fermentation (Hölker and Lenz 2005; Mascarin et al. 2019). Submerged fermentation is preferred because of its high profitability, shorter production time, and easy control of process parameters. Nevertheless, propagules have a short life span and poor tolerance to adverse environmental conditions (Muñoz et al. 1995; Zaki et al. 2020; Jaronski 2023). Solid-state fermentation is the most used cultivation system for fungi, because it recreates the natural way they grow and produces aerial conidia (De la Cruz-Quiroz et al. 2016; Lara-Juache et al. 2021). These propagules are the main active ingredient in mycopesticides due to their process reproducibility, tolerance to abiotic stresses, infection performance, and easy mass production on a low-cost substrate (Hölker and Lenz 2005; Ibrahim et al. 2015; Mascarin and Jaronski 2016; Sala et al. 2019).

The major challenge for aerial conidia obtention is to stabilize its highly variable growth and low productivity by solid-state fermentation (Fronza et al. 2017; Iwanicki et al. 2020). The manipulation of culture medium composition positively alters conidia physiological growth to provide stability during fermentation and into formulation prototypes (Muñiz-Paredes et al. 2017; Zaki et al. 2020). Although the demonstrated virulence of M. rileyi against important economic insect pests, its high sensitivity to abiotic factors, poor sporulation, and demanding nutritional requirements have not allowed the development of an optimum culture medium for aerial conidia production (Boucias et al. 1984; Edelstein et al. 2005; Faria et al. 2017; Goettel and Roberts 1991; Grijalba et al. 2018). Among Metahizium species, concentrations of propagules have been reported in submerged fermentation (2 × 108 blastospores mL−1 for M. anisopliae, 5 × 107 blastospores mL−1 for M. robertsii, 7 × 107 blastospores mL−1 for M. rileyi) and solid-state fermentation (1.2 × 109 conidia g−1 for M. anisopliae, 3.9 × 109 conidia g−1 for M. rileyi); demonstrating the highest productivity with solid systems (Grijalba et al. 2018; de Sá Santos et al. 2020; Iwanicki et al. 2021; Gotti et al. 2023). Furthermore, lethal times are shorter with aerial conidia than with blastospores for Metarhizium sp. (Gotti et al. 2023).

The selection of strategies to improve production efficiency is crucial for commercially developing biopesticides. Consequently, the screening of favorable and cost-effective conditions and additives to enhance conidial yield can expend considerable effort (Devi et al. 2001; Jaronski et al. 2023; Ravensberg 2011; Thakre et al. 2011). Moreover, quality specifications for biopesticides (microbiological, biochemical, and biological parameters) are necessary to ensure pre-determined quality and efficacy under the prescribed conditions for its use. Therefore, it is imperative to design a mass production to obtain fungal structures that withstand the downstream process and unfavorable field-application conditions, and provide consistent control of plant disease (Jeyarajan and Nakkeeran 2000). For solid-state fermentation, rice (high proportion of starch and amylase) is the most suitable substrate for quicker and better mass multiplication of M. rileyi (Thakre et al. 2011). Currently, M. rileyi conidia production systems are time-consuming (10 to 15 days) and conidial yields are unstable at times (2.2 × 106 to 8.4 × 109 conidia g−1 substrate) (Devi et al. 2001; Villamizar et al. 2004; Caro et al. 2005; Méndez et al. 2010; Thakre et al. 2011; Bich et al. 2018). Therefore, mass production of M. rileyi conidia is not sufficient to successfully incorporate it as a biological control agent in pest management.

Nutritional supplementation in a culture medium is the most effective way to improve quality conidia (germination, enzyme production, and virulence) in shorter fermentation times. For instance, the percentage of germination has been correlated with the addition of some substances, such as sugars and polyols (Hallsworth and Magan 1995; Jin et al. 1996), organic nitrogen sources (Caro et al. 2005; Devi et al. 2001), inorganic compounds (Aguirre et al. 2009; Jin et al. 1996), and cofactors (Elson et al. 1998; Jin et al. 1996). Likewise, substrate composition affects the production of virulence factors such as lipases, chitinases, and proteases. Therefore, the induction of these enzymes by different culture media could enhance biocontrol efficacy (Dhawan and Joshi 2017; Safavi et al. 2007; Mondal et al. 2016; Moon and Mun 2017).

Numerous studies on Metarhizium sp. production have demonstrated that specifically modifications of the nutritional environment impact significantly conidia development, pathogenicity, and conidial tolerance (Hallsworth and Magan 1995; Jackson and Jaronski 2009). However, to our knowledge, there is scarce information on how nutritional supplementation in M. rileyi cultures holistically affects its production, enzymatic activity, and virulence. Therefore, this study aimed to evaluate the effect of nutritional manipulation in the production of M. rileyi Nm017 on conidia quality (microbiological, enzymatic, and insecticidal activities) and process performance.

Materials and methods

Microorganism

The Colombian fungus strain used in this study was Metarhizium rileyi, encoded as Nm017, previously isolated from Anticarsia gemmatalis larvae and deposited at the Collection of Microorganisms with Interest in Biological Control of AGROSAVIA (Colombia), with an accession number 129. This isolate was cryopreserved at − 70 °C and propagated on MAYP (Edelstein et al. 2005) plus 0.1% w/v chloramphenicol (Colmed® International, Colombia), and incubated at 25 ± 0.5 °C for 7 days.

Fermentation process

Preparation of culture media

Five culture media supplements were evaluated for solid-state fermentation to produce aerial conidia at laboratory scale (Fig. 1). Each experimental unit had a mixture of broken rice supplemented with a nutritive solution (1:0.5 w/v), loaded into aluminum trays (10 cm × 6 cm × 3 cm), and subsequently sterilized at 121 °C, 15 psi for 20 min (TC-612, Gemmy Industrial Corp., China). The composition of the studied nutrient solutions was designed from three additives: yeast hydrolysate, yeast extract, and V8 juice. These were utilized in the following treatments (Fig. 1): T1, without supplements; T2, 8.2% v/v yeast hydrolysate, prepared with 100 mL hot water plus 8.2 g dehydrated yeast (Levapan®, Levapan S.A, Colombia; Caro et al. 2005); T3, 2% w/v yeast extract; T4, 2% w/v V8 juice; T5, 8.2% v/v yeast hydrolysate plus 2% w/v V8 juice; and T6, 2% w/v yeast extract plus 2% w/v V8 juice. Three replicated production sets were run for each experiment, with 15 experimental units per repetition.

Schematic representation for Metarhizium rileyi Nm017 conidia production with substrate supplemented: 1. Nutritive solutions preparation: T1 (without supplements), T2 (8.2% v/v yeast hydrolysate), T3 (2% w/v yeast extract), T4 (2% w/v V8 juice), T5 (8.2% v/v yeast hydrolysate + 2% w/v V8 juice), and T6 (2% w/v yeast extract + 2% w/v V8 juice); 2. Substrate soaking: hydration with nutritive solutions; 3. Sterilization: 121 °C, 15 psi for 20 min; 4. Spray inoculation: conidia suspension adjusted to 4.6 × 106 conidia mL−1; 5. Incubation: incubation room at 25 ± 2 °C and 70 ± 10% IHR, for seven days; 6. Drying process: incubation room at 25 ± 2 °C and 40 ± 10% EHR, for four days or until reaching a moisture content of ≤ 10%; 7. Harvesting process: vibratory sifting through a 800 μm mesh size

Inoculation and incubation

The inoculum was prepared from M. rileyi Nm017 conidia grown for seven days on MAYP agar, as a conidia suspension in 0.1% v/v Tween® 80 solution (Millipore, Merck® KGaA, Germany). Conidia concentration was adjusted to 4.6 × 106 conidia mL−1, and the suspension was sprayed in each substrate tray. Then, the trays were wrapped in a LLDPE film (porosity 45.2%) and placed in an incubation room for 7 days, at a temperature of 25 ± 2 °C and internal relative humidity (IRH) of 70 ± 10% (Fig. 1).

Drying process and conidia recovery

After inoculation, the weight of the substrate for each experiment was measured. After fermentation, each tray was covered with a porous cellulose membrane, placed in a room at 25 ± 2 °C and external relative humidity (ERH) of 40 ± 10%, for 4 days to enhance hyphal maturation, sporulation, and drying until reaching a moisture content of ≤ 10%. M. rileyi Nm017 (Fig. 1). Spore powder from the dried substrate was harvested by vibratory sifting through a mesh sieve (800 μm mesh size; U.S. Standard sieve series No. 50, The W. S. Tyley Company, U.S.A.). The weight and moisture content of the conidial powder collected were measured.

Conidial germination

Germination was assessed from each culture medium, using the recovered dry conidia (conidial powder). The microbiological parameter percentage of germination at 36 and 48 h was assessed. For each treatment, 1 g samples picked up aseptically were diluted in 0.1% v/v Tween® 80 solution, and decimal dilutions were done until 10–2. An aliquot of 100 µL of 10–2 dilution was plated on water agar plus 2% w/v yeast extract (Difco®, Thermo Fisher Scientific, U.S.A.), 2% v/v V8 juice (V8® Vegetable Juice, Campell’s, U.S.A.), and 0.00008% w/v benomyl [Benlate 50% w/w (WP), DuPont, Spain]. The Petri plates were incubated at 25 ± 2 °C for 36 and 48 h, and the germ tube growth was stopped with a lactophenol blue solution at each time (Sigma-Aldrich®, Merck KgaA, Germany). Germinated and non-germinated conidia were read in an optical microscope (400X magnification; CH30, Olympus®, Japan), and at least 100 conidia were scored per replicate. Conidia was considered germinated when its germ tube was at least twice its diameter (Ekesi et al. 1999; Milner et al. 1991). The results were reported as a percentage of germination at 36 and 48 h.

Performance parameters

The conidia/substrate yield was evaluated by counting microscopically (400X magnification; CH30, Olympus®, Japan) with a Neubauer hemocytometer (BOE 01, Boeco, Germany) from the dilutions used in conidial germination. The moisture content of the substrate samples was also determined using a halogen balance (MLS 50–3, Kern, Germany) at 121 °C to determine the moisture content (% kg water kg−1 dry material). Subsequently, concentrations were corrected as conidia per dry substrate gram (conidia g−1).

Fungus colonized substrate, conidial powder, and substrate after harvesting from each tray and treatment was taken to estimate the biomass/substrate yield (g biomass per kg dry substrate, g kg−1) (Shay et al. 1987). The percentage of the consumed substrate in each tray was calculated as the difference between weight of the dry substrate before inoculation and after harvesting (Tumuhaise et al. 2018).

Enzymatic activity

Conidia crude extracts were prepared as described by Villamizar et al. (2001), with modifications. 1 g of the colonized dried substrate of each treatment was suspended in 10 mL 1% v/v Tween® 80 solution and stirred at 3000 rpm for 1 h at room temperature. Suspensions were centrifuged for 10 min at 4000 rpm to obtain the supernatant, which was used in enzymatic assays.

Lipase activity was determined according to Beys da Silva et al. (2010) and Glogauer et al. (2011). 20 µL of crude extract were mixed with 230 µL of substrate [3 mg p-nitrophenyl palmitate, pNPP (Sigma®, Merck KgaA, Germany)] in 1 mL isopropanol (Sigma®, Merck KgaA, Germany) and 9 mL 50 mM Tris–HCl pH, containing 40 mg Triton X-100 (Sigma®, Merck KgaA, Germany) and 10 mg Arabic gum (Sigma®, Merck KgaA, Germany). The resulting solution was incubated at 37 ± 1 °C for 30 min. Absorbance was measured at 400 nm, and released p-nitrophenol was estimated using a standard curve. One unit of the enzyme was defined as the amount of enzyme that released 1 µmol p-nitrophenol per minute.

Chitinase activity was measured using 20 µL crude extract and 100 µL p-nitrophenyl-N-acetylglucosamine (Sigma®, Merck KgaA, Germany) (1 mg mL−1 in citrate buffer 0.1 M pH 5). The mixture was incubated at 37 ± 1 °C for 30 min and stopped with 150 µL NaOH-glycine pH 10.4 (Sigma®, Merck KgaA, Germany). Absorbance was measured at 400 nm, and the amount of p-nitrophenol was estimated using a standard curve. One unit of the enzyme was defined as the amount of enzyme that released 1 µmol p-nitrophenol per minute (Mejía et al. 2020).

Protease activity was determined using casein (Sigma®, Merck KgaA, Germany) at 0.65% as substrate. The reaction mixture contained 130 µL of 0.65% w/v casein and 25 µL of crude extract. The reaction was incubated for 10 min at 37 ± 2 °C, and stopped by adding 130 µL of 110 mM trichloroacetic acid (Sigma®, Merck KgaA, Germany), with incubation at 37 ± 2 °C for 20 min. The mixture was centrifuged at 10,000 rpm, for 15 min. 250 µL supernatant was mixed with 625 µL 500 mM of sodium carbonate (Sigma®, Merck KgaA, Germany) and 125 µL of 0.5 M Folin–Ciocalteu (Sigma®, Merck KgaA, Germany) solution. The mixture was incubated 30 min at 37 ± 2 °C. The absorbance was measured at 660 nm. One unit of the enzyme was defined as the amount of enzyme to release 1 µmol tyrosine per minute (Cupp-Enyard 2008).

Insecticidal activity

Insect rearing

The larvae of Helicoverpa zea were reared on an artificial diet prepared according to Greene et al. (1976) with modifications (Gómez et al. 2010), by Rearing Unit of AGROSAVIA – Tibaitatá Research Center. The rearing was in a controlled environment room at 28 ± 1 °C and a photoperiod of 12 h light/darkness.

Bioassay

Bioassays were carried out with second-instar larvae of H. zea, following the methodology described by Mejía et al. (2020). Larvae dorsum was inoculated by applying 2 µL of fungal suspension prepared in 0.1% v/v Tween® 80 solution and concentration adjusted to 1 × 106 conidia mL−1. Control larvae were inoculated with 0.1% v/v Tween® 80 solution. Inoculated larvae (sampling unit) were individually transferred to 15 mL plastic cups containing one maize grain as a feeding substrate. Twelve cups were placed in a 473 mL plastic box (experimental unit) and incubated under controlled conditions (25 ± 2 °C, 60% ERH) and a light/darkness photoperiod of 12 h. Larval mortality was recorded daily for 10 days. Each treatment had three replicates (3 experimental units) for a total of 36 larvae per treatment. The percentage of corrected mortality (treatment mortality corrected by mortality in the control treatment) was calculated using the Schneider-Orelli formula (Zar 1999).

Data analysis

The experiments in this study had three repetitions in time and three replicates per treatment. For statistical purposes, germination and efficacy were arcsine or square root transformed, and conidia concentration was log10 transformed. The results were verified for data normality (Shapiro–Wilk test) and the homoscedasticity (Bartlett's test). Statistical significance of the results was determined using one-way analysis of variance (ANOVA), and mean comparison test (Tukey HSD; confidence level of 95%), using Minitab® 19 Statistical Software (Minitab®, LLC, USA).

Results and discussion

Fermentation and drying processes

Metarhizium rileyi Nm017 grew and sporulated in all of the treatments assessed. The fermentation started with the colonization of white mycelium during the first 3–4 days for treatments T1 through T5 (Fig. 2a), and then production of olive-green aerial conidia started within 5–7 days for all media (Fig. 2b). However, T6 (2% w/v yeast extract + 2% w/v V8 juice) culture medium showed mycelium as early as the second day, and patches of conidia on its mycelial mat on the fourth day (Fig. 2). Different published protocols of mass multiplication have used yeast extract to increase aerial conidia production (Jaronski 2023; Mishra et al. 2016). Also, Devi et al. (2001) reported that yeast extract is required for the fungi mycelial growth. On the other hand, clarified V8 Juice at agar produces substantially more conidia in less time for Fusarium sp. strains (Elson et al. 1998). Moreover, these two nutritional supplements provided cheap carbon and nitrogen sources to boost better fungal growth (Jaronski 2023). Therefore, for a fungus such as M. rileyi with slow growth and sporadic sporulation on solid media, the nutrition augmented with yeast extract and V8 juice significantly influenced conidiation, and their action allowed increasing the effect that each one had individually (treatments T3 and T4).

Process fermentation of Metarhizium rileyi Nm017 with substrate supplemented (T1, without supplements; T2, 8.2% v/v yeast hydrolysate; T3, 2% w/v yeast extract; T4, 2% w/v V8 juice; T5, 8.2% v/v yeast hydrolysate + 2% w/v V8 juice; and T6, 2% w/v yeast extract + 2% w/v V8 juice): a Third day of fermentation; b Seventh day of fermentation

All nutritional supplementation proposed herein shorted the culture time of Nm017 to 7 days, traditionally ranging from 10 to 15 days (Devi et al. 2001; Villamizar et al. 2004; Caro et al. 2005; Méndez et al. 2010; Thakre et al. 2011; Bich et al. 2018). During the drying process, the loss of surface water over time caused the volume reduction of the fermentation solid matrix and, probably, the aerial conidia, which made the conidia dustier and less linked to the substrate.

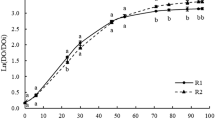

Conidial germination

Germinations of conidial powder from each culture medium assessed at 36 h and 48 h were less than 80%, except conidia from T6 (Fig. 3a and b). The findings showed that the three nutritional sources and their interaction were significantly relevant for germination at 36 h; while germination at 48 h was affected significantly by yeast extract and V8 juice (Germination at 36 h: F5,48 = 16.6, p < 0.0001; Germination at 48 h: F5,48 = 4.84, p = 0.0012). Early germination at 36 h was defined by Faria et al. (2017) as conidial vigor, which relates to the strength of conidia germination and germ tube growth. Vigor is strongly influenced by the fermentation system and downstream processing. For instance, rice substrate has been supplemented with additives to increase sporulation and germination, unlike substrates such as barley, oats, or wheat, probably due to their nitrogen and micronutrient content (Jaronski 2023). Likewise, rice contains a higher content of starch and amylase, and its hydrolysis produces glucose and maltose. Maltose released by fungal enzymes induces a series of mechanisms to accelerate fungi multiplication, including germination for mycelium production and subsequent sporulation (Thakre et al. 2011). Therefore, the substrate and additives used must provide a high availability of nutrients over a large surface area to promote germination and conidia formation (Machado et al. 2010; Mascarin et al. 2010).

Conidial germination and performance parameters of Metarhizium rileyi Nm017 conidia obtained from substrate supplemented (T1, without supplements; T2, 8.2% v/v yeast hydrolysate; T3, 2% w/v yeast extract; T4, 2% w/v V8 juice; T5, 8.2% v/v yeast hydrolysate + 2% w/v V8 juice; and T6, 2% w/v yeast extract + 2% w/v V8 juice): a Germination at 36 h (% conidia germinated per total conidia); b Germination at 48 h (% conidia germinated per total conidia); c Conidia/substrate yield (conidia g−1 dry substrate); d Biomass/substrate yield (g biomass kg−1 dry substrate); e Consumed substrate (% kg substrate consumed per kg−1 initial substrate). Treatments with no common letters are significantly different according to Tukey HDS test (α = 95%). Means are represented with the symbol ×

The germination at 36 h revealed that Nm017 conidia production requires slower drying to maintain high conidial viability, as was demonstrated with other Metarhizium sp. (Jaronski and Jackson 2012). Moreover, a previous evaluation to this study using Nm017 strain and T1 medium (without supplements), demonstrated the protective effect of the slower drying process. It was found that the colonized substrate had an initial moisture content of 54.4% and an initial conidial germination at 48 h of 81.1%, and after 4 days of drying, the substrate ended up with a moisture content of 8.9% and a conidial germination of 78.6% (unpublished data). Hence, the reduction in germination was only 3%.

The greatest increase in germination among the two evaluation times was observed with treatment T1 (30%), while the smallest increase was observed with T6 (3%). Thus, the highest and most vigorous conidia were those obtained in the T6 substrate. The V8 juice micronutrient source used in T4, T5, and T6 is rich in trace elements, vitamins, and amino acids, which are essential cofactors that stimulate the metabolic processes involved in germination (Elson et al. 1998; Jin et al. 1996). It also has a remarkable calcium content (16 mg 100 mL−1), which has been shown to modulate the growth rate of the germ tube, i.e., it is a precursor to the hyphae extension and medium colonization (Aguirre et al. 2009; Jin et al. 1996). Furthermore, Ca2+ is a signalling molecule involved in tolerance to stress conditions and virulence. Six major types of Ca2+ transporters have been reported for homeostasis and signalling (Roy et al. 2020).

Performance parameters

The highest values of the process parameters assessed were reached with the T6 treatment (Fig. 3c, d, and e). All treatments had a notable impact on conidia/substrate yield, in which T6 and T2 showed the highest and most significant values (Fig. 3c; F5,48 = 21.1, p < 0.0001), while biomass/substrate yields were statistically different between treatments (Fig. 3d; F5,48 = 41.3, p < 0.0001). However, the variable substrate consumption demonstrated equitable nutritional use of culture medium (24–31%), without significant differences between media (Fig. 3e; F5,48 = 2.22, p = 0.0678).

The culture medium without extra sources, T1, did not show significant sporulation (Fig. 3c), which may be due to the lack of suitable extra nutritional sources for conidiogenesis (Caro et al. 2005; Keppanan et al. 2018; Kumar et al. 2011; Webb and Manan 2017). On the contrary, the massive growth of M. rileyi Nm017 observed in treatments T2 (8.2% yeast hydrolysate) and T6 (2% yeast extract plus 2% V8 juice) stand out, possibly due to the presence of organic nitrogen sources, recognized as essential for mycelial growth and conidiogenesis (Devi et al. 2001). Although T2 contained a germination promoter (Caro et al. 2005) and showed significant effects over yields, its sporulation and germination had significant differences compared to T6 (Fig. 3a–c).

The commercial viability of potential biopesticides is defined by their suitability for mass production. Values achieved with both media, T2 and T6, were higher than those observed with other commercial entomopathogenic fungus, e.g., M. rileyi strains growth on a medium rich in soybeans (1.5 × 109 conidia g−1 substrate; Caro et al. 2005), wheat bran enriched with malt soda (3.0 × 109 conidia g−1 substrate; Villamizar et al. 2004), and crushed sorghum (1.4 × 109 conidia g−1 substrate; Devi et al. 2001). Also, Nm017 production presented appropriate biomass yields for commercial entomopathogenic species, like M. anisopliae (27–42.2 g kg−1) and B. bassiana (20–40 g kg−1) (Keppanan et al. 2018; Tumuhaise et al. 2018; Liu et al. 2015; Pham et al. 2010; Posada-Flórez 2008; Renuka et al. 2015). This could be due to the substrate used in this study (rice), in which most fungi reach the highest biomass production (Gouli et al. 2013; Li et al. 2010; Jaihan et al. 2016; Saldarriaga et al. 2017). Moreover, M. anisopliae isolates and Nm017 had similar substrate consumption patterns, e.g., Tumuhaise et al. (2018) reported a consumption percentage of 32.8%, and Agbessenou et al. (2021) reached values close to 25%.

Enzymatic activity

Similarly, fungal enzymes produced on solid-state fermentation have been highly regulated by the availability of carbon and nitrogen, pH, relative humidity, moisture content, and temperature, among other factors (Mondal et al. 2016; St. Leger and Wang, 1998). In this research, yeast hydrolysate, yeast extract, and V8 juice with vitamin content increased the three groups of evaluated enzymes (lipase, chitinase, and protease activity), and improved the conidial yield. Among the enzymatic activities evaluated, M. rileyi produced a higher level of proteases compared to chitinases and proteases (F17,144 = 249, p < 0.0001). The lipase activity was between 0.03 and 0.15 U g−1 in all of the treatments except T5, which was the lowest value found. The chitinase activity was substrate dependent in mass production (Fig. 4a) and the highest value was obtained in conidia produced on substrates T2 and T5 (0.10 and 0.23 U g−1, respectively). Similar to lipases, the lowest chitinase activity was measured in treatment T5. Significant differences were found in the protease activity of conidia produced on the six substrates in solid-state fermentation, with values between 0.77 and 1.3 U g−1. The highest protease activity was reached with treatments T2 and T6, like chitinases, and the lowest values were found with treatments T3 and T5.

a Enzymatic activity of Metarhizium rileyi Nm017 conidia obtained from substrate supplemented (T1, without supplements; T2, 8.2% v/v yeast hydrolysate; T3, 2% w/v yeast extract; T4, 2% w/v V8 juice; T5, 8.2% v/v yeast hydrolysate + 2% w/v V8 juice; and T6, 2% w/v yeast extract + 2% w/v V8 juice); b Conidia/substrate Yield (conidia g−1 dry substrate) vs. Enzymatic activity (U g−1 conidia); c Mortality against Helicoverpa zea second instar larvae caused by Metarhizium rileyi Nm017 conidia obtained from substrate supplemented (%); d Conidia/substrate Yield (conidia g.−1 dry substrate) vs. Mortality (% dead larvae per total larvae). Mean values (± SD) followed with no common letters are significantly different according to Tukey HDS test (α = 95%)

The results analysis showed that the enzymatic activity was affected by the nitrogen and micronutrient supplementation (Fig. 4b). Lipase activity was influenced by the three nutritional sources (yeast hydrolysate, yeast extract, and V8 juice) and their interactions, whereas the protease activity was influenced by yeast extract, and V8 juice. The chitinase activity only presented relevant effects with nitrogen and micronutrient interaction. Overall, T2, T4, and T6 supplementation affected both conidia yield and enzymatic activity (Fig. 4b). Comparably, Ferreira et al. (2021) showed that culture medium supplemented with sodium nitrate and riboflavin enhanced protease activity and conidia production of Metarhizium robertsii. Similarly, additives such as soybean protein combined with wheat bran induced the protease activity of M. anisopliae (Kim et al. 2020), and the supplementation with yeast extract improved the chitinase composition of M. anisopliae (Dhar and Kaur 2009). Also, it was demonstrated that C:N ratio is a crucial variable that induces enzyme expression, e.g., the use of potato flour substrate with a C:N ratio of 30:1 increased the enzymatic activity of B. bassiana, compared with rice powder substrate with a C:N of 10:1 (Mejía et al. 2020). Likewise, an isolate of B. bassiana produced greater protease Pr1 activity in solid media with a C:N ratio of 10:1 (Safavi et al. 2007).

Insecticidal activity

The use of supplements as enhancers of virulence has been tested before for entomopathogenic fungi. For instance, B. bassiana conidia harvested from wheat bran, rice bran, and SDAY reached the highest mortalities on the browntail moth Euproctis chrysorrhoea, compared to conidia obtained from other nutritional substrates such as millet, rice paddy, wheat, rice, and corn flour (Bena-Molaei et al. 2011). The nutritional composition of substrates could induce several virulence factors related to larvae mortality, e.g., proteins such as hydrophobins and adhesins that mediate conidia attachment to cuticle insect surface. (Butt et al. 2016; Sevim et al. 2012; Schrank and Vainstein 2010).

Although enzymes have been considered crucial virulence factors of entomopathogenic fungi, and several authors described the relatedness between enzymes and mortality (Dhawan and Joshi 2017; Gebremariam et al. 2022; Pelizza et al. 2012; Svedese et al. 2013), we did not find correlation among the high enzymatic activity of M. rileyi and the uppermost insecticidal activity against H. zea. In this study, conidia with the lowest levels of enzymes caused higher mortalities of H. zea. Accordingly, treatments T3 (2% yeast extract) and T5 (8.2% yeast hydrolysate + 2% V8 juice) with low levels of enzyme activity, significantly influenced the insecticidal activity of M. rileyi against H. zea second instar larva (Fig. 4c; F5,53 = 50.2, p < 0.0001). The lowest efficacy (18%) was found in conidia from T2. Efficacies between 48 and 50% were obtained with conidia produced in treatments T1, T4, and T6, with no significant differences between them. The highest values of efficacy were related to yeast extract and sources interaction effects (Fig. 4c). Also, Petlamul and Prasertsan (2012) characterized several Beauveria and Metarhizium isolates based on their germination rate, conidia production, radial growth, enzyme activity, and virulence against Spodoptera litura. They found that a strain of B. bassiana had the highest germination rate and was the most virulent, but the lowest enzymatic activity. On the other hand, M. anisopliae strains produced the highest chitinase and protease activities.

These results suggest that the nutritional composition could be inducing other relevant virulence factors during fungal attachment and colonization of the insect. For instance, nutrients and fermentation system have been reported to influence the expression of different virulence factors such as collagen-like protein to evade the insects´ immune response, trehalases to use trehalose from the hemolymph, and regulation of heat-shock proteins and enzymes involved in response to oxidative stress (Gotti et al. 2023; Iwanicki et al. 2023). Pang et al. (2023) evidenced that the virulence of M. rileyi against S. frugiperda was determined by both expression of protective and detoxifying enzymes from the host and resistance to oxidative stress of the fungus.

Conclusions

Through the research, we have demonstrated the effects of nutritional supplementation of the substrate on production and quality of M. rileyi Nm017 conidia. Results showed that the designed nutritional enrichment strategies enhanced the fungal viability and enzymatic activity. However, no nutritional relationship was found between conidia quality, enzyme activity, and biological activity. These findings supported the relevance of including the insecticidal activity for production strategies of potential biocontrol microorganisms as a selection criterion, in addition to germination and productivity. Further research is required to determine different virulence factors associated with insecticidal activity and production development on higher scales.

Author contribution statement

CM: conceptualization, investigation, methodology, formal analysis, writing—original draft, writing—review and editing; JR: investigation, methodology, formal analysis, writing—review and editing; JS: investigation, methodology, formal analysis, writing—original draft; MIG-Á: methodology, writing—review and editing, supervision, project administration, funding acquisition; GQ-C: conceptualization, investigation, methodology, formal analysis, writing—original draft, writing—review and editing, supervision.

Data availability

The data sets generated and analyzed in this study are available from the corresponding author on reasonable request.

References

Agbessenou A, Akutse KS, Yusuf AA, Wekesa SW, Khamis FM (2021) Temperature-dependent modelling and spatial prediction reveal suitable geographical areas for deployment of two Metarhizium anisopliae isolates for Tuta absoluta management. Sci Rep 11:1–16. https://doi.org/10.1038/s41598-021-02718-w

Aguirre N, Villamizar LR, Espinel C, Cotes AM (2009) Efecto del pH y de la actividad de agua sobre el desarrollo de Nomuraea rileyi (Hyphomycetes). Rev Colomb Entomol 35:138–144

Bena-Molaei P, Talaei-Hassanloui R, Askary H (2011) Effect of culture substrates on virulence of Beauveria bassiana (Ascomycota: Cordycipitaceae) conidia against the browntail moth, Euproctis chrysorrhoea (Lepidoptera: Lymantriidae). Biocontrol Sci Technol 21:619–624. https://doi.org/10.1080/09583157.2011.568114

Bertholdo LR, Rossato M, da Silva RR, Monteiro de Barros N (2003) Characterization of Nomuraea rileyi strains using polumorphic DNA, virulence and enzyme activity. Brazilian Arch Biol Technol 46:13–18

Beys da Silva WO, Santi L, Schrank A, Vainstein MH (2010) Metarhizium anisopliae lipolytic activity plays a pivotal role in Rhipicephalus (Boophilus) microplus infection. Fungal Biol 114:10–15. https://doi.org/10.1016/j.mycres.2009.08.003

Bich GA, Castrillo M, Villalba LL, Zapata PD (2018) Evaluation of rice by-products, incubation time, and photoperiod for solid state mass multiplication of the biocontrol agents Beauveria bassiana and Metarhizium anisopliae. Agron Res 16:1921–1930

Boucias DG (1984) Nutritional requirements for conidial germination of several host range pathotypes of the entomopathogenic fungus Nomuraea rileyi. J Invertebr Pathol 43:288–292

Boucias D, Liu S, Meagher R, Baniszewski J (2016) Fungal dimorphism in the entomopathogenic fungus Metarhizium rileyi: detection of an in vivo quorum-sensing system. J Invertebr Pathol 136:100–108. https://doi.org/10.1016/j.jip.2016.03.013

Butt TM, Coates CJ, Dubovskiy IM, Ratcliffe NA (2016) Entomopathogenic Fungi: New Insights into Host-Pathogen Interactions. In: Lovett B, St. Leger R (eds) Genetics and Molecular Biology of Entomopathogenic Fungi, Academic Press Elsevier Ltd., Amsterdam, pp 307–364.

Caro LF, Villamizar LF, Espinel C, Cotes AM (2005) Efecto del medio de cultivo en la virulencia de Nomuraea rileyi sobre Spodoptera frugiperda (Lepidoptera: Noctuidae). Rev Colomb Entomol 31:79–88

Cupp-Enyard C (2008) Sigma´s non-specific protease activity assay - casein as a substrate. J vis Exp 19:4–5

De la Cruz-Quiroz R (2016) Solid-State fermentation in a bag bioreactor: Effect of corn cob mixed with Phytopathogen biomass on spores and cellulase production by Trichoderma asperellum. IntechOpen. https://doi.org/10.5772/64643

De Sá SP, Abati K, Mendoya NVR, Mascarin GM, Delalibera I (2021) Nutritional impact of low-cost substrates on biphasic fermentation for conidia production of the fungal biopesticide Metarhizium anisopliae. Bioresour Technol Rep 13:100619. https://doi.org/10.1016/j.biteb.2020.100619

Devi PS, Chowdary A, Prasad YG (2001) Cost-effective multiplication of the entomopathogenic fungus Nomuraea rileyi (F) Samson. Mycopathologia 151:35–39

Dhar P, Kaur G (2009) Effects of carbon and nitrogen sources on the induction and repression of chitinase enzyme from Metarhizium anisopliae isolates. Ann Microbiol 59:545–551

Dhawan M, Joshi N (2017) Enzymatic comparison and mortality of Beauveria bassiana against cabbage caterpillar Pieris brassicae LINN. Braz J Microbiol 48:522–529. https://doi.org/10.1016/j.bjm.2016.08.004

Edelstein JD, Trumper EV, Lecuona RE (2005) Temperature-dependent development of the entomopathogenic fungus Nomuraea rileyi (Farlow) Samson in Anticarsia gemmatalis (Hübner) larvae (Lepidoptera: Noctuidae). Neotrop Entomol 34:593–599

Ekesi S, Maniania NK, Ampong-Nyarko K (1999) Effect of temperature on germination, radial growth and virulence of Metarhizium anisopliae and Beauveria bassiana on Megalurothrips sjostedti. Biocontrol Sci Technol 9:177–185

Elson MK, Schisler DA, Jackson MA (1998) Carbon-to-nitrogen ratio, carbon concentration, and amino acid composition of growth media influence conidiation of Helminthosporium solani. Mycologia 90:406–413

Faria M, Martins I, Souza DA, Mascarin GM, Lopes RB (2017) Susceptibility of the biocontrol fungi Metarhizium anisopliae and Trichoderma asperellum (Ascomycota: Hypocreales) to imbibitional damage is driven by conidial vigor. Biol Control 107:87–94. https://doi.org/10.1016/j.biocontrol.2017.01.015

Ferreira JM, Pinto SMN, Soares FEF (2021) Metarhizium robertsii protease and conidia production, response to heat stress and virulence against Aedes aegypti larvae. AMB Express 11:1–13. https://doi.org/10.1186/s13568-021-01326-1

Fronza E, Specht A, Heinzen H, de Barros NM (2017) Metarhizium (Nomuraea) rileyi as biological control agent. Biocontrol Sci Technol 27:1243–1264. https://doi.org/10.1080/09583157.2017.1391175

Gebremariam A, Chekol Y, Assefa F (2022) Extracellular enzyme activity of entomopathogenic fungi, Beauveria bassiana and Metarhizium anisopliae and their pathogenicity potential as a bio-control agent against whitefly pests, Bemisia tabaci and Trialeurodes vaporariorum. BMC Res Notes 15:1–6. https://doi.org/10.1186/s13104-022-06004-4

Glogauer A, Martini VP, Faoro H, Couto GH, Müller-Santos M, Monteiro RA, Mitchell DA, de Souza EM, Pedrosa FO, Krieger N (2011) Identification and characterization of a new true lipase isolated through metagenomic approach. Microb Cell Fact 10:1–15. https://doi.org/10.1186/1475-2859-10-54

Goettel MS, Roberts DW (1991) Mass production formulation and field application of entomopathogenic fungi. In: Lomer CJ, Prior C (eds) Biological control of locusts and grasshoppers. Wallingford, UK, pp 232–238

Gómez J, Guevara E, Barrera G, Cotes AM, Villamizar L (2010) Aislamiento, identificación y caracterización de nucleopoliedrovirus nativos de Spodoptera frugiperda en Colombia. Rev Fac Nac Agron 63:5511–5520

Gotti IA, Moreira CC, Delalibera I, De Fine Licht HH (2023) Blastospores from Metarhizium anisopliae and Metarhizium rileyi are not always as virulent as conidia are towards Spodoptera frugiperda caterpillars and use different infection mechanisms. Microorganisms 11:1594. https://doi.org/10.3390/microorganisms11061594

Gouli V, Provost C, Gouli S, Parker BL, Skinner M (2013) Productivity of different species of entomopathogenic fungi based on one type of technology. J Agric Technol 9:571–580

Greene GL, Leppla NC, Dickerson WA (1976) Velvet bean caterpillar: a rearing procedure and artificial medium. J Econ Entomol 69:487–488

Grijalba EP, Espinel C, Cuartas PE, Chaparro ML, Villamizar LF (2018) Metarhizium rileyi biopesticide to control Spodoptera frugiperda: stability and insecticidal activity under glasshouse conditions. Fungal Biol 122(11):1069–1076

Hallsworth JE, Magan N (1995) Manipulation of intracellular glycerol and erythritol enhances germination of conidia at low water availability. Microbiology (reading) 141:1109–1115. https://doi.org/10.1099/13500872-141-5-1109

Hölker U, Lenz J (2005) Solid-state fermentation-are there any biotechnological advantages? Curr Opin Microbiol 8:301–306. https://doi.org/10.1016/j.mib.2005.04.006

Ibrahim L, Laham L, Touma A, Ibrahim S (2015) Mass production, yield, quality, formulation and efficacy of entomopathogenic Metarhizium anisopliae conidia. Curr J Appl Scien Technol 9(5):427–440. https://doi.org/10.9734/BJAST/2015/17882

Iwanicki NS, Mascarin GM, Moreno SG, Eilenberg J, Delalibera Júnior I (2020) Growth kinetic and nitrogen source optimization for liquid culture fermentation of Metarhizium robertsii blastospores and bioefficacy against the corn leafhopper Dalbulus maidis. World J Microbiol Biotechnol 36:1–13. https://doi.org/10.1007/s11274-020-02844-z

Iwanicki NS, Mascarin GM, Moreno SG, Eilenberg J, Delalibera I (2021) Development Pf novel spray-dried and air-dried formulations of Metarhizium Robertsii blastospores and their virulence against Dalbulus Maidis. Appl Microbiol Biotechnol 105:7913–7933. https://doi.org/10.1007/s00253-021-11576-5

Iwanicki NS, Delalibera I, de Carvalho LB, L, Eilenberg J, De Fine Licht HH, (2023) Comparative transcriptomics of growth metabolism and virulence reveal distinct morphogenic profiles of yeast-like cell and hyphae of the fungus Metarhizium rileyi. Fungal Genet Biol 164:103766. https://doi.org/10.1016/j.fgb.2022.103766

Jackson MA, Jaronski ST (2009) Production of microsclerotia of the fungal entomopathogen Metarhizium anisopliae and their potential for use as a biocontrol agent for soil-inhabiting insects. Mycol Res 113:842850. https://doi.org/10.1016/j.mycres.2009.03.004

Jaihan P, Sangdee K, Sangdee A (2016) Selection of entomopathogenic fungus for biological control of chili anthracnose disease caused by Colletotrichum spp. Eur J Plant Pathol 146:551–564. https://doi.org/10.1007/s10658-016-0941-7

Jaronski ST (2023) Mass production of entomopathogenic fungi: state of the art. In: Morales-Ramos JA, Rojas MG, Shapiro-Ilan DI (eds) Mass production of beneficial organisms: invertebrates and entomopathogens. Academic Press, Elsevier, London, pp 357–413

Jaronski TS, Jackson AM (2012) Mass production of entomopathogenic Hypocreales. In: Lacey LA (ed) Manual of techniques in invertebrate pathology. Academic Press, Elsevier, London, pp 255–284

Jeyarajan R, Nakkeeran S (2000) Exploitation of microorganisms and viruses as biocontrol agents for crop disease management. In: Upadhyay RK, Mukerji KG, Chamola BP (eds) Biocontrol potential and its exploitation in sustainable agriculture. Springer, Boston, MA, pp 95–116

Jin X, Taylor AG, Harman GE (1996) Development of media and automated liquid fermentation methods to produce desiccation-tolerant propagules of Trichoderma harzianum. Biol Control 7:267–274

Keppanan R, Sivaperumal S, Ramos Aguila LC, Hussain M, Bamisile BS, Dash CK, Wang L (2018) Isolation and characterization of Metarhizium anisopliae TK29 and its mycoinsecticide effects against subterranean termite Coptotermes formosanus. Microb Pathog 123:52–59. https://doi.org/10.1016/j.micpath.2018.06.040

Kim HM, Jeong SG, Choi IS, Yang JE, Lee KH, Kim J, Kim JC, Kim JS, Park HW (2020) Mechanisms of insecticidal action of Metarhizium anisopliae on adul japanese pine sawyer beetles (Monochamus alternatus). ACS Omega 5:25312–25318. https://doi.org/10.1021/acsomega.0c03585

Kumar V, Sahai V, Bisaria VS (2011) High-density spore production of Piriformospora indica, a plant growth-promoting endophyte, by optimization of nutritional and cultural parameters. Bioresour Technol 102:3169–3175. https://doi.org/10.1016/j.biortech.2010.10.116

Lacey LA, Frutos R, Kaya HK, Vail P (2001) Insect pathogens as biological control agents: do they have a future? Biol Control 21:230–248. https://doi.org/10.1006/bcon.2001.0938

Lara-Juache HR, Ávila-Hernández JG, Rodríguez-Durán LV, Michel MR, Wong-Paz JE, Muñiz-Márquez DB, Veana F, Aguilar-Zárate P (2021) Characterization of a biofilm bioreactor designed for the single-step production of aerial conidia and oosporein by Beauveria bassiana PQ2. J Fungi 7:582. https://doi.org/10.3390/jof7080582

Li R, Jiang LX, Guan H (2010) Optimization of mycelium biomass and exopolysaccharides production by Hirsutella sp. in submerged fermentation and evaluation of exopolysaccharides antibacterial activity. Afr J Biotechnol 9:195–202

Liu H, Wang P, Hu Y, Zhao G, Liu H, Li Z, HefangW LW, Zhiming Z (2015) Optimised fermentation conditions and improved collection efficiency using dual cyclone equipment to enhance fungal conidia production. Biocontrol Sci Technol 25:1011–1023. https://doi.org/10.1080/09583157.2015.1025701

Liu S, Xu Z, Wang X, Zhao L, Wang G, Li X, Zhang L (2019) Pathogenicity and in vivo Development of Metarhizium rileyi Against Spodoptera litura (Lepidoptera: Noctuidae) Larvae. J Econ Entomol 112:1598–1603. https://doi.org/10.1093/jee/toz098

Machado ACR, Monteiro AC, Almeida AMBD, Nartins MIEG (2010) Production technology for entomopathogenic fungus using a biphasic culture system. Pesq Agropec Bras 45:1157–1163. https://doi.org/10.1590/S0100-204X2010001000015

Mascarin GM, Jaronski ST (2016) The production and uses of Beauveria bassiana as a microbial insecticide. World J Microbiol Biotechnol 32(11):177. https://doi.org/10.1007/s11274-016-2131-3

Mascarin GM, Alves SB, Lopes RB (2010) Culture media selection for mass production of Isaria fumosorosea and Isaria farinosa. Brazilian Arch Biol Technol 53:753–761

Mascarin GM, Lopes RB, Delalibera I, Fernandes EKK, Luz C, Faria M (2019) Current status and perspectives of fungal entomopathogens used for microbial control of arthropod pests in Brazil. J Invertebr Pathol 165:46–53. https://doi.org/10.1016/j.jip.2018.01.001

Mejía C, Espinel C, Forero M, Ramos FA, Brandão PFB, Villamizar L (2020) Improving ecological fitness of Beauveria bassiana conidia to control the sugar cane borer Diatraea saccharalis. Biocontrol Sci Technol 30:513–530. https://doi.org/10.1080/09583157.2020.1738343

Méndez A, del Pozo E, García I, González A (2010) Evaluación de sustratos sólidos para la producción masiva de Nomuraea rileyi (FARLOW) SAMSON. Rev Protección Veg 25:108–112

Milner RJ, Huppatz RJ, Swaris SC (1991) A new method for assessment of germination of Metarhizium conidia. J Invertebr Pathol 57:121–123

Mishra S, Kumar P, Malik A (2016) Suitability of agricultural by-products as production medium for spore production by Beauveria bassiana HQ917687. Int J Recycl Org Waste Agricult 5:179–184. https://doi.org/10.1007/s40093-016-0127-5

Mondal S, Baksi S, Koris A, Vatai G (2016) Journey of enzymes in entomopathogenic fungi. Pac Sci Rev A Nat Sci Eng 18:85–99. https://doi.org/10.1016/j.psra.2016.10.001

Moon KS, Mun SH (2017) Mode of infection of Metarhizium spp. fungus and their potential as biological control agents. J Fungi 3:1–20. https://doi.org/10.3390/jof3020030

Muñiz-Paredes F, Miranda-Hernández F, Loera O (2017) Production of conidia by entomopathogenic fungi: from inoculants to final quality tests. World J Microbiol Biotechnol 33(3):57. https://doi.org/10.1007/s11274-017-2229-2

Muñoz GA, Agosin E, Cotoras M, Martin RS, Volpe D (1995) Comparison of aerial and submerged spore properties for Trichoderma harzianum. FEMS Nicrobiol Lett 125:63–69. https://doi.org/10.1016/0378-1097(94)00474-6

Pang J, Peng Y, Di T, Du G, Chen B (2023) Virulence of Metarhizium rileyi is determined by its growth and antioxidant stress and the protective and detoxifying enzymes of Spodoptera frugiperda. InSects 14:260. https://doi.org/10.3390/insects14030260

Pelizza AS, Eliades LA, Saparrat MCN, Cabello MN, Scorsetti AC, Lange CE (2012) Screening of Argentine native fungal strains for biocontrol of the grasshopper Tropidacris collaris: relationship between fungal pathogenicity and chitinolytic enzyme activity. World J Microbiol Biotechnol 28:1359–1366. https://doi.org/10.1007/s11274-011-0935-8

Petlamul W, Prasertsan P (2012) Evaluation of strains of Metarhizium anisopliae and Beauveria bassiana against Spodoptera litura on the basis of their virulence, germination rate, conidia production, radial growth and enzyme activity. Mycobiology 40:111–116. https://doi.org/10.5941/MYCO.2012.40.2.111

Pham TA, Kim JJ, Kim K (2010) Optimization of solid-state fermentation for improved conidia production of Beauveria bassiana as a mycoinsecticide. Mycobiology 38:137–143. https://doi.org/10.4489/MYCO.2010.38.2.137

Posada-Flórez FJ (2008) Production of Beauveria bassiana fungal spores on rice to control the coffee berry borer, Hypothenemus hampei, in Colombia. J Insect Sci 8:1–13

Ravensberg WJ (2011) A roadmap to the successful development and commercialization of microbial pest control products for control of arthropods, 1st edn. Springer, Dordrecht

Raymond JSt., Leger JL, Roberts D (1998) Ambient pH is a major determinant in the expression of cuticle-degrading enzymes and Hydrophobin by Metarhizium anisopliae. Appl Environ Microbiol 64:709–713

Renuka S, Ramanuja B, Poornesha B (2015) Screening of Beauveria bassiana (Balsamo) Vuillemin isolates against maize stem borer, Chilo partellus (Lepidoptera: Pyralidae) and the Effect of solid substrates on conidial production and virulence. J Pure Appl Microbiol 9:2979–2986

Roy A, Kumar A, Baruah D, Tamuli R (2020) Calcium signaling is involved in diverse cellular processes in fungi. Mycology 12:10–24. https://doi.org/10.1080/21501203.2020.1785962

Safavi SA, Shah FA, Pakdel AK, Reza Rasoulian G, Bandani AR, Butt TM (2007) Effect of nutrition on growth and virulence of the entomopathogenic fungus Beauveria bassiana. FEMS Microbiol Lett 270:116–123. https://doi.org/10.1111/j.1574-6968.2007.00666.x

Sala A, Barrena R, Artola A, Sánchez A (2019) Current developments in the production of fungal biological control agents by solid-state fermentation using organic solid waste. Crit Ver Environ Sci Technol 49:655–694. https://doi.org/10.1080/10643389.2018.1557497

Saldarriaga JJ, D’Alessandro CP, Conceschi MR, Mascarin GM, Delalibera Júnior I (2017) Efficacy of entomopathogenic fungi against adult Diaphorina citri from laboratory to field applications. J Pest Sci 90:947–960. https://doi.org/10.1007/s10340-017-0846-z

Schrank A, Vainstein MH (2010) Metarhizium anisopliae enzymes and toxins. Toxicon 56:1267–1274. https://doi.org/10.1016/j.toxicon.2010.03.008

Sevim A, Donzelli BGG, Wu D, Demirbag Z, Gibson DM, Turgeon BG (2012) Hydrophobin genes of the entomopathogenic fungus, Metarhizium brunneum, are differentially expressed and corresponding mutants are decreased in virulence. Curr Genet 58:79–92. https://doi.org/10.1007/s00294-012-0366-6

Shay LK, Hunt HR, Wegner GH (1987) High-productivity fermentation process for cultivating industrial microorganisms. J Ind Microbiol 2:79–85

Sinha KK, Choudhary AK, Kumari P (2016) Entomopathogenic Fungi. In: Pest E (ed) Omkar. Management for Food Security. Academic Press, London, pp 475–505

Svedese VM, Tiago PV, Pereira JD, Mesquita LP, Alves EA, Figueiredo AL (2013) Pathogenicity of Beauveria bassiana and production of cuticle-degrading enzymes in the presence of Diatraea saccharalis cuticle. Afr J Biotechnol 12:6491–6497. https://doi.org/10.5897/AJB2013.11972

Thakre M, Thakur M, Malik N, Ganger S (2011) Mass scale cultivation of entomopathogenic fungus Nomuraea rileyi using agricultural products and agro wastes. J Biopestic 4:176–179

Tumuhaise V, Ekesi S, Maniania NK, Tonnang HEZ, Tanga CM, Ndegwa PN, Irungu LW, Srinivasan R, Mohamed SA (2018) Temperature-dependent growth and virulence, and mass production potential of two candidate isolates of Metarhizium anisopliae (Metschnikoff) sorokin for managing Maruca vitrata Fabricius (Lepidoptera: Crambidae) on Cowpea. African Entomol 26:73–83. https://doi.org/10.4001/003.026.0073

Villamizar L, Cotes AM, Uribe D (2001) Relación entre la actividad enzimática y la virulencia de Metarhizium anisopliae sobre la langosta llanera (Orthoptera: Acrididae). Revista Colombiana De Entomología 27:107–114

Villamizar L, Arriero C, Bosa CF, Cotes AM (2004) Desarrollo de formulados a base de Nomuraea rileyi para el control de Spodoptera frugiperda (Lepidóptera: Noctuidae). Rev Colomb Entomol 30:99–105

Webb C, Manan MA (2017) Design aspects of solid state fermentation as applied to microbial bioprocessing. J Appl Biotechnol Bioeng 4:511–532. https://doi.org/10.15406/jabb.2017.04.00094

Zaki O, Weekers F, Thonart P, Tesch E, Jacques KP, P, (2020) Limiting factors of mycopesticide development. Biol Control 144:104220. https://doi.org/10.1016/j.biocontrol.2020.104220

Zar J (1999) Biostatistical analysis, Fouth. Prentice Hall, New Jersey

Acknowledgements

The authors acknowledge Ministerio de Agricultura y Desarrollo Rural de Colombia for its financial support in the project “Desarrollo de bioplaguicidas y su validación para el control de plagas de lepidópteros en cultivos agrícolas anuales en Colombia y Brasil” – TV-17 and recognize the support of Stella Rincón in the activities carried out in the current study.

Accession Numbers: The culture collection was registered in the National Collections Registry (RNC129) and was collected under AGROSAVIA permit framework number 1466 from 2014.

Funding

Open Access funding provided by Colombia Consortium.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no financial, non-financial or competing interests to declare that are relevant to the content of this article.

Informed consent

Any informed consent was not required in the study.

Research involving human participants and/or animals

This article does not contain any studies with human participants or animals performed by any of the authors.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Mejía, C., Rocha, J., Sanabria, J. et al. Performance of Metarhizium rileyi Nm017: nutritional supplementation to improve production and quality conidia. 3 Biotech 14, 89 (2024). https://doi.org/10.1007/s13205-023-03911-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-023-03911-6