Abstract

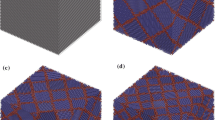

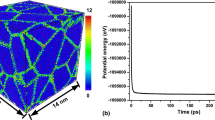

In the present study, molecular dynamics simulations have been performed to investigate the creep–ratcheting deformation behavior of nanocrystalline aluminum (NC Al) having an average grain size of ~ 8 nm. The influence of deformation temperature on creep–ratcheting behavior has been studied and associated with underlying mechanisms based on the structural evolution of the material identified. The vacancy concentrations, strains and dislocation densities have been evaluated at the end of each stage of creep–ratcheting process for two ratcheting stress ratios and three different temperatures. In the mean time, the microstructural and defect evolution has been investigated. Accumulation of creep–ratcheting strain is found to increase with the deformation temperature in the range of temperature investigated: 10–467 K. Cyclic hardening dominates in the initial stages of creep–ratcheting, whereas cyclic softening dominates in the final stages at a higher temperature. The creep–ratcheting plots exhibit a primary and steady state regions at room temperature (300 K). In addition, a tertiary region is also perceived at high temperature (467 K). The NC Al specimen is also found to be damaged earlier at a higher temperature (i.e., 467 K) than at 10 K and 300 K. The highest dislocation density is attained for room temperature creep–ratcheting deformation. Finally, it is seen from the dislocation analysis that the Shockley partial and full dislocations are the driving dislocations for the creep–ratcheting deformation process.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time because it is a part of an ongoing study.

References

Ashkenazy Y, Averback RS (2012) Irradiation induced grain boundary flow—a new creep mechanism at the nanoscale. Nano Lett 12:4084–4089

Berendsen HJ, Postma JV, van Gunsteren WF, DiNola ARHJ, Haak JR (1984) Molecular dynamics with coupling to an external path. J Chem Phys 81(8):3684–3690

Carter P (2005) Analysis of cyclic creep and rupture. Part 2: calculation of cyclic reference stresses and ratcheting interaction diagrams. Int J Pres Ves Pip 82:27–33

Chen D (1995) Structural modeling of nanocrystalline materials. Comput Mater Sci 3(3):327–333

Chen K, Liu H, Zhang Z, Li S, Todd R (2003) The improvement of constituent dissolution and mechanical properties of 7055 aluminum alloy by stepped heat treatments. J Mater Proc Technol 142(1):190–196

Faken D, Jónsson H (1994) Systematic analysis of local atomic structure combined with 3D computer graphics. Comput Mater Sci 2(2):279–286

Fedorov AA, Gutkin MY, Ovid’ko IA (2002) Triple junction diffusion and plastic flow in fine-grained materials. Scr Mater 47(1):51–55

Gleiter H (2000) Nanostructured materials: basic concepts and microstructure. Acta Mater 48(1):1–29

Honeycutt JD, Andersen HC (1987) Molecular dynamics study of melting and freezing of small Lennard-Jones clusters. J Phys Chem 91(19):4950–4963

Jiang H, Zhang J, Kang G, Xi C, Jiang C, Liu Y (2013) A test procedure for separating viscous recovery and accumulated unrecoverable deformation of polymer under cyclic loading. Polym Test 32(8):1445–1451

Jiao S, Kulkarni Y (2015) Molecular dynamics study of creep mechanisms in nanotwinned metals. Comp Mater Sci 110:254–260

Juslin N, Jansson V, Nordlund K (2010) Simulation of cascades in tungsten-helium. Philos Mag 90(26):3581–3589

Kang G (2008) Ratchetting: recent progresses in phenomenon observation, constitutive modeling and application. Int J Fatigue 30(8):1448–1472

Karvan P, Varvani-Farahani A (2020) Uniaxial ratcheting assessment of 304 stainless steel samples undergoing step-loading conditions at room and elevated temperatures. J Eng Mater Technol 142(3):031003

Kelchner CL, Plimpton SJ, Hamilton JC (1998) Dislocation nucleation and defect structure during surface indentation. Phys Rev B 58(17):11085

Koch CC (2003) Optimization of strength and ductility in nanocrystalline and ultrafine grained metals. Scr Mater 49(7):657–662

Kong QP, Cai B, Xiao ML (1997) High temperature creep of two nanocrystalline alloys. Mater Sci Eng A 234:91–93

Kreethi R, Verma P, Dutta K (2015) Influence of heat treatment on ratcheting fatigue behavior and post ratcheting tensile properties of commercial aluminum. Trans Indian Inst Metal 68:229–237

Kumar KS, Swygenhoven HV, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys. Acta Mater 51:5743–5774

Li J (2003) AtomEye: an efficient atomistic configuration viewer. Model Simul Mater Sci Eng 11(2):173

Li C, Jaramillo E, Strachan A (2013) Molecular dynamics simulations on cyclic deformation of an epoxy thermoset. Polymer 54(2):881–890

Li J, Fang Q, Liu Y (2014) Void formation of nanocrystalline materials at the triple junction of grain boundaries. Mater Res Exp 1(1):015013

Lin YC, Chen XM, Chen G (2011) Uniaxial ratcheting and low-cycle fatigue failure behaviors of AZ91D magnesium alloy under cyclic tension deformation. J Alloy Compd 509(24):6838–6843

Mendelev MI, Kramer MJ, Becker CA, Asta M (2008) Analysis of semi-empirical interatomic potentials appropriate for simulation of crystalline and liquid Al and Cu. Phil Mag 88(12):1723–1750

Meraj M, Pal S (2016) The effect of temperature on creep behaviour of porous (1 at. %) nano crystalline nickel. Trans Indian Inst Metal 69(2):277–282

Meraj M, Yedla N, Pal S (2016a) The effect of porosity- and void on creep behavior of ultra-fine grained nano crystalline nickel. Mater Lett 169:265–268

Meraj M, Yedla N, Pal S (2016b) Role of W on the dislocation evolution in Ni-W alloy during tension followed by compression loading. Metal Mater Int 22(3):373–382

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51:427–556

Mohamed FA, Yang H (2010) Deformation mechanisms in nanocrystalline materials. Metall Mater Trans A 41(4):823–837

Nie K, Wu WP, Zhang XL, Yang SM (2017) Molecular dynamics study on the grain size, temperature, and stress dependence of creep behavior in nanocrystalline nickel. J Mater Sci 52(4):2180–2191

Nordlund K, Ghaly M, Averback RS, Caturla M, de La Rubia TD, Tarus J (1998) Defect production in collision cascades in elemental semiconductors and fcc Metals. Phys Rev B 57(13):7556

Nosé S (1984) A unified formulation of the constant temperature molecular dynamics methods. J Chem Phys 81(1):511–519

Ovid’ko IA (2005) Deformation and diffusion modes in nanocrystalline materials. Int Mater Rev 50:65–82

Ovid’ko IA, Sheinerman AG (2004) Triple junction nanocracks in deformed nanocrystalline materials. Acta Mater 52:1201–1209

Pal S, Meraj M (2016) Structural evaluation and deformation features of interface of joint between nanocrystalline Fe–Ni–Cr alloy and nanocrystalline Ni during creep process. Mater Des 108:168–182

Pal S, Mishra S, Meraj M, Mondal AK, Ray BC (2018) On the comparison of interrupted and continuous creep behaviour of nanocrystalline copper: a molecular dynamics approach. Mater Lett 229:256–260

Pal S, Gururaj K, Meraj M, Bharadwaj RG (2019) Molecular dynamics simulation study of uniaxial ratcheting behaviors for ultrafine-grained nanocrystalline nickel. J Mater Eng Perform 28(8):4918–4930

Pal S, Babu PN, Gargeya BSK, Becquart CS (2019) Molecular dynamics simulation based investigation of possible enhancement in strength and ductility of nanocrystalline aluminum by CNT reinforcement. Mater Chem Phys 243:122593

Pan SP, Feng SD, Qin JW (2016) Correlation between local structure and dynamic heterogeneity in a metallic glass-forming liquid. J Alloys Compd 664:65–70

Paul SK, Sivaprasad S, Dhar S, Tarafder S (2010) Ratcheting and low cycle fatigue behavior of SA333 steel and their life prediction. J Nucl Mater 401(1–3):17–24

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19

Reddy KV, Meraj M, Pal S (2017) Mechanistic study of bending creep behaviour of bicrystal nanobeam. Comput Mater Sci 136:36–43

Shariatim M, Hatami H, Yarahmadi H, Eipakchi HR (2012) An experimental study on the ratcheting and fatigue behavior of polyacetal under uniaxial cyclic loading. Mater Des 34:302–312

Song Y, Ma Y, Zhan K (2020) Simulations of deformation and fracture of graphene reinforced aluminium matrix nanolaminated composites. Mech Mater 142:103283

Sreenivasan S, Mishra SK, Dutta K (2017) Ratcheting strain and its effect on low cycle fatigue behavior of Al 7075–T6 alloy. Mater Sci Eng A 698:46–53

Srivatsan TS, Sriram S, Veeraraghavan D, Vasudevan VK (1997) Microstructure, tensile deformation and fracture behaviour of aluminium alloy 7055. J Mater Sci 32(11):2883–2894

Stukowski A (2009) Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool. Modell Simul Mater Sci Eng 18:015012

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Modell Simul Mater Sci Eng 20(8):085007

Suryanarayana C (1994) Structure and properties of nanocrystalline materials. Bull Mater Sci 17(4):307–346

Suryanarayana C, Koch CC (2000) Nanocrystalline materials—current research and future directions. Hyperfine Interact 130:5–44

Van Petegem S, Brandstetter S, Schmitt B, Van Swygenhoven H (2009) Creep in nanocrystalline Ni during X-ray diffraction. Scr Mater 60(5):297–300

Voyiadjis GZ, Deliktas B (2010) Modeling of strengthening and softening in inelastic nanocrystalline materials with reference to the triple junction and grain boundaries using strain gradient plasticity. Acta Mech 213:3–26

Wang YJ, Ishii A, Ogata S (2012a) Grain size dependence of creep in nanocrystalline copper by molecular dynamics. Mater Trans 53(1):156–160

Wang YJ, Ishii A, Ogata S (2012b) Grain size dependence of creep in nanocrystalline copper by molecular dynamics. Mater Trans 53:156–160

Wang BB, Xue P, Xiao BL, Wang WG, Liu YD, Ma ZY (2020) Achieving equal fatigue strength to base material in a friction stir welded 5083–H19 aluminium alloy joint. Sci Technol Weld Join 25(1):81–88

Yamakov V, Wolf D, Phillpot SR, Gleiter H (2002a) Grain-boundary diffusion creep in nanocrystalline palladium by molecular-dynamics simulation. Acta Mater 50:61–73

Yamakov V, Wolf D, Phillpot SR, Gleiter H (2002b) Grain-boundary diffusion creep in nanocrystalline palladium by molecular-dynamics simulation. Acta Mater 50:61–73

Yin WM, Whang SH, Mirshams R, Xiao CH (2001) Creep behavior of nanocrystalline nickel at 290 and 373 K. Mat Sci Eng A 301:18–22

Yoshida F (1990) Uniaxial and biaxial creep-ratcheting behavior of SUS304 stainless steel at room temperature. Int J Pres Ves Pip 44:207–223

Zakavi SJ, Aghaei Y (2020) The ratcheting behavior of carbon steel piping elbows under cyclic bending moment and temperature. J Braz Soc Mech Sci Eng 42(8):1–9

Zheng XT, Xuan FZ, Zhao P (2011) Ratcheting-creep interaction of advanced 9–12% chromium ferrite steel with anelastic effect. Int J Fatigue 33:1286–1291

Zheng X, Wen X, Wang W, Gao J, Lin W, Ma L, Yu J (2017) Creep-ratcheting behavior of PTFE gaskets under various temperatures. Polym Test 60:229–235

Acknowledgments

The authors thank the National Institute of Technology Rourkela-computer center for providing the HPCF (High-performance computing facility) to be carried out these simulations.

Author information

Authors and Affiliations

Contributions

All the authors are actively involved in Conceptualization; Data curation; Formal analysis; Investigation; Methodology; Resources; Software; Supervision; Validation; Visualization; Writing—original manuscript draft; Writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Babu, P.N., Becquart, C.S. & Pal, S. Molecular dynamics simulation-based study of creep–ratcheting behavior of nanocrystalline aluminum. Appl Nanosci 11, 565–581 (2021). https://doi.org/10.1007/s13204-020-01595-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-020-01595-5