Abstract

p-Anisidine being a component of wastewater generated through dye and pharmaceutical industries is highly toxic and carcinogenic in nature. Therefore, its presence in wastewater requires prior treatment before its disposal from the point of safety of human and aquatic life. Fenton’s oxidation is a type of advanced oxidation processes which is efficient, ecofriendly and reliable, and this was not studied for the removal of p-anisidine from wastewater. In this study, the effect of influent pH, hydrogen peroxide (H2O2) concentration and ferrous ion (Fe2+) concentration on the removal of p-anisidine by Fenton’s reagent was carried out on a laboratory scale. All samples were examined for initial and final concentrations of p-anisidine using UV–Vis spectrophotometry, and also initial and final COD was analyzed. p-Anisidine shows maximum absorbance at 296 nm. At pH 2.5 and [H2O2]/[Fe2+] of 70:1 for the initial p-anisidine concentration of 0.5 mM and for 24 h reaction time, the maximum removal of p-anisidine was found to be 88.95% and maximum COD removal was 76.43%.

Similar content being viewed by others

Introduction

Background

Aniline derivatives are used in the manufacturing of dyes, pigments, paints, herbicides, plastics, pharmaceutical preparation and in the production of rubber accelerator (Datta et al. 2003). It is primarily used in the manufacture of precursors to polyurethane. Aniline compounds produced in some pharmaceutical plants are very complex in structure; although organic in nature, they show high resistance to biological degradation (Kreisberg 2007). A vast kind of dye manufacturing industries are using aniline derivatives as intermediates, if the concentration of dye is around 1000 mg/L present in the dye solution (Manu and Chaudhari 2002), approximately 50% can be found in the effluent coming out of these industries (Amritha and Manu 2016), and therefore these intermediates concentration may not be more than 300 mg/L in the dye solution.

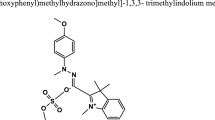

p-Anisidine is one of the aniline derivatives which appears as gray brown solid and is also known as 4-methoxyaniline, 4-aminoanisole and 4-methoxybenzenamine. p-Anisidine has several industrial applications such as in the biochemical research, in organic synthesis and also in food quality testing as it is good in detecting unsaturated aldehydes. Production of several azo dyes and pharmaceuticals needs p-anisidine as an intermediate (Alfa.com 2015). Some of the physical and chemical properties of p-anisidine are shown in Table 1.

Health and environmental concerns

p-Anisidine is the most toxic of all the three isomers of anisidine, and it can damage blood severely when inhaled, orally ingested or contacted by skin. When p-anisidine is heated strongly, toxic fumes containing nitrogen oxides are released. It can also lead to kidney damage and anemia. High levels of p-anisidine can create interference with blood’s oxygen-carrying capacity which results in fatigue, headache, dizziness and blue-colored lips and skin. For even higher concentrations, there can be trouble in breathing, subsequently collapsing of the exposed person and in extreme cases death (Fishersci.com 2018).

p-Anisidine poses serious threat to humans as well as animal and aquatic life, and still they are constantly being used and produced in several dye and pharmaceutical industries. So it is imperative to treat wastewater containing p-anisidine prior to its disposal in sewage to ensure environmental safety.

Treatment technologies

The incalcitrant nature and high toxicity of this compound show the need for further studies on its treatment. Various physical treatment methods like adsorption (Bardakcer et al. 2013; Al-Johani and Salam 2011), ultrafiltration and thermal incineration applied in treating aniline derivatives are uneconomical and not feasible due to need for high energy demand, sophistication of membranes and generation of secondary pollution as in the case of thermal incineration (Halling-Sørensen and Jorgensen 1993). Biological treatment methods being ecofriendly destroy pollutants and convert them into less toxic forms in a natural way (Padoley et al. 2008). However, due to the p-anisidine high toxicity and incalcitrant nature direct biological treatment method may not be suitable option for degrading. Therefore, pretreatment by chemical methods like the advanced oxidation treatment can be applied, because they can increase the degradability and also reduce the toxicity of the wastewater containing nitrogenous organic compounds for subsequent biological treatment (Padoley et al. 2011). AOPs depend on generating highly oxidizing substances like the hydroxyl radical (HO·). HO· has high oxidation potential of + 2.80 eV which is enough to initiate the degradation of natural and synthetic organic contaminants and to mineralize them completely to water and carbon dioxide in aqueous solution. These advanced oxidation processes had also been studied effectively on the degradation of pharmaceutical compounds wherein very high conversion of these drugs into less toxic forms was observed (Manu et al. 2011; Manu and Mahmood 2011; Karale et al. 2013; Amritha and Manu 2016). The present work focuses on the Fenton’s treatment of p-anisidine in aqua medium. The scope of this work is to study the effects of various parameters, viz. pH, Fenton’s reagent dosages (Fe2+ and H2O2 conc.), and initial concentrations of p-anisidine during Fenton’s oxidation.

Instruments and materials required

p-Anisidine extra pure (98% assay) was purchased from Loba Chem. Ltd. (India). Hydrogen peroxide (H2O2) (50%w/w) and ferrous sulfate (FeSO4·7H2O) were purchased from Loba Chem. Ltd. (India). Hydrochloric acid (HCl, Loba, India, 35% purity), sulfuric acid (H2SO4, Loba, India, 98% purity), sodium hydroxide NaOH, Loba, India, 98% purity) were also utilized in this study. A UV–Vis spectrophotometer (Agilent Technologies, Product No. G9821A) is used for analysis, COD digester (HACH DRB 200).

Experimental methodology

The laboratory experiments were performed in reactors by batch method at ambient temperature (27 ± 3 °C). A 1 L solution of known p-anisidine concentration was taken in five 2-L Erlenmeyer flasks. pH was adjusted with 6 N NaOH and 0.5 N H2SO4. The required amount of Fe2+ concentration from the freshly prepared solution of ferrous sulfate (FeSO4·7H2O) was added to the solution. Finally, H2O2 was fed to the reactor vessel to initialize the degradation reaction. The reaction solution is constantly stirred for 2 h by magnetic stirrers initially. The aliquots from reactor bath were taken and scanned under UV–VIS spectrophotometer at particular time intervals for analysis. The pre- and post-treatment COD was measured by closed reflux titrimetric method using COD digester (HACH DRB 200).

Analytical procedure

p-Anisidine concentration ranges from 0.1 to 0.5 mM were scanned from 200 to 500 nm under the UV–VIS spectrophotometer for finding wavelength for which maximum absorbance is obtained (Fig. 1). p-Anisidine shows maximum absorbance at 296 nm for all the concentrations.

A standard calibration curve of absorbance versus p-anisidine concentration was prepared by taking single wavelength of 296 nm for 0.1, 0.2, 0.3, 0.4 and 0.5 mM p-anisidine standards. This standard calibration curve was used for analyzing the p-anisidine initial and final concentrations in the solution.

Results and discussion

Influence of pH

The pH plays an important role in controlling the production of HO· and Fe2+ concentration in Fenton’s treatment. It is a necessary operational variable in the treatment of actual wastewater. Experiments were performed at pH ranges from 2.0 to 4.0 with initial 0.5 mM p-anisidine concentration to get the optimum pH for the removal of p-anisidine during Fenton’s oxidation. The initial pH of 0.5 mM p-anisidine was 6.97, and initial COD calculated by closed reflux titrimetric method was near about 190 mg/L. The pH was varied across the solutions by 0.1 N NaOH and 0.1 N H2SO4. H2O2 and Fe2+ were added in the ratio of 70:1, i.e., H2O2 = 3.5 mM and Fe2+ = 0.05 mM which is illustrated in Fig. 2.

The p-anisidine removal was maximum at pH 2.5, compared to all other pH values between 2.0 and 4.0. Maximum p-anisidine removal of 88.95% and COD removal of 76.43% were found at pH 2.5. Figure 3 shows the initial and final scan of p-anisidine concentration at optimum pH under UV–Vis spectrophotometer.

The effective range of pH for the removal of p-anisidine was 2.5–3.5. When pH was greater than 3.5, oxidation of p-anisidine got rapidly reduced by the self-decomposition of H2O2 at high pH and also ferrous catalyst got deactivated due to the generation of ferric hydroxide [Fe(OH)3] complexes, which leads to the depletion of HO· radical, which results in the decrease in oxidation potential of HO· when pH values is increased (Lucas and Peres 2006). Less removal at pH > 3.5 can also be explained by the auto-decomposition and dissociation of H2O2 (Badawy et al. 2006). For pH below 2.5, H2O2 and Fe2+ reaction was hindered causing low production of HO·. The lesser removal below pH 2.5 was caused by the scavenging of H+ ions by HO· itself to produce water (Lucas and Peres 2006). At pH above 3.0, the oxidizing potential of H2O2 is greatly affected (Malik and Saha 2003) and very less removal was observed at pH above 4 for p-anisidine.

Influence of Fenton’s reagent

Experiments were performed with varying H2O2 and Fe2+ dosages only one at a time while keeping the all others parameters like pH and reaction time constant for a particular initial pollutant concentration to obtain the optimum Fenton’s dosages in Fenton oxidation of p-anisidine. Optimization for any particular concentration of p-anisidine was done in two parts as follows:

Influence of H2O2

The concentration of H2O2 is one of the major parameters which affects the Fenton’s treatment. At first, H2O2 dosage was optimized for 0.5 mM p-anisidine initial concentration, and the study was carried out with varying H2O2 concentration from 2.5 to 4.5 mM at pH 2.5 with keeping the Fe2+ concentration constant at 0.05 mM which is shown in Fig. 4.

The maximum p-anisidine removal was 87.45% and maximum COD removal was 75.41% for [Fe2+] = 0.05 mM at 3.5 mM H2O2 concentration. When H2O2 concentration was at 2.5 mM, the p-anisidine removal was found to be 74.22% and COD removal was 64.21%. As the H2O2 concentration increased from 3.0 to 3.5 mM, the removal of p-anisidine has increased from 77.32 to 87.45% and COD removal got increased from 69.54 to 75.41%. When the H2O2 concentration was 4.0 mM, the decreased removal of 75.23% of p-anisidine and COD removal of 68.42% was obtained. And for 4.5 mM of initial H2O2 concentration, p-anisidine removal and COD removal got further decreased to 68.4% and 60.21%, respectively, as shown in Fig. 5.

This was because of the decreased catalytic activity with the increased H2O2 concentration. Also, with the increase in the concentration of H2O2 from 3.5 to 4.5 mM, the removal rate of p-anisidine reduced. This is due to the consumption of the reactive HO· by H2O2 itself to generate less reactive OOH radical (Chen and Pignatello 1997; Walling and Kato 1971; Kang et al. 2002).

The reduction in removal of pollutant was observed as the concentration of H2O2 increased, which can be explained by the following reactions:

H2O2 itself consumed the HO· as shown in Eqs. (1)–(3). The removal rate of the contaminants was more for higher concentrations of H2O2 till a critical concentration of H2O2 was achieved after which removal of contaminants started depleting, which agrees with literature (Hsueh et al. 2005; Tambosi et al. 2006).

Influence of Fe2+

After H2O2 dosage was optimized, the optimization of Fe2+ dosage is done by changing Fe2+ concentration from 0.025 to 0.125 mM keeping the H2O2 concentration constant as 3.5 mM for p-anisidine dosage of 0.5 mM (Fig. 5). Maximum removal was obtained at 0.05 mM Fe2+ concentration, the optimum p-anisidine removal was observed to be 88.27%, and COD removal was 74.93% as shown in Fig. 5. As Fe2+ concentration increased from 0.025 mM to 0.05 mM, removal of p-anisidine was increased. For initial Fe2+ concentration of 0.025 mM, removal of p-anisidine was 79.24% which got increased to 88.27% maximum for 0.05 mM Fe2+ concentration, and also COD removal got increased from 68.31 to 74.93%. The removal of p-anisidine and COD removal rapidly decreased to a minimum of 38.39% and 35.76%, respectively, when Fe2+ concentration was at 0.125 mM.

It is clear that for p-anisidine concentration of 0.5 mM, maximum removal was obtained at H2O2 concentration of 3.5 mM and 0.05 mM concentration of Fe2+ when the pH was set at 2.5. For higher Fe2+ concentration, the removal of p-anisidine and the COD removal got severely decreased as a huge amount of ferric ions Fe3+ from the H2O2 decomposition process by Fe2+ was precipitated into Fe(OH)2+ in acidic environment.

Influence of initial p-anisidine concentration

Initial concentration of p-anisidine was varied from 0.5 to 2.5 mM after the successful optimization of pH, H2O2 and Fe2+. For higher concentrations of pollutant, more H2O2 is consumed than expected, while Fe2+ requirement increases in the usual order as summarized in Table 2.

The trend which was observed in p-anisidine removal (%) during the Fenton’s oxidation of p-anisidine is shown in Fig. 6. It is clear from Fig. 6 as the initial concentration of p-anisidine was increased, the removal of p-anisidine and COD got decreased. Also there was a gradual increase in Fenton’s dosages as we increase the initial pollutant concentrations.

Conclusion

Results obtained in this study concluded that lower concentration of pollutant is favored by Fenton’s treatment method, i.e., removal efficiency decreases as the initial concentration of p-anisidine increases. The maximum p-anisidine removal of 88.95% and COD removal of 76.43 were observed at pH 2.5, H2O2 concentration 3.5 mM, and Fe2+ concentration of 0.05 mM for 0.5 mM initial concentration of p-anisidine.

Also the Fe2+ has key role in the Fenton’s oxidation of p-anisidine. For 0.5 mM initial concentration, the p-anisidine removal and COD removal increased to 88.27% and 74.93%, respectively, till reaching a critical Fe2+ concentration of 0.05 mM after which removal got rapidly decreased when Fe2+ concentration was further increased. This can be explained as at high Fe2+ concentration and acidic pH, the Fe3+ obtained from the reaction between H2O2 and Fe2+ was transformed into Fe(OH)2+ which resulted in lesser removal of p-anisidine.

p-Anisidine showed an increasing removal rate when the concentration of H2O2 was increased till a critical concentration of 3.5 mM H2O2 for initial p-anisidine concentration of 0.5 mM. The removal rate of p-anisidine got gradually decreased when initial H2O2 concentration was increased beyond the critical concentration as the free HO· was consumed by H2O2 itself.

Overall Fenton’s oxidation process was proven to be very efficient in removing p-anisidine successfully from aqueous solution to a large extent. The effluent of this process can be sent for further biological treatment to completely remove p-anisidine from the wastewater.

References

Alfa.com (2015) p-Anisidine product overview. (Online) Available at: https://www.alfa.com/en/catalog/A10946/. Accessed 25 May 2018

Al-Johani H, Salam MA (2011) Kinetics and thermodynamic study of aniline adsorption by multi-walled carbon nanotubes from aqueous solution. J Colloid Interface Sci 360(2):760–767

Amritha AS, Manu B (2016) Fenton and photo Fenton oxidation of 2-Nitroaniline. Int J Res Eng Technol 5(Special Issue: 18):102–104

Badawy MI, Ghalyb MY, Gad-Allaha TA (2006) Advanced oxidation processes for the removal of organophosphorus pesticides from wastewater. Desalination 194:166–175

Bardakcer B, Kaya N, Taner K (2013) Anisidine adsorption on CO-supported pumice. Environ Earth Sci J 70:849–856

Chen R, Pignatello J (1997) Role of quinine intermediates as electron shuttles in Fenton and photoassisted Fenton oxidations of aromatic compounds. Environ Sci Technol 31(8):2399–2406

Datta S, Bhattacharya PK, Verma N (2003) Removal of aniline from aqueous solution in a mixed flow reactor using emulsion liquid membrane. J Membr Sci 226:185–201

Fishersci.com (2018) p-Anisidine safety data sheet. (online) Available at: https://www.fishersci.com/store/msds?partNumber=AC104830050&productDescription=P-ANISIDINE+99%25+5G&vendorId=VN00032119&countryCode=US/. Accessed 25 May 2018

Halling-Sørensen B, Jorgensen SE (1993) The removal of nitrogen compounds from wastewater, vol 54. Elsevier, Amsterdam

Hsueh CL, Huang YH, Wang CC, Chen S (2005) Degradation of azo dyes using low iron concentration of Fenton and Fenton-like system. Chemosphere 58:1409

Kang N, Lee DS, Yoon J (2002) Kinetic modeling of Fenton oxidation of phenol and monochlorophenols. Chemosphere 47(9):915–924

Karale R, Manu B, Shrihari S (2013) Degradation of toxic 2-aminopyridine pharmaceutical compound from aqueous environments using advanced Fenton and photo-Fenton oxidation processes. Int J Adv Technol Civ Eng 2:34–38

Kreisberg J (2007) Pharmaceutical pollution: ecology and toxicology. Teleosis: J Sustain Med (Spring/Summer):5–13

Lucas MS, Peres JA (2006) Decolorization of the azo dye Reactive Black 5 by Fenton and photo-Fenton oxidation. Dyes Pigm 71(3):236–244

Malik PK, Saha SK (2003) Oxidation of direct dyes with hydrogen peroxide using ferrous ion as catalyst. Sep Purif Technol 31(3):241–250

Manu B, Chaudhari S (2002) Anaerobic decolourization of simulated textile wastewater containing azo dyes. Biores Technol 82:225–231

Manu B, Mahamood S (2011) Enhanced degradation of paracetamol by UV-C supported photo-Fenton process over Fenton oxidation. Water Sci Technol 64(12):2433–2438

Manu B, Mahamood S, Vittal H, Shrihari S (2011) A novel catalytic route to degrade paracetamol by Fenton process. IJRCE 1:157

National Center for Biotechnology Information. PubChem Compound Database; CID=7732. https://pubchem.ncbi.nlm.nih.gov/compound/7732. Accessed 25 May 2018

Padoley KV, Mudliar SN, Pandey RA (2008) Heterocyclic nitrogenous pollutants in the environment and their treatment options-an overview. Biores Technol 99(10):4029–4043

Padoley KV, Mudliar SN, Banerjee SK, Deshmukh SC, Pandey RA (2011) Fenton oxidation: a pretreatment option for improved biological treatment of pyridine and 3-cyanopyridine plant wastewater. Chem Eng J 166(1):1–9

Tambosi JL, Di Domenico M, Schirmer WN, José HJ, Moreira RDF (2006) Treatment of paper and pulp wastewater and removal of odorous compounds by a Fenton-like process at the pilot scale. J Chem Technol Biotechnol 81(8):1426–1432

Walling C, Kato S (1971) Oxidation of alcohols by Fenton’s reagent effect of copper ion. J Am Chem Soc 93(17):4275–4281

Funding

No funding or grants have been received for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there is no conflict of interest.

Ethical approval

This work does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

For this type of work, formal consent is not required.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Chaturvedi, N.K., Katoch, S.S. Effect of various parameters during degradation of toxic p-anisidine by Fenton’s oxidation. Appl Water Sci 10, 18 (2020). https://doi.org/10.1007/s13201-019-1106-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13201-019-1106-6