Abstract

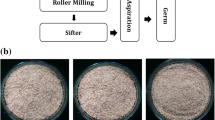

Rheological and nutritional quality of ready-to-eat rice (Oryza sativa ) -legume viz. black gram (Vigna mungo), green gram (Vigna radiata), lentil (Lens culinaris) and peas (Pisum sativum) based extrudates were studied using low cost collet extruder. Extrudates were prepared keeping constant feed rate (25 kg/h) and moisture content (14% wb) at 0, 5, 10 and 15% legume incorporation levels. Rheological properties of porridge made of extrudate flour were evaluated using Rapid Visco Analyser (RVA). Maximum and minimum peak viscosity for rice extrudates alone and rice extrudates blended with 15% peas were 697 cp and 523 cp, respectively. There was a decreasing trend in degree of gelatinization with increase in legume incorporation level. Other RVA rheological parameters like trough break down and final viscosity were in the range of 266-226 cp, 431-297 cp and 452-375 cp respectively. Maximum values of protein, fat, fibre and ash contents were found in rice extrudates at 15% legumes blend levels. There was an increasing trend in nutrient contents with legume content in rice extrudates. Degree of gelatinization for rice alone extrudate was 29.4% and showed a decrease in gelatinization with increase in legumes extrudate and was minimum (22.4%) for rice blended with 15% dehulled green gram. Sensory evaluation scores for all extrudates showed the most acceptable range of 6 to 8. Thus, legume blend level (up to 15%) of dehulled legumes fetched good scores and showed promising trend for the production of low cost expanded extrudates and its instant flour.

Similar content being viewed by others

References

Colonna P, Doublier JL, Melcion JP, De Monredon F, Mercier C (1984) Extrusion cooking and drum drying of wheat starch. I. Physical and macromolecular modifications. Cereal Chem 61:538–544

Deliza R, Macfie H, Hedderley D (1996) Information affects consumer assessment of sweet and bitter solutions. J Food Sci 61:1080–1083

Fardet A, Abecassis J, Hoebler C, Baldwin PM, Buleon A, Berot S (1999) Influence of technological modifications of the protein network from pasta on in vitro Starch Degradation. J Cereal Sci 30:133–145

Gopalan C, Rama Sastry BV, Balasubramanian SC (1991) Nutritive value of Indian foods. National Institute of Nutrition, Indian Council of Medical Research, Hyderabad, pp 47-48–95-96

Harper J (1995) Low-cost extrusion: possibilities for Africa. The South-African J Food Sci Nutr 7:142–147

Harper J, Jansen G (1985) Production of nutritious precooked foods in developing countries by low-cost extrusion technology. Food Rev Int 1:27–97

Hart FL, Fischer HJ (1971) Análisis moderno de los alimentas. In: Acribia, Zaragoza, p 249

Hoebler C, Karinthi A, Chiron H, Champ M, Barry JL (1999) Bioavailability of starch in bread rich in amylase: metabolic responses in healthy subjects and starch structure. Eur J Clin Nutr 53:360–366

ICC (1995) Rapid pasting method using the Newport rapid visco analyser. ICC-Draft Standard No. 162, International Association for Cereal Science and Technology

Jenkins DJA, Jenkins AL, Wolever TMS, Vuksan V, Rao AV, Thompson LU, Josse RG (1994) Low glycemic index: Lente carbohydrates and physiological effects of altered food frequency. Am J Clin Nutr 59:706S–709S

Kearsley MW, Sicard PJ (1989) The chemistry of starches and sugars present in food. In: Dobbing J (ed) Dietary starches and sugars in man: a comparison. Springer, London, pp 1–34

Kim SY, Wiesenborn DP, Orr PH, Grant LA (1995) Screening potato starch for novel properties using differential scanning calorimetry. J Food Sci 60:1060–1065

Lai HM (2001) Effects of hydrothermal treatment on the physicochemical properties of pregelatinized rice flour. Food Chem 72:455–463

Liang XM, King JM (2003) Pasting and crystalline property differences of commercial and isolated rice starch and added amino acids. J Food Sci 68:832–838

Liang XM, King JM, Shih FF (2002) Pasting property differences of commercial and isolated rice starch with added lipids and β-cyclodextrin. Cereal Chem 79:812–818

Lin S, Hseih F, Huff HE (1997) Effect of lipids and processing conditions on degree of starch gelatinization of extruded dry pet food. Lebens Wiss Technol 30:754–761

Sadasivam S, Manickam A (1992) Biochemical methods for agricultural sciences. Wiley, New Delhi, pp 20–21

Said NW (2000) Dry extruders. In: Riaz MN (ed) Extruders in food applications. Technomic, Texas, pp 51–62

Sajilata MG, Singhal RS, Kulkarni PR (2006) Resistant starch- a review. Comp Rev Food Sci Food Safety 5:1–17

Sivaramakrishnan HP, Senge B, Chattopadhyay PK (2004) Rheological properties of rice dough for making rice bread. J Food Eng 62:37–45

Thorburn AW, Brand JC, Truswell AS (1987) Slowly digested and absorbed carbohydrate in traditional bushfoods: a protective factor against diabetes? Am J Clin Nutr 45:98–106

Wiesenborn DP, Orr PH, Casper HH, Tacke BK (1994) Potato starch paste behaviour as related to some physical/chemical properties. J Food Sci 59:644–648

Wotton M, Bamunuarachchi A (1978) Water binding capacity of commercial produced native and modified starches. Starch/Starke 33:159–161

Wootton M, Weedon D, Munk N (1971) A rapid method for the estimation of starch gelatinization in processed foods. Food Technol Australia 23:612–615

Zobel HF (1984) Gelatinization of starch and mechanical properties of starch pastes. In: Whistler RL, BeMiller JN, Paschall EF (eds) Starch: chemistry and technology, 2nd edn. Academic, London, pp 285–309

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Balasubramanian, S., Borah, A., Singh, K.K. et al. Rheological and nutritional quality of selected dehulled legumes blended rice extrudates. J Food Sci Technol 49, 632–637 (2012). https://doi.org/10.1007/s13197-010-0206-y

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13197-010-0206-y