Abstract

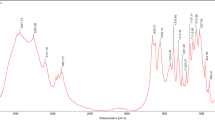

This study investigated the bioprocessing of shrimp wastes to obtain chitin and its deacetylated product chitosan by a fermentation process mediated by Lactobacillus plantarum. The concentrations of glucose, bacterial inoculum, and shrimp wastes in the Man, Rogosa and Sharpe medium were optimized for the fermentation process performed in shake flasks to achieve the maximum titratable acidity to obtain chitin. The experiments were scaled up in a 700-mL working volume bioreactor, and the resulting chitin was deacetylated by the autoclave method. The bioextracted chitosan was characterized (Fourier transform infrared spectroscopy [FTIR], deacetylation degree, and molecular weight) and evaluated for its antimicrobial effects by comparing it with a commercial chitosan sample in the context of the ethanolic fermentation process for fuel alcohol production. The effect of chitosan on such a fermentation process has not been determined yet. The bacterial contaminant Lactobacillus fermentum and the main agent of ethanolic fermentation Saccharomyces cerevisiae were cultured in semi-synthetic medium and co-cultured in sugarcane juice to verify the effect of chitosan on their growth. The bioextracted chitosan (molecular weight 4.0 × 105 g mol−1 and deacetylation degree 80%) was comparable to commercial chitosan, although higher concentrations of the former were required to achieve similar antimicrobial activities. Both commercial and bioextracted chitosan samples exhibited antimicrobial activity against S. cerevisiae and L. fermentum, but the concentration that caused the inhibition of yeast growth was almost tenfold higher than for the bacterium. Moreover, bioextracted chitosan showed no yeast inhibition or lethality in the range of 0.0075–0.96% while for the bacterium, growth inhibition occurred in concentrations varying from 0.24 to 0.48% and lethality of more than 99% at 0.96%. These results indicate the potential use of chitosan and especially of bioextracted chitosan in the bioethanol industry as a safer and more natural approach to combat unwanted bacterial contamination.

Similar content being viewed by others

References

AOAC (1995) Official methods of analysis. Association of Analytical Chemists, Washington DC

Basso TO, Gomes FS, Lopes ML, Amorim HV, Eggleston G, Basso LC (2014) Homo- and heterofermentative lactobacilli differently affect sugarcane-based fuel ethanol fermentation. Antonie Van Leeuwenhoek 105:169–177. https://doi.org/10.1007/s10482-013-0063-6

Beckner M, Ivey ML, Phister TG (2011) Microbial contamination of fuel ethanol fermentations. Lett Appl Microbiol 5:387–394. https://doi.org/10.1111/j.1472-765X.2011.03124.x

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Brugnerotto J, Lizardi J, Goycoolea FM, Argüelles-Monal J, Desbrières J, Rinaudo M (2001) An infrared investigation in relation with chitin and chitosan characterization. Polymer 42:3569–3580. https://doi.org/10.1016/S0032-3861(00)00713-8

Campana-Filho SP, Britto D, Curti E, Abreu FR, Cardoso MB, Battisti MV, Sim PC, Goy RC, Signini R, Lavall RL (2007) Extraction, structures and properties of α- and β-chitin. Quím Nova 30:644–650. https://doi.org/10.1590/S0100-40422007000300026

Ceccato-Antonini SR (2018) Conventional and nonconventional strategies for controlling bacterial contamination in fuel ethanol fermentations. World J Microbiol Biotechnol 34:80. https://doi.org/10.1007/s11274-018-2463-2

Chen X, Chew SL, Kerton FM, Yan N (2014) Direct conversion of chitin into a N-containing furan derivative. Green Chem 16:2204–2212. https://doi.org/10.1039/c3gc42436g

Du J, Tan E, Kim HJ, Zhang A, Bhattacharya R, Yarema KJ (2014) Comparative evaluation of chitosan, cellulose acetate, and polyethersulfone nanofiber scaffolds for neural differentiation. Carbohydr Polym 99:483–490. https://doi.org/10.1016/j.carbpol.2013.08.050

El Knidri H, El Khalfaouy R, Laajeb A, Addaou A, Lahsini A (2016) Eco-friendly extraction and characterization of chitin and chitosan from the shrimp shell waste via microwave irradiation. Process Saf Environ Protect 104:395–405. https://doi.org/10.1016/j.psep.2016.09.020

Ghorbel-Bellaaj O, Hajji S, Younes I, Chaabouni M, Nasri M, Jellouli K (2013) Optimization of chitin extraction from shrimp waste with Bacillus pumilus A1 using response surface methodology. Int J Biol Macromol 61:243–250. https://doi.org/10.1016/j.ijbiomac.2013.07.001

Gomes LP, Anjo SI, Manadas B, Coelho AV, Paschoalin VMF (2020) Proteomic analyses reveal new insights on the antimicrobial mechanisms of chitosan biopolymers and their nanosized particles against Escherichia coli. Int J Mol Sci 21:225. https://doi.org/10.3390/ijms21010225

Hamed I, Ozogul F, Regenstein JM (2016) Industrial applications of crustacean by-products (chitin, chitosan, and chitooligosaccharides): a review. Trends Food Sci Technol 48:40–50. https://doi.org/10.1016/j.tifs.2015.11.007

Herigstad B, Hamilton M, Heersink J (2001) How to optimize the drop plate method for enumerating bacteria. J Microbiol Methods 44:121–129. https://doi.org/10.1016/s0167-7012(00)00241-4

Hong KN, Cho YI, Kim HR, Meyers SP (2000) Effective deacetylation of chitin under conditions of 15 psi/121 °C. J Agric Food Chem 48:2625–2627. https://doi.org/10.1021/jf990842l

Hu Z, Gänzle MG (2018) Challenges and opportunities related to the use of chitosan as a food preservative. J Appl Microbiol 126:1318–1331. https://doi.org/10.1111/jam.14131

Jeon YJ, Park PJ, Kim SK (2001) Antimicrobial effect of chitooligosaccharides produced by bioreactor. Carbohydr Polym 44:71–76. https://doi.org/10.1016/S0144-8617(00)00200-9

Jung WJ, Jo GH, Kuk JH, Kim KY, Park RD (2006) Extraction of chitin from red crab shell waste by cofermentation with Lactobacillus paracasei subsp. Tolerans KCTC-3074 and Serratia marcescens FS-3. Appl Microbiol Biotechnol 71:234–237. https://doi.org/10.1007/s00253-005-0126-3

Khanafari A, Marandi R, Sanatei S (2008) Recovery of chitin and chitosan from shrimp waste by chemical and microbial methods. Iran J Environ Health Sci Eng 5:19–24

Kong M, Chen XG, Xing K, Park HJ (2010) Antimicrobial properties of chitosan and mode of action: a state of the art review. Int J Food Microbiol 144:51–63. https://doi.org/10.1016/j.ijfoodmicro.210.09.012

Lee HW, Park YS, Jung JS, Shin WS (2002) Chitosan oligosaccharides, dp 2–8, have prebiotic effect on the Bifidobacterium bifidium and Lactobacillus sp. Anaerobe 8:319–324. https://doi.org/10.1016/S1075-9964(03)00030-1

Li J, Wu Y, Zhao L (2016) Antibacterial activity and mechanism of chitosan with ultra high molecular weight. Carbohydr Polym 148:200–205. https://doi.org/10.1016/j.carbpol.2016.04.025

Liu M, Bayjanov JR, Renckens B, Nauta A, Siezen RJ (2010) The proteolytic system of lactic acid bacteria revisited: a genomic comparison. BMC Genom 11:36. https://doi.org/10.1186/1471-2164-11-36

Liu S, Sun J, Yu L, Zhang C, Bi J, Zhu F, Qu M, Jiang C, Yang Q (2012) Extraction and characterization of chitin from the beetle Holotrichia parallela Motschulsky. Molecules 17:4604–4611. https://doi.org/10.3390/molecules17044604

Mao X, Zhang J, Kan F, Gao Y, Lan J, Zhang X, Hu Z, Li Y, Lin H (2013) Antioxidant production and chitin recovery from shrimp head fermentation with Streptococcus thermophilus. Food Sci Biotechnol 22:1023–1032. https://doi.org/10.1007/s10068-013-0179-5

Marquez IG, Akuaku J, Cruz I, Cheetham J, Golshani A, Smith ML (2013) Disruption of protein synthesis as antifungal mode of action by chitosan. Int J Food Microbiol 164:108–112. https://doi.org/10.1016/j.ijfoodmicro.2013.03.025

Mellegard H, Strand S, Christensen B, Granum P, Hardy S (2011) Antibacterial activity of chemically defined chitosans: influence of molecular weight, degree of acetylation and test organism. Int J Food Microbiol 148:48–54. https://doi.org/10.1016/j.ijfoodmicro.2011.04.023

Muzzarelli RAA (1977) Chitin. Pergamon Press, Oxford

Neves AC, Zanette C, Grade ST, Schaffer JV, Alves HJ, Arantes MK (2017) Optimization of lactic fermentation for extraction of chitin from freshwater shrimp waste. Acta Sci Technol 39:125–133. https://doi.org/10.4025/actascitechnol.v39i2.29370

No HK, Park NY, Lee SH, Meyers SP (2002) Antibacterial activity of chitosans and chitosan oligomers with different molecular weights. Int J Food Microbiol 74:65–72. https://doi.org/10.1016/S0168-1605(01)00717-6

O’Callaghan KAM, Kerry JP (2016) Preparation of low- and medium-molecular weight chitosan nanoparticles and their antimicrobial evaluation against a panel of microorganisms, including cheese-derived cultures. Food Control 69:256–261. https://doi.org/10.1016/j.foodcont.2016.05.005

Panchakshari V, Srikanth K, Krishna PV, Babu CS (2016) Extraction of chitin and chitosan from biowaste of scampi Macrobrichum rosenbergii and tiger shrimp Penaeus monodon. Int J Curr Microbiol Appl Sci 5:751–758. https://doi.org/10.20546/ijcmas.2016.507.086

Ploydee E, Chaiyanan S (2014) Production of high viscosity chitosan from biologically purified chitin isolated by microbial fermentation and deproteinization. Int J Polym Sci 2014:1–8. https://doi.org/10.1155/2014/162173

Prameela K, Mohan CM, Smitha PV, Hemalatha KPJ (2010) Bioremediation of shrimp biowaste by using natural probiotic for chitin and carotenoid production—an alternative method to hazardous chemical method. Int J Appl Biol Pharmac Technol 1:903–910

Raafat D, Sahl HG (2009) Chitosan and its antimicrobial potential—a critical literature survey. Microb Biotechnol 2:186–201. https://doi.org/10.1111/j.1751-7915.2008.00080.x

Raafat D, von Bargen K, Haas A, Sahl HG (2008) Insights into the mode of action of chitosan as an antibacterial compound. Appl Environ Microbiol 74:3764–3773. https://doi.org/10.1128/AEM.00453-08

Rao MS, Stevens W (2005) Chitin production by Lactobacillus fermentation of shrimp biowaste in a drum reactor and its chemical conversion to chitosan. J Chem Technol Biotechnol 80:1080–1087. https://doi.org/10.1002/jctb.1286

Rinaudo M, Milas M, Dung P (1993) Characterization of chitosan. Influence of ionic strength and degree of acetylation on chain expansion. Int J Biol Macromol 15:281–285. https://doi.org/10.1016/0141-8130(93)90027-J

Ristić T, Lasič S, Kosalec I, Bračič M, Fras-Zemljič L (2015) The effect of chitosan nanoparticles onto Lactobacillus cells. React Funct Polym 97:56–62. https://doi.org/10.1016/j.reactfunctpolym.2015.10.007

Sedaghat F, Yousefzadi M, Toiserkani H, Najafipour S (2017) Bioconversion of shrimp waste Penaeus merguiensis using lactic acid fermentation: an alternative procedure for chemical extraction of chitin and chitosan. Int J Biol Macromol 104:883–888. https://doi.org/10.1016/j.ijbiomac.2017.06.099

Sini TK, Santhosh S, Mathew PT (2007) Study on the production of chitin and chitosan from shrimp shell by using Bacillus subtilis fermentation. Carbohydr Res 342:2423–2429. https://doi.org/10.1016/j.carres.2007.06.028

Tonhi E, Plepis AMG (2002) Obtenção e caracterização de blendas colágeno-quitosana. Quím Nova 25:943–948. https://doi.org/10.1590/S0100-40422002000600011

Varun TK, Senani S, Jayapai N, Chikkerur J, Roy S, Tekulapally VB, Gautam M, Kumar N (2017) Extraction of chitosan and its oligomers from shrimp shell waste, their characterization and antimicrobial effect. Vet World 10:170–175. https://doi.org/10.14202/vetworld.2017.170-175

Verlee A, Mincke S, Stevens CV (2017) Recent developments in antibacterial and antifungal chitosan and its derivatives. Carbohydr Polym 164:268–283. https://doi.org/10.1016/j.carbpol.2017.02.001

Wahyuntari IB, Junianto SS, Setyahadi S (2011) Process design of microbiological chitin extraction. Microbiol Indones 5:39–45. https://doi.org/10.5454/mi.5.1.7

Ydens I, Moins S, Degée P, Dubois P (2005) Solution properties of well-defined 2-(dimethylamino) ethyl methacrylate-based (co) polymers: a viscometric approach. Eur Polym J 41:1502–1509. https://doi.org/10.1016/j.eurpolymj.2005.02.002

Zhang H, Jin Y, Deng Y, Wang D, Zhao Y (2012) Production of chitin from shrimp shell powders using Serratia marcescens B742 and Lactobacillus plantarum ATCC 8014 successive two-step fermentation. Carbohydr Res 362:13–20. https://doi.org/10.1016/j.carres.2012.09.011

Zhang H, Yun S, Song L, Zhang Y, Zhao Y (2017) The preparation and characterization of chitin and chitosan under large-scale submerged fermentation level using shrimp by-products as substrate. Int J Biol Macromol 96:334–339. https://doi.org/10.1016/j.ijbiomac.2016.12.017

Zheng LY, Zhu JF (2003) Study on antimicrobial activity of chitosan with different molecular weights. Carbohydr Polym 54:527–530. https://doi.org/10.1016/j.carbpol.2003.07.009

Acknowledgements

This work was supported by Fundação de Amparo à Pesquisa do Estado de São Paulo (research grant numbers 2014/17794-2, 2017/20006-4 and 2018/19139-2) and by Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (grant number PNPD/33001014051P7; finance code 001).

Author information

Authors and Affiliations

Contributions

ICT was involved in the experimental design, performed the experiments and wrote the manuscript draft; LDS was involved in the experimental design, in the discussion of the results and in the edition of the manuscript; MAS and KRF were involved in the chitosan characterization and in the edition of the manuscript; SRCA was involved in the experimental design, in the discussion of the results and in the edition of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest in the publication.

Rights and permissions

About this article

Cite this article

Tanganini, I.C., Shirahigue, L.D., Altenhofen da Silva, M. et al. Bioprocessing of shrimp wastes to obtain chitosan and its antimicrobial potential in the context of ethanolic fermentation against bacterial contamination. 3 Biotech 10, 135 (2020). https://doi.org/10.1007/s13205-020-2128-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13205-020-2128-3